Bodine 34R6BXPP User guide

07401151.B

www.bodine-electric.com

Bodine Electric Company

Type 34R6BXPP Motors & Gearmotors

AC 3-Phase, Inverter-Duty 230VAC or 460VAC

This apparatus is suitable for use in Hazardous Locations

Class I, Division 1, Groups C & D.

Instructions for Installation and Operation

U

L

L

I

S

T

E

D

F

O

R

O

P

E

R

A

T

I

O

N

C

L

A

S

S

I

/

D

I

V

1

H

A

Z

A

R

D

O

U

S

L

O

C

A

T

I

O

N

S

•

PROOF

IP-66

EX-

www.bodine-electric.com

2www.bodine-electric.com

© Copyright 2021 Bodine Electric Company.

All rights reserved. All data subject to change without notice. Printed in U.S.A.

TABLE OF CONTENTS

This manual contains the basic information needed to install and operate a

Bodine type 34R6BXPP three-phase AC motor or gearmotor that is certified

for use in Class I Division 1 hazardous locations. This manual does not profess

to cover all details or variations in equipment, nor to provide for every possible

contingency associated with installation, operation, or maintenance. No

warranty of fitness for purpose is expressed or implied. It is the responsibility

of the user to determine whether the installation location is hazardous, and to

what degree it is hazardous. Should further information be desired or should

particular problems arise which are not covered sufficiently for the user’s

purpose, the matter should be referred to the Bodine Electric Company.

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Step 1: Mount the 34R6BXPP Motor or Gearmotor . . . . . . . . . . . . . . .6

Step 2: Attach a Conduit Outlet Box to the Motor . . . . . . . . . . . . . . . .8

Step 3: Make Electrical Connections . . . . . . . . . . . . . . . . . . . . . . .8

Step 4: Operate the 34R6BXPP Motor or Gearmotor . . . . . . . . . . . . . 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Bodine Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

FIGURES

Figure 1a – Dimensions for Standard 34R6BXPP Motor . . . . . . . . . . . 6

Figure 1b – Dimensions for Standard 34R6BXPP-FX Gearmotor. . . . . . . 7

Figure 2 – A Typical Conduit Outlet Box . . . . . . . . . . . . . . . . . . . . 8

Figure 3 – Motor after Conduit Outlet Box Installation . . . . . . . . . . . 8

Figure 4a – Electric Connections –

Thermal Switch with Logic Control to Disable Motor Power . . . 10

Figure 4b – Electric Connections –

Thermal Switch with AC Relay to Interrupt Supply . . . . . . . 10

Figure 4c – Electric Connections –

Thermal Switch with 3 Pole AC Relay to Interrupt Supply . . . 11

RoHS COMPLIANCE

This document certifies that the Bodine Electric type 34R6BXPP motor

and type 34R6BXPP-FX gearmotors are manufactured with materials and

processes that comply with European Directive 2011/65/EU, as amended by

council directive 2015/863/EU, on the Restriction of Hazardous Substances

(RoHS).

www.bodine-electric.com 3

!WARNING

IMPORTANT SAFETY PRECAUTIONS

The use of electric machines, like that of all other utilization of concentrated

power, is potentially hazardous. The degree of hazard can be greatly reduced

by proper design, selection, installation, and use, but hazards cannot be

completely eliminated. The reduction of hazard is the joint responsibility

of the user, the manufacturer of the driven or driving equipment, and the

manufacturer of the machine.

The Bodine type 34R6BXPP motor and 34R6BXPP-FX gearmotor

were designed to meet the requirements of UL 674 and CSA C22.2

No. 145-M2017, electric motors for use in Division 1 Hazardous

Locations. The motor ratings were established for operating temperatures

from -20C to +40C. They have a T4A temperature code rating Reference UL

file number E318315. These products bear the UL mark shown above.

Please read through this operations manual in detail and observe those

paragraphs with the safety alert symbol.

This indicates a potentially hazardous situation, which,

if not avoided, could result in death or serious injury.

!WARNING/AVERTISSEMENT

• CAUTION–To reduce the risk of ignition of hazardous atmospheres,

disconnect the equipment from the supply circuit before opening. Keep

assembly tightly closed when in operation.

• Leads factory-sealed. Do not disassemble any part of this product as that

will compromise its safety in hazardous atmospheres.

• This product should be installed, inspected, and maintained by a qualified

electrician only, in accordance with all applicable electrical codes.

