Boga NKBD-6 User manual

[MBA_NKBD_EN] Rev.: 10/2015 8

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

Installation- and Operation Instructions

NKBD-6, -12, -18, -24, -30, -36, -42

Type

Item No.

Description

Capacity

NKBD-6

7900106

Duct humidifier with 6 outlets

3.6 kg/h

NKBD-12

7900112

Duct humidifier with 12 outlets

7.2 kg/h

NKBD-18

7900118

Duct humidifier with 18 outlets

10.8 kg/h

NKBD-24

7900124

Duct humidifier with 24 outlets

14.4 kg/h

NKBD-30

7910130

Duct humidifier with 30 outlets

18.0 kg/h

NKBD-36

7910136

Duct humidifier with 36 outlets

21.6 kg/h

NKBD-42

7910142

Duct humidifier with 42 outlets

25.2 kg/h

Ultrasonic Duct Humidifier

2 [MBA_NKBD_EN] Rev.: 10/2015

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH • Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 • Fax: +49 2921 96943-29 • info@airwin.net • www.airwin.net

Contents

1. References ........................................................................................................................................................................................3

2. Safety Instructions....................................................................................................................................................................................3

3. Scope of delivery......................................................................................................................................................................................4

4. Optional accessories................................................................................................................................................................................4

5. General information..................................................................................................................................................................................6

5.1 Technical terms ...........................................................................................................................................................................6

5.2 Physical principles of piezo ceramics...........................................................................................................................................6

5.3 Functional description - ultrasonic air humidifier...........................................................................................................................7

6. Advantages of ultrasonic air humidification...............................................................................................................................................8

7. Equipment overview.................................................................................................................................................................................9

8. The NKBD-System.................................................................................................................................................................................10

9. Installation ......................................................................................................................................................................................11

9.1 Installation conditions –General notes.......................................................................................................................................11

9.2 Installation conditions –special notes ........................................................................................................................................12

9.3 Suction operation.......................................................................................................................................................................14

9.4 Adjustment of the NKBD to the direction of airflow.....................................................................................................................15

10. Hydraulic connection..............................................................................................................................................................................16

10.1Hydraulic conditions...................................................................................................................................................................16

10.2 Establishing and detaching connections with connectors ...........................................................................................................17

11. Electrical Connection..............................................................................................................................................................................18

11.1 Transformer...............................................................................................................................................................................18

11.2 Humidifier ..................................................................................................................................................................................19

11.3 Control and regulation................................................................................................................................................................20

11.3.1 Hygrostat control...........................................................................................................................................................20

11.3.2 Continuous control.........................................................................................................................................................20

11.3.3 Control signal encoding.................................................................................................................................................20

12. AquaDrain - hygiene management.........................................................................................................................................................21

12.1 Description.................................................................................................................................................................................21

12.2 Features ....................................................................................................................................................................................22

12.2.1 Flushing of water supply line..........................................................................................................................................22

12.2.2 Drainage of fluid tank.....................................................................................................................................................24

12.3 AquaDrain diagrams..................................................................................................................................................................25

13. Dimensioning of cable cross section.......................................................................................................................................................26

14. Commissioning ......................................................................................................................................................................................29

15. Technical data ......................................................................................................................................................................................31

16. Device dimensions / weights ..................................................................................................................................................................32

17. Spare parts list ......................................................................................................................................................................................33

17.1 Assembly body duct support.....................................................................................................................................................33

17.2 Assembly fluid tank...................................................................................................................................................................34

17.3 Assembly Control housing.........................................................................................................................................................36

18. Circuit diagrams .....................................................................................................................................................................................38

19. Protection against overvoltage peaks.....................................................................................................................................................50

20. Care ......................................................................................................................................................................................50

20.1 Care plan...................................................................................................................................................................................51

21. Standards ......................................................................................................................................................................................55

21.1 CE Declaration of conformity......................................................................................................................................................55

21.2 RoHS / WEEE............................................................................................................................................................................55

21.3 Legal notice - Copyright.............................................................................................................................................................55

[MBA_NKBD_EN] Rev.: 10/2015 3

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH •Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 •Fax: +49 2921 96943-29 •info@airwin.net • www.airwin.net

1. References

All AIRWIN®ultrasonic duct humidifiers of NKBD series are designed for installation in supply air ducts and

air conditioning units.

These installation and operation instructions contain important notes for professional installation, start-up,

trouble-free operation and proper maintenance and cleaning.

In addition to regular maintenance, proper installation and care of the NKBD help to preserve the value of the

device and are conditions for warranty claims.

2. Safety Instructions

The humidifier described in these instructions was designed and constructed in accordance with the interna-

tional safety regulations. Like any other electrical device is has to be handled with extreme care, to ensure

safe usage.

In order to guarantee safe operation in all operating conditions, the following safety instructions must be ob-

served.

The electrical system may only be set up by qualified electricians.

In this context, the regulations of DIN VDE series 0100 are fundamental.

The regulations of the local power supplier concerning the electrical connection

(e.g. residual current circuit breaker, additional potential equalisation etc.) must be

complied with. If in doubt, ask your electrician.

An intended choice of electrical cables and connectors must be used.

Mains voltage and mains frequency of the voltage supply must correspond to the

parameters indicated on the identification plate of the humidifier.

Do not connect a damaged humidifier (e.g. damaged during transport) to the

mains.

Contact your customer service if you have any queries about the electrical

connection, the features or the security of the humidifier.

Disconnect the humidifier from mains, if it does not work perfectly or if damage

has occurred.

Disconnect the humidifier from mains, if the electrical supply line is damaged.

Work on the humidifier may only be carried out as described in these instructions.

Never use high pressure cleaners to clean the humidifier.

Use grease and oil-free materials only.

4 [MBA_NKBD_EN] Rev.: 10/2015

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH • Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 • Fax: +49 2921 96943-29 • info@airwin.net • www.airwin.net

