Bodine PACESETTER 2701 User guide

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Instructions for Installation and Operation

High Performance Drives for 3-Phase AC Induction Motors

115V MODELS115V MODELS

nn Model 2701, 1/4 HP

nn Model 2703, 1/2 HP

P/N 074 01023A (BW)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

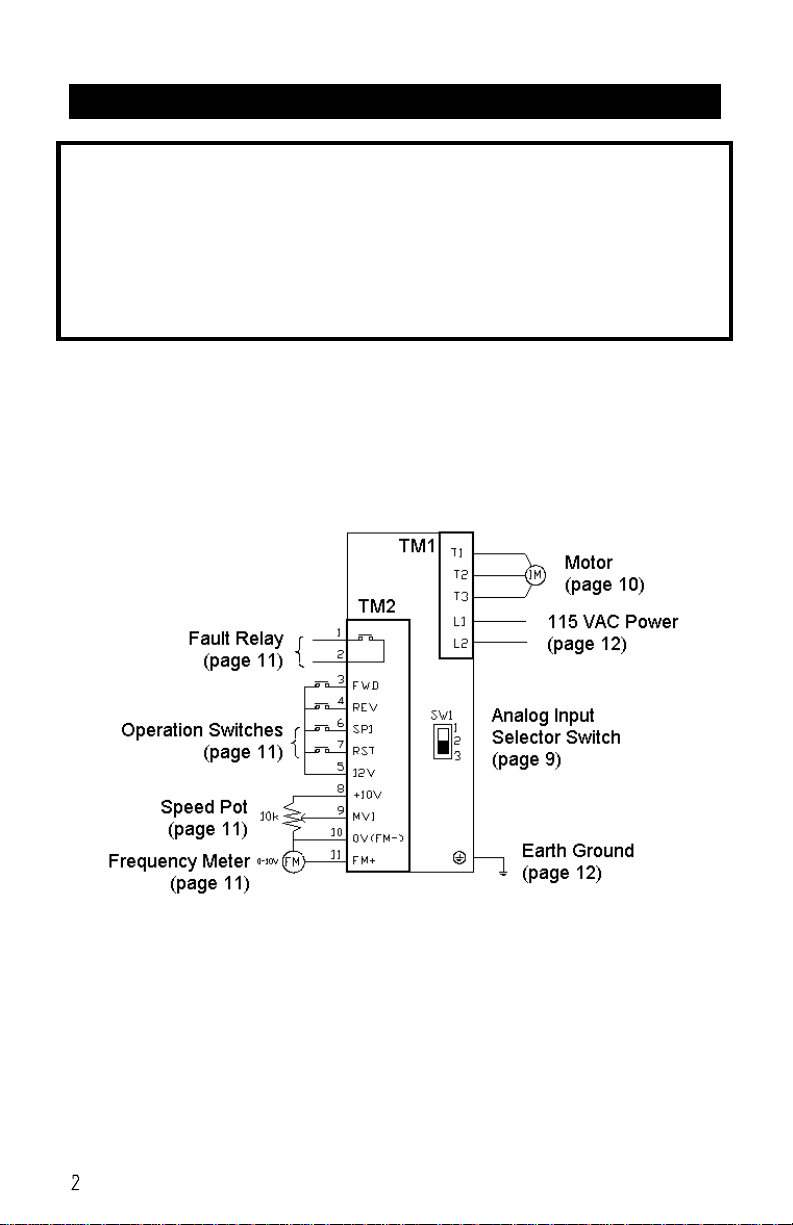

QUICK REFERENCE

IMPORTANT

Read this manual completely and carefully. Pay special attention

to all warnings, cautions, and safety rules. Failure to follow the

instructions could produce safety hazards which could injure

personnel or damage the control, motor, or other equipment. If

you have any doubts about how to connect the control or motor,

refer to the detailed sections of this manual.

