Healthy Climate HCSteam?16 User manual

05/12 506746−01

*2P0512* *P506746-01*

Page 1

THIS MANUAL MUST BE LEFT WITH THE

HOMEOWNER FOR FUTURE REFERENCE

Shipping and Packing List

Items shipped

Model HCSteam−16(Cat. No. Y3478) Duct steam injec-

tion, 16 gallons per day (5.5 Lbs per hour) 110−120 VAC.

Model HCSteam−35(Cat. No. Y3479) Duct steam

injection, 35 gallons per day (12 Lbs per hour) 220−240

VAC.

Humidifier installation parts10 ft. steam hose, steam

hose adapter, steam nozzle, water fill hose, condensate

hose, mounting template, installation instructions, product

warranty, steam hose clamps (2), condensate hose clamp.

Air proving switch kit (Cat. no. Y3786)includes 6’ tubing,

switch installation sheet, two ductwork pressure tube taps,

mounting screws and anchors.

Other required items

1/2" water line

25 Amp dedicated electrical circuit

1−1/4" extension tube (can be plumbed into a open drain or

water drain receiver or a condensate pump that can hold 1

gallon of 140º F water then plumbed into a 3/4" drain line)

Before beginning installation

Check for shipping damage to cartons. Mark the shipping

waybill accordingly.

Open cartons and check equipment for shipping damage

or missing components; if found, immediately report any

discrepancies to the last carrier.

INSTALLATION

INSTRUCTIONS

HCSteam−16/−35 Residential

Healthy Climate®Steam

Humidifier

INDOOR AIR QUALITY

506746−01

05/12

Supersedes 01/12

Table of Contents

Shipping and Packing List 1. . . . . . . . . . . . . . . . . . . . . .

Clearances, Unit Dimensions, and

Component/Feature Specifications 2. . . . . . . . . . . . .

General 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic humidifier operation 3. . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plumbing 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steam Distribution 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start up / Start up checklist 16. . . . . . . . . . . . . . . . . . . . .

Controller 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the humidifier 16. . . . . . . . . . . . . . . . . . . . . . . . . .

Starting with a new cylinder 16. . . . . . . . . . . . . . . . . . . . .

Operating the humidifier 17. . . . . . . . . . . . . . . . . . . . . . . .

Displaying humidifier information 17. . . . . . . . . . . . . . . .

Changing the maximum production percentage 17. . . .

Activating manual drain 17. . . . . . . . . . . . . . . . . . . . . . . .

Resetting the hour counter 17. . . . . . . . . . . . . . . . . . . . . .

Alarms 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Periodic checks 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder maintenance 21. . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement parts 23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical specifications 23. . . . . . . . . . . . . . . . . . . . . . . .

NOTICE

The humidifier must be installed in accordance with

all local and national standards.

Installation, adjustments, alterations, service and

maintenance must be performed by a qualified ser-

vice technician.

WARNING

Before installing or handling the humidifier, please

carefully read and follow the instructions and safety

standards described in this manual and on the la-

bels attached to the HCSteam−16/−35 Residential

Steam Humidifier.

Page 2

506746−01 05/12

Table 1. Clearances, Unit Dimensions, and Component/Feature Specifications

in. (mm) Lbs. (kg)

A13−1/2 (343) 16 (8)

B8−1/8 (206) 22 (10)

C23−3/4 (603) 26 (12)

in. (mm)

A6 (150)

B6 (150)

C6 (150)

D6 (150)

E24 (600)

Fmax. 0.2º

angle

Clearances Unit Dimensions

AB

C

A

B

C

D

E

F

Component/Feature Nominal Specifications/Range Tolerance

Steam capacity (HCSteam−35) 12 lb/h (5.4 kg/h) −15% +10%

Steam capacity (HCSteam−16) 5−1/2 lb/h (2.5 kg/h) −15% +10%

Water supply pressure limits 15 psi to 116 psi (0.1 to 0.8 MPa) −− −−

Water supply temperature limits 34°F to 104°F (1°C to 40°C) −− −−

Water supply flow minimum 0.12 gpm (0.45 L/min) −− −−

Power supply (HCSteam−35) 220−240 VAC −15% +10%

Power supply (HCSteam−16) 110−120 VAC −15% +10%

Total Drain Water Flow 7 gpm (26.2 L/min) −10% +10%

Ambient temperature operating 34°F to 104°F (1°C to 40°C) −− −−

Ambient humidity operating 10 to 60% rH −− −−

Ambient temperature storage 14°F to 158°F (−10°C to 70°C) −− −−

Ambient humidity storage 5 to 95% rH −− −−

General

The HCSteam−16/−35 humidifier produces non−pressur-

ized steam which is then used to humidify the air.

The quality of the water used affects the operation of this

unit, so the humidifier may be supplied with untreated wa-

ter, as long as it is drinkable and not softened or demineral-

ized. The water converted into steam is automatically re-

placed through an electric fill valve. Periodically, based on

the water quality, the unit will also drain some water to di-

lute the build−up of minerals in the steam generator.

This humidifier has been designed to directly humidify

ducts using a distribution system. The installation, use and

maintenance operations must be carried out according to

the instructions contained in this manual and on the labels

applied internally and externally.

Disconnect the humidifier from the main power supply be-

fore accessing any internal parts.

The conditions of the environment and the power supply

voltage must comply with the specified values listed on the

data label in the humidifier.

All other uses and modifications made to the humidifier

that are not authorized by Lennox are considered unautho-

rized, and Lennox assumes no liability for the conse-

quences of any such unauthorized use.

Please note that the humidifier contains powered electrical

devices and hot surfaces.

NOTICE

The humidifier requires water to operate.

Do NOT mount it above materials or machinery that

could be damaged if a leak occurs. Lennox assumes

no responsibility for consequential or inconse-

quential damage as a result of any leaks.

If unit must be located where any leaking water

could cause damage, an auxiliary drain pan is rec-

ommended.

Disposal of humidifier parts

The humidifier is made up of metallic and plastic parts. All

parts must be disposed of according to the local standards

on waste disposal.

Page 3 HCSTEAM−16/−35 SERIES

Basic Humidifier Operation

STEAM

CYLINDER

FILL CUP

USER INTERFACE / DISPLAY

ON / OFF & SET BUTTONS

DRAIN PUMP

FILL VALVE

DRAIN TANK

TEMPERING VALVE

STEAM HOSE ADAPTER

WATER

INLET AND

FILTER

Figure 1. Basic humidifier components

CAUTION

SCALDING HAZARD!

The humidifier has heated parts (1005C/ 2125F).

The HCSteam−16/−35 is an electrode humidifier. It produces

steam for humidification by passing electric current through

metal electrodes (7, figure 2) immersed in water inside a

plastic steam cylinder (5). There are no heating elements.

Steam output is directly proportional to the conductivity of the

water, and the amount of electrode immersed in the water.

On a call for humidity, the HCSteam−16/−35 humidifier con-

troller opens the water fill valve (1) and allows water to en-

ter the cylinder. A flow restrictor (4) prevents the unit from

filling too quickly or with too much pressure. The water

flows up the fill tube (2) and into the fill cup (3).Water then

flows over the dam in the fill cup (3), creating a 1" air gap

that prevents contaminated water backflow into feed lines.

Water then flows through the fill tube (6) and into the bot-

tom of the steam cylinder (5). Any backflow or overflow of

water travels through the overflow hose (13) to the drain.

HL

DT

13

OVERFLOW

HOSE

2

FILL TUBE

6

FILL TUBE

3

FILL CUP

4

FLOW

RESTRICTOR

1

FILL VALVE

11

DRAIN

PUMP

10

TEMPERING

VALVE

CYLINDER

FULL PROBE

9

STEAM

OUTLET

8

ELECTRODE

7

STEAM

CYLINDER

5

STRAINER

12

Figure 2. Basic humidifier operation

As the water fills the cylinder, it will reach the electrodes (7)

and current will begin to flow. As the water continues to fill

the cylinder, the current will increase, and this is monitored

by an amperage transformer connected to one of the pow-

er wires and located on the electronic controller. When the

Page 4

506746−01 05/12

desired current is reached, the fill valve (1) will close and

the water will then begin to warm and produce steam. If the

water reaches the cylinder full probe (9) or if current rises

too much, the drain pump (11) will be activated to drain

away some water and reduce the current flow to accept-

able levels. Note that, any time the drain pump is activated,

the tempering valve (10) will be opened for tempering the

hot drained water down to 140º F (60ºC) in accordance to

local and national standards.

Periodically, based on the incoming water conductivity, the

unit will run drain pump (11) and drain some water to re-

duce the mineral concentration. A strainer (12) in the cylin-

der helps to prevent mineral debris from jamming the drain

pump (11).

