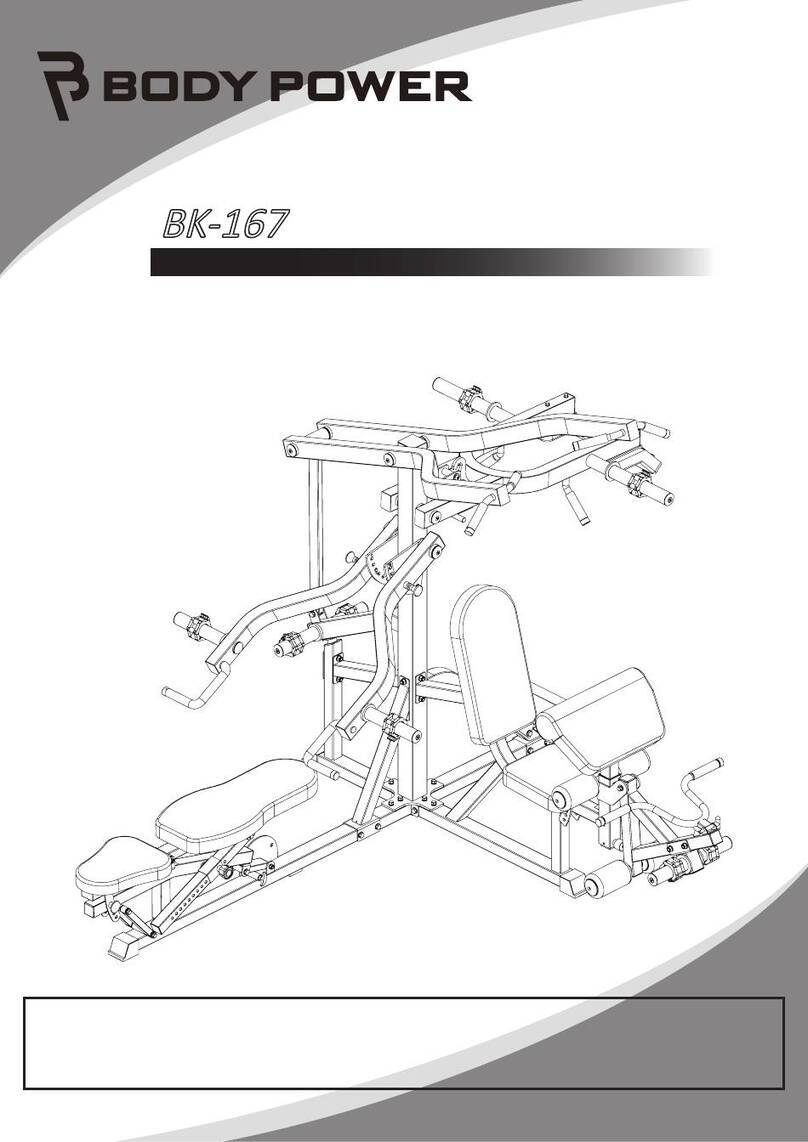

body Power BPGYPHG User manual

综合训练器

BPGYPHG

Pro-Home Gym

Installaon Instrucons

IMPORTANT: Please read the Safety Guidelines and Installaon

Instrucons in this manual before assembly of this product.

•Before beginning assembly, please take the me to read the instrucons thoroughly.

•Read each step in the assembly instrucons and follow the steps in sequence. Do not skip

ahead. If you skip ahead, you may learn later that you have to disassemble components and

that you may have damaged the equipment.

•Assemble and operate the product on a solid, level surface.

•Locate the unit a few feet from the walls or furniture to provide easy access.

•The product is designed for your enjoyment. By following these precauons and using

common sense, you will have many safe and pleasurable hours of healthful exercise with

your new product.

•Aer assembly, you should check all funcons to ensure correct operaon.

•If you experience problems, first recheck the assembly instrucons to locate any possible

errors made during assembly. If you are unable to correct the problem, call our product

service team who will be able to assist.

•It is highly recommended that you consult your physician before beginning any exercise

programme. This is especially important for individuals over the age of 35, or persons with

pre-exisng health problems.

