Maintenance

Maintenance UK

It is a legal requirement, under regulation 9 of the COSHH

regulations that all local exhaust ventilation systems are

thoroughly examined and tested at least once every 14

months (typically carried out annually). The approved code

of practice recommends that a visual check should be

carried out at least once a week.

COSHH requires the annual inspection and testing to be

carried out by a competent person and specifies that

documentation results are recorded in a log.

Contact the seller for more information about inspection

and certification.

Maintenance General

User maintenance is limited to cleaning the unit and filter

replacement, only the manufacturers trained maintenance

technicians are authorised to carry out component testing

and replacement. Unauthorised work or the use of

unauthorised replacement filters may result in a potentially

dangerous situation and/or damage to the extractor unit

and will invalidate the manufacturer’s warranty.

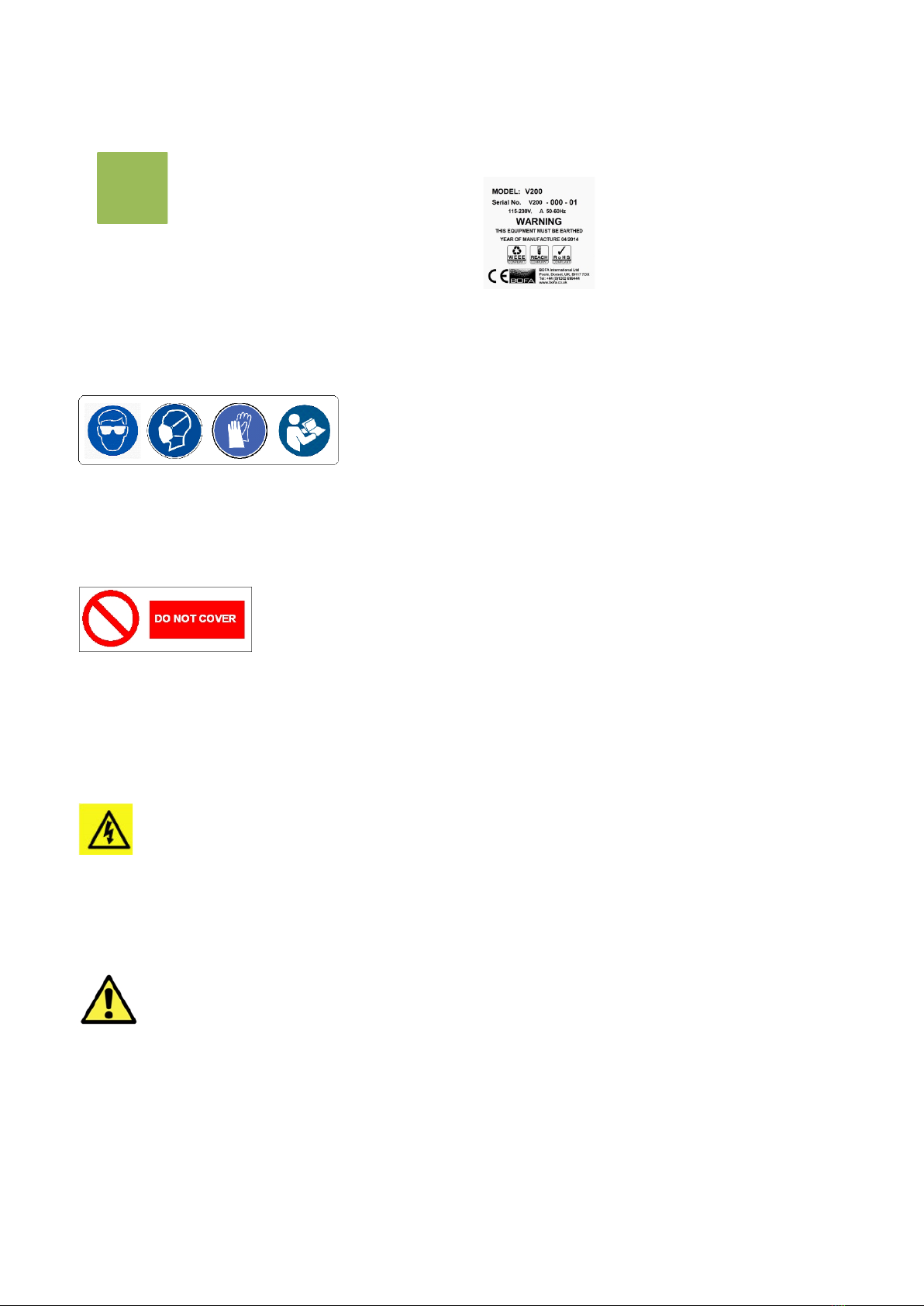

Cleaning the unit

The powder coat finish can be cleaned with a damp cloth

and non-aggressive detergent, do not use an abrasive

cleaning product as this will damage the finish.

The cooling inlets and outlets should be cleaned once a year

to prevent build-up of dust and overheating of the unit.

Filter Information

A log of filter changes should be maintained by the user.

The filters require attention when the display shows the

configuration shown on the next page or when the extractor

no longer removes fume efficiently.

All filters are tested to BS3928. A certificate of conformity

for each filter is available on request.

It is recommended that a spare set of filters are kept on site

to avoid prolonged unit unavailability. Part numbers for

replacement filters can be found on the filters fitted in your

system.

To prevent overheating, units should not be run with a

blocked filter condition, or with dust obstruction of Inlets /

Outlets.

Fire Risk Warning

In the very rare event that a burning ember or spark is

drawn into the fume extraction unit, it may be possible that

the filters will ignite.

Whilst any resultant fire would typically be retained within

the fume extraction unit, the damage to the extractor could

be significant.

It is therefore essential to minimise the possibility of this

occurring by undertaking an appropriate Risk assessment to

determine:-

a). Whether additional fire protection equipment should be

installed.

b). Appropriate maintenance procedures to prevent the risk

of build-up of debris which could potentially combust.

This unit should not be used on processes where sparks

could occur, with explosive dusts and gases, or with

particulates which can be pyrophoric (can spontaneously

ignite), without implementation of additional precautions

It is essential that nozzles or other extraction/ fume capture

devices and hoses/pipework are cleaned regularly to prevent

the build-up of potentially ignitable debris