Maiman Electronics LLC SF8300

2

Table of content

1. Laser diode driver features.................................................................................................................. 3

2. Applications ......................................................................................................................................... 3

3. TEC controller features ........................................................................................................................ 3

4. Controls................................................................................................................................................ 3

5. Description...........................................................................................................................................3

6. Package set ..........................................................................................................................................3

7. Overall dimensions and weight ...........................................................................................................3

8. Versions ............................................................................................................................................... 4

9. Absolute maximum ratings..................................................................................................................4

10. Recommended operating conditions .................................................................................................. 4

11. Power supply requirements ................................................................................................................ 4

12. Electrical characteristics ...................................................................................................................... 5

13. Typical Performance Characteristics ...................................................................................................6

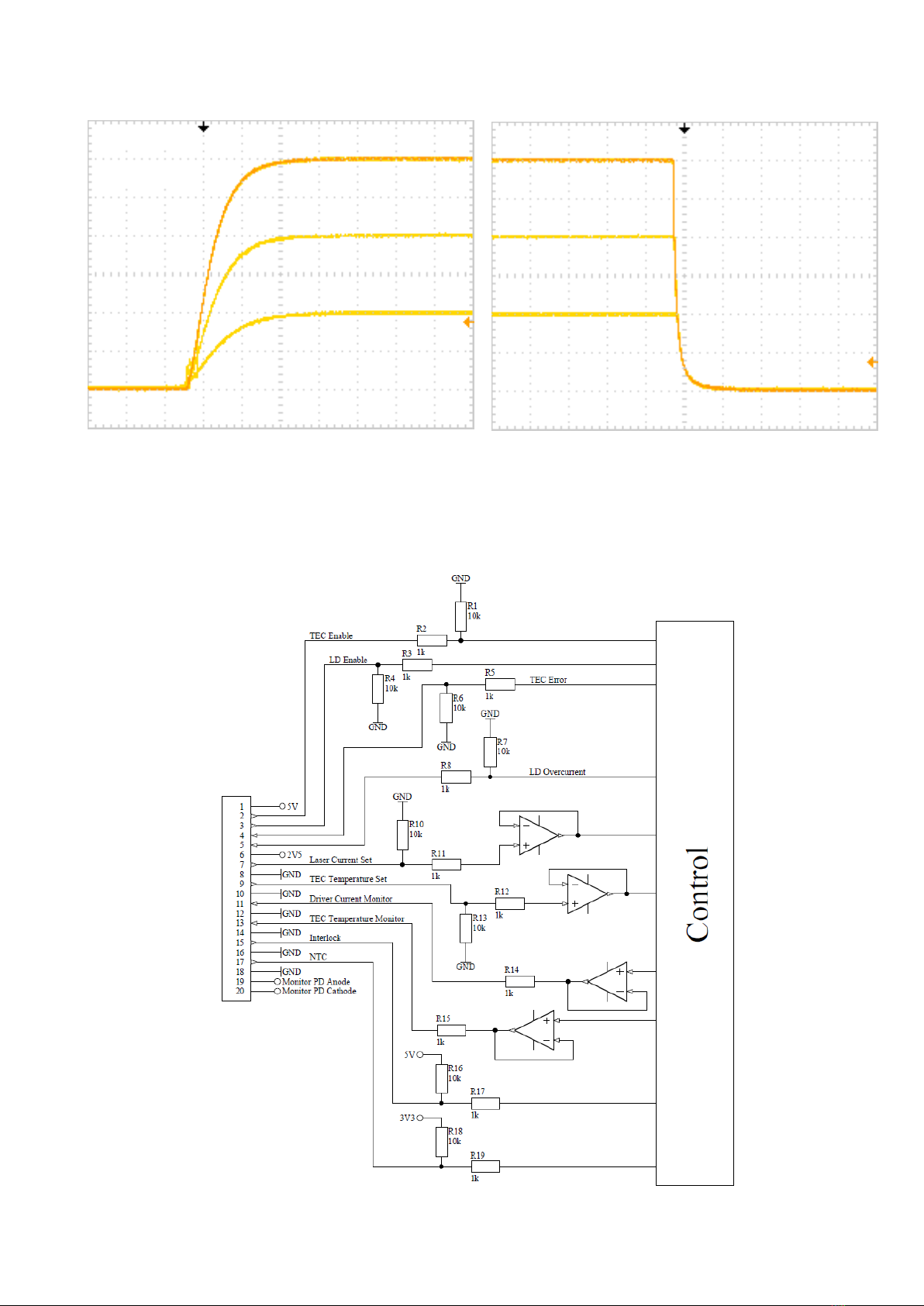

14. Functional scheme............................................................................................................................... 6

15. Pin and terminal functions ..................................................................................................................7

16. Analogue control description ............................................................................................................ 10

17. Current / Temperature setting variants ............................................................................................ 11

18. How to get started.............................................................................................................................12

19. Cooling ............................................................................................................................................... 13

20. Internal protections ...........................................................................................................................13

21. Software............................................................................................................................................. 14

22. Digital control description .................................................................................................................14

23. Digital control description (extended)............................................................................................... 20

24. Troubleshooting guide.......................................................................................................................23

25. Mechanical dimensions .....................................................................................................................24

26. Warranty............................................................................................................................................ 26