3. Scope of delivery

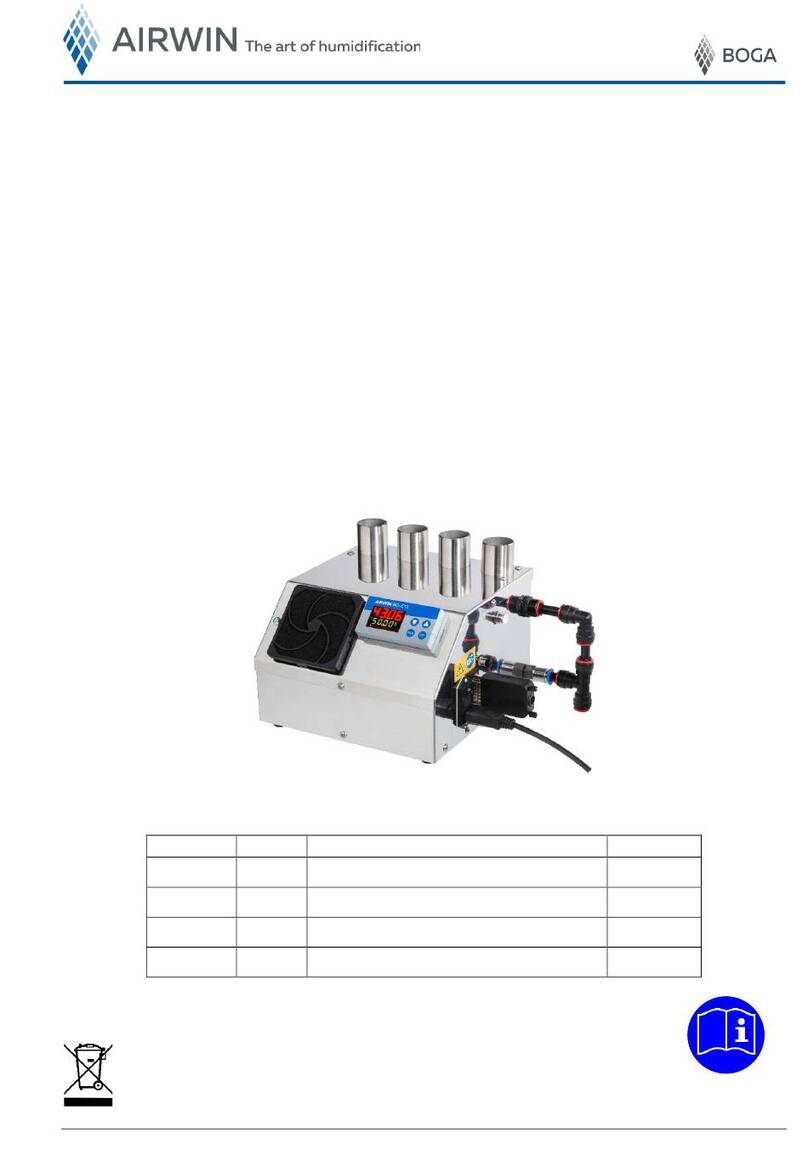

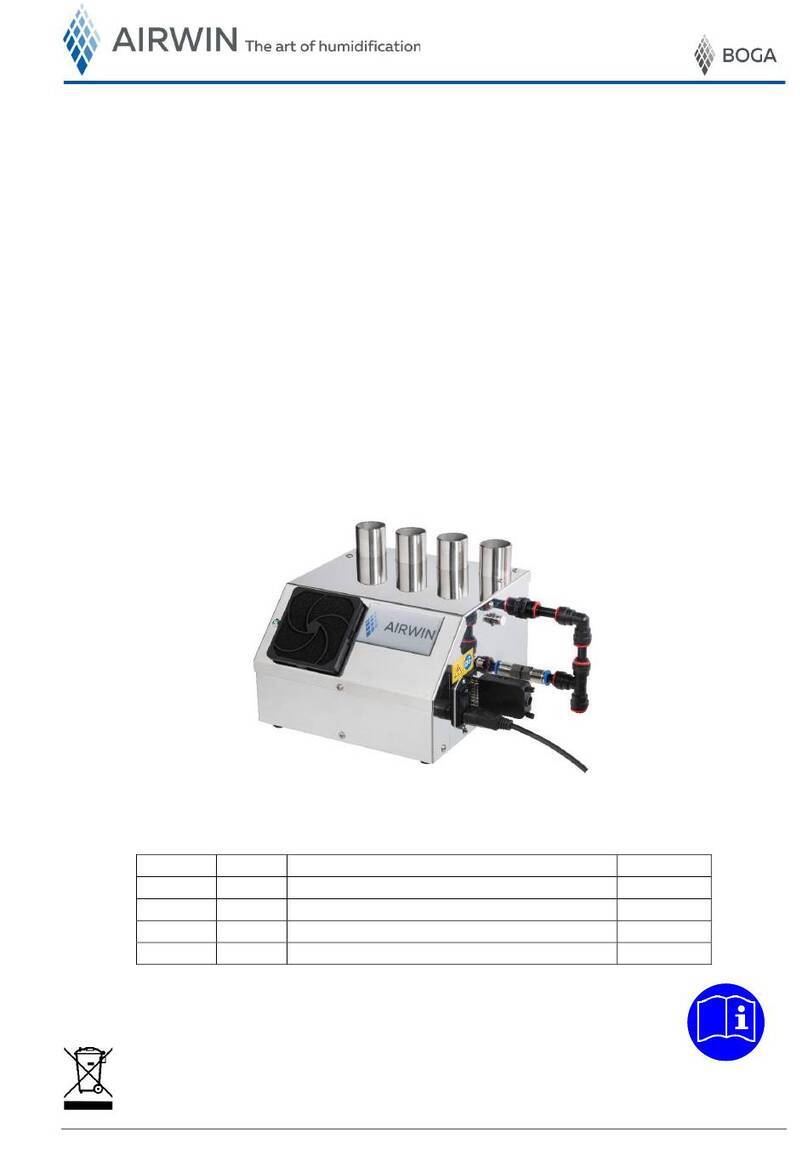

Duct Humidifier NKBD

Fig.: NKBD-24

Installation and operating instructions

Stop cock Ø 10 mm

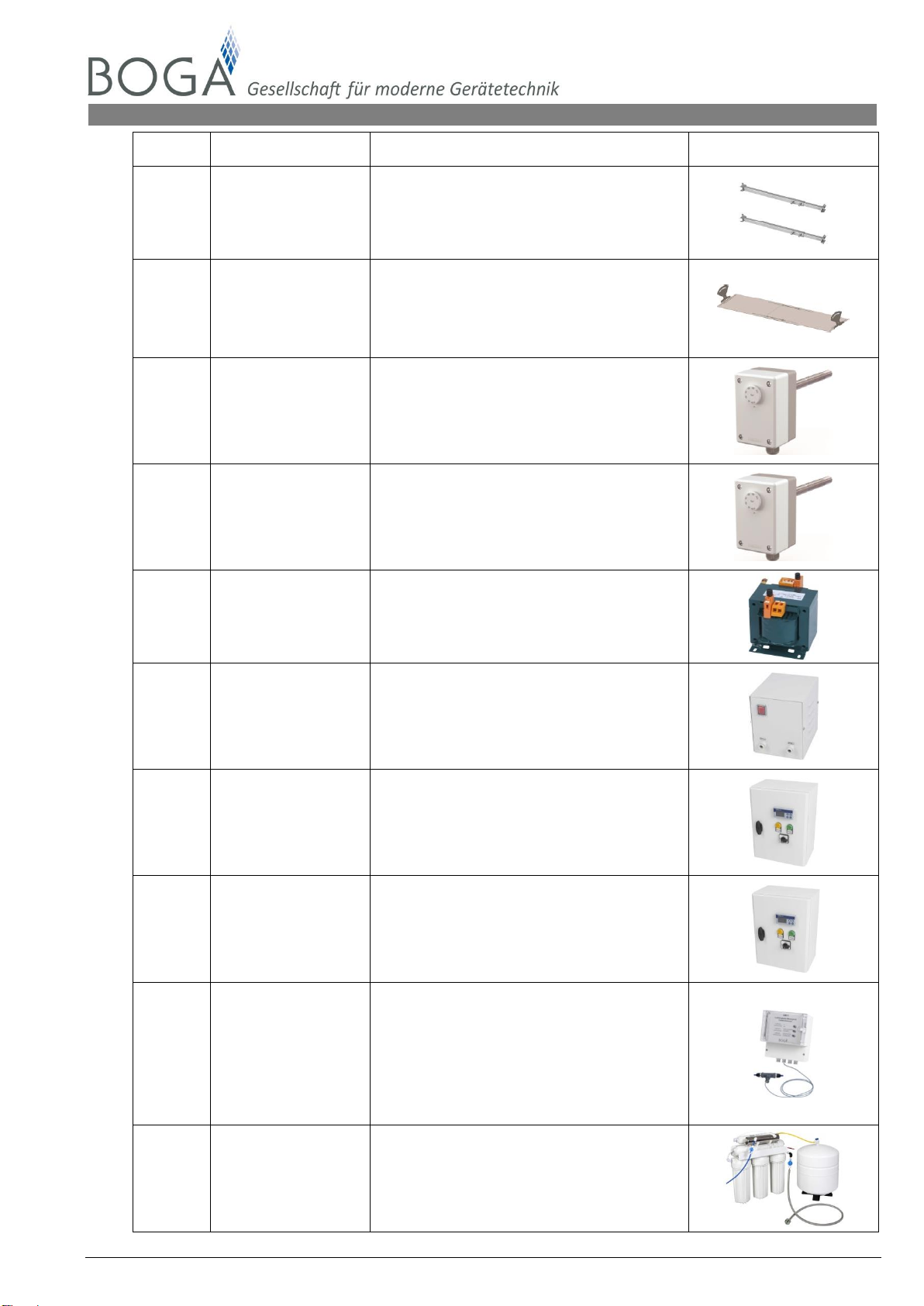

4. Optional accessories

Item no.

Type

Description

Illustration

0001196

Tube, PA

D/d=10/8 mm,

blue

Tube water supply D = 10 mm (blue)

0001847

Tube, PE

D/d=14/11 mm,

nature

Tube water drainage D = 14 mm (nature)

2000105

Mounting brackets

For easy installation of NKBD on a

mounting frame in the air duct, made of

V2A-stainless steel, incl. adjustable foot.

Needs: 2 pcs for NKBD-6 to NKBD-24

3 pcs for NKBD-30 to NKBD-42

200140..

Vertical frame

To build a mounting frame in the air duct,

made of V2A-stainless steel,

height adjustable from 500-700 mm or

700-1200 mm or 1200-2000 mm

PU = 1 set (2 pcs)

[MBA_NKBD_EN] Rev.: 10/2015 5

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH •Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 •Fax: +49 2921 96943-29 •info@airwin.net • www.airwin.net

Item no.

Type

Description

Illustration

200141..

Telescopic strut

To build a mounting frame in the air duct,

made of V2A-stainless steel,

length adjustable from 500-800 mm or

800-1400 mm or 1400-2000 mm

PU = 1 set (2 pcs)

200130..

Air vortex sheet

To reduce the humidification distance,

made of V2A-stainless steel,

width adjustable from 500-750 mm or

750-1000 mm or 1000-1500 mm or 1500-

2000 mm

6100097

BO-80

Duct hygrostat for ON/OFF control of the

humidification system, 1-step

6100095

BO-80/2

Duct hygrostat for ON/OFF control of the

humidification system, 2-step

77001..

ST200 –ST1600

Transformer for control cabinet

installation, from 200 VA to 1600 VA,

with primary and secondary protection

77002..

STH200 –STH1600

Transformer in powdered steel housing,

with illuminated ON / OFF switch and ca-

ble glands from 200 VA to 1600 VA, with

primary and secondary protection

6002100

SUR/P-4b

Control cabinet with room humidity

sensor or duct humidity sensor for

continuous control

60121..