• ATTENTION–Pour réduire le risque d’inflammation des atmosphères

dangereuses, débranchez l’équipement du circuit d’alimentation avant de

l’ouvrir. Gardez l’assemblage bien fermé lorsqu’il est en fonctionnement.

• Fils scellés en usine. Ne démontez aucune pièce de ce produit car cela

compromettrait sa sécurité dans les atmosphères dangereuses.

• Ce produit doit étre installè, inspecté et entretenu par un électricien

qualifié seulement, conformément avec tous les codes de l’électricité

pertinents.

4www.bodine-electric.com

IMPORTANT

Read this manual completely and carefully before making any connections.

Pay special attention to all warnings, cautions, and safety rules. Failure to

follow the instructions could produce safety hazards, which could injure

personnel or damage the motor, gearmotor, or other equipment. If you

have any doubts about how to connect the motor or gearmotor, refer to the

detailed sections of this manual..

PRODUCT SPECIFICATIONS

The motors are 3-Phase AC induction motors. The 34R6BXPP is a 3-Phase AC

induction motor, available with or without an integral gearbox, and a normally

closed, self-resetting thermal switch attached to the motor windings.

Table 1 lists the specifications common to all variations of this product. Table

2 lists the specifications unique to each gear ratio that is offered.

TABLE 1

Parameter

Specification

Locations: Hazardous locations Class I, Division 1, Groups C & D, or

unclassified (non-hazardous) locations.

Temperature Code: T4A or T3C

Horsepower: ¼ HP

Volts: 230 VAC, 3 Phase or 460 VAC, 3 Phase (separate models)

Line Frequency: 60 Hz

Inverter Frequency: 10 – 120 Hz for motors, 10 – 90 Hz for gearmotors

Ambient Temperature: -20C to 40C

Insulation: F8

TABLE 2

LINE VOLTAGE RATINGS INVERTER DUTY RATINGS

Product Type Gear

Ratio

Speed

(rpm)

Torque

(lb-in)

Speed Range

(rpm)

Torque @

60 Hz

(lb-in)

34R6BXPP N/A 1600 9.9 214 – 3259 9.9, VT*

34R6BXPP-FX1 5:1 320 46 43 – 474 46, VT*

34R6BXPP-FX2 10:1 160 89 21 – 237 89, VT*

34R6BXPP-FX2 15:1 107 133 14 – 158 133, VT*

34R6BXPP-FX3 20:1 80 178 11 – 119 178, VT*

34R6BXPP-FX3 30:1 53 267 7.1 – 79 267, VT*

34R6BXPP-FX3 40:1 40 265 5.4 – 59 265, VT*

34R6BXPP-FX3 60:1 27 350 3.6 – 40 350, VT*

34R6BXPP-FX4 120:1 13 350 1.8 – 20 350, CT*

34R6BXPP-FX4 180:1 8.9 350 1.2 – 13 350, CT*

34R6BXPP-FX4 300:1 5.3 350 0.7 – 7.9 350, CT*

* VT = “Variable Torque, CT = “Constant Torque”

www.bodine-electric.com 5

INSTALLATION

This product should only be installed by a qualified person familiar with its

operation and associated hazards, and knowledgeable about the special

requirements for installation in hazardous locations. The National Electrical

Code (NEC), local electrical and safety codes, and when applicable, the

Occupational Safety and Health Act (OSHA) should be observed to reduce

hazards to personnel and property. NEC section 500 (Hazardous Locations) is

particularly important. See pages 6 and 7 for motor and gearmotor dimensions.

!WARNING/AVERTISSEMENT

• CAUTION–To reduce the risk of ignition of hazardous atmospheres,

disconnect the equipment from the supply circuit before opening. Keep

assembly tightly closed when in operation.

• Leads factory-sealed. Do not disassemble any part of this product as that

will compromise its safety in hazardous atmospheres.

• This product should be installed, inspected, and maintained by a qualified

electrician only, in accordance with all applicable electrical codes.

• ATTENTION–Pour réduire le risque d’inflammation des atmosphères

dangereuses, débranchez l’équipement du circuit d’alimentation avant de

l’ouvrir. Gardez l’assemblage bien fermé lorsqu’il est en fonctionnement.

• Fils scellés en usine. Ne démontez aucune pièce de ce produit car cela

compromettrait sa sécurité dans les atmosphères dangereuses.