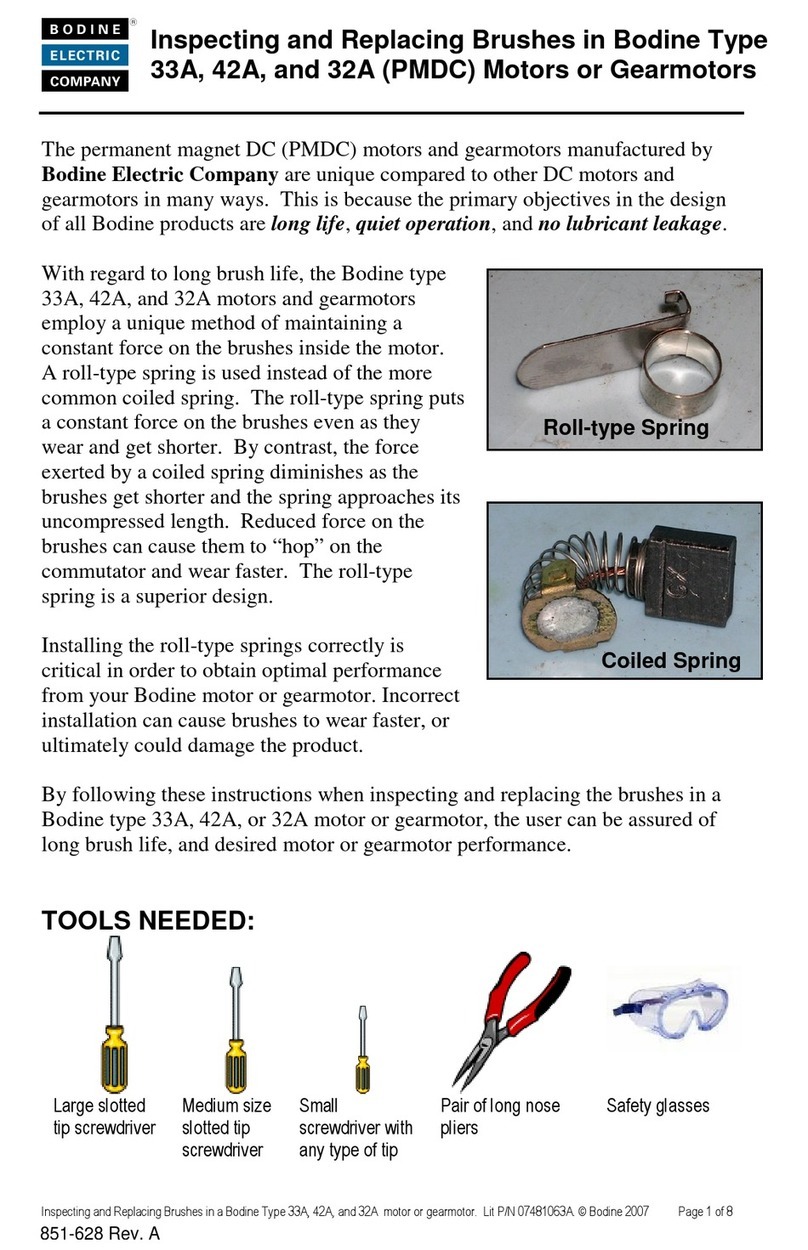

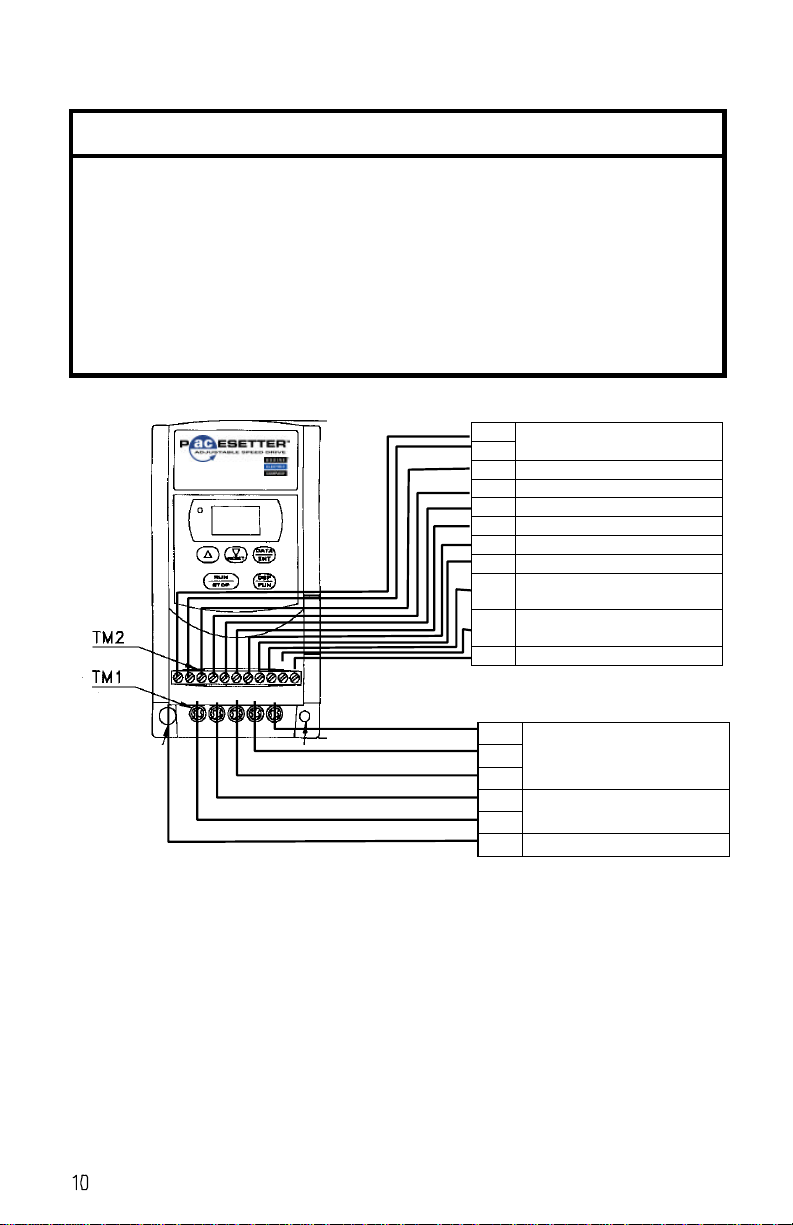

FIGURE 1– Basic Connection Diagram. Refer to noted pages for details.

Function F25 returns all functions to their factory settings.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

TABLE OF CONTENTS

PAGE

QUICK REFERENCE 2

INTRODUCTION 4

PRODUCT SPECIFICATIONS 5

IMPORTANT SAFETY PRECAUTIONS 6

INSTALLATION 7

Step 1 –Examine Before Installation 7

Step 2 –Choose a Suitable Location 7

Step 3 –Mount the Control 8

Step 4 –Preliminary Setup 9

Step 5 –Make Electrical Connections 10

Step 5a –Connect Motor 10

Step 5b –Connect Remote Control Devices (optional) 11

Step 5c –Ground the Inverter 12

Step 5d –Connect Circuit Breaker 12

Step 5e –Connect AC Line 12

Step 6 –Check System Before Starting 13

OPERATION 14

Step 7 –Operate the Control 14

Step 7a –Operate Inverter Using Keypad 14

Step 7b –Operate Inverter Using Remote Devices (optional) 14

Step 7c –Change Other Parameters (optional) 15

Parameter List 15

Parameter Descriptions 17

TROUBLESHOOTING 23

WARRANTY 27

copyright 2000 Bodine Electric Company. All Rights Reserved. Printed in U.S.A.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

INTRODUCTION

ABOUT THIS MANUAL -This manual contains the basic information

needed to install and operate Bodine PACESETTERTM 115V “NANO”

series inverters, models 2701 and 2703.