SUR/PT…

Control cabinet with room humidity

sensor or duct humidity sensor for

continuous control and 500, 1000 or 1600

VA Transformer

8003204

BO-CM-1

Conductivity meter with conductance sen-

sor, cable glands,

conductivity range display,

Conductivity preliminary warning,

conductivity - EMERGENCY/ STOP,

C green : <5 µS/cm

C yellow : 5 µS/cm < C < 20 µS/cm

C red : > 20 µS/cm

8005..

BO-RO-…

Reverse osmosis system 6 l/h and more,

with permeate storage tank,

other models on request

6 [MBA_NKBD_EN] Rev.: 10/2015

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH • Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 • Fax: +49 2921 96943-29 • info@airwin.net • www.airwin.net

5. General information

5.1 Technical terms

Transducer : Piezo ceramic transducer

Aerosols : Finely distributed material (solids or liquids) in air or other gases,

manifestations are e.g. in smoke, dust, vapour and fog

Demineralised water : Pure water, permeate

Concentrate : Concentrated water, waste water of reverse osmosis system

5.2 Physical principles of piezo ceramics

If certain crystals are deformed by mechanical stress, electrical charges will build up proportional-

ly on their surface, producing electric field strength in the crystal.

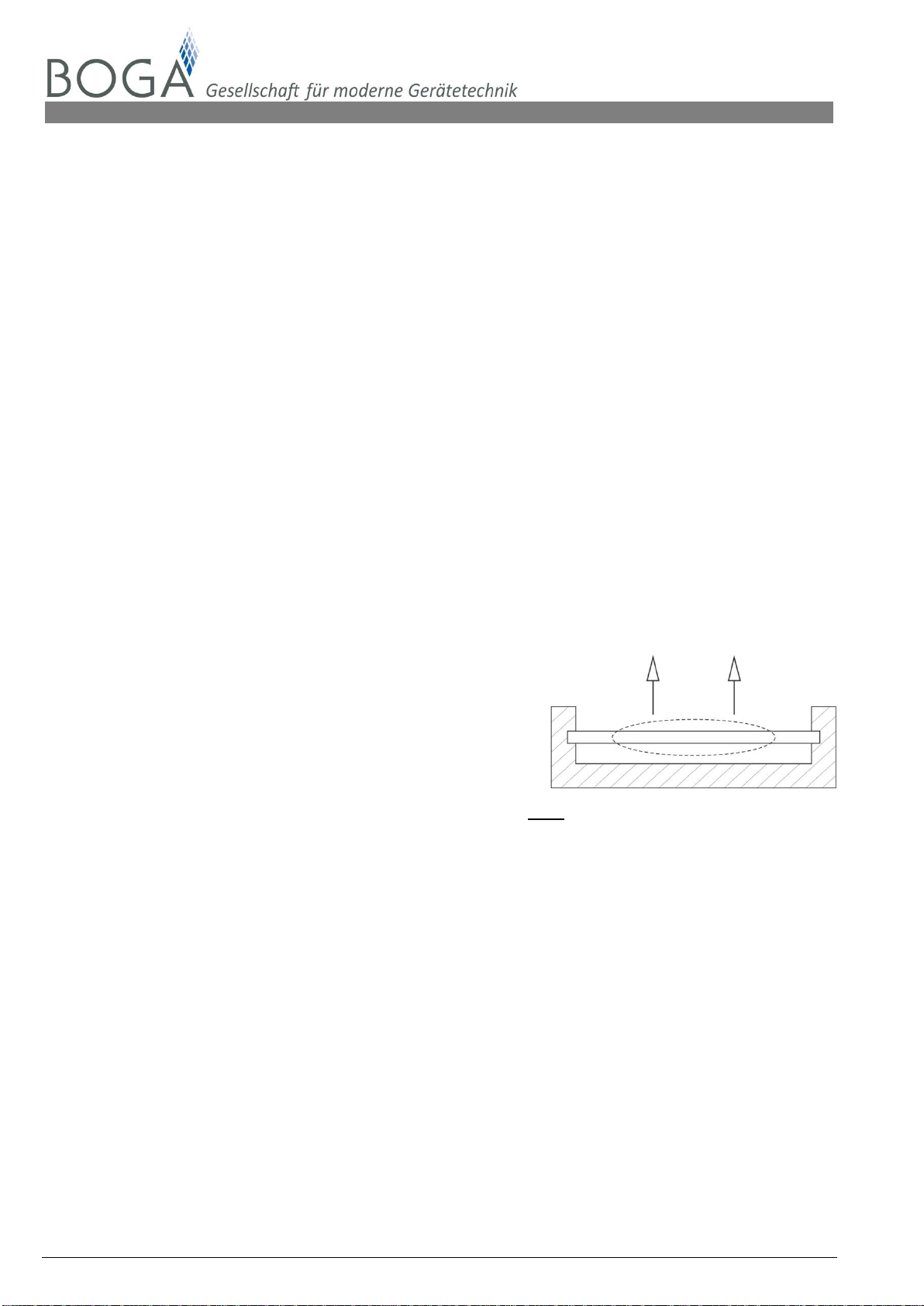

Oscillation line - piezo ceramics

This effect was discovered by Pierre and Jacques Curie

in 1880. Even the reversal of this so-called piezoelectric

effect or piezo-effect is possible. The same materials

change their dimensions under the influence of an

electric field.

fig. 1 - Schematic sketch of piezo-effect

Ceramic piezoelectric materials are hard, chemically inactive and completely insensitive to humidity

or other atmospheric influences.

[MBA_NKBD_EN] Rev.: 10/2015 7

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH •Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 •Fax: +49 2921 96943-29 •info@airwin.net • www.airwin.net

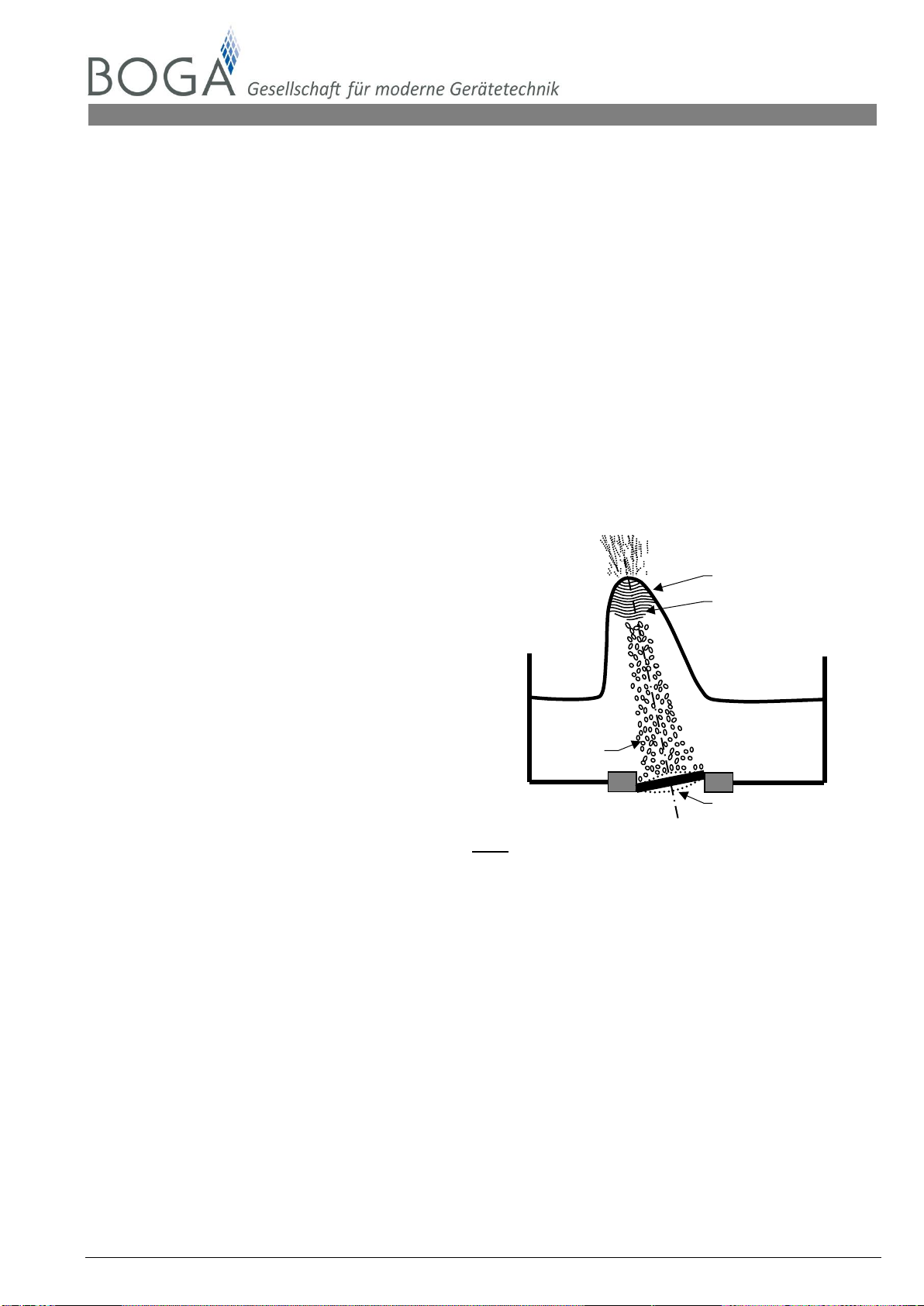

Fluid tank

Capillary waves

Ultrasonic transducer

5.3 Functional description - ultrasonic air humidifier

All frequencies above 20,000 Hz are called ultrasonic.