• Ce produit doit étre installè, inspecté et entretenu par un électricien

qualifié seulement, conformément avec tous les codes de l’électricité

pertinents.

6www.bodine-electric.com

Step 1: Mount the 34R6BXPP Motor or Gearmotor

Install the 34R6BXPP motor or gearmotor onto a secure mounting surface

using the appropriate hardware for the desired mounting orientation, as

indicated in Figure 1a and 1b. For example, if a gearmotor is to be mounted

by the holes in the face where the output shaft exits, then four ¼-28 UNC-

2B screws are used (the max screw length is to be determined by the user).

Figure 1a – Dimensions for Standard 34R6BXPP Motor

9.534 Max

4.78 Max sq

.483±.010 2.06±.03

4x 3/8-16 UNC-2B

90° ± 1” apart

on ø5.875 ± .010 b.c.

4x 1/4-20 UNC-2B

.31 Min Deep

90.0° apart

on ø3.750 b.c.

ø 4.500 / 4.497

5.32±.02 sq

ø 3.000 / 2.997

ø .6250

.1875/.1855

x 1.38 long key

1” NPT x 11-1/2

threads per inch

.6245

.125

(.125)

(2.13) sq Flange

4.01 Max.

(7.16)

17 / 18

Number of

leads may vary

.50±.06 Typ.

4.885

Max

2x .800 2x .39 Base

mounting holes

4x 1/4-20 UNC-2B

.47 min deep

Base mounting holes 1.50

9.534 Max

4.78 Max sq

.483±.010 2.06±.03

4x 3/8-16 UNC-2B

90° ± 1” apart

on ø5.875 ± .010 b.c.

4x 1/4-20 UNC-2B

.31 Min Deep

90.0° apart

on ø3.750 b.c.

ø 4.500 / 4.497

5.32±.02 sq

ø 3.000 / 2.997

ø .6250

.1875/.1855

x 1.38 long key

1” NPT x 11-1/2

threads per inch

.6245

.125

(.125)

(2.13) sq Flange

4.01 Max.

(7.16)

17 / 18

Number of

leads may vary

.50±.06 Typ.

4.885

Max

2x .800 2x .39 Base

mounting holes

4x 1/4-20 UNC-2B

.47 min deep

Base mounting holes 1.50

The 5.875” B.C. meets NEMA-56C specifications with optional base mount kit, mod# 0931 installed

www.bodine-electric.com 7

4.78 Max sq

3.60±.015

2.00±.03

2x .800 2x 2.951

±.010

17 / 18

Number of

leads may vary

4.66±.02 sq

.862 Typ

[4]1/4-28 UNF-2B

.625 Min Deep

Base mounting

holes

4x 1/4-20 UNC-2B

.47 min deep

.1875/.1855 sq.

x 1.12 long key

Base mounting holes

3.380 Typ

ø.6250

.6245 3.390

±.006

.1875 /.1855 sq x

1.12 Long Key

3.380 Typ

.50±.06 Typ.

(2.13) sq Flange

(9.24)

11.617 Max

1” NPT x 11-1/2

Threads per inch

4.01 Max

1.590 Typ

(.90)

1.50

ø1.536±.016

Not Machined

4.885

Max

Figure 1b – Dimensions for Standard 34R6BXPP-FX Gearmotor

4.78 Max sq

3.60±.015

2.00±.03

2x .800 2x 2.951

±.010

17 / 18

Number of

leads may vary

4.66±.02 sq

.862 Typ

[4]1/4-28 UNF-2B

.625 Min Deep

Base mounting

holes

4x 1/4-20 UNC-2B

.47 min deep

.1875/.1855 sq.

x 1.12 long key

Base mounting holes

3.380 Typ

ø.6250

.6245 3.390

±.006

.1875 /.1855 sq x

1.12 Long Key

3.380 Typ

.50±.06 Typ.

(2.13) sq Flange

(9.24)

11.617 Max

1” NPT x 11-1/2

Threads per inch

4.01 Max

1.590 Typ

(.90)

1.50

ø1.536±.016

Not Machined

4.885

Max

If mounting from the four ¼-20 UNC-2B base holes, the screw length should

not exceed a maximum thread engagement depth of 0.45”. See Figure 1a and

1b for the location of the mounting holes on Bodine’s stock models. For custom

variations of our stock models, refer to Bodine’s “INFS” drawing instead.