In case the HCSteam−16/−35 humidifier remains powered

but idle, i.e. without producing steam, for more than 48

hours (2 days), the cylinder will be emptied to not have

stagnant water inside.

If there is no water in the cylinder, there will be no current

flow and no steam production. The electrodes do not burn

out, but they will eventually become completely coated

with mineral and the cylinder will then need to be replaced.

Cleaning cylinders may cause electrode damage, there-

fore voiding its warranty. See maintenance section on

Page 21.

Installation

Installing the nozzle

The HCSteam−16/−35 humidifier’s nozzle must be installed

onto the ductwork near the humidifier. Refer to the Steam

Distribution section (Page 8) for information on how to

properly locate the nozzle, for dimensions for the hole

mounting pattern, and for connections to the humidifier

and to the condensate drain. (Also see figure 6 for a typical

installation diagram.)

Drill a 2−1/4" (57 mm) hole in the ductwork at the selected

location for inserting the nozzle into the duct work. Position

the nozzle in the hole. Mark and drill 1/16" mounting holes

and use self−tapping sheet metal screws to attach the

nozzle to the duct.

Removing the humidifier front cover

The front cover is secured by four screws located at the

four corners of the unit. Using a Phillips head screwdriver,

loosen the four cover screws and then pull the front cover

away from the back part of the unit (see figure 3).

Installing the humidifier

CAUTION

Do not install the humidifier in an location that is

within the reach of children.

If unit must be located where any leaking water

could cause damage, an auxiliary drain pan is rec-

ommended.

Do not install humidifier in a location where freezing

temperatures may occur. Water supply and drain

lines may freeze causing water damage.

Positioning the humidifier

The HCSteam−16/−35 humidifier has been designed for

on−wall installation. The simplest and most efficient instal-

lation would have the humidifier installed just below the

duct where the steam nozzle is to be installed. This mini-

mizes steam hose length and the amount of condensate.

Certain clearances must be maintained around the

unit for safety and maintenance (see table 1 on

Page 2)..

If present, remove packing as shown in figure 4.

REMOVE PROTECTIVE

FILM FROM COVER

Figure 3. Removing the front cover

REMOVE PACK-

ING BEFORE

INSTALLING

LATCH THE CYLINDER

CLAMP

REMOVE PACKING

BEFORE INSTALLING

REMOVE

RESTRAINT

BEFORE

INSTALLING

REMOVE PRO-

TECTIVE FILM

FROM DISPLAY

Figure 4. Removing Packing

Page 5 HCSTEAM−16/−35 SERIES

Installing humidifier on a wall

Fastening to the wallDrill mounting holes in the wall using the installation template; then secure the humidifier firmly to

the wall using the supplied screws and anchors (see figure 5).

2−3/8"

(60)

2−3/4

(70)

5

(128)

5

(128)

10−1/8

(257)

2−1/2

(65)

Dimensions in inches (mm)

1−7/8

(48)

2−3/4

(70)

2−1/8

(54)

3/8

(9)

17−5/8

(448)

3−7/8

(98)

1−1/2

(38)

2−3/8

(60)

2−3/8

(60)

23−5/8

(600)

3−5/8

(92)

5/8 (16)

3−1/4

(82)

1−3/8

(35)

2 dia. (51) 7/8 dia. (23)

1−5/8

(40)

7/8

(24)

3−1/8

(78)

1−1/2

(37)

2−1/8

(53)

2

(51)

2−1/2

(62)

1−3/8

(36)

3−7/8

(98)

4

(102)

1−1/8 dia. (30)

1−5/8 dia. (40)

MOUNTING

HOLES

STEAM

CONDENSATE

DRAIN

ELECTRICAL

ELECTRICAL

FILL

FILL

DRAIN

STEAM

CONDENSATE

C L

C L

13−7/16

(341)

8 (204)

Figure 5. Installation dimensions and details

Page 6

506746−01 05/12

Installing the air proving switch (included)

IMPORTANT − Failure to install the air proving switch

will void the humidifier warranty!

The air proving switch (Cat. no. Y3786; provided with hu-

midifier) is a differential pressure switch that is required to

make sure that the blower is running prior to steam produc-

tion. Six feet of 3/16" tubing is provided along with two

pressure taps (mounting screws are not included) to con-

nect both pressure taps to the switch, however, install the

switch first, and then install one pressure tap in only the

supply duct (positive pressure application, step 2. below).

See figure 6.

1. Install switch and pressure tap

Select a mounting location near the supply duct which

will not be subject to vibration or where the switch

could be damaged. Mount the air proving switch in any

vertical plane except with the tubing connections di-

rected upward.

Connect the normally open terminals on the air proving

switch to the low voltage terminal strip in the humidifi-

er. See wiring diagrams in figures 13 through 17.

2. Positive pressure applicationUse the positive

pressure application when large amounts of air flow or

high static is present at the pressure tap in the supply

duct.

Install the duct air sampling tap to the supply duct work

as close to the switch as possible on the positive side

of the blower (see figure 6).

From the 6’ tubing provided, cut just enough 3/16" tub-

ing to reach from the pressure tap to the P1 switch

port. (P2 remains open).

NOTE − Check for closure of the blower switch using

the lowest blower speed setting. If the switch fails to

close the open set of contacts, you must use the differ-

ential application.

3. Differential pressure applicationUse the differen-

tial pressure application when small amounts of air

flow or low static is present across the pressure tap.

Install the 2nd pressure tap in the return duct work (see

figure 6).

Use the remaining 3/16" tubing to connect P2 switch

port to the negative pressure tap. Check for closure of

the switch when blower is turned on.

Plumbing

Water characteristic requirements

The humidifier must be supplied with water with the

following characteristics:

SPressure between 20 psi and 110 psi (0.137 MPa and

0.758 MPa; [1.4 and 7.6 bar])

STemperature between 33º F and 104º F (1ºC and

40ºC)

SFlow−rate minimum of 0.21 gpm (0.45 L/m)

SHardness no greater than 400 ppm3of CaCO (40º fH)

SConductivity from 125 to 1250 μS/cm

SAbsence of organic compounds

SThe characteristics of the water supply must fall within

the following limits:

MPa = Megapascals

fH = French degrees of hardness

μS/cm = microsiemens per centimeter

Unacceptable water types:

SSoftened Wateras this will lead to foam, electrode

corrosion and greatly shortened cylinder life.

SWater containing disinfectants or corrosion inhibiters,

as these are potential irritants.

SIndustrial water, boiler water or water from cooling cir-

cuits.

SAny potentially chemically or bacteriologically

contaminated water.

SHeated water.

Testing Water

A conductivity

meter is

recommended for

testing the water: Cat # Y3480 (AP−2 AquaPro Water

Quality Tester). Specifications:

EC Range: 0−9999 μS.

Temperature Range: 0−80 °C; 32−176 °F.

Resolution: 1 μS; Temp. resolution is 0.1°C/F.

Accuracy: +/− 2%

Calibration: Digital calibration by push button.

Housing: Water−resistant.

Power source: 1 x 3V button cell (included) (model

CR2032).

Dimensions: 15 x 2.8 x 1.3 cm (5.9 x 1.1 x .5 inches) .

Weight: 42.5 g (1.5 oz.).

Water supply connection

The recommended connection between the fill valve and

the water supply line is by way of the provided fill hose (5’

[1.5 m] hose with one straight 3/4" fitting and one 90 de-

gree 3/4" fitting). The provided hose absorbs water "ham-

mering" in order to avoid fill valve damage.

The water line may be routed through the back or through

the bottom of the unit. The fitting then threads onto the

valve assembly inlet located on the bottom of the humidifi-

er (see figure 6) using a 3/4" female garden hose connec-

tion. Note that there is a strainer built into the fill valve fitting

underneath the unit, which will require periodic cleaning,

so be sure to allow clearance for access.

Page 7 HCSTEAM−16/−35 SERIES

SUPPLY

RETURN

STEAM

NOZZLE

STEAM HOSE

STEAM CONDEN-

SATE RETURN LINE

MIN 5º

slope

DRAIN LINE

DETAIL A

DRAIN

LINE

DETAIL A

DRAIN

LINE

WATER FILL HOSE

SHUTOFF VALVE AND

FILTER (Recommended)

SUPPLY

WATER

EXTENSION

TUBE

SHUTOFF VALVE AND

FILTER (Recommended)

OPEN

DRAIN

DRAIN

LINE

Water inlet with filtering

screen (3/4" hose con-

nection)

1−1/4"

Water

drain

STEAM

HOSE

ADAPTER

FILL CUP

FILL

HOSE

OPEN

DRAIN

TO SUPPLY

AIR TAP

TO RETURN

AIR TAP

(if used)

AIR PROVING SWITCH

INSTALL TRAP IN

CONDENSATE LINE

PER FIGURE 9.