According to their physical nature, acoustic waves consist of mechanical oscillations of compressible

media. These oscillations develop due to the deflection of the particles of a compressible material from

their equilibrium position. Acoustic waves are bound to a medium and thus do not occur in the vacu-

um.

Oscillations develop as a result of a change in pressure. Repeated pressure increase and pressure

reduction produce different acoustic waves.

In order to be able to use ultrasonic waves for air humidification, electrical energy must be converted

into mechanical energy. This takes place in the piezoelectric transducer.

A vibration unit consists of the resonance circuit where the high frequency of

~ 1.7 MHz is produced and the piezoelectric transducer to convert the electrical frequency into a pro-

portional mechanical oscillation. This frequency is not audible for human beings or animals.

The piezoceramic transducers are attached

to the bottom of the fluid tank. During

excitation of the transducer, the water leads

the ultrasonic vibrations to the boundary

layer between water and air. Constant

compression and decompression of the

water gauge over the transducer causes

cavitation in the immediate proximity of the

water surface. Thus, crossing capillary

waves are developed, the finest water

particles of which, the aerosols, are

produced in the wave crest.

fig. 2 - Schematic sketch aerosol production

The aerosols are delivered by the air flow in the humidifier and quickly mix with the ambient air. They

have a small diameter (0.001 - 0.005 mm) and thus form a freely floating mist. The droplet diameter

depends on the surface tension and the density of the medium, but also on the excitation frequency.

The higher the excitation frequency, the smaller is the diameter of the droplets.

Demineralised

water

Point of focusing

Air bubbles

8 [MBA_NKBD_EN] Rev.: 10/2015

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH • Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 • Fax: +49 2921 96943-29 • info@airwin.net • www.airwin.net

6. Advantages of ultrasonic air humidification

1. maximum energy saving Compared to steam and infrared humidifiers with the

same humidification output, ultrasonic air humidifiers

need up to 93 % less electricity.

2. lowest connected load Compared to electrode steam humidifiers with the same

humidification output, only approx. 7 % of the power input

is required. Thus, lower third-party connection costs are

possible.

3. energy-saving cooling effect During humidification with the ultrasonic air humidifiers,

the room air is cooled at the same time due to the adia-

batic humidification principle. The result is a lower heat

load reducing the cooling output requirements.

4. lowest water consumption Atomiser humidifiers lose up to 70 % of the water, steam

humidifiers up to 30 %. AIRWIN® ultrasonic air humidifiers

do not have any water loss apart from the cyclical empty-

ing process of the fluid tank on AquaDrain.

5. immediate max. humidification Simultaneously with the request impulse, humidification

is carried out without any delay.

Exception: during automatic drainage and line flushing.

6. max. evaporation of the water Ultrasonic air humidifiers produce a very fine aerosol

mist. On average, the diameter of the aerosols is only

0.001 - 0.005 mm. Thus, the mist spreads quickly and is

taken up by the air after a very short time

[MBA_NKBD_EN] Rev.: 10/2015 9

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH •Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 •Fax: +49 2921 96943-29 •info@airwin.net • www.airwin.net

7. Equipment overview

fig. 3 - NKBD-24

Input for power supply

48 V / 50 Hz

Input and output for

control signals

Water overflow and drainage

Push-in-connection Ø 14 mm

Demineralised water inlet

Push-in-connection Ø 10 mm

Outlets

Air baffle,

height adjustable

10 [MBA_NKBD_EN] Rev.: 10/2015

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH • Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 • Fax: +49 2921 96943-29 • info@airwin.net • www.airwin.net

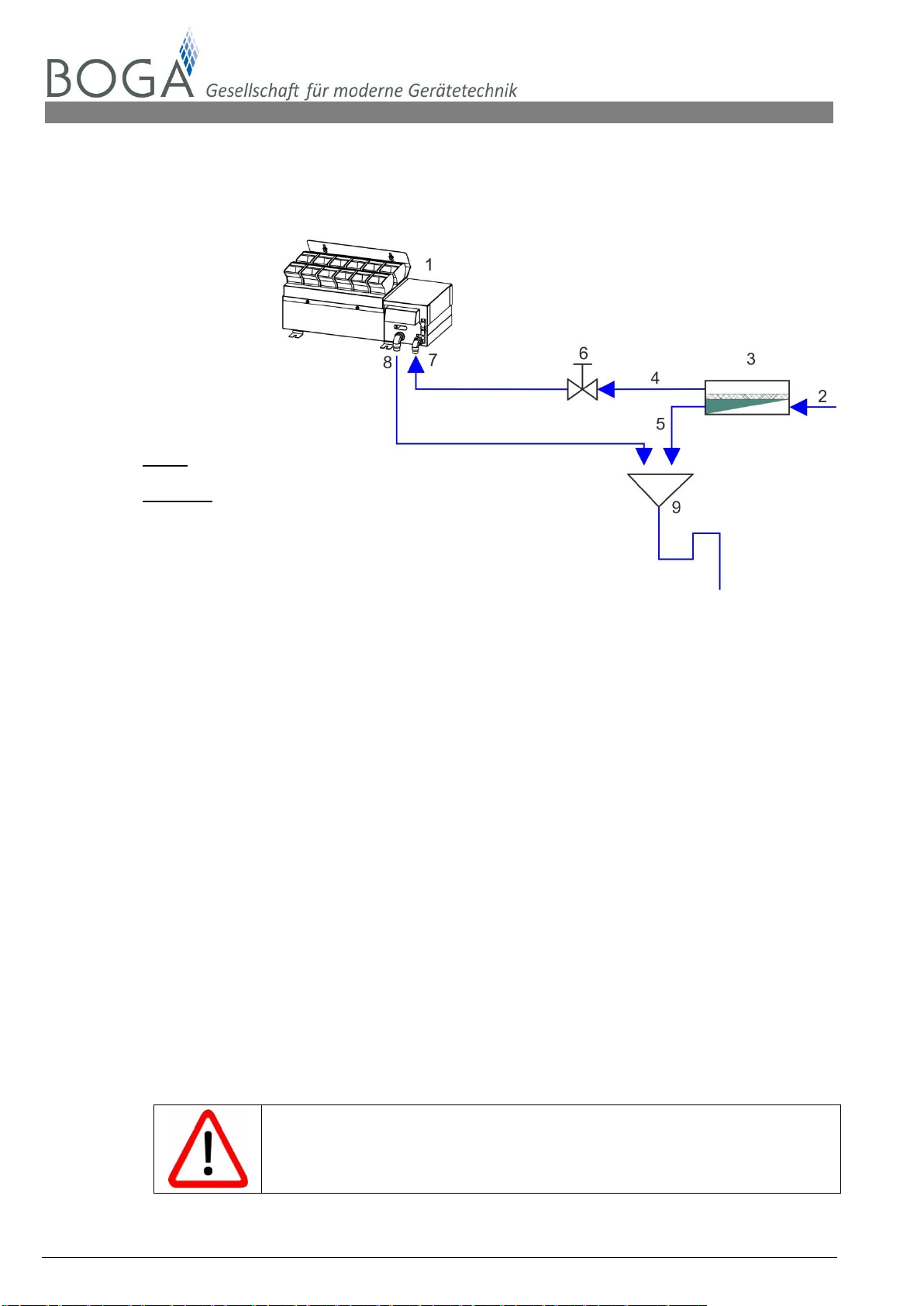

8. The NKBD-System

fig. 4 - Schematic illustration of NKBD air humidification system

Definitions

1. NKBD

2. Stop cock (included in the scope of delivery)

3. External control (hygrostat or continuous control signal - see BOGA product range)

4. Drinking water supply (on site)

5. Free discharge according to DIN 1988 part 4, EN 1717 (on site)

6. Transformer (see BOGA product range)

7. Reverse osmosis system (see BOGA product range)

8. Conductivity meter (e.g. CM-1) to check the quality of the demineralised water

(see optional accessories, BOGA product range)

[MBA_NKBD_EN] Rev.: 10/2015 11

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH •Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 •Fax: +49 2921 96943-29 •info@airwin.net • www.airwin.net

9. Installation

Proper installation in accordance with the following instructions will ensure trouble-free operation of the

NKBD.

The location of the NKBD installation is predetermined by the requirements of the ventilation system and

should be defined before installation work is commenced.