This manual does not profess to cover all details or variations in

equipment, nor to provide for every possible contingency associated with

installation, operation, or maintenance. No warranty of fitness for

purpose is expressed or implied. Should further information be desired or

should particular problems arise which are not covered sufficiently for the

user’s purpose, the matter should be referred to the Bodine Electric

Company.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

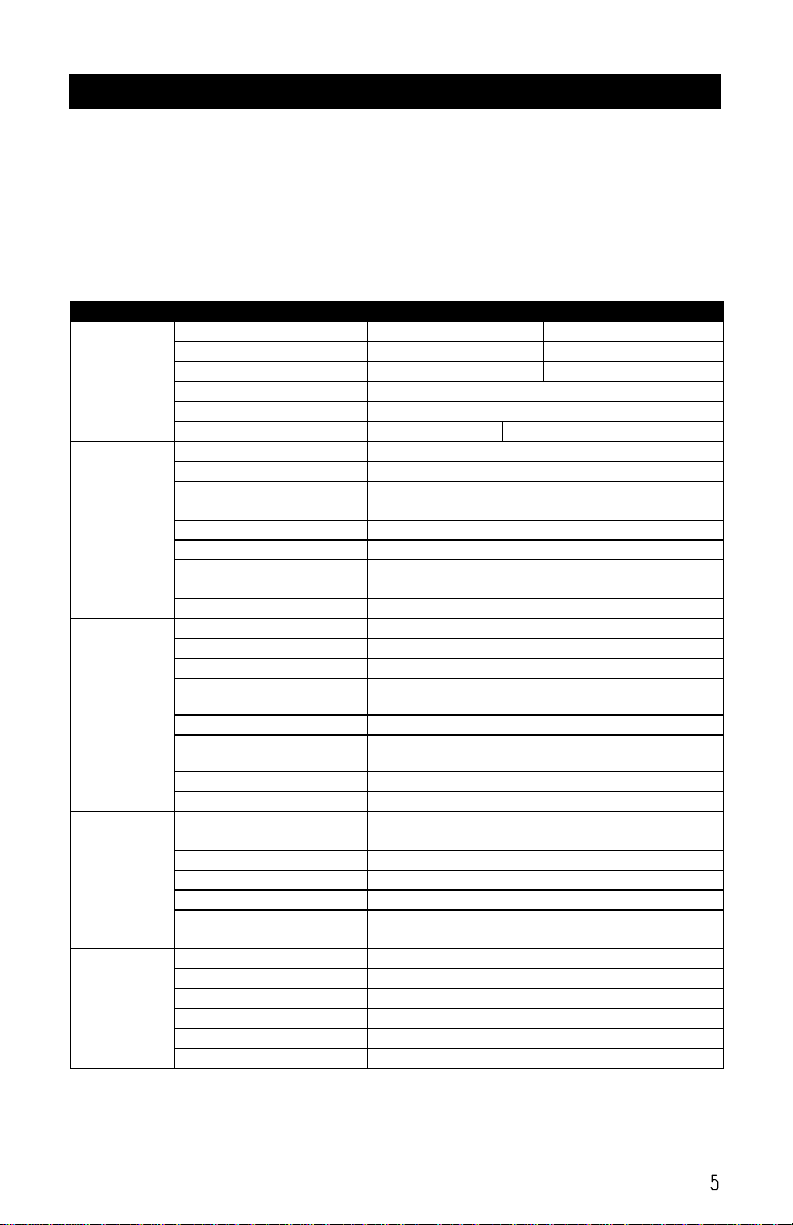

PRODUCT SPECIFICATIONS

ABOUT THIS PRODUCT -Bodine’s PACESETTERTM “NANO” series

inverter is a PWM type inverter that converts a single phase AC input

voltage into an adjustable frequency three phase AC output voltage.

Since the speed of AC induction motors is proportional to the line

frequency, adjusting the output frequency of the inverter enables

adjustable speed operation of the motor.

Model Number:

2701 2703

Motor HP 1/4 1/2

Motor kW 0.2 0.4

Output Amps 1.4 2.3

Input Volts Single phase 100-120V (+10%-15%) , 50/60Hz (+/-5%)

Output Volts Three phase 200-240V +10%-15% (Input Voltage Max)

Ratings

Weight, Lb (Kg ) 1.5 (0.7) 1.6 (0.72)

Carrier Frequency 1 –16 kHz

Frequency Control Range 0 –200 Hz

Frequency Resolution Digital: 0.1 Hz (0 -99.9Hz); 1 Hz (100~200Hz)

Analog: 1 Hz / 60Hz

Frequency Setting Signal Keypad or external signal (0-10 V, 4–20 mA, 0–20 mA)

Accel / Decel Time 0.1 -999 Seconds

Braking Torque About 20% without external braking resistor (no provisions

for external resistor)

Control

Characteristics

V/F Pattern 3 Patterns each for 50 Hz & 60 Hz

Overload protection 150% for 1 min.

Over-voltage DC voltage > 410V

Under voltage DC voltage < 200V

Momentary

Power Loss 0 -2 seconds: inverter can be restarted by speed search

Stall Prevention Accelerate / Decelerate / Constant speed

Output terminal

short-circuit Electronic circuitry protection

Grounding fault Electronic Circuitry protection

Protection

features

Other function Heat sink temperature protection, Current limit

Indication function 3 character LED display indicates frequency or inverter

parameter or fault record or program version.

Inputs 2 multi-function, PNP type (source)

Output 1 multi-function

Torque control Torque boost level adjustable (manual torque boost)

Operation

Conditions

Other function Decelerate or free run stop, Auto reset, DC braking

frequency / Voltage / Time can be setup by constants.

Ambient Temperature -10 to +40OC

Humidity 0 -95% RH non-condensing.

Vibration Under 1 G (9.8 m/s2)

Enclosure IP20

Dimensions, W x H x D 2.83” x 5.20” x 4.64” (72 mm x 132 mm x 118 mm)

Environmental

Conditions

Mounting Install by mounting screw or DIN rail (Option).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

IMPORTANT SAFETY PRECAUTIONS

The AC Drive is a power electronic device. For safety reasons, please

read through this operations manual in detail and observe those

paragraphs with the safety alert symbol.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

CAUTION CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, may result in

property damage.

WARNING

lDo not touch printed circuit board (PCB) right after

turning off power. Wait until power light turns off.

lDo not attempt to wire circuitry while power is on.

lDo not attempt to examine components and signals on

the PCB while the inverter is operating.

lDo not attempt to disassemble or modify internal

circuitry, wiring, or components of the inverter.

lInverter must be properly grounded using 200V class

type III standard.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

INSTALLATION

This control should only be installed by a qualified person familiar

with its operation and associated hazards. The National Electrical

Code (NEC), local electrical and safety codes, and when

applicable, the Occupational Safety and Health Act (OSHA) should

be observed to reduce hazards to personnel and property.

Step 1. Examine before installation

Check the items you received against your purchase order. The model number is

printed on an adhesive label on the side of the inverter. Carefully examine the control

for shipping damage. Parts errors should be reported to Bodine. Shipping damage

claims should be made to the freight carrier.

CAUTION

Do not connect the AC inverter to the power supply if there

is any sign of damage. Notify the carrier and your distributor

immediately.

Step 2. Choose a Suitable Location

The installation site of the inverter directly impacts the full functionality and lifespan of

the inverter. Because the PACESETTERTM “NANO” series inverter has a ventilated

enclosure (IP 20 rating) and is fan-cooled, the following guidelines should be adhered

to:

lMount the unit vertically so that the fan is on top for better heat dissipation.

lMake sure the temperature around the inverter is between -10OC and +40OC

(avoid locations in direct sunlight or near heating equipment). If inverter is

installed in a control panel, an additional cooling fan may be needed.

lPrevent liquid from dripping into the enclosure vent holes.

lAvoid humid environments.

lAvoid environments with corrosive gas.

lPrevent solid objects, such as dust and metal scraps, from falling into the

enclosure vent holes.

lAvoid locations near radioactive matter or flammable material.

lAvoid locations near equipment that generate electromagnetic interference

(soldering or power machinery).

lAvoid mounting the inverter to a surface that vibrates.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Step 3 –Mount the Control

Install the inverter onto firm metal base or other inflammable material by inserting

screws through the three 4.5 mm diameter holes in the enclosure base.