SUPPLY

AIR TAP

RETURN

AIR TAP

Figure 6. Typical Installation

Page 8

506746−01 05/12

Water drain

WARNING

The drain pipe must be free without back pressure.

We recommend an external anti−flooding device

(not supplied) to protect from faults of external

hydraulic circuits.

The HCSteam−16/−35 humidifier also requires a connec-

tion to a drain. The drain line may be routed out the back or

bottom of the unit using the included angle fitting. The drain

line can be 1−1/4" PVC, CPVC or polypropylene tubing

(drain line must be able to withstand 140°F water). The

drain line is not glued or otherwise attached to the humidifi-

er so it must be supported by itself. The humidifier includes

a drain tempering valve that runs whenever the drain pump

runs and flushes cool water into the drain line to insure the

drain water temperature never exceeds 140°F (60°C).

The drain water characteristics are:

SDrain Rate 7.1 gal/min. (26.8 lit/min.)

SConnection 1−1/4" (32mm)

STemperature 140°F (60°C)

Drain connections

When using a rear outlet drain passing through drywall, we

suggest using a 1−1/4" extension tube. When using a bot-

tom outlet drain, attach the included 90°fitting to the drain

outlet. The drain outlet may be rotated. Then connect a

1−1/4" trap adaptor to connect to drain pipe.

Steam Distribution

CAUTION

Do not touch steam hose when humidifier is operat-

ing!

The steam hose is a heated part. Allow to cool before

servicing.

Duct steam injection

The maximum allowed duct static pressure is 2" w.c.

The HCSteam−16/−35 humidifier include a plastic injection

nozzle (figure 7).

CONDENSATE

CONNECTION

2−1/2"

(63m)

2−1/2"

(63m)

STEAM

INLET

O.D. − 2.2" (56mm);

drill 2−1/4" (57mm)

hole in duct

Figure 7. Plastic injection nozzle

A typical installation is shown in figure 6.

NOTICE

Nozzle location is very important to the proper ab-

sorption of the steam in the air stream. Select a loca-

tion observing the following:

Snozzle must be installed in supply duct,

Snozzle location must be easily accessible,

Snozzle location must allow at least 3’ (1m) of

straight metal duct without elbows or obstruc-

tions,

Sduct must be un−insulated interior, and if in un-

conditioned spaces, insulated exterior,

Sclearances shown in figure 8 must be maintained.

Installing return condensate hose

The return condensate hose from the nozzle must be

trapped. Coil the hose into a vertical loop and secure it be-

low the nozzle. This trap prevents steam from being re-

leased into the cabinet. The hose end may be run through

the knockout at the top of the humidifier and be inserted

into the hole located on top of the fill cup. See figures 6 and

9.

height

min. 8"

1/3 height

centered

min. 8"

Figure 8. Plastic nozzle installations

Installing steam hoses

NOTICE

Ninety percent (90%) of all operation problems are

created by improper steam piping from the humidifi-

er unit to the duct steam nozzle.

Make the connection between the humidifier steam hose

adapter and nozzle using only the provided hose (unsuit-

able hoses may weaken and crack causing steam leaks).

Page 9 HCSTEAM−16/−35 SERIES

SAvoid the formation of pockets or traps where conden-

sate may form.

SAvoid choking the hose due to tight bends or twisting.

SFasten the end of the hose to the steam hose adapter

on the humidifier and the steam nozzle using metal

hose clamps, so that these do not detach due to the

high temperature.

NOTES −

Slope piping up in direction of steam flow at 20º or greater (2−1/2" per foot [63 mm per 305 mm])

Slope piping down in direction of steam flow at 5º or greater (3/4" per foot [19 mm per 305 mm])

Max. length of rubber steam hose is 10’ (3 m)

TYPICAL INSTALLATION

WHEN UNIT IS ABOVE

THE STEAM NOZZLE

5 ft (1.5 M) MAX. 5 ft (1.5 M) MAX.

IF NO SLOPE

3" (.9M) MAX.

>20º >5º

10 ft (3M) MAX.

5ft (1.5 M) MAX.

>20º >5º

GENTLE

BEND

OBSTRUCTION

SUPPORTED STEAM HOSE

AND/OR COPPER PIPE

DRAINS

P−trap

NOTE − Height of traps must be greater than the

duct static pressure

DRAINS

>20º

>20º

Figure 9. Installing steam hoses

NOTE − Maximum length of rubber steam hose is 10 ft. (3 m). Insulated copper tubing may be up to 20 ft. (6 m) in length. In all

cases, minimize sharp bends and elbows. Use 2 − 45elbows instead of 90 elbows. Hose inner diameter = 7/8" (22 mm);

Hose outer diameter = 1−1/4" (30 mm).

NO DISTRIBUTION

PIPE DRAIN

UN-

DRAINED

ELBOW

NO

SLOPE

UN-

DRAINED

ELBOW

SAG

NO TRAP

NO SLOPE

KINKED

Figure 10. Unacceptable examples of installing steam hoses

Page 10

506746−01 05/12

Wiring

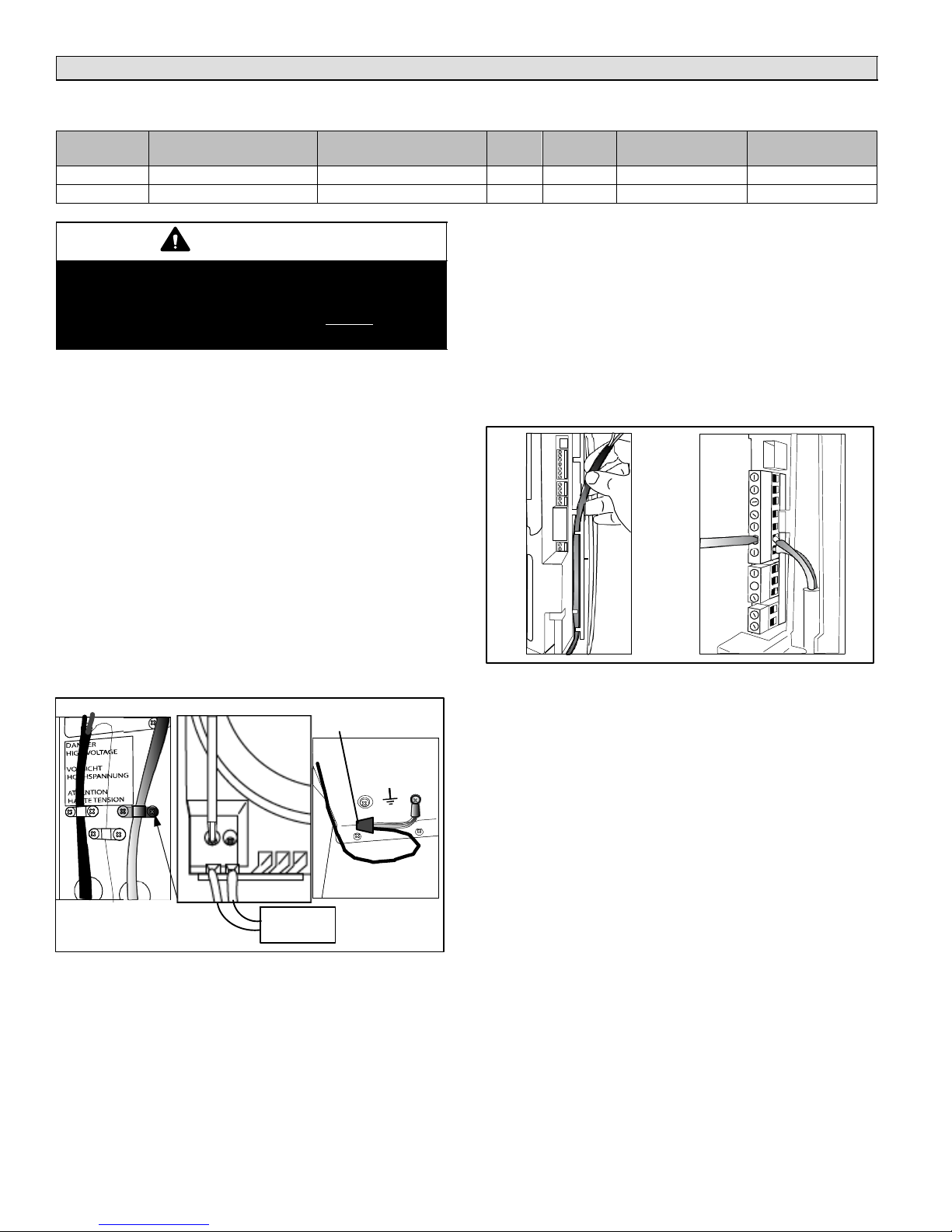

Power wiring

All wiring must be in accordance with local, state and national electric codes.

