Boga AIRWIN UB-1 4/3.1 Series User manual

[MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions valid from serial number: 4720

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Installation and Operating Instructions

AIRWIN®

Ultrasonic Universal Humidifier

UB-1...4/3.1

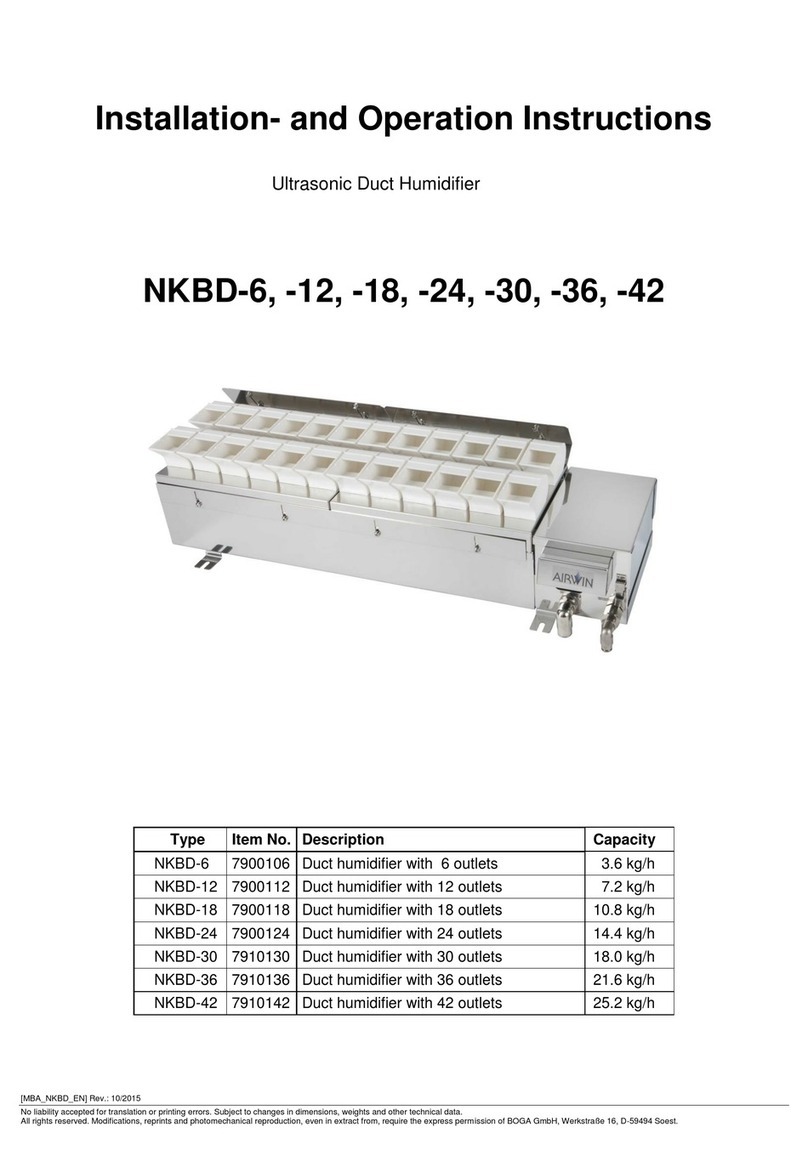

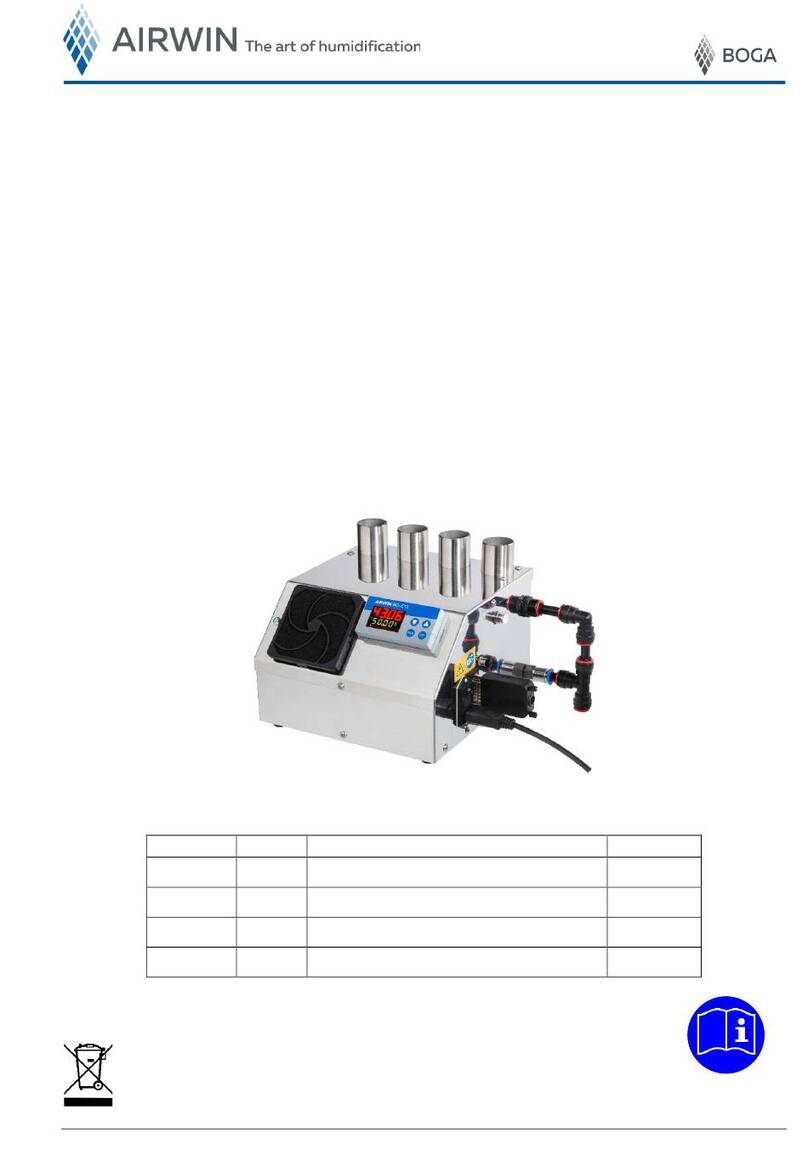

Type

Item no.

Description

Max. output

UB-1/3.1

7900259

Universal humidifier with 1 active aerosol outlet

0.5 kg/h

UB-2/3.1

7900260

Universal humidifier with 2 active aerosol outlets

1.0 kg/h

UB-3/3.1

7900261

Universal humidifier with 3 active aerosol outlets

1.5 kg/h

UB-4/3.1

7900262

Universal humidifier with 4 active aerosol outlets

2.0 kg/h

Please read and keep these instructions!

2 [MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Contens

1. General Informations and intended use ............................................................................................................ 4

2. Safety Instructions ............................................................................................................................................. 4

3. Scope of delivery ............................................................................................................................................... 5

4. Optional accessories ......................................................................................................................................... 6

5. General information ........................................................................................................................................... 8

5.1 Technical terms.................................................................................................................................. 8

5.2 Physical principles of piezo ceramics................................................................................................. 8

5.3 Functional description - ultrasonic air humidifier................................................................................ 9

6. Advantages of ultrasonic air humidification..................................................................................................... 10

7. Device overview............................................................................................................................................... 11

7.1 The UB-1…4/3.1-System................................................................................................................. 12

8. Installation conditions ...................................................................................................................................... 13

9. Aerosol distribution systems............................................................................................................................ 14

9.1 Aerosol Jet ....................................................................................................................................... 14

9.2 Aerosol pipes.................................................................................................................................... 15

9.3 Joined aerosol outlets ...................................................................................................................... 15

10. Hydraulic connection ....................................................................................................................................... 16

10.1 Hydraulic conditions......................................................................................................................... 16

10.1 Establishing and detaching the connections with connectors.......................................................... 17

11. Electric connection........................................................................................................................................... 18

11.1 Control connection ........................................................................................................................... 18

11.1.1 Safety chain ...................................................................................................................... 20

11.1.2 Status Message Operation - Error.................................................................................... 20

11.2 Device control................................................................................................................................... 21