Protect humidifier interiors necessarily from pollution! The protective foil should only be

removed immediately prior to commissioning when the air ducts have been cleaned!

9.1 Installation conditions –General notes

Installing an insulated tubular lamp in the duct and a window will significantly facilitate visual func-

tion checks on the humidifier.

The place of installation must allow the humidifier to be easily removed and replaced.

The NKBD must be installed in absolutely horizontal position to ensure that ALL the ultrasonic

transducers are covered by the same level of water

The automatic drainage of the fluid tank and the automatic flushing of the pure water line require

a free discharge on site according to DIN 1988 part 4, EN 1717

In the immediate vicinity of the duct humidifier, the ventilation unit should be of waterproof design

(stainless steel or with corrosion-proof coating) and should be provided with a water discharge

outlet.

The air velocity in the free duct cross section (net area after installation of the humidifiers)

V = 1.0 - 4.0 m/s. In the case of higher air velocities, perforated metal plates should be installed in

the vicinity of the humidifiers.

The distance from the bottom edge of the NKBD to the ceiling of the air duct must be min. 390

mm (fig. 5 and 7).

The distance between the NKBD and the duct/trough base must be min. 100 mm (fig. 5 and 7).

The distance between the NKBD control housing and the duct side wall must be min. 70 mm

(fig. 6 und 8).

The distance between the NKBD and the duct side wall must be min. 200 mm (fig. 6 and 8).

The distance necessary from fixtures in direction of flow differs widely (aerosol disintegration dis-

tance). It is dependent on air velocity, air temperature, actual and set point humidity and must be

determined at the planning stage.

To achieve the nominal humidification, it is important that the air velocity is in the range

specified. Furthermore, it is very important that the humidifier is installed in an even

laminar air flow. Maybe a perforated plate or a flow straightener is necessary.

12 [MBA_NKBD_EN] Rev.: 10/2015

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH • Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 • Fax: +49 2921 96943-29 • info@airwin.net • www.airwin.net

9.2 Installation conditions –special notes

9.2.1 Standard configuration

Mounting example on mounting frame (on site) with mounting bracket NKBD (Item no.

2000105).

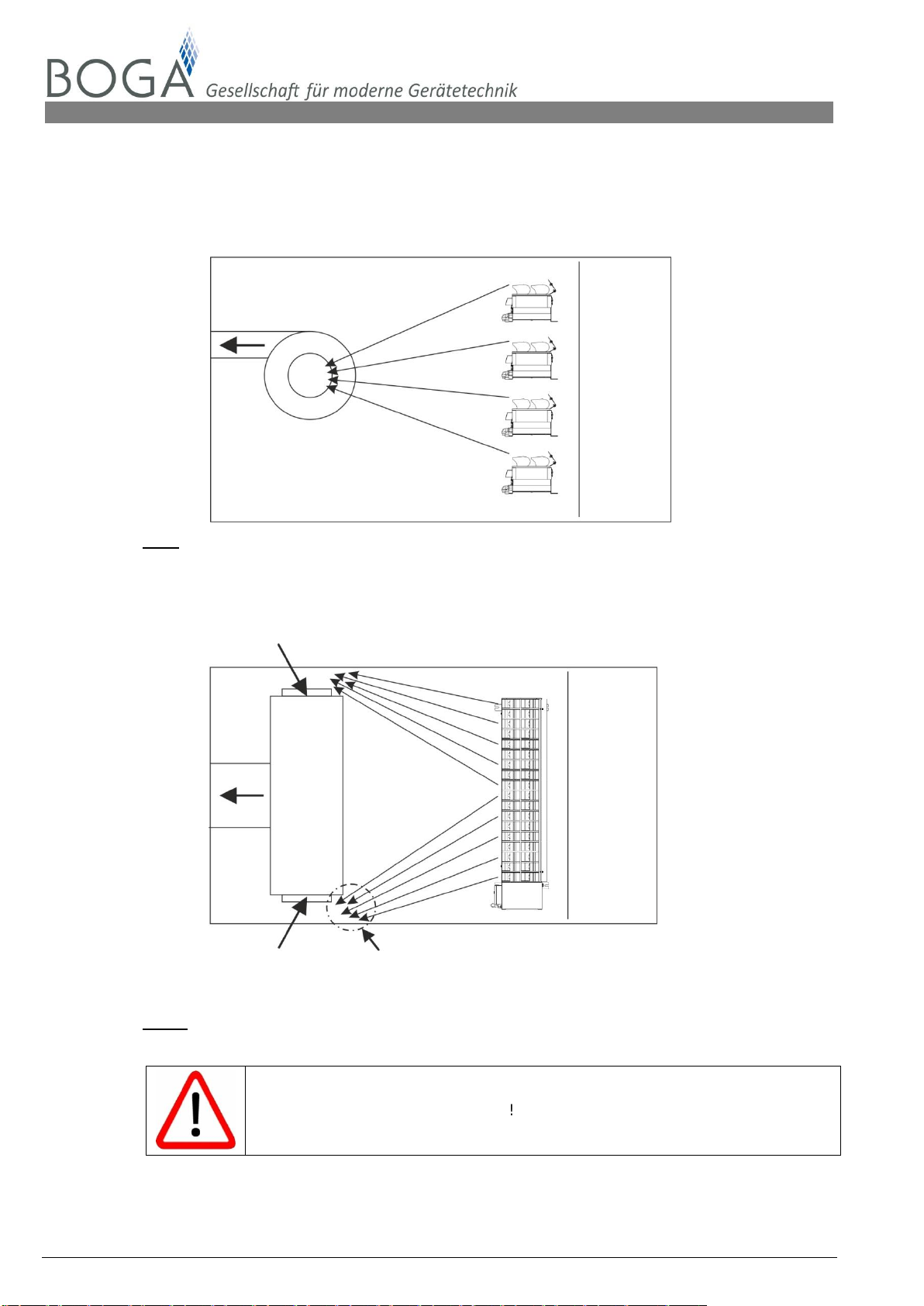

fig. 5 - Side view into an air duct with one NKBD

The humidifiers can be arranged directly above one another. The vertical distance between

the humidifiers should be 140 mm.

fig. 6 - View into an air duct in direction of air flow, two NKBD mounted above each

other

[MBA_NKBD_EN] Rev.: 10/2015 13

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH •Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 •Fax: +49 2921 96943-29 •info@airwin.net • www.airwin.net

9.2.2 Stepped configuration

Humidifiers are mounted above one another; offset horizontally (fig. 7 and 8).

Mounting example on tubular frame (on site) with NKBD mounting brackets (Item No.

2000105).

Stepped configuration is necessary

if the permissible air velocity would be exceeded on standard configuration or

if more humidification is necessary than would be possible with the standard con-

figuration. The minimum vertical distances are smaller than with the standard con-

figuration, which permits installation of more units and thus increased humidifica-

tion.

Requirements:

With stepped configuration, the vertical distance between several humidifiers must

be ≥ 70 mm

The minimum horizontal distance between several humidifiers must be ≥80 mm.

Several humidifiers should be evenly distributed over the entire duct width, observ-

ing the minimum distance of 200/100 mm from the duct walls.

fig. 7 - Side view into an air duct with three NKBD

fig. 8 - View into an air duct in direction of air flow, three NKBD mounted above each

other

14 [MBA_NKBD_EN] Rev.: 10/2015

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH • Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 • Fax: +49 2921 96943-29 • info@airwin.net • www.airwin.net

9.3 Suction operation

During suction operation is to ensure that the aerosol mist of the humidifiers is not constricted by the

suction of the fan! As may be the case fit a 50 % perforated plate - consider pressure loss.

Fan

fig. 9 - Side view NKBD in the air duct

Suction opening

Suction opening constriction

fig. 10 - Top view NKBD in the air duct

Avoid constriction of the aerosol mist!