DIMENSION Millimeters Inches

A132 5.20

B116 4.57

C130 5.12

D8.2 0.32

E118 4.64

F61 2.40

G72 2.83

FIGURE 2– Mounting dimensions.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

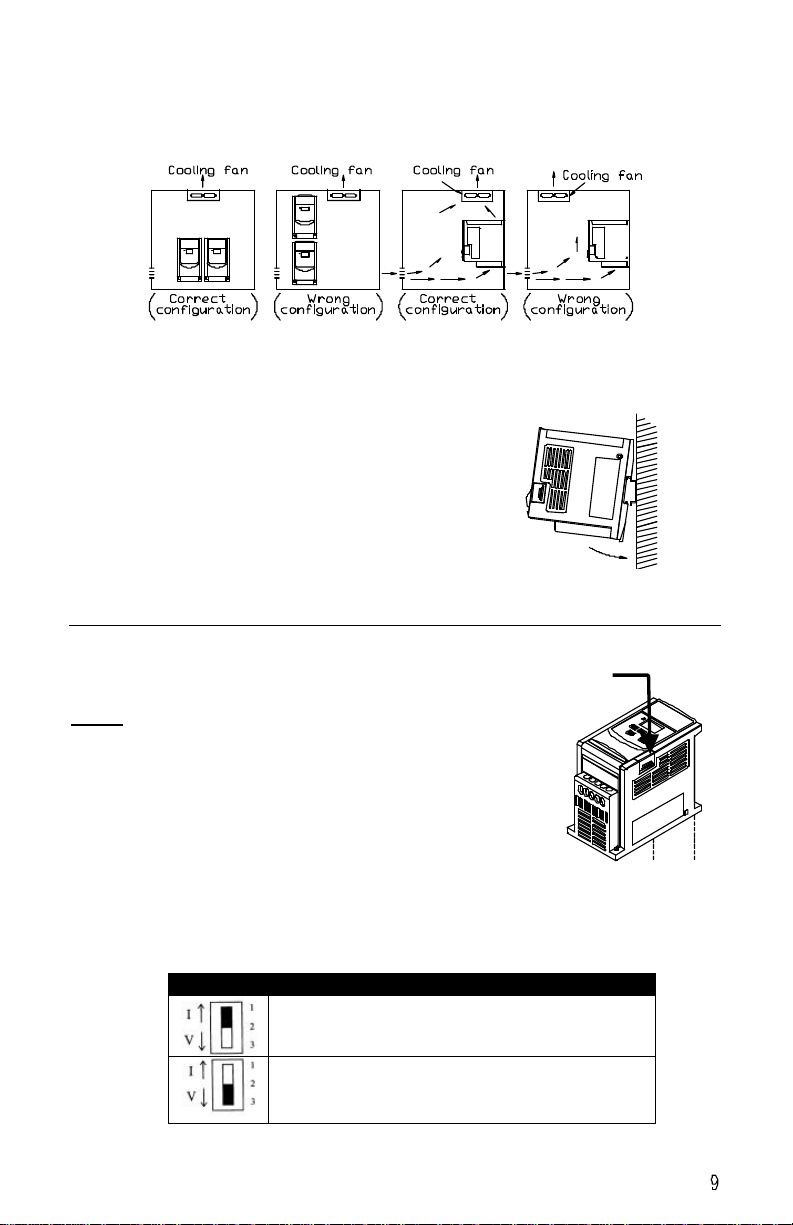

MULTIPLE DRIVES IN ONE PANEL -If several inverters are installed into one control

panel, then observe the guidelines in Fig. 3 in order to maximize the usefulness of the

fan in dissipating heat from the inverter. Inverters should be mounted side by side

and not one above the other.

FIGURE 3– Layout of several inverters inside one panel showing

front view (left) and side view (right).

DIN RAIL MOUNTING – Purchase Bodine’s DIN Rail

Mounting Kit, model 2730, and follow the instructions

that come with it.

FIGURE 4– Inverter installed on DIN Rail.

Step 4 –Preliminary Setup

This step is only required when a remote analog

current signal is to be used to adjust motor speed.

Refer to Fig. 5 and remove the small sliding cover

on the side of the inverter. Inside is a small slide

switch on the printed circuit board. The factory

setting of the switch is for an analog voltage input

and is in the “down” position where “V” is printed on

the circuit board. To configure the drive for an

analog current signal input, slide the switch “up” to

the side where “I” is printed on the circuit board.

FIGURE 6 –Switch settings for analog input signal

SWITCH 1 External signal type

0~10 VDC analog signal ( When Fn11 set to 1 )

0~20mA analog signal (When Fn_11 is set to 1 )

OR

4~20mA analog signal (When Fn_11 is set to 2 )

FIGURE 5 –

Location of

sliding cover

Sliding cover

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Step 5 –Electrical Connections

CAUTION

lThe PCB of the inverter is vulnerable to static electrical

charges. Do not contact the PCB.

lChoose the appropriate power source with correct

voltage settings for the input voltage specification of the

AC inverter.

lDo not use a separate device to switch ON or OFF

motor during operation. Otherwise, the inverter may

experience an over-current breakdown.

1Trip Relay

2

3FORWARD Run Switch

4REVERSE Run Switch

5+12V Terminals 3, 4, 6, 7

6SET SPEED 1 Run Switch

7RESET Switch

8+10V Power for Speed Pot

9Analog Input or Wiper for Speed

Pot

10 0V Common for Analog Input,

Speed Pot, and Analog Output

11 Analog Output

FIGURE 7– Electrical connections with remote inputs and outputs.

Step 5a –Connect the Motor

Connect a 230 VAC three-phase squirrel-cage induction motor with appropriate

ratings for the inverter to the “T1”, “T2”, and “T3” screw terminals on terminal block

TM1. Use a Phillips screwdriver to clamp the stripped motor wires. Tighten to 12 lb-

in. It doesn’t matter which motor wires go to which terminal. If the motor doesn’t

rotate in the desired direction as connected, swap any two of the three motor wires.

T3 230V Three Phase

T2 Motor Connections

T1

L2 115V Single Phase

L1 Power Connections

Ground Screw

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Step 5b –Connect Remote Control Devices (optional)

The drive can be completely controlled by the keypad and it is recommended that

your operate the inverter this way first to verify that it is operating properly by itself

before proceeding to connect external devices to it. For remote operation, the

following devices can be connected to terminal block TM2.