11.2.1 Operation control on-off.................................................................................................... 21

11.2.2 Operation control continuous............................................................................................ 21

11.2.3 Control via Modbus RTU................................................................................................... 21

11.2.4 Control via remote control................................................................................................. 21

12. Structure and functions of the control board AIRWIN 3.1 ............................................................................... 22

12.1 Connections ..................................................................................................................................... 22

12.2 Functional description of the controller ............................................................................................ 24

12.3 Standard Settings............................................................................................................................. 25

12.4 Settings ............................................................................................................................................ 26

12.5 State diagram................................................................................................................................... 28

12.6 Status messages.............................................................................................................................. 29

12.7 LED-Indicator and decoding............................................................................................................. 29

12.8 Resetting the maintenance interval.................................................................................................. 30

12.9 Troubleshooting................................................................................................................................ 31

13. AquaDrain plus - hygiene management.......................................................................................................... 32

13.1 Description ....................................................................................................................................... 32

[MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions 3

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

13.2 Features............................................................................................................................................33

13.2.1 Flushing of water supply line .............................................................................................33

13.2.2 Drainage of fluid tank.........................................................................................................35

13.3 AquaDrain plus diagrams..................................................................................................................36

14. Commissioning.................................................................................................................................................37

14.1 Manual functions...............................................................................................................................37

14.2 Automatic functions...........................................................................................................................38

14.3 Make applied settings .......................................................................................................................38

15. Operation..........................................................................................................................................................39

16. Technical data ..................................................................................................................................................40

17. Equipment dimensions / weights......................................................................................................................41

18. Circuit diagrams................................................................................................................................................42

19. Care..................................................................................................................................................................51

20. Standards .........................................................................................................................................................53

20.1 EC declaration of conformity according to Machinery directive 2006/42/EC, Annex II 1.A..............53

20.2 WEEE................................................................................................................................................53

20.3 Legal notice - Copyright....................................................................................................................53

21. List of figures....................................................................................................................................................54

22. List of tables .....................................................................................................................................................54

4 [MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

1. General Informations and intended use

The device is designed for the humidification of demineralised water according to the technical

specifications.

Nebulization of other liquids is not permitted.

These installation and operation instructions apply to all AIRWIN®ultrasonic universal humidifiers of UB-

1…4/3.1 series, hereafter referred to as humidifier. It contains important notes for professional installation,

start-up, trouble-free operation, proper maintenance and cleaning.

In addition to regular maintenance, proper installation and care of the humidifier help to preserve the value of

the humidifier and are conditions for warranty claims.

2. Safety Instructions

The humidifier described in these instructions was developed and manufactured in accordance with

international safety regulations. However, the device must be handled with care, in particular to ensure electric

safety.

In order to guarantee safe operation in all operating conditions, the following safety instructions must be

observed.

•The electrical system may only be set up by qualified electricians.

In this context, the regulations of DIN VDE series 0100 are fundamental.

•The regulations of the local power supplier concerning the electrical connection (e.g.

residual current circuit breaker, additional potential equalisation etc.) must be

complied with. If in doubt, ask your electrician.

•An intended choice of electrical cables and connectors must be used.

•Mains voltage and mains frequency of the voltage supply must correspond to the

parameters indicated on the identification plate of the device.

•Do not connect a damaged device (e.g. damaged during transport) to the mains.

•Contact your customer service, if you have any queries about the electrical

connection, the features or the security of the humidifier.

•Disconnect the device from mains, if it does not work perfectly or if damage

has occurred.

•Disconnect the device from mains, if the electrical supply line is damaged.

•Work on the device may only be carried out as described in these instructions.

•Never use high pressure cleaners to clean the device.

•Use grease and oil-free materials only.

[MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions 5

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

3. Scope of delivery

Universal Humidifier UB-1...4/3.1

Fig. UB-4/3.1

Installation and Spare part list

operating instructions

Water filter for tube connection D/d = 6/4 mm

and Stop cock Ø 6 mm

Item No. 0009178

Discharge tube UB-1...4

(comprising:) tube Ø 12 mm, elbow connection,

T-connector, screw-on connector)

Item No. 0009085

Schuko power cable IEC 2m

Item No. 0001773

SUB-D Connector male, 15-pol, housing

Item No. 0002865

6 [MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

4. Optional accessories

Item no.