[MBA_NKBD_EN] Rev.: 10/2015 15

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH •Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 •Fax: +49 2921 96943-29 •info@airwin.net • www.airwin.net

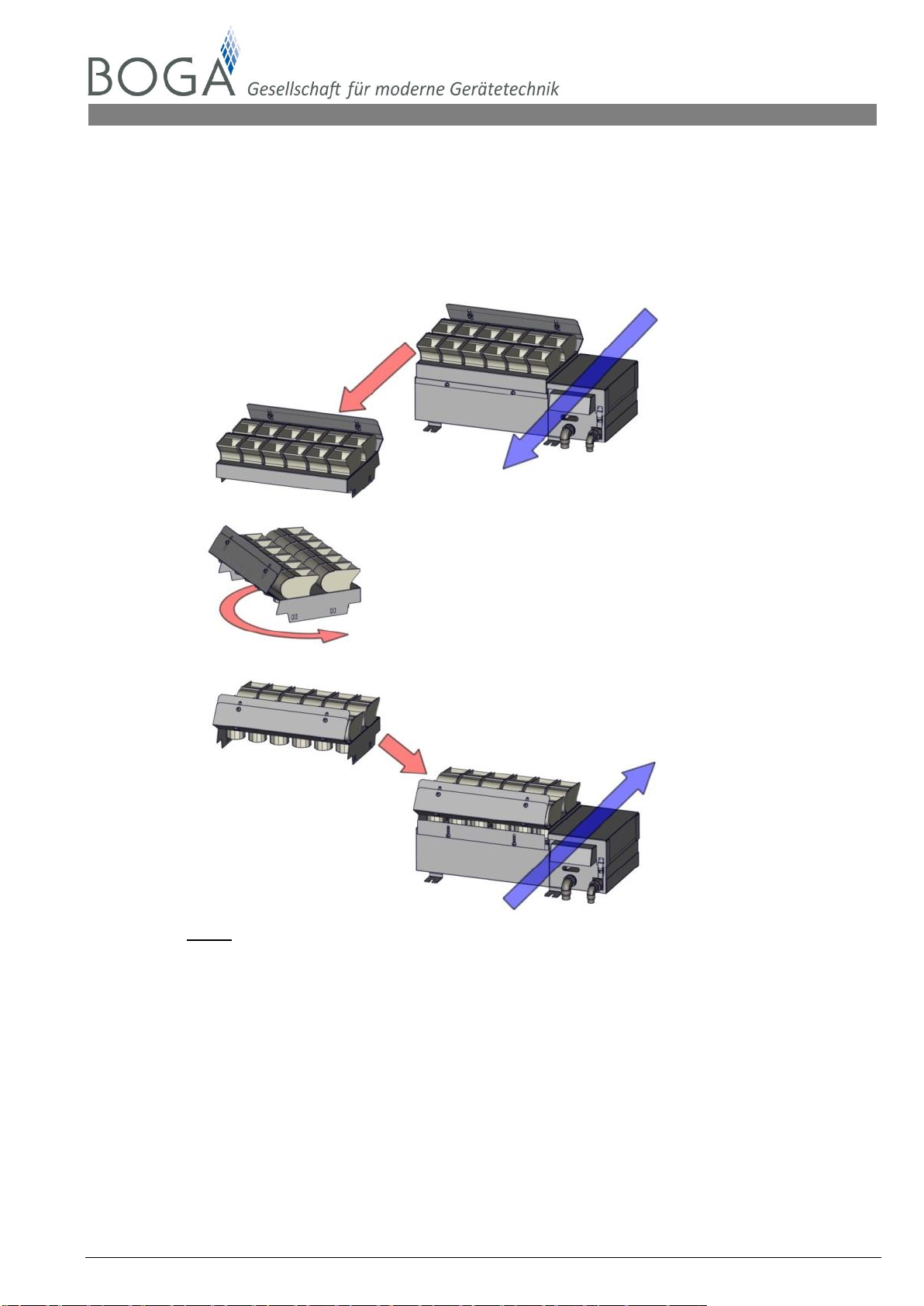

9.4 Adjustment of the NKBD to the direction of airflow

The NKBD can be adjusted to the flow direction of the duct air. Therefore the duct support must

be rotated by 180° if necessary. This allows the humidifier to be situated in a favourable position

for the water and electrical connection.

NKBD direction of the air stream

Body duct support

180°

direction of the air stream

fig. 11 - rotate body duct support

16 [MBA_NKBD_EN] Rev.: 10/2015

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH • Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 • Fax: +49 2921 96943-29 • info@airwin.net • www.airwin.net

10. Hydraulic connection

10.1 Hydraulic conditions

fig. 12 - Schematic diagram of hydraulic conditions

definitions

1. NKBD

2. Drinking water supply (on site)

3. Water demineralisation system (reverse osmosis system)

4. Demineralised water:

1 bar < pressure ≤ 4 bar

5 µS/cm < conductivity ≤ 20 µS/cm

5. Concentrate

6. Stop cock (included in the scope of delivery)

7. Water supply for plastic tube Ø 10 mm

8. Water overflow and discharge, for plastic tube Ø 14 mm

9. Drainage (on site)

Connections 7-8 are marked with stickers.

Important notes:

The NKBD may be operated with fully demineralised water only (produced for example by a re-

verse osmosis system). The demineralised water must have a conductivity of min. 5 µS/cm and

max. 20 µS/cm.

The contamination of drinking water may not exceed the max. values laid out in the drinking wa-

ter regulations

The demineralised water is corrosive, therefore use stainless steel or plastic only. Non-ferrous

metals (e.g. copper, brass) must not be used.

Water pressure must be minimum 1 bar and maximum 4 bar.

The drainage system on site must be set in accordance with DIN 1988 part of 4, EN 1717.

For easy revision, the stop cock included in the scope of delivery must be installed in the

demineralised water supply line close to the device.

All materials coming into contact with the demineralised water must be resistant

to demineralised water. Observe pressure and temperature resistance.

Demineralised water pipes must be flushed prior to starting the humidifier.

[MBA_NKBD_EN] Rev.: 10/2015 17

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH •Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 •Fax: +49 2921 96943-29 •info@airwin.net • www.airwin.net

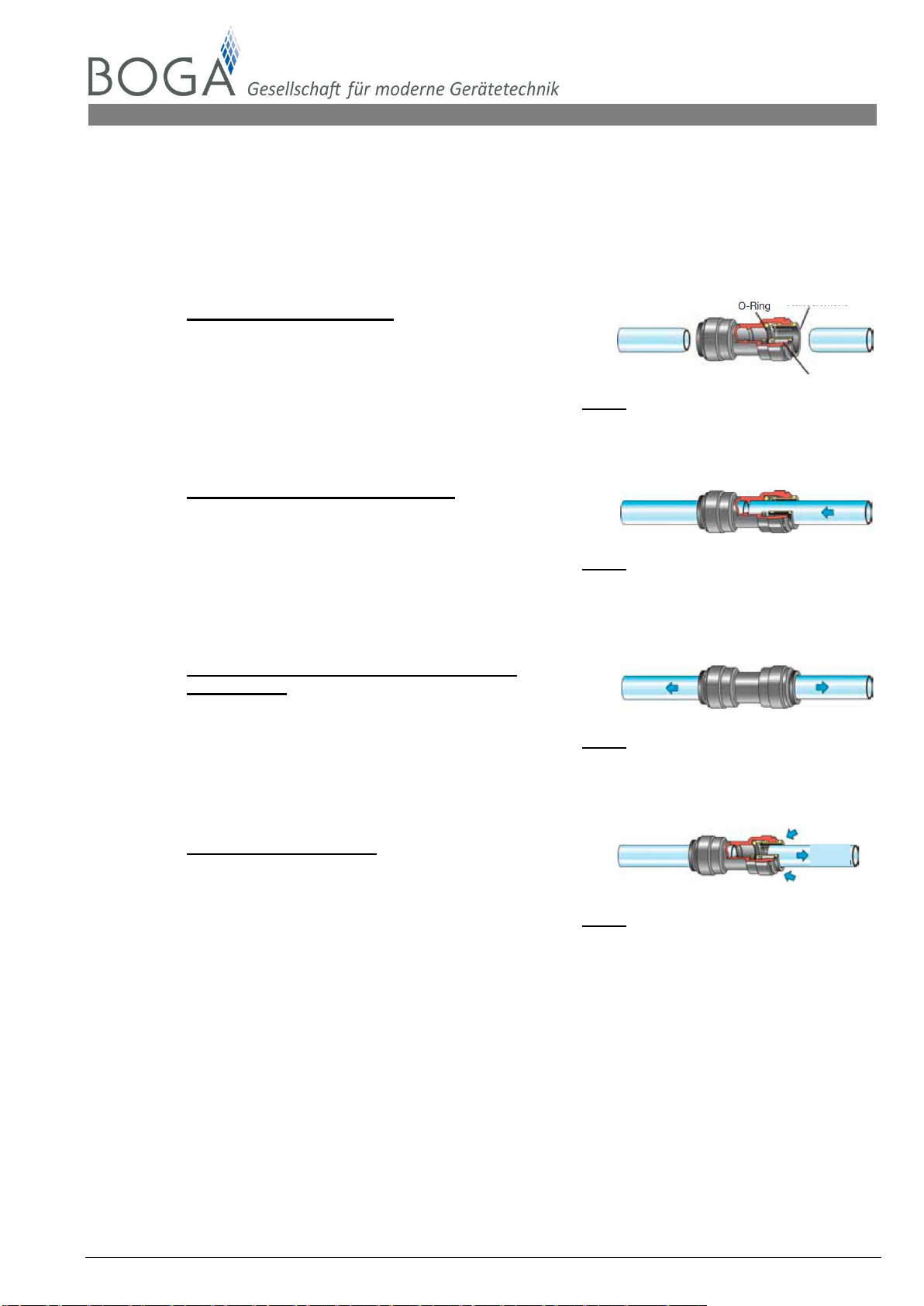

10.2 Establishing and detaching connections with connectors

The connectors provide durable, safe and watertight connections between tube and connecting ele-

ment. The tube is simply inserted by hand. The retaining element holds the tube safely without

pressing it or decreasing the flow.