FORWARD RUN/STOP SWITCH & REVERSE RUN/STOP SWITCHES – To enable these

switch inputs, change programmable parameter F10 to “001” (refer to Step 7 for

procedure). Use 20 AWG wire to connect switches with low voltage contacts

between terminals 3 and 5 (FWD) and between 4 and 5 (REV). When the FWD

(or REV) switch is closed, motor will run in forward (or reverse) direction at the

set speed. When the switch is opened, motor will stop. The function of these

switch inputs can be changed with programmable function F03.

PRESET SPEED RUN/STOP SWITCH (SP1) -Use 20 AWG wire to connect a switch

with low voltage contacts to terminals 6 and 5. When switch is closed, and when

motor is commanded to run, motor will run at the speed set by programmable

parameter F08. When switch is opened, motor will run at the speed set by either

the keypad or a remote signal. The function of this switch input can be changed

with programmable function F19.

RESET SWITCH (RESET) -Use 20 AWG wire to connect a switch with low voltage

contacts to screw terminals 7 and 5 on terminal block TM2. Close the switch to

reset the drive after a fault condition. The function of this switch input can be

changed with programmable function F20.

SPEED SIGNAL INPUT (Vin) –To make this input functional, programmable

parameter F11 must be changed to “001” or “002” (refer to Step 7 for

procedure). Use 20 AWG wire to connect a remote analog voltage or current

signal screw terminal 9 on terminal block TM2, using terminal 10 as the signal

common. The drive will accept a 0 –10 VDC, 0 –20 mA, or 4 –20 mA signal

(refer to Step 4 if using a current signal). Alternatively, a speed potentiometer

can be connected to the drive as shown in Fig. 1 with the wiper connected to

terminal 9 and the two end terminals of the speed pot connected to terminals 8

and 10 on the drive.

ANALOG OUTPUT (FM+) –This output produces a 0 –10 VDC signal proportional

to the output frequency of the drive. Use 20 AWG wire to connect a remote

readout or programmable controller to screw terminals 10 and 11 on terminal

block TM2.

FAULT OUTPUT (TRIP RELAY) –This relay output has a contact rating of 250 VAC,

1 Amp or 30 VDC, 1 Amp. Use 20 AWG wire to connect a remote device to

screw terminals 1 and 2 on terminal block TM2. The relay is normally open and

closes when there is a fault condition. This can be used to close the circuit of an

alarm or to signal a programmable controller to shut down.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Step 5c –Ground the Inverter

The grounding terminal of the inverter must be correctly grounded in compliance with

200V class type three grounding.

lGrounding wire should be wired in accordance to electrical equipment

(AWG) with the length of the grounding wire as short as possible.

lThe grounding wire of the inverter must not be grounded together with

other large current loading (such as soldering machine or large power motor).

They should be grounded separately.

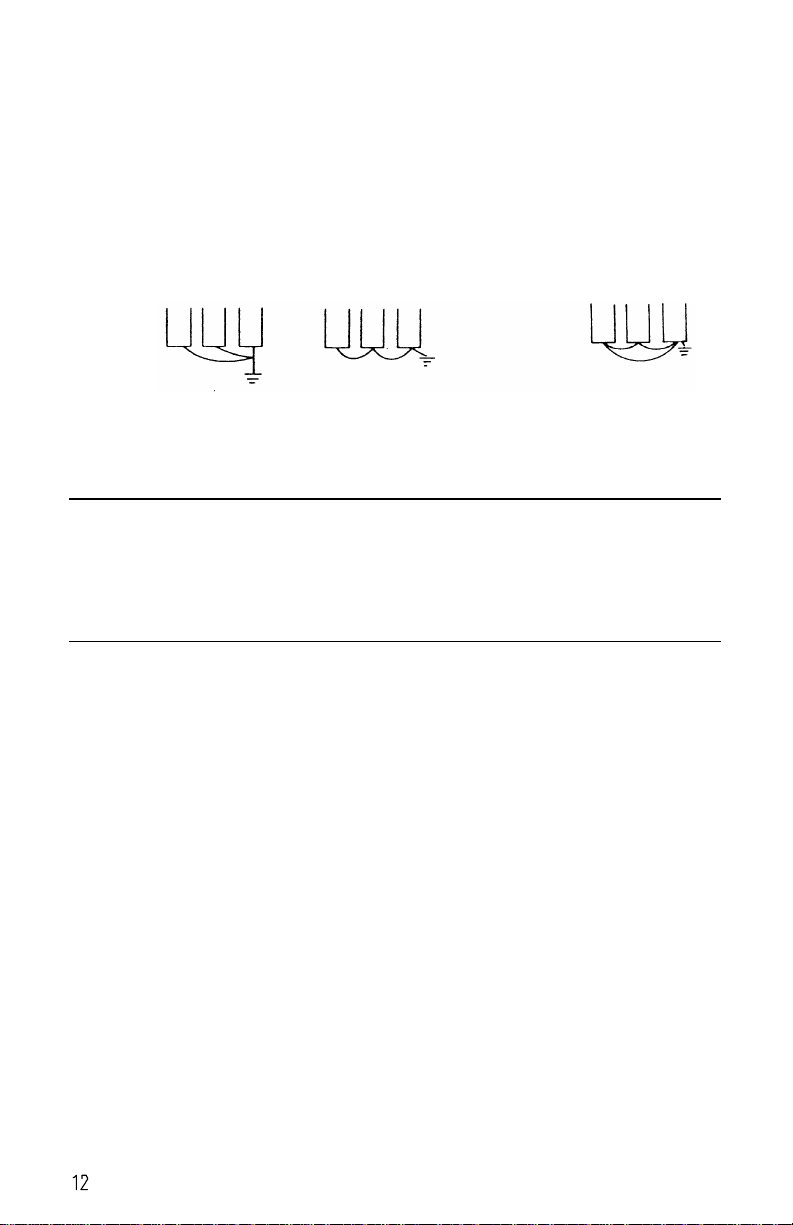

lPrevent ground loops when grounding several inverters together.

FIGURE 8– Grounding multiple drives. The two circuits on the left are correct.

The circuit on the right creates a ground loop and is incorrect.

Step 4h –Connect Circuit Breaker

Connect a 2-pole circuit breaker between terminals L1 & L2 on terminal block TM1

and the 115 VAC single phase supply.

Step 5d –Connect the AC Line

Connect the 115 VAC single-phase power line to the “L1” and “L2” screw terminals

on terminal block TM1. Terminations to the Inverter must be made with either UL

listed field wiring lug kits or UL listed crimp type ring terminals.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

OPERATION

Step 6 –Check System Before Starting

WARNING

lRecheck all connections.

lDo not remove the front cover of the inverter when the

power is ON to avoid personnel injury caused by

electrical shock.

lWhen the automatic restart function is enabled, the

motor and machinery will be restarted automatically.

lDo not attempt to install or remove input or output

connectors of inverter when the power supply is turned

on. Otherwise, the inverter may be damaged due to the

surge peak caused by the insertion or removal.

lDo not attempt to wire circuitry while power is on.

lDo not attempt to examine the components and signals

on the PCB while the inverter operating.

lDo not touch the heat-sink base during operation.