Model

Power supply

(single phase)

Steam Output

lbs/hr (kg/h) kW Amps

External Power

Wire Gauge

External Fuse (A)

or Breaker

HCSteam−16 110−120 VAC 50/60Hz 5.5 (2.5) 1.80 16.40 AWG10 25

HCSteam−35 220−240 VAC 50/60Hz 12 (5.4) 3.89 16.95 AWG10 25

WARNING

ELECTRIC SHOCK HAZARD!

The humidifier uses electrical power.

Always disconnect the main power before opening

or servicing the humidifier!

NOTE − To avoid unwanted interference, the power cables

should be kept separate from any control wiring.

NOTE − Tolerance allowed on main voltage =−15% to

+10%.

Insert the power and ground connection cables into the

electrical panel compartment using the strain reliefs sup-

plied (see figure 11, A), and connect to the terminals. An

external fused disconnect must be installed.

Check that the power supply voltage to be connected

matches the value indicated on the rating plate inside the

electrical panel.

Connect power wires to the power terminal block located at

the bottom left of the control module, polarity does not mat-

ter (see figure 11, B).

Connect the ground wire to the unit’s chassis ground, lo-

cated just behind the power wiring terminal block (see fig-

ure 11, C).

L1 L2

ABC

SERVICE

DISCONNECT

STRAIN

RELIEF

L1 L2

GND

GND

WIRE NUT

POWER

CONTROL

Figure 11. Power wiring connections

Control wiring

The humidifier is controlled by humidistat and safety

devices such as high−limit humidistat, air proving switch,

and remote on/off.

The humidifier is operated by the closing of a mechanical

humidistat, or by the closing of a normally open dry con-

tact. The most common is a combination of a humidistat

and air proving switch. Diagrams A and B in figure 12 show

the routing to the terminal block.

AB

Figure 12. Routing control wiring to terminal

block

Connect control devices to humidifier using the diagrams

shown in figures 13 through 17. Following each diagram is

an explanation of the sequence of operation associated

with each wiring configuration.

Air Proving Switch and Safety switches

Remove the jumper between terminals AB−AB and con-

nect air proving switch. DO NOT apply any voltage to AB−

AB.

Thread the control wiring through the bottom of the unit,

and the strain relief (see figure 12) and then up the side of

the control module to the top right wiring terminal blocks.

Connect the control wiring to the control wiring terminal

blocks found at the top right side of the control module.

Page 11 HCSTEAM−16/−35 SERIES

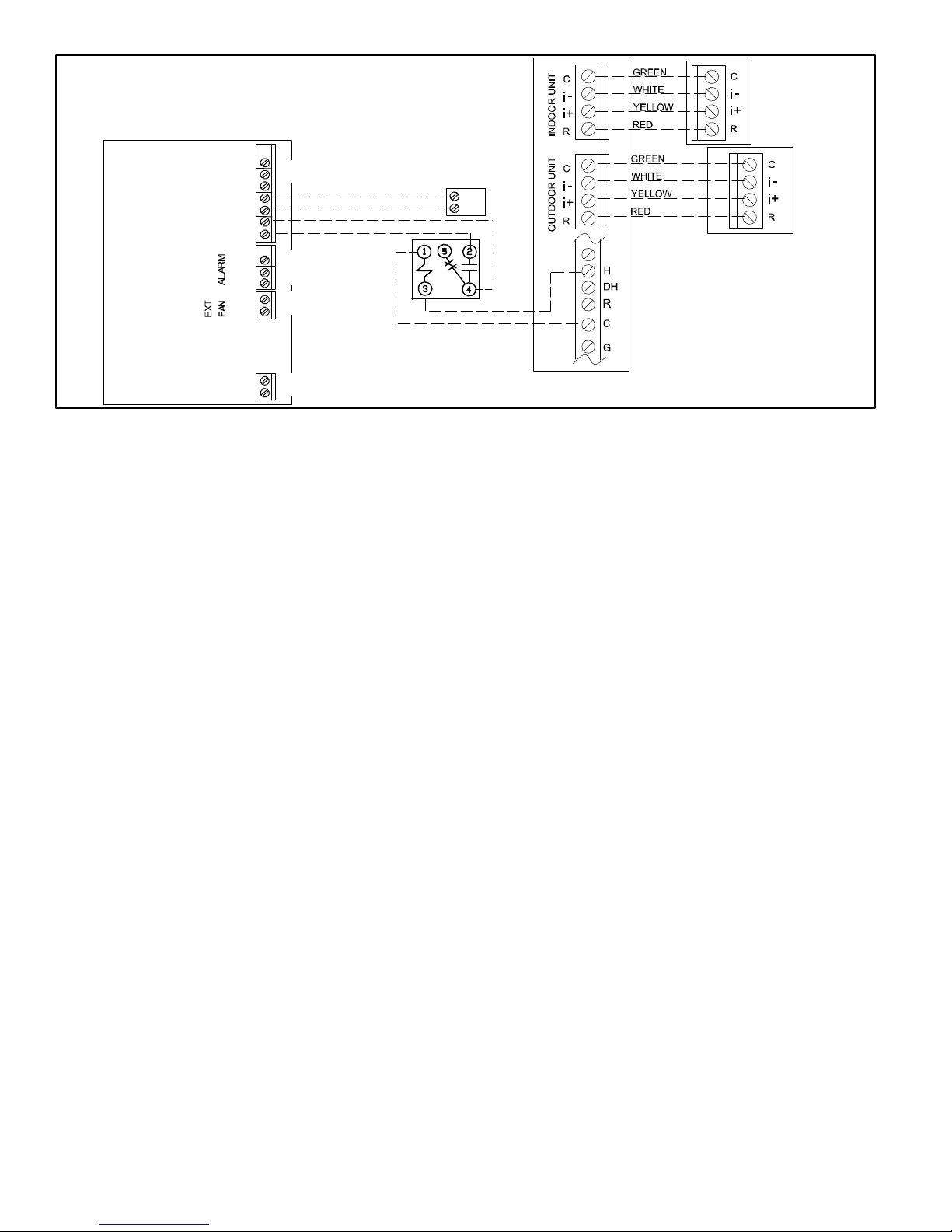

Conventional 24 VAC

Humidistat (Cat no.

X9553 or equivalent)

NO

C

NC

C

NO

Alarm

terminals

(if used)

Outdoor AC Unit

Note 1. Blower interlock is required.

Note 2. 48G96 relay field supplied.

Note 3. Remove factory jumper between AB−AB

48G96 SPDT Interlock Relay

C

NO

Thermostat

Required Air Proving

Switch (provided)

GND

24VAC

N2

GND

N1

AB

AB

GND

IN

Typical Air Handler /

Furnace Control

(AHC or IFC)

(not

used)

(not

used)

Humidifier

low voltage

wiring panel

Figure 13. Humidifier with conventional 24V humidistat and interlocked with HVAC blower

SWhen the humidity in the space falls below the conventional humidistat’s RH set point, the circuit closes from "GND" to "IN"

on the humidifier controller and in turn, closes the EXT FAN contacts ("NO" to "C") in the humidifier controller.

STerminal R on the furnace or air handler feeds 24V to the EXT FAN contacts (now closed) and to the blower interlock relay

coil. The interlock relay normally−open contacts close to energize G" on the furnace or air handler and start the indoor blower

(if not already running by a heating demand). The interlock relay also isolates G" from the thermostat to prevent a back feed

that would start the outdoor unit.

SWhen the indoor blower achieves sufficient speed, the air proving switch contacts close completing the circuit from "AB" to

"AB" on the humidifier controller. Steam production will now start and continue until the humidistat demand is satisfied.

SWhen the humidistat has reached its RH set point, its contacts open stopping steam production. The humidifier controller EXT

FAN contacts open, de−energizing the blower interlock coil and stopping the indoor blower (if not running due to a heating

demand or thermostat blower demand). When the indoor blower stops, the air proving switch contacts will open.

SLP98 Furnace /

CBX40 Air Handler

C

NO

Note 1. Do not connect H" on CS7000 to H" on furnace

or air handler control board.

Note 2. Set up humidifier per CS7000 thermostat installa-

tion instructions.

Note 3. 48G96 relay field supplied.

Note 4. Remove factory jumper between AB−AB.

Outdoor AC Unit

ComfortSense®7000

Thermostat

48G96 Relay

Alarm

terminals

(if used)

(not

used)

(not

used)

(not

used)

Required Air Proving

Switch (provided)

NO

C

NC

C

NO

GND

24VAC

N2

GND

N1

AB

AB

GND

IN

Humidifier

low voltage

wiring panel

Figure 14.Humidifier with ComfortSense®7000 thermostat used as humidistat and interlocked with

HVAC blower

SHumidification is controlled by the humidity sensor in the thermostat. When the humidity in the space falls below the thermo-

stat’s humidity RH set point, 24 volts goes on the thermostat’s "H" terminal to energize the humidifier isolation relay coil which

closes the open set of contacts in the relay, and completes the circuit between "GND" and "IN" on the humidifier controller.

