Bodine BSL10T3 User manual

SAVE THESE INSTRUCTIONS

THIS PRODUCT CONTAINS A RECHARGEABLE LITHIUM-ION BATTERY.

THE BATTERY MUST BE RECYCLED OR DISPOSED OF PROPERLY.

Bodine © 2022 Signify Holding. All rights reserved.

Collierville, TN USA 38017 • Tech Support 888-263-4638 • www.bodine.com

442295716651

BSL10T3/BSL06T3

8/19/22

Li - ion

Self-Testing Emergency LED Driver

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

! IMPORTANT SAFEGUARDS ! WHEN USING ELECTRICAL EQUIPMENT, BASIC

SAFETY PRECAUTIONS SHOULD ALWAYS BE

FOLLOWED, INCLUDING THE FOLLOWING:

1. This product is for use with an emergency LED lighting load and supplies nominally 10.0 W/6.0 W

(depending on model) of power, with a voltage of 15-54 VDC in emergency mode for a minimum of 90

minutes, in compliance with NFPA 101 and NEC 700.12.

2. Make sure all connections are in accordance with the National Electrical Code or Canadian Electrical

Code and any local regulations.

3. To reduce the risk of electric shock, disconnect both normal and emergency power supplies before

servicing. Follow the instructions in the OPERATION section to disable the output of this LED driver.

4. This emergency driver is suitable for both factory or field installation.

5. This product is suitable for use in damp locations where the ambient temperature is 0ºC minimum,

+55ºC maximum. Product is also suitable for installation in sealed and gasketed fixtures. Product is

not suitable for heated air outlets and wet or hazardous locations. Maximum allowable case temp is

65ºC. See unit label for Tc measurement location.

6. An unswitched AC power source is required (120-277 VAC, 50/60 Hz).

7. Do not install near gas or electric heaters.

8. Do not attempt to service the battery. A sealed, no-maintenance battery is used that is not field

replaceable. Contact the manufacturer for information on service.

9. The use of accessory equipment not recommended by the manufacturer may cause an unsafe

condition.

10. Do not use this product for other than intended use.

11. Servicing should be performed by qualified service personnel.

12. Equipment should be mounted in locations and at heights where it will not be subjected to tampering

by unauthorized personnel.

13. For Canadian application the output terminals should be in compliance with the accessibility

requirement of the Canadian Electric Code.

14. This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

15. This product must be grounded. See the wiring diagrams for details.

Installation Instructions

INSTALL ATION

22

STEP 1 - DETERMINE SUITABILITY

> Disconnect AC power from the LED luminaire.

> Mount the emergency LED driver by the mounting tabs using the supplied screws. The

luminaire’s installation

instructions may provide guidance on the recommended mounting location.

>Mounting Height: Many factors influence emergency illumination levels, such as the lamp

load selected, luminaire design, and environmental factors therefore end use verification is

necessary. For field installations, when the attached luminaire is mounted at heights greater

than 7.17ft (2.2m), the level of illumination must be measured in the end application to ensure

the requirements of NFPA 101 and local codes are satisfied.

>Remote Mounting: The emergency LED driver may be remote mounted from the luminaire it

enclosed and installed in accordance with the NEC. If used in conjunction with an AC driver the

allowed distance is up to half the distance the AC driver manufacturer recommends remote

mounting the AC driver from the LED load. If used without an AC driver, and remote mounting

more than 5 feet from the luminaire, please consult the factory to determine the necessary

wire gauge. CAUTION: Remote mounting can result in reduced power output.

1. Ensure the LED load’s rated power is greater than or equal to the power output of this emergency LED

driver. This is to ensure that this emergency product will not produce more power than the LED load can

handle, thus ensuring that the LED load will not be damaged when the system is in the emergency mode.

2. Verify that the forward voltage of the luminaire’s LED array is within the limits of this emergency LED driver.

The forward voltage of the LED array is commonly designated as Vf and should be found on the luminaire

markings, in the luminaire specifications, or imprinted directly on the LED arrays. If multiple LED arrays are to

be driven, verify that the total forward voltage is within the limits of this product. Using a voltage meter, it

may be possible to directly measure the voltage across the LED arrays when operating from the AC driver.

3. Ensure the output current of the AC LED driver does not exceed 3.0 Amps. This is the current into the blue

wire connector.