Establishing the connection

Cut tube squarely and free of burrs.

Make sure that the tube has no sharp edges,

longitudinal grooves or other damage.

fig. 13 - Establishing the connection

Connection is stable prior to sealing

Insert the tube up to the stop.

The supporting element holds the tube in the

connector. With the help of the O-ring,

a tight connection is established. fig. 14 - Insert tube

Check the connection by pulling towards the

opposite side

By pulling towards the opposite side check

whether the tube was safely inserted.

fig. 15 - Check connection

Detaching the connection

The tube can be detached by pushing back the

supporting element.

fig. 16 - Detaching the connection

remove

tube

press back

support element

press back

support element

support element

stainless steel teeth

18 [MBA_NKBD_EN] Rev.: 10/2015

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH • Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 • Fax: +49 2921 96943-29 • info@airwin.net • www.airwin.net

11. Electrical Connection

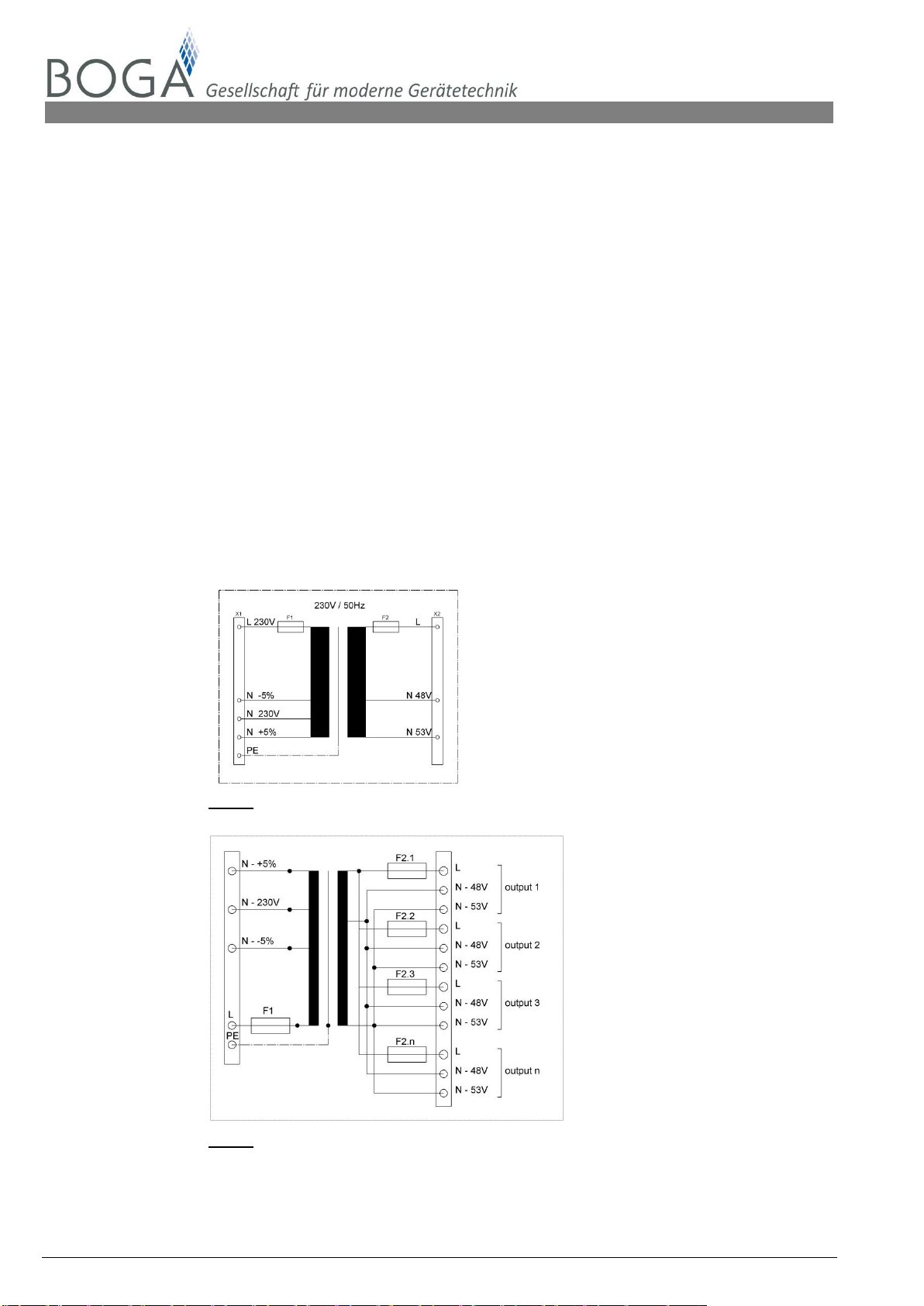

11.1 Transformer

11.1.1 The transformers are available either loose or installed in a sheet metal housing. When in-

stalling in the control cabinet, it is essential to make allowance for the heat dissipated from

the transformers. The control cabinet may have to be provided with forced-air cooling.

11.1.2 A single large transformer may be selected to serve several humidifiers. In such cases,

make sure that each outgoing secondary circuit is fuse-protected, either external in the

control cabinet or within the transformer ex- factory.

11.1.3 The transformer transforms the primary voltage of 230 V / 50 Hz to the secondary voltage

of 48 / 53 V.

11.1.4 The power connection cable leading to the transformer and from the transformer to the

humidifier must at least satisfy H05VV or H05RR specifications.

11.1.5 The transformers of BOGA are manufactured according to the following specifications:

Single-phase control-power transformer in accordance with VDE 0550 Parts 1+3 and VDE

0113, IP00, Protection Class 1, Insulation Class T40E, separate windings, screw-

connection in accordance with VBG4, 50/60 Hz.

fig. 17 - Transformer with a secondary output

fig. 18 - Transformer with multiple secondary outputs

[MBA_NKBD_EN] Rev.: 10/2015 19

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH •Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 •Fax: +49 2921 96943-29 •info@airwin.net • www.airwin.net

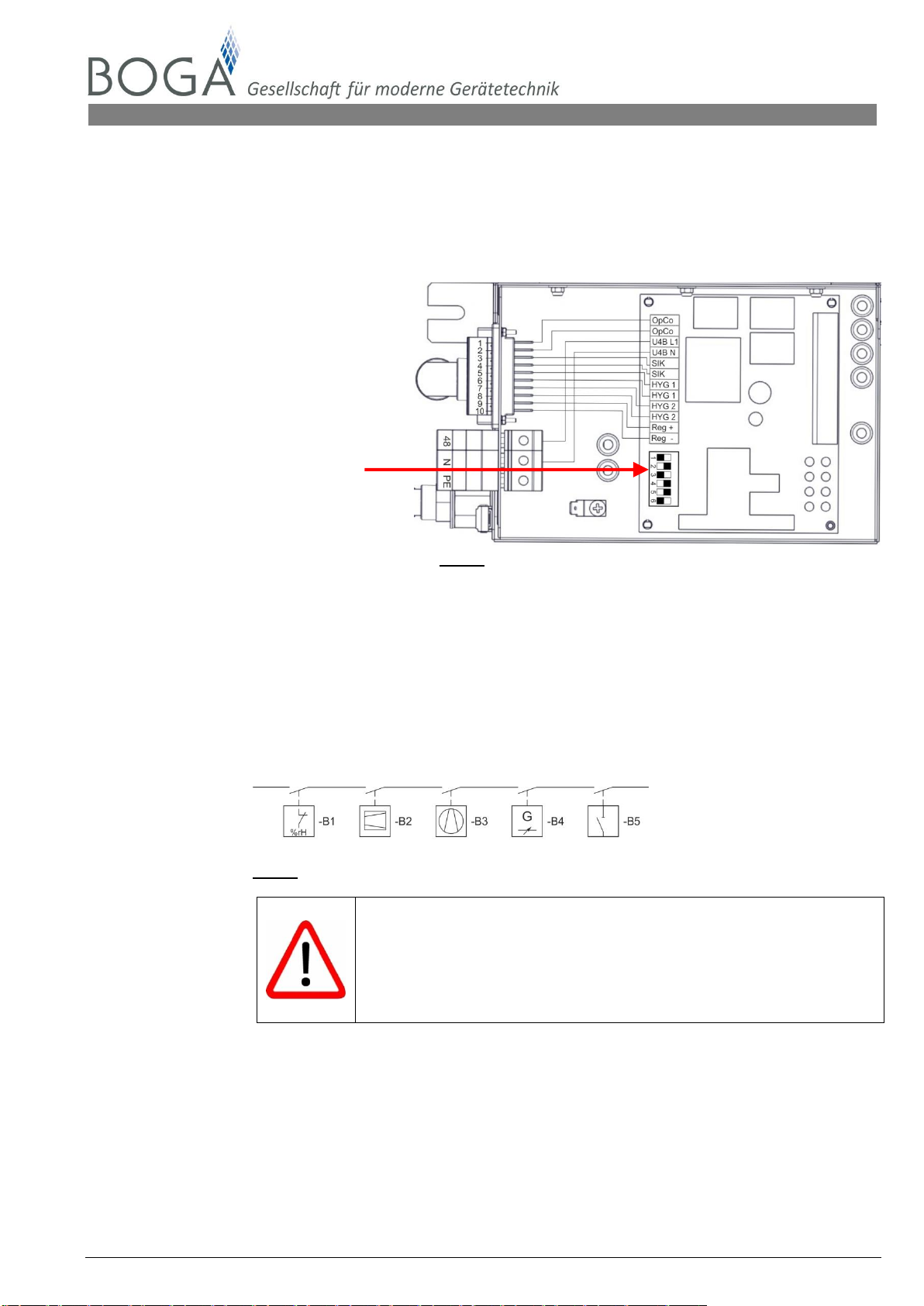

11.2 Humidifier

The humidifier is connected at the 48 V (L, N, PE) bushing terminals for electrical power and at the

10-pole connector (located in the centre section of the control housing) for control/safety

chain/function control. The connections will be exposed by releasing the toggle fasteners on the con-

trol housing cover and removing the cover.