SThe thermostat will also send power to the "G" terminal on the air handler or furnace control to start the indoor blower.

SWhen the indoor blower achieves sufficient speed, the air proving switch contacts close completing the circuit from "AB" to

"AB" on the humidifier controller. Steam production will now start and continue until the humidity demand is satisfied.

SWhen the RH set point is reached, the thermostat removes 24 volts from H" which opens the isolation relay circuit and, in

turn, opens the circuit between "GND" and "IN" on the humidifier controller, stopping steam production. The G" signal will

also be removed to turn off the blower (if not running due to a heating demand or thermostat blower demand). When the indoor

blower stops, the air proving switch contacts will open.

Page 12

506746−01 05/12

SLP98 / icomfort enabled

CBX40UHV / CBX32MV ONLY

icomforttenabled

outdoor unit

icomfort

Touch®

thermostat

Note 1. Humidification must be added in icomfort Touch®

thermostat during commissioning. Refer to icomfort

Touch®Installer Guide for details.

Note 2. 48G96 relay field supplied.

Note 3. Remove factory jumper between AB−AB.

C

NO

48G96

Relay

Alarm

terminals

(if used)

(not

used)

(not

used)

(not

used)

Required Air Proving

Switch (provided)

NO

C

NC

C

NO

GND

24VAC

N2

GND

N1

AB

AB

GND

IN

Humidifier

low voltage

wiring panel

Figure 15. Humidifier with icomfort Touch®thermostat used as humidistat with an icomfortten-

abled SLP98 gas furnace or icomforttenabled CBX40UHV or CBX32MV air handler

SHumidification is controlled by the humidity sensor in the thermostat. When the humidity in the space falls below the thermo-

stat’s humidity RH set point, a demand message for humidification is sent to the HVAC unit control board.

SThe demand message starts the indoor blower and sends a 24 volt signal from the H" terminal on the furnace control to the

humidifier isolation relay coil. The isolation relay contacts close to complete the circuit from GND" and IN" terminals on the

humidifier controller.

SWhen the indoor blower achieves sufficient speed, the air proving switch contacts close completing the circuit from "AB" to

"AB" on the humidifier controller. Steam production will now start and continue until the humidity demand is satisfied.

SWhen the RH set point is reached, the thermostat removes the demand to the furnace board which removes the 24 volt output

from the H" terminal and opens the isolation relay circuit and, in turn, opens the circuit between GND" and IN" on the humidi-

fier controller, stopping steam production. The indoor blower will be turned off (if not running due to a heating demand or ther-

mostat blower demand).

Page 13 HCSTEAM−16/−35 SERIES

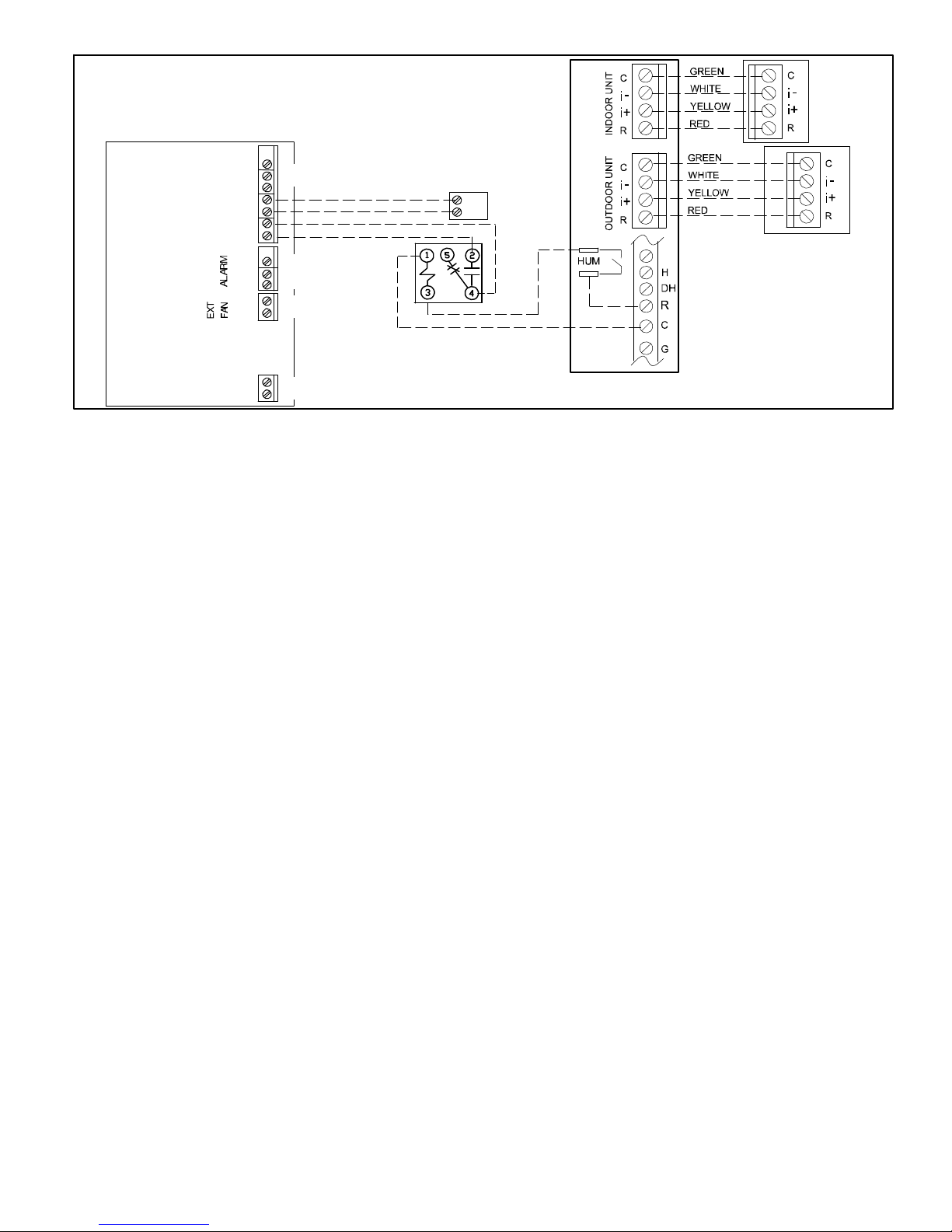

SL280 ONLY

Note 1. Humidification must be added in icomfort Touch®

thermostat during commissioning. Refer to icomfort

Touch®Installer Guide for details.

Note 2. 48G96 relay field supplied.

Note 3. Remove factory jumper between AB−AB.

C

NO

48G96

Relay

Alarm

terminals

(if used)

(not

used)

(not

used)

(not

used)

Required Air Proving

Switch (provided)

NO

C

NC

C

NO

GND

24VAC

N2

GND

N1

AB

AB

GND

IN

Humidifier

low voltage

wiring panel

icomforttenabled

outdoor unit

icomfort

Touch®

thermostat

Figure 16. Humidifier with icomfort Touch®thermostat used as humidistat with an icomfortten-

abled SL280 gas furnace

SHumidification is controlled by the humidity sensor in the thermostat. When the humidity in the space falls below the thermo-

stat’s humidity RH set point, a demand message for humidification is sent to the furnace control board.

SThe demand message starts the indoor blower and closes the "HUM" contacts on the furnace control. 24 VAC passes through

a field−installed jumper from the "R" terminal on the control board, through the closed "HUM" terminals, and to the humidifier

isolation relay coil. The isolation relay contacts close to complete the circuit from "GND" and "IN" terminals on the humidifier

controller.

SWhen the indoor blower achieves sufficient speed, the air proving switch contacts close completing the circuit from "AB" to

"AB" on the humidifier controller. Steam production will now start and continue until the humidity demand is satisfied.

SWhen the RH set point is reached, the thermostat removes the demand to the furnace board which opens the HUM contacts,

opens the isolation relay circuit and, in turn, opens the circuit between "GND" and "IN" on the humidifier controller, stopping

steam production. The indoor blower will be turned off (if not running due to a heating demand or thermostat blower demand).