Please visit our website for optional base mount accessory kit, model 0931.

8www.bodine-electric.com

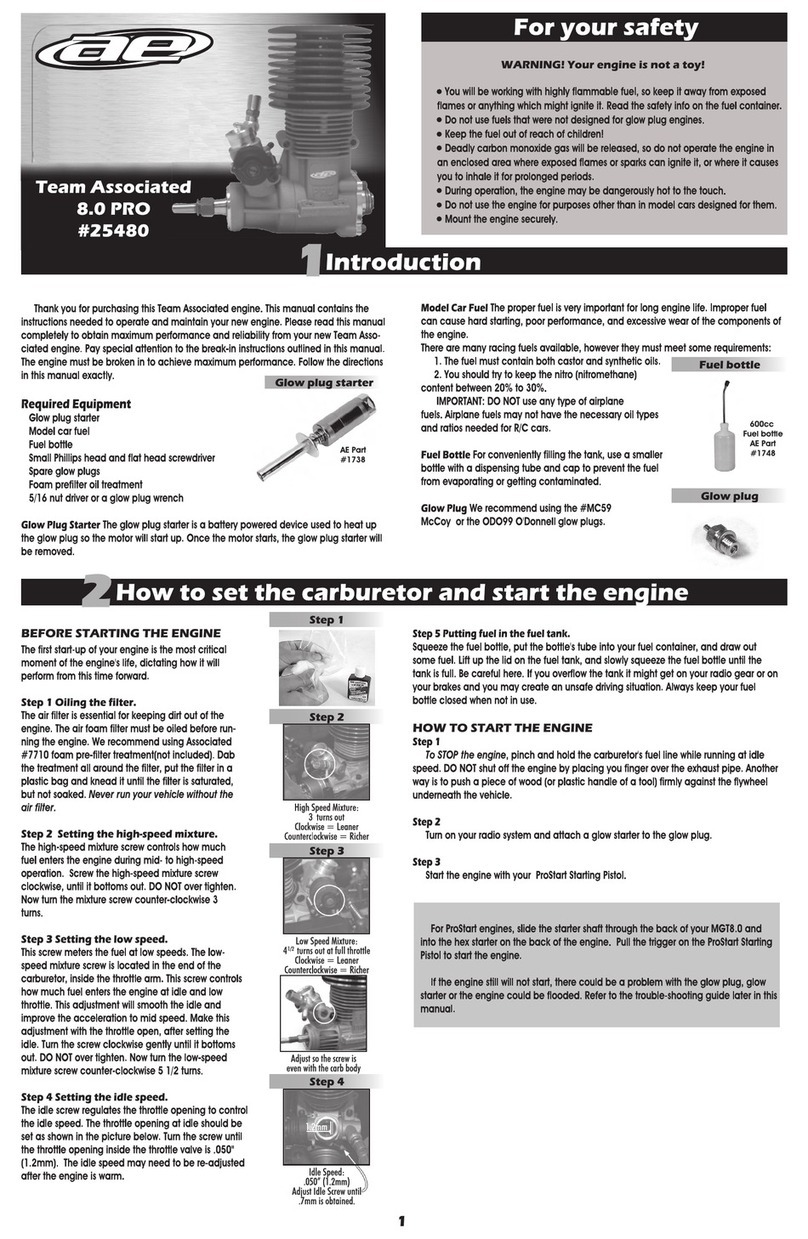

Step 2: Attach a Conduit Outlet Box to the Motor

Proper installation of this product in a hazardous location requires the use of

a conduit outlet box listed for Class I, Division 1, Groups C & D. The conduit

outlet box is not supplied by Bodine with the motor, so it must be purchased

separately by the user. The conduit outlet box must have a hole with a 1”

NPT, 11.5 threads per inch female thread in order to fit onto the Bodine

motor. A minimum of 5 threads of engagement is required to meet the UL 674

standard. This conduit outlet box should be sized per NEC 314.16. Figure 2

shows one example of an appropriate conduit outlet box and Figure 3 shows

that box installed on a Bodine motor. Regardless of what box is used, follow

the manufacturer’s instructions for installing it onto the Bodine motor and for

attaching conduit to the exit hole.