1-2 Function control

3-4 Safety chain

5-6 Hygrostat 50 % *

7-8 Hygrostat 100 % *

9-10 Control signal

DIP-Switch

*of nominal humidifying capacity fig. 19 - Electrical power connection

11.2.1 Humidifier power connection

Connect power (L 48 V - N ) to the appropriately marked bushing terminals

Connect protective earth conductor to the green/yellow bushing terminal

11.2.2 Safety chain

Connect safety chain to the screw-type connectors marked 3and 4.

Observe the 48 VAC power supply.

B1: limit hygrostat

B2: flow monitor

B3: fan locking

B4: conductivity measurement

B5: ON/OFF switch

fig. 20 - Safety chain

The input of the safety chain must always be supplied with a voltage of

48 V. Cable bridges are always mounted ex-factory between connections

1-2 safety chain and 9-10 48 V.

The humidifier does NOT work otherwise.

When connecting several humidifiers, the safety chain must be connected

in parallel to each humidifier.

CAUTION: the 48 V supply must only be taken once.

11.2.3 Operation Control

As soon as the humidifier starts humidifying a relay will close on the control circuit board of

the NKBD. This information may be used for further processing (e.g. building services

management system). Connection at 1 and 2 on the screw-type connector

Load rating of potential-free output: 120 VAC 6 A

48 VAC 6 A

28 VDC 6 A

20 [MBA_NKBD_EN] Rev.: 10/2015

No liability accepted for translation or printing errors. Subject to changes in dimensions, weights and other technical data.

All rights reserved. Modifications, reprints and photomechanical reproduction, even in extract from, require the express permission of BOGA GmbH, Werkstraße 16, D-59494 Soest.

BOGA GmbH • Werkstraße 16 •D-59494 Soest •Fon: +49 2921 96943-0 • Fax: +49 2921 96943-29 • info@airwin.net • www.airwin.net

11.3 Control and regulation

If a hygrostat and continuous controller are connected at the same time, the hu-

midifier always runs first the larger request.

11.3.1 Hygrostat control

HYG 1: 50 % of nominal humidifying capacity - connection 3 and 4

HYG 2: 100 % of nominal humidifying capacity - connection 5 and 6

When connecting several NKBD humidifiers to one hygrostat, they must

be connected in parallel; see circuit diagram (see chapter 18).

11.3.2 Continuous control

The NKBD is capable of processing 10 different external controlled variables (Tab. 11.1).

Coding is shown on the circuit diagrams, including load.

The control cable must be connected at 9(+) and 10(-) paying attention to correct phase

sequence (+/-). From the factory, the control variable 0-10 VDC is always coded.

The connection of the continuous control is shown in the circuit diagrams in Chapter 18.

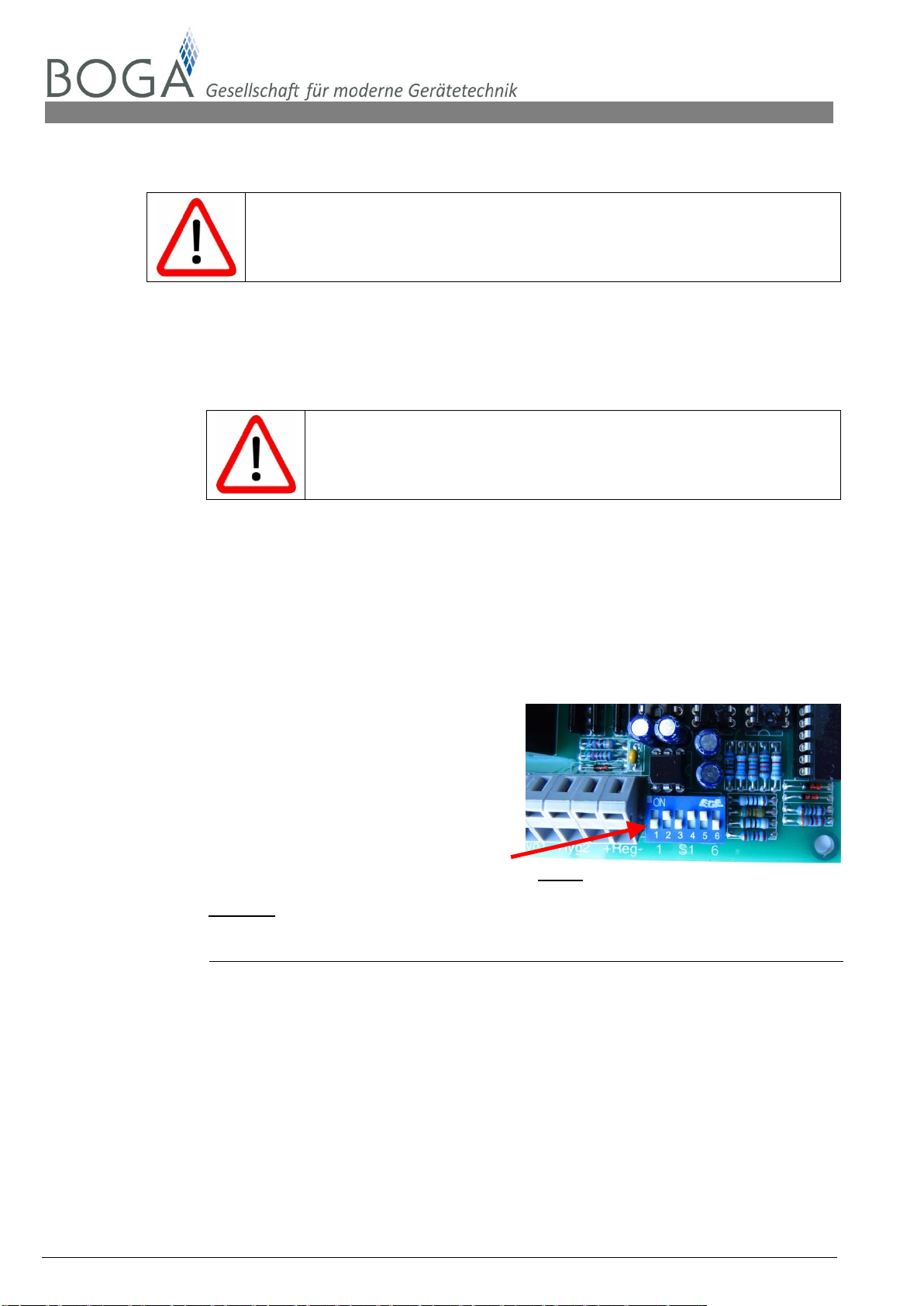

11.3.3 Control signal encoding

The encoding of the input variables below

usually carried out by the 6-pin DIP-switch

S1 on the control board.

DIP-

switch

fig. 21 - control board

Tab. 11.1 Coding table for DIP-switch

Control

1

2

3

4

5

6

Load

input resistance

0 - 20 mA

on

on

-

on

-

-

110.0 mW

275 Ω

4 - 20 mA

on

-

on

on

-

-

110.0 mW

275 Ω

0 - 5 VDC

-

on

-

on

-

-

7.3 mW

3425 Ω

1 - 5 VDC

-

-

on

on

-

-

8.0 mW

3125 Ω

0 - 10 VDC

-

on

-

on

on

-

30.0 mW

3333 Ω

2 - 10 VDC

-

-

-

-

on

-

30.0 mW

3333 Ω

0 - 16 VDC

-

on

-

-

-

on

77.0 mW

3325 Ω

3 - 16 VDC

-

-

on

on

-

on

77.0 mW

3325 Ω

0 - 20 VDC

-

on

-

-

on

on

140.0 mW

2857 Ω

4 - 20 VDC

-

-

on

on

on

on

130.0 mW

3077 Ω

Hyg 1/2

-

-

-

-

-

-

This manual suits for next models

6

Table of contents

Other Boga Humidifier manuals