Page 14

506746−01 05/12

C

NO

ON DIP

1 2 3 4

ON

OFF

OFF

ON

HC DIGITAL AUTOMATIC HUMIDISTAT

DIP SWITCH SETTINGS FOR HUMIDISTAT−

ONLY OPERATION

1

2

5G0

6G

7AOUT

8G0

9NTCE

10DIN Outdoor

Sensor

Outdoor AC Unit

48G96 SPDT Interlock Relay

Thermostat

Typical Air Handler / Fur-

nace Control (AHC or IFC)

Alarm

terminals

(if used)

(not

used)

Required Air Proving

Switch (provided)

HC Digital

Automatic

Humidistat

(Cat.. no.

Y3760)

NO

C

NC

C

NO

GND

24VAC

N2

GND

N1

AB

AB

GND

IN

Humidifier

low voltage

wiring panel

Note 1. Blower interlock is required.

Note 2. 48G96 relay field supplied.

Note 3. Set signal type to 1" for modulating (Step 5, Figure

22 [Page 17]).

Note 4. Remove factory jumper between AB−AB.

Note 5. Connected for Modulating Operation.

Figure 17. Humidifier with HC Digital Automatic Humidistat connected for modulating operation

SSteam production is modulated between 20% and 100% of the maximum production proportionally to the signal provided by

the humidistat.When the humidity in the space falls below the humidistat’s RH set point, the humidistat sends a 0 to 10Vdc

from 7AOUT" terminal to the "IN" terminal on the humidifier controller and in turn, closes the EXT FAN contacts (NO" to C")

in the humidifier controller.

STerminal R on the furnace or air handler feeds 24V to the EXT FAN contacts (now closed) and to the blower interlock relay

coil. The interlock relay normally−open contacts close to energize G" on the furnace or air handler and start the indoor blower

(if not already running by a heating demand). The interlock relay also isolates G" from the thermostat to prevent a back feed

that would start the outdoor unit.

SWhen the indoor blower achieves sufficient speed, the air proving switch contacts close completing the circuit from "AB" to

"AB" on the humidifier controller. Steam production will now start and continue until the humidity demand is satisfied.

SWhen the humidistat has reached its RH set point, its contacts open stopping steam production. The humidifier controller EXT

FAN contacts open, de−energizing the blower interlock coil and stopping the indoor blower (if not running due to a heating

demand or thermostat blower demand). When the indoor blower stops, the air proving switch contacts will open.

C

NO

ON DIP

1 2 3 4

ON

OFF

OFF

ON

HC DIGITAL AUTOMATIC HUMIDISTAT

DIP SWITCH SETTINGS FOR HUMIDISTAT−

ONLY OPERATION

1

2

5G0

6G

7AOUT

8G0

9NTCE

10DIN

Outdoor

Sensor

Outdoor AC Unit

48G96 SPDT Interlock Relay

Thermostat

Typical Air Handler /

Furnace Control

(AHC or IFC)

Alarm

terminals

(if used)

(not

used)

Required Air Proving

Switch (provided)

HC Digital

Automatic

Humidistat

(Cat.. no.

Y3760)

NO

C

NC

C

NO

GND

24VAC

N2

GND

N1

AB

AB

GND

IN

Humidifier

low voltage

wiring panel Note 1. Blower interlock is required.

Note 2. 48G96 relay field supplied.

Note 3. Remove factory jumper between AB−AB.

Note 4. Connected for ON/OFF configuration.

Figure 18. Humidifier with HC Digital Automatic Humidistat connected for ON/OFF operation

SWhen the humidity in the space falls below the humidistat’s RH set point, the circuit closes humidistat terminals 1" and 2"

to complete humidifier controller circuit to IN" and GND" and then closes the humidifier controller EXT FAN contacts ("NO"

to C").

STerminal R on the furnace or air handler feeds 24V to the EXT FAN contacts (now closed) and to the blower interlock relay

coil. The interlock relay normally−open contacts close to energize G" on the furnace or air handler and start the indoor blower

(if not already running by a heating demand). The interlock relay also isolates G" from the thermostat to prevent a back feed

that would start the outdoor unit.

SWhen the indoor blower achieves sufficient speed, the air proving switch contacts close completing the circuit from "AB" to

"AB" on the humidifier controller. Steam production will now start and continue until the humidity demand is satisfied.

SWhen the humidistat has reached its RH set point, output to the humidifier controller "IN" and GND" terminals falls to 0 Vdc,

stopping steam production, then opens the EXT FAN contacts which will stop the indoor blower (if not running due to a heating

demand). When the indoor blower stops, the air proving switch contacts will open.

Page 15 HCSTEAM−16/−35 SERIES

Interlock between HCSteam−16/−35 humidifier and furnace or air handler fan

The following sequence of events must occur for

HCSteam−16/−35 to produce steam:

SExternal humidistat contacts must close between ter-

minals IN and GND providing a steam humidification

demand.

SThe air proving switch NO contacts wired between hu-

midifier terminals AB and AB must close when signifi-

cant air volume is provided to allow the humidifier to

operate.

The HCSteam−16/−35 humidifier must be connected to an

air proving switch (that is, a device that senses the flow of

air in the duct provided by the furnace or air handler). This

air proving switch should be connected to the remote en-

abling input (terminals AB−AB). In some applications a

field−provided limit humidistat (normally closed) may be

installed in series with the air proving switch connected to

terminals AB−AB).

Table 2. Wiring Connections

Terminals Functions Electrical specifications

L1−L2 −GROUND Power supply and Ground

connections

Power supply 110−120 VAC 1−phase 50−60Hz 1.86kW or 220−240 VAC 1−phase 50−60Hz

4.05kW

KEY Programming port Connecting to Programming port or supervisor (factory use only)

AB−AB Remote enabling input Imposes an external NO contact ; Rmax=300 Ohm; Vmax=33 Vdc; Imax=6mAdc;

humidifier enabled = contact closed

IN−GND Control signal input Humidistat connection

NC−C−NO NC alarm contact

Common alarm contact

NO alarm contact

250V; 8Amp max with resistive load; 4 Amp max with inductive load.

In the event of an active alarm, the alarm LED will come on and the relay is energized.

NO−C External fan relay 250V; 8Amp max with resistive load; 4 Amp max with inductive load

24−GND Power for external humidistat Power supply for external humidistat 24 VAC; 2 Watt

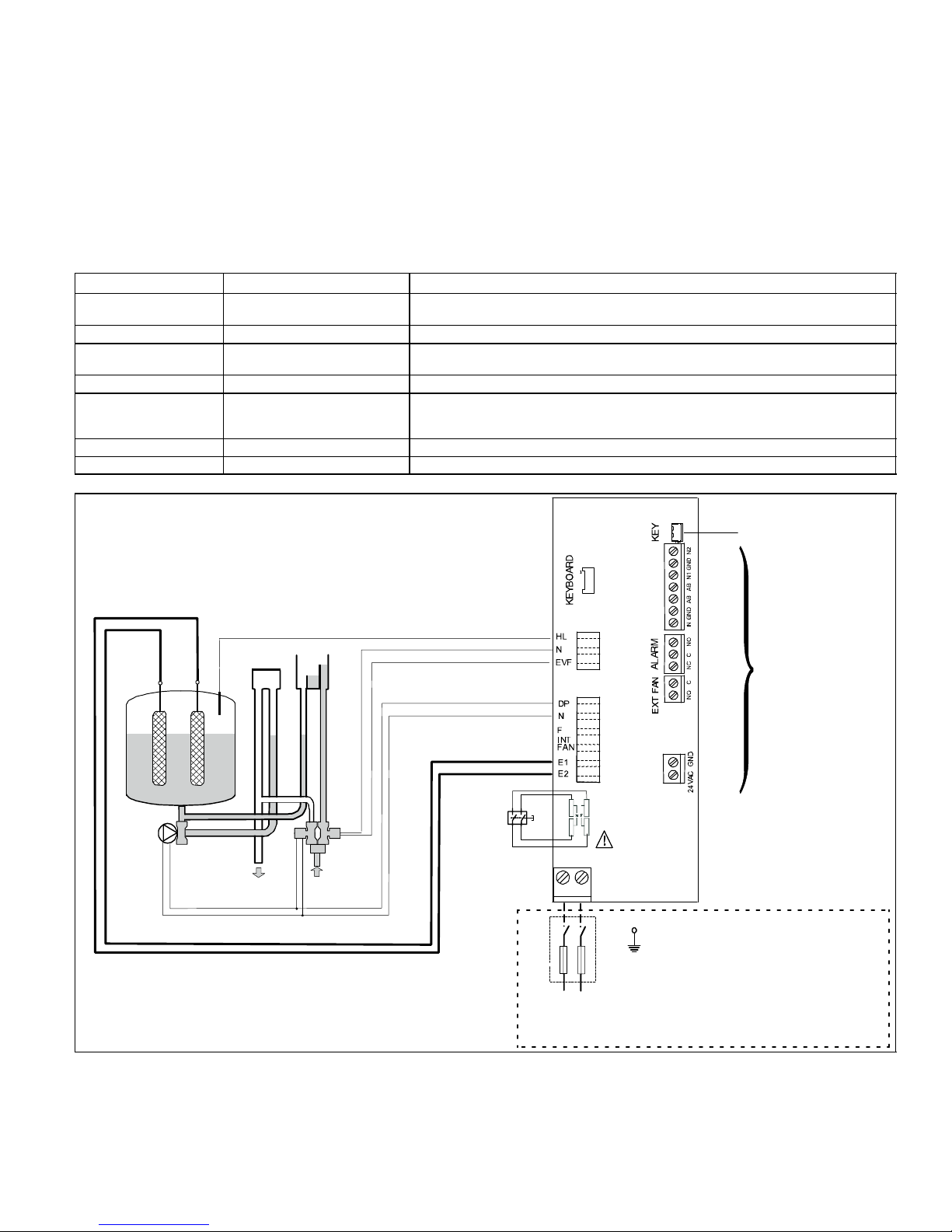

Programming port

for factory use

(see low voltage

control diagrams

figures 13

through 17 for

control wiring

options)