CAUTION

lCheck that motor is securely mounted.

lTest motor unloaded first to verify proper setup.

lCheck all rotating members. Be sure keys, pulleys, etc.

are securely fastened and safety guards are in place.

lCheck for proper mounting and alignment of products,

and verify safe loading on shafts and gears.

lThis product is not provided with over speed protection.

The inverter can be easily operated from a low-speed to

high-speed range. Please reconfirm the operating range

of motor and the machinery you are controlling.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Step 7: Operate the Control

FIGURE 9– Keypad location and layout

Step 7a –Operate the Inverter using the Keypad

The PACESETTERTM “NANO” series inverter is factory-set for operation using the

pushbutton keypad. Use the following procedure to start the motor and adjust speed.

1) Turn the AC power ON. The LED display will illuminate and show the current

setting for output frequency. The power light just to the left of the LED display will

also illuminate.

2) Press the button labeled “RUN/STOP”. The display will change to show actual

output frequency, which will start at “000” and ramp up to the set frequency.

Simultaneously, the motor will start and accelerate.

3) Press the button labeled “p” to increase the output frequency. The motor will

accelerate until the “p” button is released. Note that the output frequency

changes at a progressively faster rate the longer you hold the button down.

Press the “q” button to decrease the output frequency.

4) Press the button labeled “RUN/STOP” again to stop the motor.

5) If the motor does not start promptly and run smoothly, refer to

“TROUBLESHOOTING”.

Step 7b –Operate the Inverter using remote devices

To enable operation from remote inputs, some of the programmable parameters

need to be changed. Assuming the drive is connected as shown in Fig. 7, use the

following procedure to enable remote control of start/stop operation, speed

adjustment, and direction.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1. Switch on the AC power.

2. Press the “DSP/FUN” key. The LED display will change from set output

frequency to a function number between “F00” and “F30”.

3. Press either the “q/RESET” key or the “p” key to scroll through the

available function numbers until you reach “F11”. This is the function that

enables remote control of speed adjustment.

4. Press the “DATA/ENT” key. This will change the LED display from the

function number to the current setting of the parameter. The factory setting

for parameter F11 is “000” for keypad control of speed.

5. Press either the “q/RESET” key or the “p” key to change the setting to

either “001” or “002” (see “Speed Control Method (F11)” on page X).

6. Press the “END” key to save the new setting. The LED display will change

to “End” for 1/2 second and then back to the function number.

7. Repeat the above steps, changing the setting of function number F10 to

“001” to enable remote control of direction andstart/stop operation.

8. When finished programming, press the “DSP/FUN” key. The LED display

will change back to the set output frequency.

Step 7c –Change other parameters (optional)

Before changing the programmable parameters, first stop the motor if necessary.

Only acceleration time (F01), deceleration time (F02), motor direction (F04), and

torque compensation (F13) can be changed while motor is running. Use the same

procedure described in Step 7b to change other parameters. The following pages

give a brief description of each parameter. To clear the inverter of all changes and

return it to the factory settings, change function F25 to “020”.

Parameter List, Functions F01 –F11

Function Description Range Factory setting

F01 Acceleration time 00.1 –999 seconds 05.0

F02 Deceleration time 00.1 –999 seconds 05.0

F03 External operation mode 000: FWD/Stop, REV/Stop

001: Run/Stop, FWD/ REV 000

F04 Direction selection 000: Forward

001: Reverse 000

F05 V/F pattern setting 001: 50 Hz General application

002: 50 Hz High starting torque

003: 50 Hz Variable torque

004: 60 Hz General application

005: 60 Hz High starting torque

006: 60 Hz Variable torque

004

F06 Maximum frequency 01.0 -200 Hertz 60.0

F07 Minimum frequency 00.0 -200 Hertz 00.0

F08 Preset speed 1 (SP1) 01.0 -200 Hertz 10.0

F09 JOG frequency 01.0 –200 Hertz 06.0

F10 Operation control method 000:keypad

001: external terminal 000

F11 Speed control method 000: keypad

001: external signal (0~10v/0~20mA )

002: external signal ( 4~20mA )

000

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Paramter List, Functions F12 –F27

Function Description Range Factory setting

F12 Switching frequency 001: 4 kHz 006: 10 kHz

002: 5 kHz 007: 12 kHz

003: 6 kHz 008: 14.4 kHz

004: 7.2 kHz 009: 15 kHz

005: 8 kHz 010: 16 kHz

005

F13 Torque boost adjustment 00.0 -10.0% 00.0

F14 Stopping method 000: decelerate stop

001: free run stop 000

F15 Braking time 00.0 -25.5 seconds 00.5

F16 Braking starting frequency 01.0 -10.0 Hertz 01.5

F17 Braking level 00.0 -20.0% 08.0

F18 Currentlimit 000 -200% 100

F19 Input terminal 6 function 001: Jog

002: SP1

003: Emergency stop

004: External Base Block

005. Reset

006: SP2

002

F20 Input terminal 7 function 001: Jog

002: SP1

003: Emergency stop

004: External Base Block

005. Reset

006: SP2

005

F21 Output terminal function 001: Operating

002: Frequency reached

003: Fault

003

F22 Reverse enable 000: REV command enabled

001: REV command disabled 000

F23 Auto restart enable 000: Auto restart enabled

001: Auto restart disabled 000

F24 Auto restart times 000 –005 times 000

F25 Restore factory settings 010: Restore to 50Hz settings

020: Restore to 60Hz settings 000

F26 Preset speed 2 (SP2) 01.0 -200 Hertz 020

F27 Preset speed 3 (SP3) 01.0 -200 Hertz 030

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Description of Programmable Functions

F01: Acceleration Time

Function F01 can be changed to adjust the acceleration time from the default

setting of 5.0 seconds to any time between 0.1 and 999 seconds.

Set Frequency

Acceleration time = F01 x

60 Hz

F02: Deceleration Time

Function F02 can be changed to adjust the deceleration time from the default

setting of 5.0 seconds to any time between 0.1 and 999 seconds.

SetFrequency

Deceleration time = F02 x

60Hz

F03: Start / Stop Control from TM2

Function F03 sets the function of input terminals 3 and 4, provided that function

F10 is set at “001” for external control operation. The default setting of F03 is

“000”, which configures input terminal 3 for a “Forward/Stop” switch (close to

run forward, open to stop) and input terminal 4 for a “Reverse/Stop” switch

(close to run reverse, open to stop). The alternate setting of F03 is “001”, which

configures input terminal 3 for a “Run/Stop” switch (close to run, open to stop)

and input terminal 4 for a “Forward/Reverse” switch (close for forward direction,

open for reverse).