Type

Description

Illustration

0009180

Remote Control

Wired remote control, 4-channel,

with lead (2m)

0001144

Tube, PE

D/d=6/4 blue

Tube water supply D=6mm (blue)

0001197

Tube, PE D/d=12/9

black

Tube water drainage D=12mm (black)

6100096

BO-120/1

Room hygrostat for ON/OFF control of the

humidification system, 1-stage

6100097

BO-80

Duct hygrostat for ON/OFF control of the

humidification system

8005062

BO-RO-6/UV-EC

Reverse osmosis system 6 l/h with

permeate storage tank, UV treatment and

U-beam, powder-coated. Other models on

request.

2001130

Leakage tray for

UB-1..4

with flanged sockets, made of V2A stainless

steel with 3D surface (glossy)

[MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions 7

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Item no.

Type

Description

Illustration

0001327

Aerosol tube

IW = 40 mm, made of PU with plastic spiral,

microbe and hydrolysis resistant,

-30 °C to +90 °C, black

0003503

Hose bracket

for aerosol tube Ø 40 mm

2010005

Aerosol jet 63 NCH

Aerosol distribution pipe 524 mm long

with 12 drill holes

2010004

Aerosol jet 125 NCH

Aerosol distribution pipe 1149 mm long

with 24 drill holes

2001118

Hose adapter 75

screwed to the suction side, Douter = 76 mm,

made of V2A stainless steel, for hose or HT

pipe 75 mm

2001119

Hose adapter 80

screwed to the suction side, Dinner = 80 mm,

made of V2A stainless steel, suitable for

reduction DN 100/80

2001205

Reduction DN 100/80

DN 100/80, galvanised, with seal,

in connection with hose adapter 80

2001206

Aluminium flexpipe

DN 100, compressed approx. 42 cm,

expandable to 10 m

2001201

2001202

Filter box G4

Filter box M6

with connection Ø 100 mm,

filter class ISO coarse 50% (G4)

with connection Ø 100 mm,

filter class ISO ePM10 70% (M6)

8 [MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

5. General information

5.1 Technical terms

Transducer : Piezo ceramic transducer

Aerosols : Finely distributed material (solids or liquids) in air or other gases,

manifestations are e.g.: in smoke, dust, vapour and fog

Demineralised water : Pure water, permeate

Concentrate : Concentrated water, waste water of reverse osmosis system

5.2 Physical principles of piezo ceramics

If certain crystals are deformed by mechanical stress, electrical charges will build up proportionally

on their surface, producing electric field strength in the crystal.

Oscillation line - piezo ceramics

This effect was discovered by Pierre and Jacques Curie

in 1880. Even the reversal of this so-called piezoelectric

effect or piezo-effect is possible. The same materials

change their dimensions under the influence of an

electric field.

Ceramic piezoelectric materials are hard, chemically inactive and completely insensitive to humidity or

other atmospheric influences.

Fig. 1 - Schematic sketch of piezo-effect

[MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions 9

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Fluid tank

Capillary waves

Ultrasonic transducer

5.3 Functional description - ultrasonic air humidifier

All frequencies above 20,000 Hz are called ultrasonic.

According to their physical nature, acoustic waves consist of mechanical oscillations of compressible

media. These oscillations develop due to the deflection of the particles of a compressible material from

their equilibrium position. Acoustic waves are bound to a medium and thus do not occur in the vacuum.

Oscillations develop as a result of a change in pressure. Repeated pressure increase and pressure

reduction produce different acoustic waves.

In order to be able to use ultrasonic waves for air humidification, electrical energy must be converted

into mechanical energy. This takes place in the piezoelectric transducer.

A vibration unit consists of the resonance circuit where the high frequency of

~ 1.7 MHz is produced and the piezoelectric transducer to convert the electrical frequency into a

proportional mechanical oscillation. This frequency is not audible for human beings or animals.