Figure 3 –

Motor after Conduit

Outlet Box Installation

1 in., NPT, 11.5 threads

per inch female thread

O-ring Cover

A

A

Figure 2 – A Typical Conduit Outlet Box

Step 3: Make Electrical Connections

!WARNING/AVERTISSEMENT

• CAUTION–To reduce the risk of ignition of hazardous atmospheres,

disconnect the equipment from the supply circuit before opening. Keep

assembly tightly closed when in operation.

• Leads factory-sealed. Do not disassemble any part of this product as that

will compromise its safety in hazardous atmospheres.

• This product should be installed, inspected, and maintained by a qualified

electrician only, in accordance with all applicable electrical codes.

• ATTENTION–Pour réduire le risque d’inflammation des atmosphères

dangereuses, débranchez l’équipement du circuit d’alimentation avant de

l’ouvrir. Gardez l’assemblage bien fermé lorsqu’il est en fonctionnement.

• Fils scellés en usine. Ne démontez aucune pièce de ce produit car cela

compromettrait sa sécurité dans les atmosphères dangereuses.

• Ce produit doit étre installè, inspecté et entretenu par un électricien

qualifié seulement, conformément avec tous les codes de l’électricité

pertinents.

www.bodine-electric.com 9

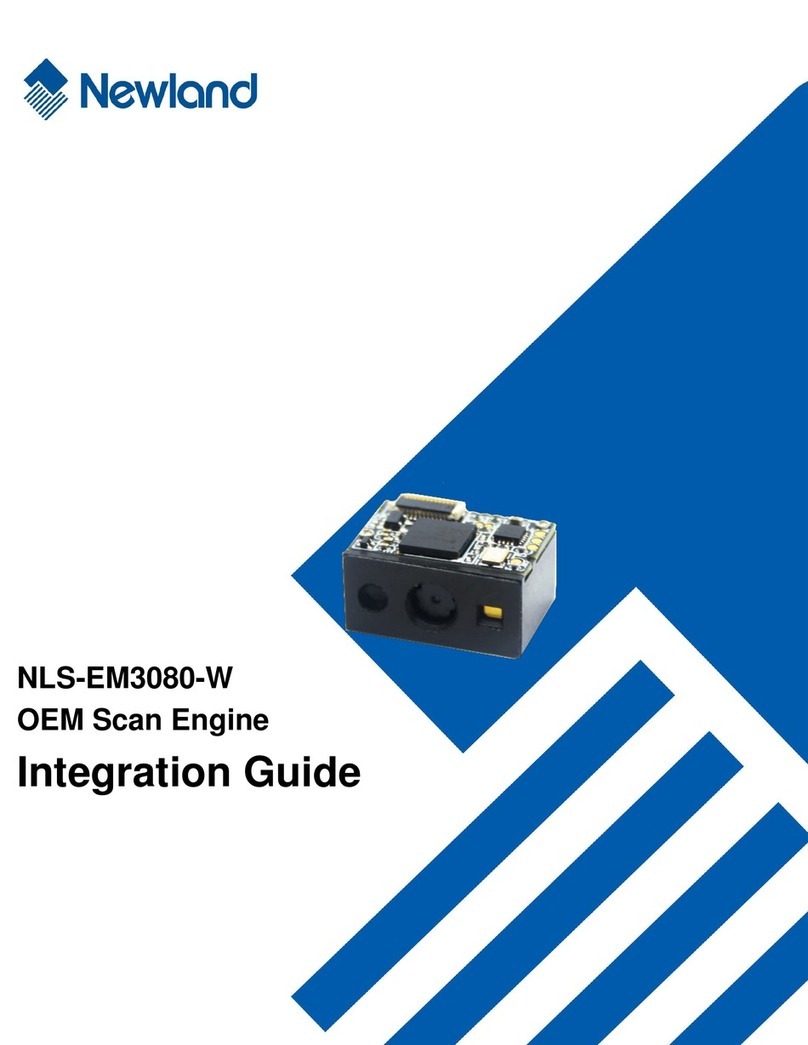

These motors are 3-Phase AC induction motors. The 34R6BXPP is a 3-Phase

AC induction motor, with or without an integral gearbox, and with a normally

closed, self-resetting thermal switch attached to the motor windings and is

represented schematically in Figures 4a, 4b, and 4c on pages 10 and 11.

!WARNING/AVERTISSEMENT

• CAUTION–The motor may automatically restart, depending on how it is

wired to the power source, after the temperature has cooled sufficiently

to allow the protector contacts to reset and if AC power is present.