F04: Direction Selection

Although there is no Forward/Reverse push button on the digital control panel, it

is possible to change motor direction without changing the motor connection by

changing function F04. The factory setting is “000” for forward direction.

Changing F04 to “001” will result in reverse direction. NOTE: When F22 =

“001”, reverse is disabled and F04 can not be set to “001”. If it is, the keypad

indication will display the error message “LOC”.

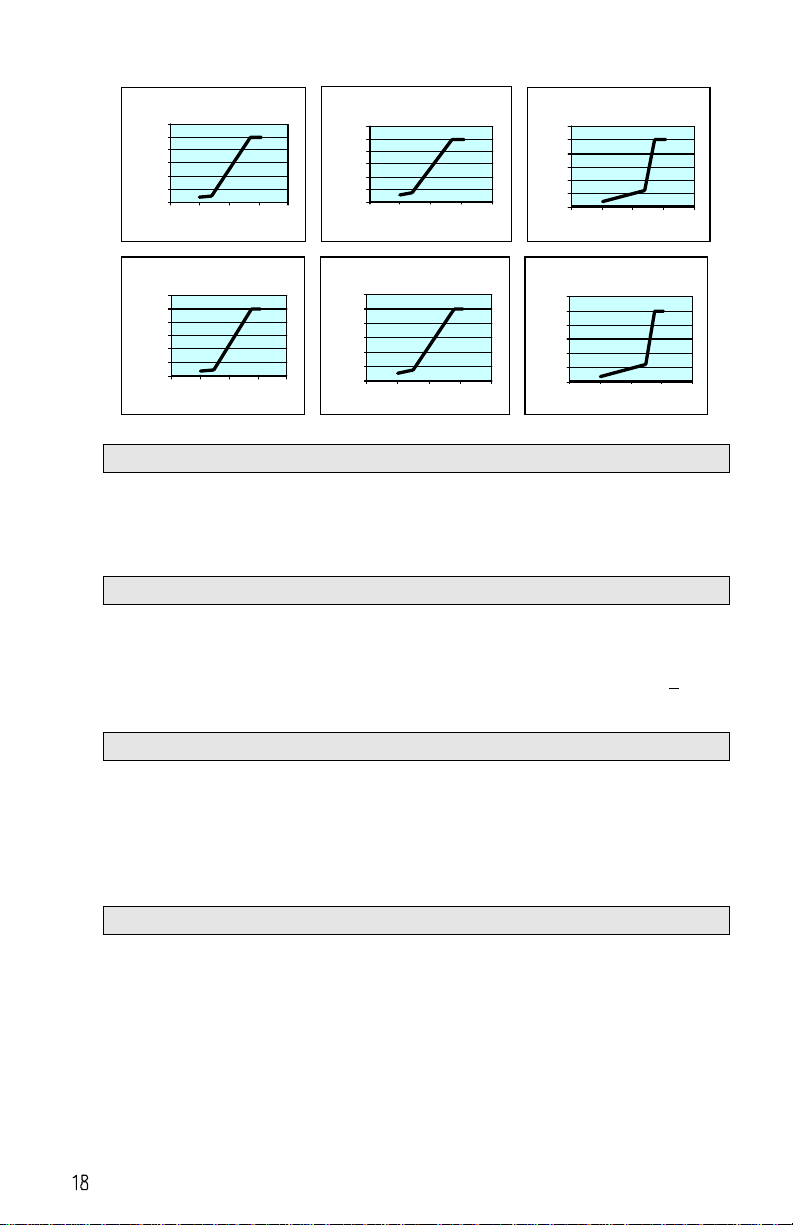

F05: V/F Pattern Setting

Function F05 can be changed from its factory setting of “004” to any number

between “001” and “006”. Settings “001” through “003” are to be used only

when the inverter is configured for 50 Hz input power. Settings “004” through

“006” are to be used only when the inverter is configured for 60 Hz input power.

The three different settings for each input frequency control the ratio of output

voltage to output frequency. The factory setting of “004” with 60 Hz input power

produces a constant volts/frequency ratio between output frequencies of 0 to 60

Hz (above 60 Hz, the output voltage is fixed). The alternate settings either

boost the voltage at lower frequencies for higher starting torque (F05 = “002” or

“005”) or reduce the voltage at lower frequencies for applications where the

torque increases with speed, like a fan (F05 = “003” or “006”). See Fig. 10.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

FIGURE 10 – Six different V/F settings.

V/F Pattern for F05 = 001

(50 Hz General Application)

0%

20%

40%

60%

80%

100%

120%

0.1 1 10 100 1000

Output Frequency, Hz

Volts,% of max.

V/F Pattern for F05 = 002

(50 Hz High Starting Torque)

0%

20%

40%

60%

80%

100%

120%

0.1 110 100 1000

Output Frequency, Hz

Volts,% of max.

V/F Pattern for F05 = 003

(50 Hz Variable Torque)

0%

20%

40%

60%

80%

100%

120%

0.1 1 10 100 1000

Output Frequency, Hz

Volts,% of max.

V/F Pattern for F05 = 004

(60 Hz General Application)

0%

20%

40%

60%

80%

100%

120%

0.1 1 10 100 1000

Output Frequency, Hz

Voltage, % of max.

V/F Pattern for F05 = 005

(60 Hz High Starting Torque)

0%

20%

40%

60%

80%

100%

120%

0.1 1 10 100 1000

Output Frequency, Hz

Voltage, % of max.

V/F Pattern for F05 = 006

(60 Hz Variable Torque)

0%

20%

40%

60%

80%

100%

120%

0.1 110 100 1000

Output Frequency, Hz

Voltage,% of max.

F06: Upper Frequency Limit

Use function F06 to change the upper frequency limit, and hence the maximum

motor speed limit, by changing F06 from the factory setting of “60.0” (60 Hz) to

any number between “01.0” and “200” in increments of 0.1 Hz up to 100 Hz and

increments of 1 Hz after that.

F07: Lower Frequency Limit

Use function F07 to change the lower frequency limit, and hence the minimum

motor speed limit, by changing F07 from the factory setting of “00.0” (0.0 Hz) to

any number between “00.0” and “200” in increments of 0.1 Hz up to 100 Hz and

increments of 1 Hz after that. If F07 > “00.0” and the frequency command<F07,

the inverter will output according to F07 setting.