The piezoceramic transducers are attached

to the bottom of the fluid tank. During

excitation of the transducer, the water leads

the ultrasonic vibrations to the boundary

layer between water and air. Constant

compression and decompression of the

water gauge over the transducer causes

cavitation in the immediate proximity of the

water surface. Thus, crossing capillary

waves are developed, the finest water

particles of which, the aerosols, are

produced in the wave crest.

The aerosols are delivered by the air flow in the humidifier and quickly mix with the ambient air. They

have a small diameter (0.001 - 0.005 mm) and thus form a freely floating mist. The droplet diameter

depends on the surface tension and the density of the medium, but also on the excitation frequency.

The higher the excitation frequency, the smaller is the diameter of the droplets.

Demineralised

water

Point of focusing

Air bubbles

Fig. 2 - Schematic sketch aerosol production

10 [MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

6. Advantages of ultrasonic air humidification

1. maximum energy saving Compared to steam and infrared humidifiers with the same

humidification output, ultrasonic air humidifiers need up to

93 % less electricity.

2. lowest connected load Compared to electrode steam humidifiers with the same

humidification output, only approx. 7 % of the power input

is required. Thus, lower third-party connection costs are

possible.

3. energy-saving cooling effect During humidification with the ultrasonic air humidifiers,

the room air is cooled at the same time due to the adiabatic

humidification principle. The result is a lower heat load

reducing the cooling output requirements.

4. lowest water consumption Nebulizer humidifiers lose up to 70 % of the water, steam

humidifiers up to 30 %. AIRWIN® Ultrasonic air humidifiers

do not have any water loss apart from the cyclical

emptying process of the fluid tank on AquaDrain plus.

5. immediate max. humidification Simultaneously with the request impulse, humidification

is carried out without any delay.

Exception: during automatic drainage and line flushing.

6. max. evaporation of the water Ultrasonic air humidifiers produce a very fine aerosol mist.

On average, the diameter of the aerosols is only 0.001 -

0.005 mm. Thus, the mist spreads quickly and is taken up

by the air after a very short time

[MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions 11

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Fig. 3 - UB-4/3.1 Overview

7. Device overview

Interface

control signals

15-poles

ON/OFF switch,

Fuse 2.5 A T

and device connection

Green indicator light:

Lights up when

the humidifier is

switched on

Demineralised water inlet

1 bar < pressure ≤ 4 bar

5 µS/cm < conductivity ≤ 20 µS/cm

Water drainage

Push-in connection Ø 12 mm

Water overflow

Push-in connection Ø 12 mm

Axial fan

120 m³/h

Aerosol outlet pipes

Ø 40 mm

Outlet to the on-site drainage

Push-in connection Ø 12 mm

Stop cock

for Ø 6 mm

Water filter

Screwed connection for Ø 6/4 mm

Interface

Remote control

(optional accessories)