•Always warm up before starng a workout. Try to do a total body warm up before you

start. It is especially important to warm up the specific muscle groups you are going to be

using. This can be as simple as performing a warm up set of high repeons and light

weight for each

Safety Guidelines When Using This Product

Personal Safety during Assembly.

Successful resistance training programmes have one prominent feature in

common...safety.Resistance training has some inherent dangers, as doall physical

acvies.The chance of injury can be greatly reduced or completely removed by using

correct liing techniques, proper breathing, and maintaining equipment in good

working condion, and by wearing the appropriate clothing.

Assistance may be required during assembly of this

product.

exercise.

•Use proper form. Focus on only working the muscle groups intended for the exercise you

are doing. If there is strain elsewhere, you may need to re-evaluate the amount of weight

that is involved with the li. Keeping proper form also includes maintaining control through

an enre range of moon.

•Breath properly. Inhale during the eccentric phase of the exercise, and exhale during the

liing, or concentric phase. Never hold your breath during any part of an exercise.

•Always wear the appropriate clothing and shoes when exercising. Wearing comfortable

athlec shoes with good support and loose fing, breathable clothing will reduce the risk of

injury.

•Maintaining equipment in proper operang condion is of utmost importance for a safe

resistance training program. Pulleys and cables should be checked for wear frequently and

replaced as needed. Equipment should be lubricated as indicated by the manufacturer.

•Read and study all warning labels on this machine. It is absolutely necessary that you

familiarize yourself and all others with the proper operaon of this machine prior to use.

•Keep hands, limbs, loose clothing and long hair well out of the way of all moving parts.

•Do not aempt to limore weight than you can control safely.

•Inspect the machine daily for loose or worn parts. If a problem is found do not allow the

machine to be used unl all parts are ghtened or worn or defecve parts are repaired or

replaced.

When the machine is not in use carefully run your fingers along the cable to feel for thinning

or bulging areas. Replace cables immediately at the first sign of damage or wear. Do not

use equipment unl damaged cable has been replaced.

Visually inspect the cables for fraying, cracking, peeling or discoloraon.

Check slack in cables and re-adjust cable tension if needed.

Check that the jam nut on the selector rod top bolt is ght.

Wipe down aer every workout.

Periodically take the me to use a mild soap or a mild vinyl upholstery cleaner. Avoid using

any abrasive cleaner not intended for use on vinyl.

Keep sharp or pointed objects out of your pockets and clear of all upholstery.

Periodically inspect all nuts and bolts. Tighten if needed. If bolts seem to loosen

periodically, use Locte 242 for a long-term cure.

Go through a re-ghtening sequence periodically to ensure that all hardware is properly

tensioned.

Product Maintenance

CABLES:

UPHOLSTERY:

NUTS/BOLTS/FASTENERS:

GUIDE RODS:

ADJUSTMENTS / LOCKING PINS / TIGHTENING KNOBS:

ANTI-SKID SURFACES:

WARNING INSTRUCTION LABELS:

Product Service Team;

Tel No.: 01604 673029

Email:

Wipe clean with a dust free rag. Lubricate with a Silicon or Teflon based lubricant.

Check all pieces for signs of visible wear or damage.

Check springs in Snap Links and Pop Pins for proper tension and alignment.

If the spring scks or has lost its rigidity, replace it immediately.

Replace if they appear worn or become slippery.

Inspect and familiarize yourself with all safety warnings and other user informaon on

decals.

service@bodypower.co.uk

Contents

spare part list....................................................................................................................3-7

Assembly step 1.............................................................................................................8-10

Assembly step 2.............................................................................................................11-12

Assembly step 3...........................................................................................................13-15

Assembly step 4...........................................................................................................16-18

Assembly step 5...........................................................................................................19-21

Assembly step 6...........................................................................................................22-24

Assembly step 7...........................................................................................................25-27

Assembly step 8...........................................................................................................28-30

Assembly step 9...........................................................................................................31-33

Assembly step 10...........................................................................................................34-35

Assembly step 11...........................................................................................................36-38

Assembly step 12...........................................................................................................39-40

Assembly step 13...........................................................................................................41-44

Assembly step 14...........................................................................................................45-47

Assembly step 15...........................................................................................................48-49

Assembly step 16...........................................................................................................50-51

Assembly step 17...........................................................................................................52-54

Table of contents

Other body Power Home Gym manuals