F08: Preset Speed 1 (SP1) Frequency

Change the frequency of the SP1 input by changing F08 from the factory setting

of “10.0” (10 Hz) to any number between “01.0” and “200” in increments of 0.1

Hz up to 100 Hz and increments of 1 Hz after that. When F19 or F20 = “002”

and the corresponding input terminal is ON, the inverter operates at the

frequency set by F08. The priority of reading frequency setting is: Jog setting g

SP1 setting gkeypad setting or external frequency signal

F09: Jog Speed Reference

Use function F09 to change the frequency of the JOG input by changing F09

from the factory setting of “06.0” (6 Hz) to any number between “01.0” and “200”

in increments of 0.1 Hz up to 100 Hz and increments of 1 Hz after that. When

F19 or F20 = “001” and the corresponding input terminal is ON, the inverter

operates at the frequency set by F09. The priority of reading frequency setting

is: Jog setting gSP1 setting gkeypad setting or external frequency signal

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

F10: Start / Stop Control Method

Use function F10 to select between the keypad (F10 = “000”) or an external

signal (F10 = “001”) for run/stop instruction. The factory setting of F10 is “000”.

When F10 = “001”, emergency stop on the keypad is enabled.

F11: Frequency Command Selection

Use function F11 to select where the frequency command comes from. The

factory setting of F11 is “000”, so that the frequency command comes from the

keypad. Alternate settings allow the frequency command to come from an

analog signal on TM2, either 0 ~ 10V or 0 -20mA (F11 = “001”), or 4 -20mA

(F11 = “002”).

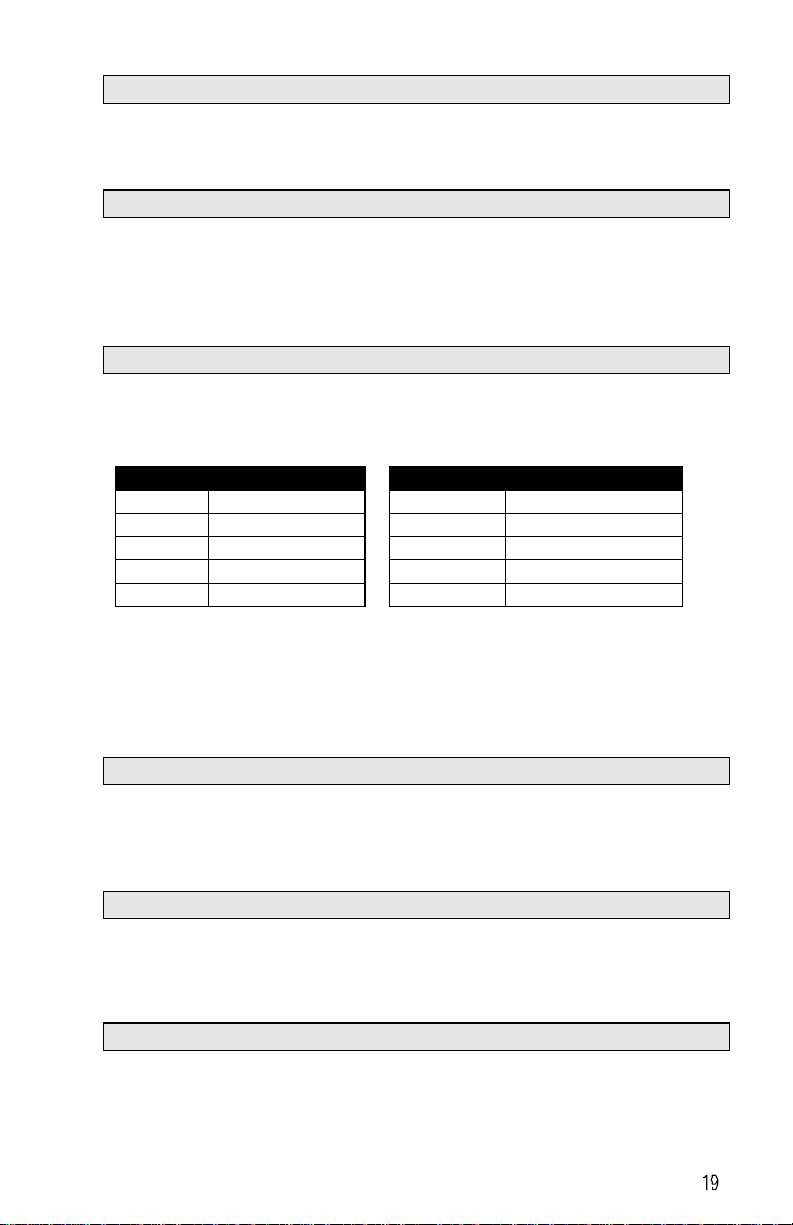

F12: Carrier Frequency

Use function F12 to change the PWM switching frequency from the factory

setting of 8 kHz (F12 = “005”) to any one of the settings listed in Fig. 11.

FIGURE 11 – Ten different PWM switching frequencies to choose from.

F12 carrier frequency F12 carrier frequency

001 4 kHz 006 10 kHz

002 5 kHz 007 12 kHz

003 6 kHz 008 14.4 kHz

004 7.2 kHz 009 15 kHz

005 8 kHz 010 16 kHz

If F12 = 007 thru 010, the inverter will run hotter than normal. Additional cooling

may be required or a motor smaller than the normal rating should be used.

Although IGBT TYPE inverters can provide a low audible noise environment

during operation, it is possible that high frequency switching may interfere with

external electronic components (or other controllers).

F13: Torque compensation gain

Function F13 changes torque compensation gain from the factory setting of

0.0% (“000”) to any number between 0.0% (“000”) and 10% (“010”). The

voltage at the B and C points on the V/F patterns (refer to F05 description) are

boosted by the percentage set by F13 to enhance output torque.

F14: Stopping Mode

Function F14 changes the stopping method. If F14 = “000” (factory setting) and

the inverter receives a stop instruction, it decelerates to the frequency set by

F16 by applying the output voltage level set by F17 for the time duration set by

F15. If F14 = “001”, the motor coasts to a stop.

F15: DC Braking Time

Function F15 changes DC braking time from the factory setting of 0.5 seconds

to any number between 0.0 and 25.5 in increments of 0.1 second.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

1

Table of contents

Other Bodine Engine manuals

Popular Engine manuals by other brands

Ventus

Ventus BOW5512D Operation manual and installation instructions

Aqua-Scope

Aqua-Scope KFRLWE01 User and installation manual

LZ design

LZ design FES-DG-M100 manual

Crestron

Crestron QMT CSM-QMTDC Programming guide

Leroy-Somer

Leroy-Somer HPM 250 Installation and Maintenance

wsm

wsm 70mm STROKE SERIES Workshop manual