• ATTENTION–Le moteur peut redémarrer automatiquement, en fonction

de la façon dont il est câblé à la source d’alimentation, une fois que la

température a suffisamment refroidi pour permettre aux contacts de

protection de se réinitialiser et si une alimentation CA est présente.

Installation of this motor requires either a 3 phase AC voltage source, or a

controller (inverter) capable of operating a 3-Phase AC induction motor.

The controller must incorporate or be used in conjunction with one of the

following capabilities to prevent the motor from exceeding its temperature

ratings under overload conditions:

• A logic input that will interrupt the power to the motor windings when the

thermal switch opens

• A suitable electronic overload protection system integrated within the

controller

• A suitable relay circuit that can be driven by the thermal switch to

interrupt the controller’s power supply

• A motor protection system suitable for operation with a motor in the

hazardous locations environment

10 www.bodine-electric.com

The following three figures illustrate three different recommended

connections between the motor and the voltage source or control (inverter).

When a controller (inverter) is used, refer to the controller’s documentation

for additional information regarding operation of the system.

AC Supply

(N.O.)

(N.C.)

AC Inverter

(L1)

(L2)

(U)

(V)

(W)

Power Supply

Connections

Motor Phase

Connections

Class I, Division 1 Environment

34R6BXPP Motor or Gearmotor

Motor Phases/Thermal Switch Black

Thermal

Switch White

White

Blue

Red

Green-Yellow Tracer

Frame

U

W V

L1

L2

Figure 4b – Electric Connections – Thermal Switch with AC Relay to Interrupt Supply

Class I, Division 1 Environment

34R6BXPP Motor or Gearmotor

Motor Phases/Thermal Switch Black

Thermal

Switch White

White

Blue

Red

Green-Yellow Tracer

Frame

U

W V

AC Inverter

AC Supply

(L1)

L1

L2

Enable Input

Common

(L2)

(U)

(V)

(W)

Power Supply

Connections

Motor Phase

Connections

Figure 4a – Electric Connections – Thermal Switch with Logic Control to Disable Motor Power

www.bodine-electric.com 11

Class I, Division 1 Environment

AC Supply

34R6BXPP Motor or Gearmotor

Motor Phases/Thermal Switch

Black

L1

L2

L3

Thermal

Switch

White

White

Blue

Red

Green-Yellow Tracer Frame

U

W V

(N.C.)

(N.O.)

(N.C.)

(N.C.)

(N.O.)

(N.O.)

Figure 4c – Electric Connections – Thermal Switch with 3 Pole AC Relay to Interrupt Supply

THERMAL SWITCH NOTES:

Motor thermal switch must be connected to interrupt power to the controller

and / or motor windings when the contact opens to limit motor temperature.

Thermal switch contact ratings:

AC–250VAC @ 2.5A 1.0 P.F., 250VAC @ 1.6A 0.6 P.F.

DC–24VDC @ 3.5A 48VDC @ 1.5A

WARNING: motor will automatically restart if allowed by control logic.

12 www.bodine-electric.com

Step 4: Operate the 34R6BXPP Motor or Gearmotor

!WARNING/AVERTISSEMENT

• CAUTION–To reduce the risk of ignition of hazardous atmospheres,

disconnect the equipment from the supply circuit before opening. Keep

assembly tightly closed when in operation.

• Leads factory-sealed. Do not disassemble any part of this product as that

will compromise its safety in hazardous atmospheres.

• This product should be installed, inspected, and maintained by a qualified

electrician only, in accordance with all applicable electrical codes.

• ATTENTION–Pour réduire le risque d’inflammation des atmosphères

dangereuses, débranchez l’équipement du circuit d’alimentation avant de

l’ouvrir. Gardez l’assemblage bien fermé lorsqu’il est en fonctionnement.

• Fils scellés en usine. Ne démontez aucune pièce de ce produit car cela

compromettrait sa sécurité dans les atmosphères dangereuses.

• Ce produit doit étre installè, inspecté et entretenu par un électricien

qualifié seulement, conformément avec tous les codes de l’électricité

pertinents.

!CAUTION

• Check that gearmotor is securely mounted.

• Check all rotating members. Be sure keys, pulleys, etc. are securely

fastened and safety guards are in place.

• Check for proper mounting and alignment of products, and verify safe

loading on shafts and gears.