Connected to

ground

ON/

OFF

Button

EVF Fill valve

DP Drain pump

DT Drain tempering valve

HL High−level sensor

Power supply

110−120 VAC 1−phase 50−60 Hz

or

220−240 VAC 1−phase 50−60 Hz

External disconnect to

be installed (not sup-

plied); respect local

codes.

For 110−120 VAC, only

switch the hot wire (not

neutral); for 220−240

VAC, switch both hot &

neutral.

2

4

6

8

L1 L2

DP

DT

EVF

HL

Water outlet Water inlet

Steam cylinder unit

NOT

USED

N2

GND

N1

AB

AB

GND

IN

NO

C

NC

C

NO

GND

24VAC

Figure 19. Humidifier internal controller wiring diagram

Page 16

506746−01 05/12

Start−Up

HCSteam−16/−35 humidifier controller

The HCSteam−16/−35 humidifier controller features a com-

prehensive information display that shows the operation of

the system at a glance:

1

2

4

5

6

9

1012

13

14

11

3

7

8

1. Display is % of nominal

capacity

2. Maintenance or adjust-

ment

3. Display is amperage

(default)

4. Steam is being pro-

duced

5. Cylinder filling

6. Foaming

7. Water presence inside

the cylinder

8. Cylinder draining

9. LED icons indicate: left:

operation (green);

middle: power (yellow);

right: alarms (red)

10. Drain button for manual

draining of cylinder and

confirming parameter

values

11. ON/OFF button ("I" de-

pressed is the ON posi-

tion; O" depressed is

OFF)

12. Reset button to reset

alarms and access pa-

rameters

13. Level of output: 33%,

66%, 100%

14. Fan relay is activated.

operation power alarm

Figure 20. Humidifier Controller

WARNING

Before starting, check that the humidifier is in per-

fect condition, that there are no water leaks and that

the electrical parts are dry.

Do not connect power if the humidifier is damaged

or even partially wet!

When installation is complete, flush the supply pipe for 10

minutes by piping water directly into the drain, without

sending it into the humidifier; this will eliminate any scale or

residues that may cause foam when boiling.

Pre start−up checklist

Before starting the humidifier, the following should be

checked:

SWater is connected, the line has been flushed, and ex-

ternal valves are open.

SDrain is connected, run to an open drain, and has a

trap under the unit.

SElectricity is connected in accordance with instruc-

tions, local codes and data labels in the unit.

SMake sure all electrical connections to the cylinder are

tight.

SThe power fuses are installed and intact.

SAll control wiring is complete and tested.

SAir proving switch is wired to close when air flow is

proved.

SHi−limit humidistat (if used) is wired to open on humid-

ity rise above setpoint.

SUnit wires have been checked to make sure they and

all connectors are tight from shipping.

SThe steam hose(s) are run correctly with no sags or

kinks and sloped properly according to the manual.

SCondensate hoses are run correctly with no sags or

kinks and sloped properly according to the manual.

SAn auxiliary drain pain is installed under humidifier if

humidifier is installed in area where a water leak could

cause damage.

Humidifier start up checklist

SInsure that the external power to the humidifier is on.

SPress the I" part of the On/Off button IN. The yellow

Power LED (middle) will light. The HCSteam−16/−35

humidifier is now ready to operate.

SWith a call for humidity, the humidifier will close its

power relays and send power to the electrodes in the

plastic steam generator. The green Operation LED will

light, indicating that operation has begun.

Operation checkout

Check that the air proving switch closes on the lowest

blower speed:

SAfter 10 minutes of operation, check duct for signs of

excessive condensation or wetness by inspecting in-

side of duct (using an access door or by removing the

nozzle).

SIf wetness exists, increase blower cfm or reduce hu-

midifier output capacity.

Initial Start−up with new cylinder

When starting with a new cylinder, you should activate the

cylinder cleaning function as follows:

1. Make sure the humidifier

switch is off (press "O" part

of switch).

2. While pressing and HOLD-

ING both reset/sel" and

drain" buttons, switch the

humidifier back on. DO NOT

release reset/sel" and

drain" buttons until the

wrench icon blinks; then re-

lease both buttons.

3. Press and hold reset/sel" until the display

shows 04. WARNING: DO NOT confirm

any value higher than 04. If 05 or higher is

displayed, press reset/sel" until the dis-

play goes back to the normal operating

mode and restart from step 1.

4. Press and hold drain" (minimum 1

second); the cleaning starts.

Page 17 HCSTEAM−16/−35 SERIES

During cleaning, the electrodes are powered and water fills

until it touches the high−level sensor or the phase current

equals 20A, whichever occurs first. After either of the

events is detected, the steam cylinder is fully discharged

with the electrodes un−powered (the drain pump and the

drain tempering valve are activated for 3 minutes). Lennox

recommends to perform two cleanings when starting a

new humidifier. After the cleaning ends, the humidifier

starts regular operation. The HCSteam−16/−35 humidifier

is now ready for operation.

Operation

Amperage: the amount of current

flowing through the water causing

the water to heat, boil, and pro-

duce steam (default display).

Production %: the amount of

steam being produced (ex-

pressed as a percentage of the

humidifier’s capacity).

Hour counter, expressed in tens;

for instance, when the display

shows 13 the real hour value will

be between 130 and 139 hours.

(Amperage is repeated)

Figure 21. Displaying Information

Displaying information

By pressing the reset/sel" button for 2 seconds, the dis-

play will loop from amperage to production in % of the max-

imum production to the hour counter and back to amper-

age (see figure 21).

Selecting the signal type

NOTE − The HCSteam−16/−35 humidifier is preset for a

manual humidistat with only an ON/OFF feature and nor-

mally does not require any change. Should the need ever

arise to reset it, proceed as follows:

1. Switch the humidifier off.

2. While pressing and HOLD-

ING both reset/sel" and

drain" buttons, switch the

humidifier back on. DO NOT

release reset/sel" and

drain" buttons until the

wrench icon blinks; then re-

lease both buttons.

3. Press reset/sel" until the display shows

02. DO NOT confirm any value higher than

02. Values of 03 or higher not applicable for

these models. If value is higher than 02,

press reset/sel" until the display goes

back to the normal operating mode and re-

start from step 1.

4. Press and hold drain" (mini-

mum 1 second); the display

shows P1" then the present

signal type and then set".

5. Press reset/sel" for signal type of 0 or 1:

0 = On−Off humidistat

1 = external 0...10 Vdc modulating signal

humidistat.

6. Press and hold drain" (minimum 1

second) when done to confirm the new

value of P1 and exit to the normal op-

erating mode.

7. Switch the humidifier off.

Figure 22. Selecting Signal Type

Changing the maximum production percentage

The maximum production can be adjusted between 20%

and 100% of the nominal production in steps of 5% in order

to suit either the 110−120 VAC or 220−240 VAC unit. Default

settings are factory set at 100% (110−120 VAC unit) 70%

(220−240 VAC unit). Adjust capacity per humidity calcula-

tion or system application air flow. Table 3 shows the hu-

midification load requirements. This chart will be helpful in

setting the correct production percentage.

1. Switch the humidifier off.

2. While pressing and HOLD-

ING both reset/sel" and

drain" buttons, switch the

humidifier back on. DO NOT

release reset/sel" and

drain" buttons until the

wrench icon blinks; then re-

lease both buttons.

3. Press reset/sel" until the display shows

01. DO NOT confirm any value higher than

01. Values of 02 or higher not applicable for

these models. If value is higher than 01,

press reset/sel" until the display goes

back to the normal operating mode and re-

start from step 1.

4. Press and hold drain" (mini-

mum 1 second); the display

shows P0" then the current

maximum production percent-

age and then set".