12 [MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

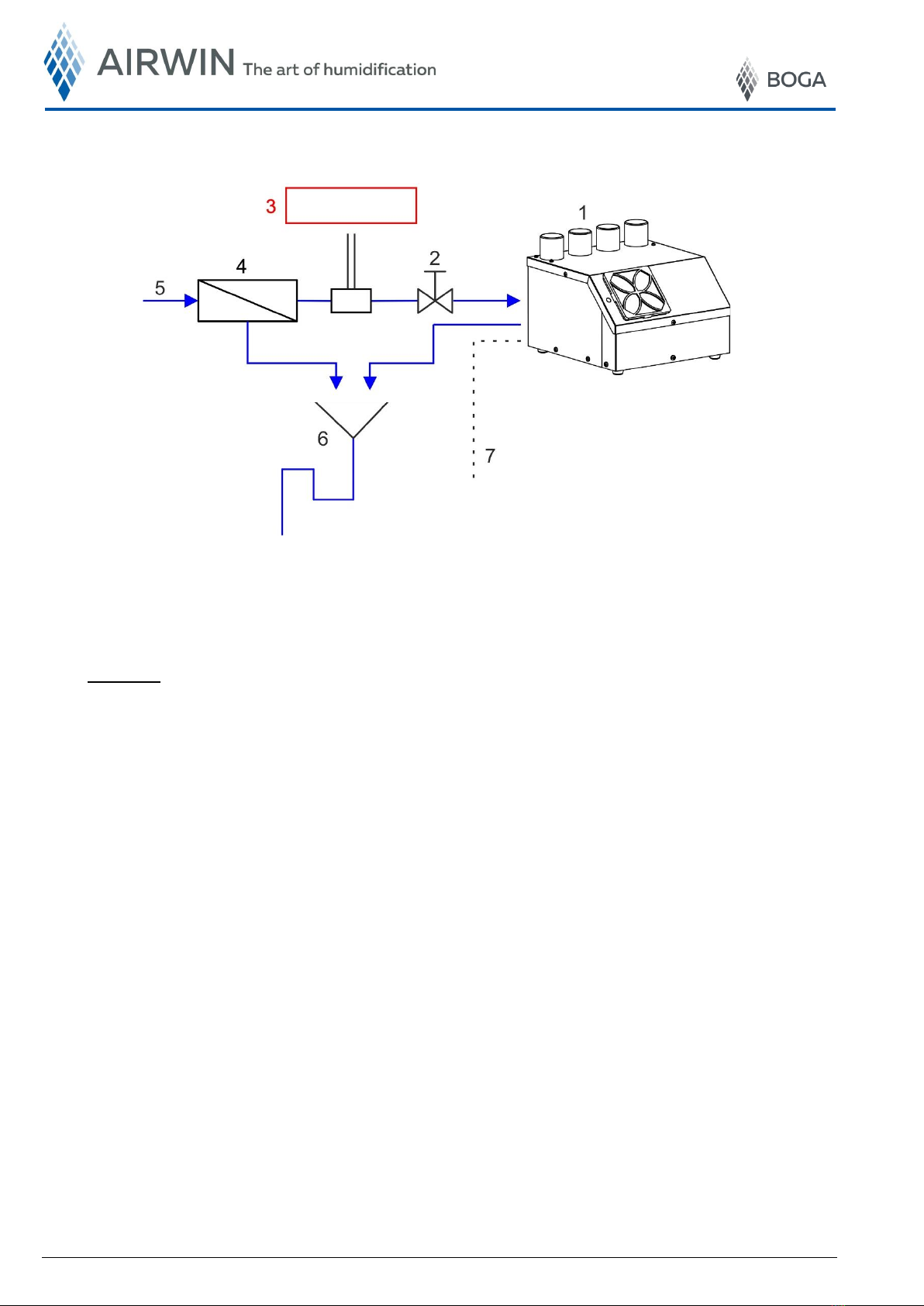

7.1 The UB-1…4/3.1-System

Definitions

1. UB-4/3.1

2. Stop cock (included in the scope of delivery)

3. Conductivity meter to check the quality of the demineralised water

4. Reverse osmosis system (see BOGA product range)

5. Drinking water supply (on site)

6. Free discharge according to DIN 1988-100 (on site)

7. External control (hygrostat or continuous control signal - see BOGA product range)

Fig. 4 - Schematic illustration of UB-4/3.1 humidification system

[MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions 13

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

8. Installation conditions

Correct installation in accordance with the following instructions ensures trouble-free operation of the device.

The device must not be exposed to large temperature differences during installation,

otherwise there is a risk of condensation forming inside the device. This can lead to a failure

of the electronics.

•Visual checks of the device at the installation site should be possible.

•The installation site must allow for simple assembly and disassembly of the device for

maintenance and inspection purposes.

•The device must be installed exactly in the horizontal position to ensure that the water level is the

same above ALL ultrasonic transducers.

•Automatic drainage of the fluid tank and automatic flushing of the demineralised water pipeline

require that a free discharge exists in accordance with DIN 1988-100.

•The humidity sensor must be positioned in such a way that it is located in the area of the

humidifier, but that direct influence by the aerosol flow of air is excluded.

•The stainless steel outlet pipes for the aerosol mist have a diameter of 40 mm and are located so

far away from each other that it is possible to connect commercially HT pipes with integrated lip

seals. The extensive delivery range of HT pipes provides cost-favourable, fast and highly flexible

aerosol guidance; so it is also possible to combine aerosol outputs.