4. Ensure there will be sufficient light output in the end application. Estimate the egress lighting illumination

levels by doing the following:

A. Find the efficacy of the LED load. This can be given by the luminaire manufacture. This number will be

given in lumens per watt (lm/w). It is the installer’s responsibility to validate the luminaire manufacturer’s

efficacy data.This can be accomplished by direct measurement, by review of independent 3rd party test

data (UL, ETL, etc.), accessing a public database of 3rd party data (such as Design Lights Consortium,

www.designlights.org), or other comparable means.

B. Lumens can be calculated by multiplying the output power of the emergency LED driver by the efficacy

of the LED load. In many cases the actual lumen output in emergency mode will be greater than this

calculation gives, however it will provide a good estimate for beginning the lighting design of the system.

Lumens In Emergency Mode = Lumens per Watt of Fixture * Output Power of Chosen Product

(Lumens) = (lm/W) * (W)

C. Using the results of this calculation and industry standard lighting design tools, calculate the

anticipated illumination levels in the path of egress.

This product is suitable for field installation with suitable LED loads including LED luminaires, DC voltage

driven LED replacements for fluorescent lamps and others. There are four (4) checks to determine if

your luminaire is eligible for field installation.

NOTE: This product has been designed to reliably interface with a wide selection of LED loads and is electrically

compatible with every simple LED array that meets criteria 1 and 2 above. However, compatibility cannot be

guaranteed with all current and future LED systems. Compatibility testing of the end-use system is suggested.

Please contact the factory with any questions.

NOTE: After installation, it will be necessary to measure the egress lighting illumination levels to ensure it

complies with national, state, and local code requirements.

Make sure the necessary branch circuit wiring is available. An unswitched source of power is

required. The emergency driver must be fed from the same branch circuit as the AC driver.

Installation of this emergency LED driver will vary based on the luminaire type, however,

generally follow these steps:

STEP 2 - INSTALLING THE EMERGENCY DRIVER

OPERATION

3

STEP 3 - INSTALLING THE ILLUMINATED TEST SWITCH

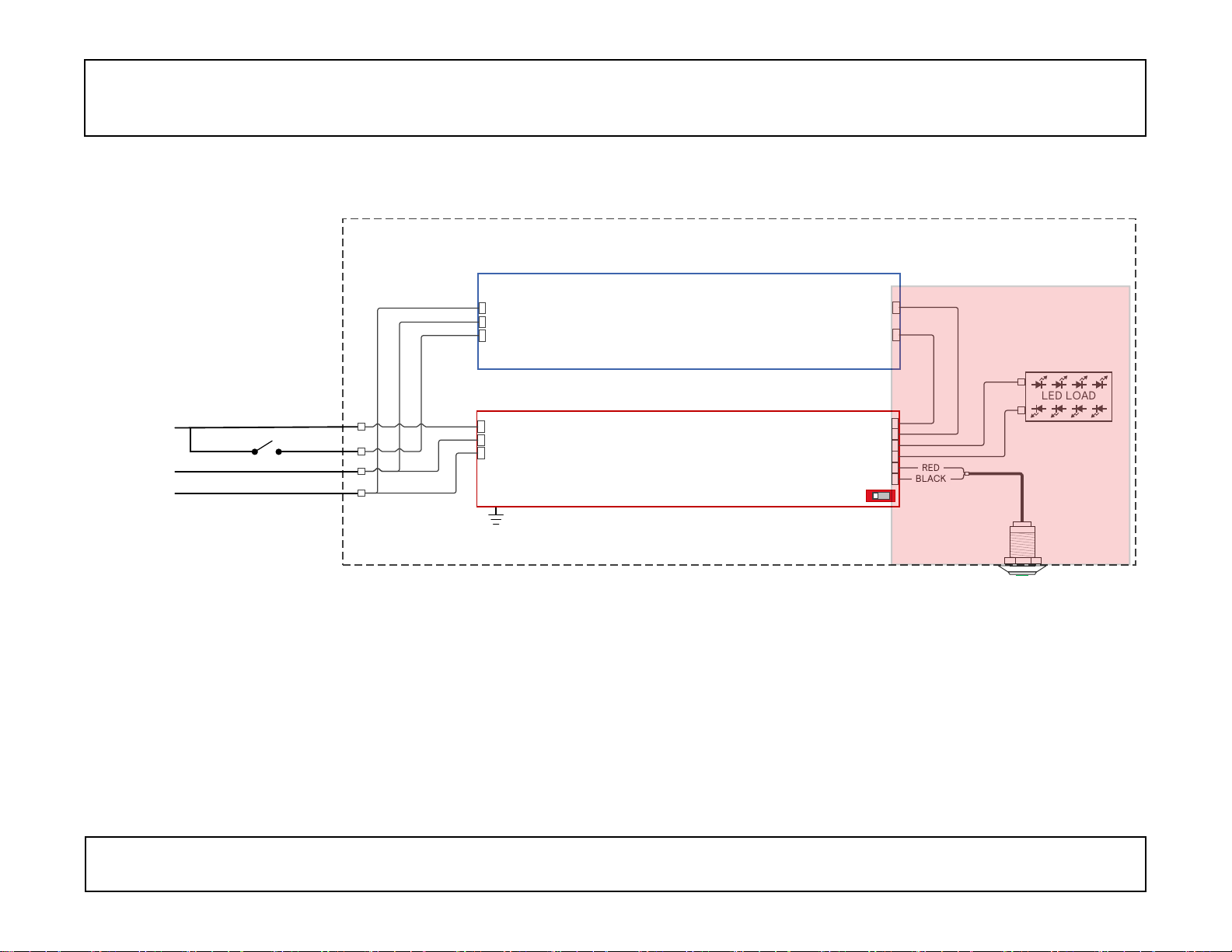

> See wiring diagram to connect the emergency driver to the AC driver and LED load. Make sure all

connections are in accordance with the National Electrical Code and any local regulations.

> After installation is complete, supply AC power to the emergency driver and the AC driver.

> At this point, the Charging Indicator Light should illuminate indicating the internal battery is charging.

> After the emergency driver has been charged for one-hour automatic commission test will be

performed. The emergency driver will switch to the emergency mode for 30 seconds and store in its

memory the current level of the connected load. If, during future self-test, this level deviates by more

than 25%, an error will be triggered.

> A short-term discharge test may be conducted after the emergency driver has been charged for one

hour. Charge for 24 hours before conducting a long-term discharge test. Refer to OPERATION.

> In a readily visible location, attach the label "CAUTION - This Unit Has More Than One Power

Connection Point. To Reduce The Risk Of Electric Shock, Disconnect Both The Branch Circuit-

Breakers Or Fuses And Emergency Power Supplies Before Servicing."

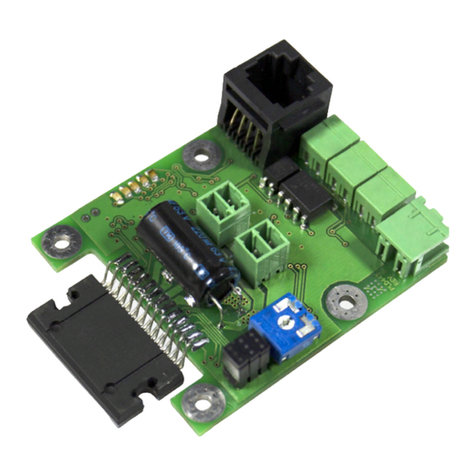

> Mount the supplied Illuminated test switch in a location that is visible

and accessible by maintenance personnel. The test switch mounts

through a ½” hole which may need to be made in the luminaire or

could come pre-punched by the luminaire supplier.

> Connect the test switch per wiring diagrams provided on these

instructions.

> If wired correctly, the indicator light should be ON when AC power

is supplied to the fixture indicating that the unit is charging. After

installing, mark with the "PUSH TO TEST" and "CHARGING INDICATOR

LIGHT" labels.

STEP 4 - WIRING THE EMERGENCY DRIVER

Fixture or

Test/Monitor Plate

2 Wire Illuminated

Test Switch

Hex Nut

Red

Black

When AC power fails, the emergency driver automatically switches to emergency mode, powering

the LED load per the rating of the emergency driver for a minimum of 90 minutes. When AC power is

restored, the emergency driver returns to charging mode.

ABConnect:

Applying AC power to the unit activates the charger circuit, and supplies power to the control/monitor

circuit and charging indicator light.

To deactivate the unit for storage or shipping, press and hold the test button while the unit is in

emergency mode until the LED load is turned off.

Self-Test:

This unit contains a control/monitor circuit that if enabled automatically performs a 30-second discharge

test once a month and a full 90-minute discharge test once a year. During routine testing, the self-testing

emergency driver simulates an AC power failure causing the unit to automatically switch to emergency

mode. The unit will monitor the operation of the LED load, battery voltage, and emergency duration. If the

emergency system functions properly, then the unit will return to normal mode. Should the unit detect any

problems, the indicator light will flash per failure condition (see Troubleshooting Guide) until the condition

has been corrected and the unit passes the next test.