5. Press reset/sel" to change the

Maximum Production in steps of

5% between 20% and 100%.

6. Press and hold drain" (minimum 1

second) to confirm the new maximum

production percentage and exit to the

normal operating mode.

Figure 23. Changing Maximum Production Per-

centage

Page 18

506746−01 05/12

Table 3. Humidification Load Required, Gallon/day [Liter/day] (Ref: AHRI−Guideline F−2008)

Type of

Construction

Volume of Building ft3[m3(approximate)]

8000 [227] 10000 [282] 12000 [340] 16000 [453] 20000 [566] 24000 [680] 32000 [906] 40000 [1133]

Tight 4.3 [16] 5.3 [20] 6.4 [24] 8.5 [32] 10.6 [40.2] 12.7 [48.2] 17.0 [64.4] 21.2[80.4]

Average 8.6 [32] 10.6 [40.2] 12.8 [48.4] 17.0 [64.4] 21.3 [80.2] 25.4 [96.5] 34.0 [148] 42.6 [160]

Loose 12.7 [48.3] 15.9 [60.3] 19.1 [72.6] 25.5 [96.6] 31.8 [121] 38.1 [145] 51.0 [193] 63.6 [241]

Legend: HCSteam−16 HCSteam−35 Exceeds capacity of HCSteam units

Resetting the hour counter

The hour counter must be reset every time the cylinder is

changed in order to reset and restart the internal mainte-

nance timer:

1. Switch the humidifier off.

2. While pressing and HOLD-

ING both reset/sel" and

drain" buttons, switch the

humidifier back on. DO NOT

release reset/sel" and

drain" buttons until the

wrench icon blinks; then re-

lease both buttons.

3. Press reset/sel" until the display shows

03. DO NOT confirm any value higher than

03. Values of 04 or higher not applicable for

these models. If value are higher than 03,

press reset/sel" until the display goes

back to the normal operating mode and re-

start from step 1.

4. Press and hold drain" (minimum 1

second) to confirm: the hour counter

will be reset at once and

HCSteam−16/−35 humidifier will go

back to the normal operating mode.

Figure 24. Resetting Hour Counter

Activating the manual drain

Press and hold the drain" button on the front of the unit

until the cylinder is drained.

NOTE − Water will continue to flow from the tempering

valve after the cylinder is empty. Draining should take

around 20 seconds if the cylinder was full.

Sequence of operation

For a complete description of how the humidifier operates

using the various control devices, see the wiring section

(Page 11 through Page 14).

Page 19 HCSTEAM−16/−35 SERIES

Alarms

In the event of an alarm, the red alarm LED ( ) will flash, the alarm relay will energize and the alarm code will flash in the

display. Multiple alarms will flash in sequence, alternating with the main display. Pressing the reset/sel" button for 2 sec-

onds will reset the alarms, although still active alarms will continue to display.

Display Description Action

Red Alarm

Symbol Notes

−− Remote on−off open. Unit disabled. Off

EE Internal memory error. Unit disabled. On

Replace control for EE & E0

E0 Control board configuration not

valid.

Unit disabled. On

E1 High current alarm. Unit disabled. On Turn off, check connections,

check cylinder (no limescale

bridges between electrodes,

no electrodes short−circuited).

Use a ohm−meter to check

whether they are

short−circuited. Look through

the steam outlet to see

whether the electrodes are

loose.

E2 Low production, low supply water

conductivity or excessive

foam/limescale in the cylinder.

Unit disabled.

Press reset/sel" key for 1 seconds to

reset.

On Check supply water

conductivity (too low?),

replace the cylinder.

E3 Cylinder almost exhausted,

already used for 2000 hrs.

Press reset/sel" key for 1 seconds to

reset.

Off Change cylinder (not urgent).

E4 Fill alarm, unable or slow fill

(current does not increase within

timeout).

Press reset/sel" key for 1 seconds to

reset, otherwise the warning will be reset

automatically every 10 minutes until the

supply water is available again.

On Check water supply, water

inlet strainer, and fill valve;

check drain pump for leakage.

E5 Drain alarm, unable to drain

(current does not decrease within

timeout).

Press reset/sel" key for 1 seconds to

reset.

On Check drain pump operation;

check drain connection.

E6 Cylinder exhausted

(critical performance detected).

The warning is automatically reset if

HCSteam−16/−35 can produce the

demand, otherwise turn off and then on.

Off Change cylinder (urgent).

E7 Foam detected. Press reset/sel" key for 1 seconds to

reset.

Off If it continues, perform some

cleaning cycles (read section

Initial Start−up with a new

cylinder, Page 16)".

E8 Cylinder lifetime expired (3000

hours).

Unit disabled.

Reset the hour counter (read section

Resetting the hour counter").

On Change the cylinder.

E9 High controller temperature

(above 176 °F / 80 °C).

The warning is automatically reset if the

temperature decreases below 176 °F / 80

°C.

Off Check the ambient

temperature near the

controller, replace the

controller if the temperature is

OK.

Page 20

506746−01 05/12

Troubleshooting

Problem Causes Solutions

The humidifier does not turn on 1. No electrical power.

2. On/off switch of the humidifier in position O"

(OFF).

3. Control connectors improperly connected.

4. Power source failure; blown fuse; tripped

breaker.

5. Transformer failure.

1. Check the safety devices upstream from the humidifier and

the presence of power.

2. Close the switch on the panel: position I" (ON).

3. Check that connectors are properly inserted in terminal

block.

4. Check the power source; check condition of fuses; check

for tripped breaker.

5. Check for proper voltage across 24VAC and GND on

control. If no voltage present, replace controller.

The humidifier does not start

operation

1. Remote ON/OFF contact open.

2. The humidistat has not been connected

correctly.

3. Humidistat failure.

4. Control signal not compatible with the type set.

5. Value measured by the humidistat sensor(s)

higher than the corresponding RH set point.

6. Low conductivity water.

1. Close ON/OFF contacts.

2. Check the external connection.

3. Replace the humidistat.

4. Confirm for correct signal type for connected humidistat

using Selecting the signal type procedure on Page 17.

5. Using RH meter, confirm accuracy of RH sensor(s).

6. If 220−240 VAC humidifier, consider installing the Low

Conductivity cylinder (Y3484) listed on Page 23.

The humidifier fills with water

without producing steam

1. High steam back pressure.

2. Fill valve strainer clogged.

3. Mineral buildup in the fill cup.

1. Check that the steam hose is not kinked or sagging,

trapping condensate.

2. Clean the fill valve strainer.

3. Clean the fill cup.

The humidifier wets the duct 1. The steam nozzle is not installed correctly (too

near the top of the duct or the condensate return

is blocked).

2. Air flow rate is too low.

3. Humidifier active when the fan in the duct is off.

1. Check that the steam nozzle is installed correctly.

2. Increase air flow in duct or decrease maximum steam

production setting (see Page 17).

3. Check the connection of the device (flow switch or

differential pressure switch) controlling the humidifier to the

ventilation in the duct.

The humidifier wets the floor below 1. The humidifier drain is blocked.

2. The supply water or overflow circuit has leaks.

3. The condensate drain pipe does not bring the

water back to the drain pan.

4. The steam hose is not properly fastened to the

cylinder.

1. Clean the drain assembly and pan.

2. Check the entire water circuit.

3. Check the correct position of the condensate drain hose in

the drain pan.

4. Check the fastening of the hose clamps on the steam

outlet.

Water in the cylinder turns black 1. Minerals in the cylinder have over concentrated

and are deteriorating the electrodes.

1. Check for sags & kinks that could trap condensate in the

steam hoses that could cause a back pressure on the

cylinder.

2. Check the duct static pressure.

3. Check the fill valve and inlet strainer.

4. Check the drain pump operation.

5. Correct installation problems and replace cylinder.

Heavy arcing occurs within hours

of startup

1. The feed water contains large amounts of Iron,

Copper or other conductive contaminants.

1. If you are using a softener, discontinue use.

2. Check the electrodes in the cylinder to be sure they were

not damaged in shipping. Use a ohm−meter to check

whether they are short−circuited. Look through the steam

outlet to see whether the electrodes are loose.

Humidifier continuously fills and

drains without producing steam

1. Mineral has bridged between the electrodes.

2. There is back pressure from the steam hoses or

duct.

3. The flow regulator in the fill valve is broken or

out of place.

4. Water conductivity is very high.

5. Water is foaming excessively.

1. Perform cleaning cycles or replace the cylinder.

2. Check the steam hoses for kinks or gullies that might be

trapping condensate.

3. Replace the fill valve (stuck open).

4. Consider using a mix of demineralized water with raw

water.

5. Check cylinder − replace if exhausted.

This manual suits for next models

2

Table of contents

Other Healthy Climate Humidifier manuals