Do not use any greasy lubricants for the installation of the aerosol pipes and tubes, because

that would change the surface tension of the water and nebulisation would no longer be

possible!

The interior areas of the device should always be protected against pollution! (Air filter boxes

see optional accessories)

14 [MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Fig. 6 - Cross-section of aerosol jet

9. Aerosol distribution systems

Basic conditions:

1. The humidifier must always be operated with an external aerosol distribution system (tube/pipe).

2. Aerosol distribution may not be done in such a way that the device sucks the aerosols in again through

the built-in axial fan and thus works in the aerosol short circuit. As a result, the device could be damaged.

3. For aerosol distribution, all pipes/tubes must be equally long.

9.1 Aerosol Jet

The flexible tubes may be connected to the aerosol jet as shown in Fig. 5 in accordance with variants

a) or b). The optimal solution would be a). In that case, aerosol density is the same along the length

of the aerosol jet whereas in b) the aerosol density decreases nearly linearly towards the end of the

aerosol jet.

Attention:

Aerosol jet holes

are burr-free!

from the

device

The angle between

the aerosol inlet and

outlet must always

be > 90°

Aerosol mist

The aerosol jet must

always be inclined

towards the conden-

sate drain

Condensate drain

to the drainage

Difference in height "h" as low

as possible. The lower "h", the

higher the humidity output at the

openings of the aerosol jet.

Variant a)

Variant b)

Ø 40 mm

> 0°

h

Fig. 5 - Aerosol Jet

[MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions 15

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

9.2 Aerosol pipes

The aerosols may also be distributed without an aerosol jet. The transport of the aerosols is then done

only via pipes or tubes directly to the place of humidification. This place may be in a different room,

even in an aggressive environment.

The pipes or tubes must be placed in such a way that the return of the condensate

is always possible along the entire pipe / tube length. It must be ensured that the

flow resistances of the individual exhaust systems are all the same.

9.3 Joined aerosol outlets

Merging the aerosol outlets may result in a loss of power due to condensation.

Fig. 8 - UB-4/3.1 with joined aerosol outlets

Fig. 7 - UB-4/3.1 with pipes for aerosol transport

Place of humidification

16 [MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Fig. 9 - Schematic diagram

of hydraulic conditions

10. Hydraulic connection

10.1 Hydraulic conditions

Definitions

1. UB-4/3.1

2. Stop cock (included in the scope of delivery)

3. Demineralised water:

1 bar < pressure ≤ 4 bar

5 µS/cm < conductivity ≤ 20 µS/cm

4. Water demineralisation system (reverse osmosis system)

5. Drinking water supply (on site)

6. Concentrate

7. Water supply for plastic tube Ø 6 mm

8. Water overflow for plastic tube Ø 12 mm

9. Water discharge for plastic tube Ø 12 mm

10. Water overflow hose

11. Free discharge according to DIN 1988-100 (on site)

Important notes:

•The humidifier may be operated with fully demineralised water only (produced for example by a

reverse osmosis system). The demineralised water must have a conductivity of min. 5 µS/cm

and max. 20 µS/cm.

•The contamination of drinking water may not exceed the max. values laid out in the drinking

water regulations.

•The demineralised water is corrosive, therefore use stainless steel or plastic only. Non-ferrous

metals (e.g. copper, brass) must not be used.

•Water pressure must be minimum 1 bar and maximum 4 bar.

•The drainage system on site must be set in accordance with DIN 1988-100.

•The water overflow- and discharge hose must be laid with a constant slope of min. 3% (3 cm on

1 m) to the free discharge.

•For easy revision, the stop cock included in the delivery must be installed in the demineralised

water supply line close to the device.

All materials coming into contact with the demineralised water must be resistant

to demineralised water (observe pressure and temperature resistance).

Demineralised water pipes must be flushed prior to starting the device.

[MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions 17

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Fig. 10 - Establishing the connection

Fig. 11 - Insert tube

10.1 Establishing and detaching the connections with connectors

The connectors provide durable, safe and watertight connections between tube and connecting

element. The tube is simply inserted by hand. The retaining element holds the tube safely without

pressing it or decreasing the flow.

Establishing the connection

Cut tube squarely and free of burrs.