1. Start the Motor or Gearmotor

a. Turn the AC power supply on.

b. Turn the inverter on, if one is being used.

c. The motor should start running at rated speed (if no inverter is used) or the

set speed (if an inverter is used).

2. Adjust Speed

a. If an inverter is being used, adjust the speed control of the inverter and

observe if the motor also changes speed.

3. Stop the Motor or Gearmotor

a. Turn the inverter off, if one is being used.

b. Turn the AC power supply off.

www.bodine-electric.com 13

TROUBLESHOOTING

!WARNING/AVERTISSEMENT

• CAUTION–To reduce the risk of ignition of hazardous atmospheres,

disconnect the equipment from the supply circuit before opening. Keep

assembly tightly closed when in operation.

• Leads factory-sealed. Do not disassemble any part of this product as that

will compromise its safety in hazardous atmospheres.

• This product should be installed, inspected, and maintained by a qualified

electrician only, in accordance with all applicable electrical codes.

• ATTENTION–Pour réduire le risque d’inflammation des atmosphères

dangereuses, débranchez l’équipement du circuit d’alimentation avant de

l’ouvrir. Gardez l’assemblage bien fermé lorsqu’il est en fonctionnement.

• Fils scellés en usine. Ne démontez aucune pièce de ce produit car cela

compromettrait sa sécurité dans les atmosphères dangereuses.

• Ce produit doit étre installè, inspecté et entretenu par un électricien

qualifié seulement, conformément avec tous les codes de l’électricité

pertinents.

If you encounter a problem, read all instructions and double-check the

wiring. Even if the 34R6BXPP motor or gearmotor itself shows obvious signs

of damage, it may be that another component in the system or an incorrect

installation or incorrect electrical connection caused it to fail. In which case,

replacing the gearmotor alone and not tending to the root cause of the failure

may result in another damaged product.

If problems persist, contact your source of purchase or a Bodine Authorized

Service Center and describe the problem in detail. Do not disassemble the

product. Performing unauthorized repairs will void the warranty and invalidate

third-party certifications.

14 www.bodine-electric.com

BODINE LIMITED WARRANTY

The Bodine Electric Company warrants all products it manufactures to be free

of defects in workmanship and materials when used under Normal Operating

Conditions and when applied in accordance with nameplate specifications.

When Bodine motors and gearmotors have been purchased with and used

only with appropriately applied Bodine controls, this warranty shall be in

effect for a period of twenty-four months from date of purchase or thirty

months from date of manufacture, whichever comes first. Bodine motors and

gearmotors used with non-Bodine controls and Bodine controls used with

non-Bodine motors and gearmotors are covered by a standard twelve-month

warranty period.

The Bodine Electric Company will repair, replace, or refund at its option,

any of its products, which has been found to be defective and is within the

warranty period, provided that the product is shipped freight prepaid, with

previous authorization, to Bodine Electric, or to the nearest Bodine Authorized

Service Center. At its option, all return shipments are F.O.B. Bodine’s plant or

Authorized Service Center. Bodine is not responsible for removal, installation,

or any other incidental expenses incurred in shipping the products to or from

Bodine.

This warranty is in lieu of any other expressed or implied warranty - including

(but not limited to) any implied warranties of merchantability and/or fitness for

a particular use or purpose.

Bodine’s liability under this warranty shall be solely limited to repair or

replacement of the Bodine product within the warranty period and Bodine

shall not be liable, under any circumstances, for any consequential, incidental

or indirect damages or expenses associated with the warranted products.

Commutator and/or brush wear and its associated effects are normal

occurrence and are not covered by this warranty unless otherwise agreed

to by Bodine in writing.

Proof of purchase of motor or gearmotor and matching control as a system

must be provided with any claim.

Product Type:_____________________ Serial No.____________________

Date of Purchase:____________ Place of Purchase:_______________

Bodine offers the widest selection of variable-speed

AC, permanent magnet DC and brushless DC fractional

horsepower gearmotors and motors in the industry. For

complete specifications, 3D CAD drawings, or to order

online, visit bodine-electric.com.

[email protected] | www.bodine-electric.com | 201 Northfield Rd. | Northfield IL 60093 USA | Tel: 773.478.3515

Visit www.bodine-electric.com

for more information

07401151.B

Bodine offers over 1,400 standard

gearmotors, motors and

system-matched speed controls.

This manual suits for next models

4

Table of contents

Other Bodine Engine manuals