Commissioning: After the emergency driver has been charged for one-hour an automatic

commissioning test will be performed. The emergency driver will switch to the emergency mode for 30

seconds and store in its memory the current level of the connected load. If, during future self-test, this

level deviates by more than 25%, an error will be triggered.

Caution:Once commissioned, connecting this equipment to higher voltage loads will result in reduce

current levels triggering the derangement signal indicating the equipment requires re-calibration to ensure

proper operation.

4

MAINTENANCE

This self testing emergency driver automatically performs required routine testing. Results are

reported to maintenance personnel via the indicator light.

Note: Maintenance personnel should periodically check the indicator light. If the indicator light is

flashing, follow steps in the Troubleshooting Guide.

TROUBLESHOOTING GUIDE

Bi-Color indicator

(color/flashing) ERROR CORRECTIVE ACTION

Green/ No Flashes None The unit is operating correctly, and the internal battery is fully charged

Green/ Slow Flashes None

1. The Unit is charging. The main light is operating normal.

2. The Unit is running a self-diagnostic test. The LED Load is operating in

Emergency level.

OFF None In Emergency mode, or emergency run-time is ended and unit is de-activated.

Red / 2x Flashes Battery

Indicates that a self-test/self-diagnostic test did not meet full duration

1. Charge the unit for the rated recharge time and perform a manual self-

diagnostic test.

2. If error is still present, then the battery is past it's useful life and should be

replaced.

Red / 3x Flashes Charging

1. Check input AC mains wiring of Unswitched Hot, Neutral and Ground.

2. Verify Voltage and Frequency are stable and match the product's input rat-

ing on the label

Red / 4x Flashes LED Load,

Commissioning

During a self-test/self-diagnostic test, the unit detected the LED load has

changed more than 25% from the initial commissioned value.

1. Replace the LED Load and perform a manual self-diagnostic.

2. If error is still present, then recalibrate the commission value by deactivating

the unit. Apply AC mains to activate unit and it will recommission itself after

one h o ur.

3. Check for Open or Short circuit on the output connections.

Red / 5x Flashes Temperature

Product temperature is beyond its rated temperature range.

1. Ensure unit is within the rated temperature range stated on the product

label.

2. Confirm by measuring at the Tc point on the product label.

If the unit has encountered a problem after installation, then the Illuminated Test Switch will flash the error code

with the indicator light. Count the number of times the indicator is OFF to read the number of flashes. Then use

the troubleshooting steps to solve the issue.

To reset a failure indication, briefly push the Test Switch. If the condition has not been corrected by the

next scheduled test, the unit will once again detect the failure and signal the failure indicator.

To perform a manual self-diagnostic test, push and hold the Test Switch for minimum of 5 seconds. Once

test switch is released the emergency driver will perform a 30 second diagnostic test. During this test, unit

will monitor the operation of the LED load, and battery voltage. If the emergency system functions properly,

the unit will return to normal mode. Should the unit detect any problems, the indicator light will flash per

failure condition (see Troubleshooting Guide) until the condition has been corrected and the unit passes the

next test.

Self-test select feature:

Switch Position Function

ON Self-test feature Enabled

1 Self-test feature Disabled

A slide switch is used to enable and disable the self-test feature of the product.

AC Driver

Ground

Neutral

Line

LED -

LED +

Unswitched Line

Neutral

Ground

Wall Switch Bodine EM Driver

Line

Neutral

Ground

Driver In +

Driver In -

LED Load +

LED Load -

Test Switch +

Test Switch -

LED LOAD

ON

BLACK

RED

UL Class 2 Circuits

WIRING DIAGRAMS

NOTE: Emergency driver case and green connector must be grounded

EMERGENCY DRIVER AND AC DRIVER MUST BE FED FROM THE SAME BRANCH CIRCUIT

TYPICAL SCHEMATICS ONLY. MAY BE USED WITH OTHER DRIVERS. CONSULT THE FACTORY FOR OTHER WIRING DIAGRAMS.

NOTE 1: For short-term testing of the emergency function, the battery must be charged for at least one hour. The emergency driver must be

charged for at least 24 hours before conducting a long-term test.

This manual suits for next models

1

Table of contents

Other Bodine DC Drive manuals