Make sure that the tube has no sharp edges,

longitudinal grooves or other damage.

Connection is stable prior to sealing

Insert the tube up to the stop.

The supporting element holds the tube in the

connector. With the help of the o-ring,

a tight connection is established.

Check the connection by pulling towards the

opposite side

By pulling towards the opposite side check

whether the tube was safely inserted.

Then slide on the locking ring.

Detaching the connection

First remove the locking ring.

The tube can be detached by pushing back the

supporting element.

All pipes, tubes and connecting elements must be resistant to demineralised

water.

The surface hardness of pipes and tubes must not exceed 225 HV. Otherwise

the retaining teeth in the connector do not securely hold on it.

Soft tubes are also to be avoided.

support element

stainless steel teeth

Fig. 12 - Check connection

Fig. 13 - Detaching the connection

Slide on

locking clip

remove

tube

press back

support element

press back

support element

Remove

locking clip

18 [MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Fig. 14 - Electric connection

Fig. 15 - 15-pole D-SUB connector

11. Electric connection

The electric connections of the humidifier are found on the side of the housing. Confusion is prevented by

form-coded plugs.

11.1 Control connection

The 15-pole D-SUB connector must be used for the control signals for operating the humidi-fier.

Control signals

see wiring diagram

Power supply

230 V / 50 Hz

[MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions 19

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Tab. 11-1 - Connection diagram plug D-SUB 15-pin

Clamp

Shortcut

Funktion

Technical description interface

1

SIC

Release

humidification operation

Input for normally control contact

safety chain

2

SIC

Release

humidification operation

Input for normally control contact

safety chain

3

Error

Collective error message

Output potential-free contact

Fault status

4

Error

Collective error message

Output potential-free contact

Fault status

5

Operate

Operational message

Output potential-free contact

Operation status

6

Operate

Operational message

Output potential-free contact

Operation status

7

Hyg 1 (-)

Humidification requirement

50% power

Input for normally control contact

Humidification

8

Hyg 2 (-)

Humidification requirement

100% power

Input for normally control contact

Humidification

9

Hyg (+)

Supply hyg

Common supply hyg

10

Reg-Com

Common

Common ground analog control

11

+Reg-1 mA

Analog input 4...20 mA

Control input 4-20 mA

12

+Reg-2 V

Analog input 0…10 V

Control input 0-10 V

13

RS-485 A

Interface RS-485

RS-485 Modbus A

14

RS-485 B

Interface RS-485

RS-485 Modbus B

15

RS-485 GND

Interface RS-485

RS-485 Modbus Com

20 [MBA_UB-1...4_3.1_EN] Rev.: 02/2022 Translation of the original instructions

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Fig. 16 - Safety chain

11.1.1 Safety chain

Connect safety chain on the terminals marked 1 and 2 on the 15-pole plug.

Use potential-free contact.

The input of the safety chain must always be connected to safety devices

with an NC contact.

A cable bridge is always wired at the factory between connections 1-2 /

safety chain.

The humidifier does NOT work otherwise.

If several humidifiers are connected to the safety chain, this must be

isolated and connected to each humidifier with separate switching

contacts.

11.1.2 Status Message Operation - Error

There are two signal outputs via PhotoMOS relay.

Umax : 24 V-DC

Imax : 50 mA

Ron max : 25 Ω

Tab. 11-2 - Status messages operation / error

Status message

Message type

Connection terminal on 15-pole plug

1

Operational message

5 + 6

2

Collective Error message

3 + 4

Fig. 17 - PhotoMOS Relais

B1: limit hygrostat

B2: flow monitor

B3: fan locking

B4: conductivity measurement

B5: ON/OFF switch

This manual suits for next models

8

Table of contents

Other Boga Humidifier manuals

Popular Humidifier manuals by other brands

TaoTronics

TaoTronics TT-AH046 user guide

Trion

Trion HERRMIDIFIER HERRTRONIC MD Series Installation and operation manual

Gorenje

Gorenje ULTRA MYSTIC H50W instruction manual

Holmes

Holmes HCM1100 user manual

Healthy Climate

Healthy Climate HCSteam?16 installation instructions

ElectrIQ

ElectrIQ AC100R user manual