Boge S 40-3 User manual

Operating instructions

Belt-driven

screw compressors

Series

S 40-3...S 150-3

SF 60-3...SF 150-3

Separate manuals:

Compressor control

Frequency converter (SF)

Operating instructions for S 40-3...S 150-3 series screw compressors Page I

Operating instructions

for belt-driven

screw compressors

– S 40-3 (40 Hp)

– S 50-3 (50 Hp)

– S 60-3 (60 Hp)

–S 61-3 (60 Hp)

– S 75-3 (74 Hp)

– S 100-3 (101 Hp)

– S 101-3 (101 Hp)

– S 125-3 (121 Hp)

– S 150-3 (147 Hp)

– SF 60-3 (60 Hp)

– SF 100-3 (101 Hp)

–SF 150-3 (147 Hp)

BOGE KOMPRESSOREN

Postfach 10 07

33507 Bielefeld

Otto-Boge-Straße 1-7

33739 Bielefeld

Phone: +49 5206 601-0

Fax: +49 5206 601-200

Mail: [email protected]

Net: www.boge.com

Issue: 07 / 2013

No. 596.1252.18

Operating instructions for S 40-3...S 150-3 series screw compressors Page III

Contents

Contents

Part 1:

General information

1.1 General safety instructions ........................................................... 1

Safety instructions for compressor operation ................................... 1

Special hazard warnings................................................................... 2

Dangers of electricity ........................................................................ 3

Obligations of the operator ............................................................... 3

Personnel requirements.................................................................... 4

Personal protective equipment ......................................................... 4

Safety instructions for maintenance and repair of the compressor... 4

Accident prevention regulations........................................................ 5

1.2 Introduction..................................................................................... 6

Symbols used ................................................................................... 7

Warning signs on the compressor .................................................... 7

Intended use................................................................................... 13

Foreseeable misuse ....................................................................... 13

Transport damage .......................................................................... 13

Data on the rating plate .................................................................. 14

Service............................................................................................ 14

Part 2:

Product description

2.1 Technical data............................................................................... 15

2.2 Operating principle of compressor............................................. 20

Functional principle of the air end................................................... 20

Air circuit......................................................................................... 21

Oil circuit......................................................................................... 22

2.3 Compressor control ..................................................................... 23

Network pressure............................................................................ 23

Operating states ............................................................................. 23

Operating modes ............................................................................ 23

Controlled operation (frequency control) ........................................ 24

Short operating times...................................................................... 24

2.4 Control devices............................................................................. 24

Operating pressure transmitter ....................................................... 24

Proportional controller (optional accessory for S series) ................ 25

2.5 Safety and monitoring devices.................................................... 25

General information ........................................................................ 25

Safety temperature limiting device.................................................. 25

Contents

Page IV Operating instructions for S 40-3...S 150-3 series screw compressors

Safety valve .................................................................................... 26

Monitoring the drive and fan motor ................................................. 26

Rotational direction monitoring (optional accessory) ...................... 26

System pressure build-up (optional accessory).............................. 26

2.6 Water cooling ................................................................................ 27

Water cooling.................................................................................. 27

Serial connection ............................................................................ 27

Parallel connection ......................................................................... 27

2.7 Cooling water ................................................................................ 28

Water connection (for water cooling) .............................................. 28

Cooling water quality ...................................................................... 28

Part 3:

Installation

3.1 Transport and storage.................................................................. 29

General information ........................................................................ 29

How to transport the compressor.................................................... 29

Intermediate storage....................................................................... 30

3.2 Compressor room......................................................................... 31

Installation conditions for horizontal or free-standing compressed

air receivers .................................................................................... 31

Installation surface.......................................................................... 31

Fire protection................................................................................. 32

Sound protection............................................................................. 32

Admissible ambient temperatures .................................................. 32

Frost protection............................................................................... 33

Ventilation ....................................................................................... 33

Cooling air requirement .................................................................. 34

Ventilation possibilities.................................................................... 35

Condensate disposal ...................................................................... 35

3.3 Installation..................................................................................... 36

General information ........................................................................ 36

Checking the scope of delivery....................................................... 36

Installing the compressor................................................................ 36

Connecting the compressor to the compressed air network........... 37

Connecting the cooling water (optional accessory) ........................ 37

Removing the transport securing bolts ........................................... 38

Activating the belt tensioning device............................................... 38

Checking the oil level...................................................................... 38

3.4 Electrical connection.................................................................... 39

3.5 Commissioning............................................................................. 40

Check installation requirements...................................................... 41

Checking the rotational direction of drive and fan motor ................ 41

Check compressed air outlet for leak tightness .............................. 42

Operating instructions for S 40-3...S 150-3 series screw compressors Page V

Contents

Opening the stop valves ................................................................. 42

Checking for leaks .......................................................................... 42

Conduct trial run ............................................................................. 43

Commissioning following extended stoppages............................... 43

3.6 Dismantling ................................................................................... 44

Part 4:

Faults

4.1 General information...................................................................... 45

4.2 General faults................................................................................ 45

Part 5:

Accessory equipment

5.1 BOGE Duotherm BPT ................................................................... 47

Function.......................................................................................... 47

Installation....................................................................................... 47

Commissioning ............................................................................... 48

Maintenance ................................................................................... 48

5.2 BOGE Duotherm BSW.................................................................. 49

Function.......................................................................................... 49

Commissioning ............................................................................... 50

Maintenance ................................................................................... 50

Part 6:

Maintenance

6.1 Safety instructions for maintenance........................................... 51

6.2 The BOGE maintenance concept................................................ 53

Maintenance through BOGE customer service .............................. 53

List of maintenance and service work............................................. 54

Maintenance intervals..................................................................... 55

General information concerning the lubricants used ...................... 57

Disposal of used operating material ............................................... 58

Pressure hoses............................................................................... 58

Spare and wearing parts................................................................. 58

6.3 Maintenance work between scheduled services....................... 58

Weekly: Inspect / replace supply air filter (optional accessory) ...... 59

Monthly: Clean the suction filter...................................................... 60

Monthly: Check oil level / top up with oil if necessary..................... 61

Every 1,500 operating hours: Clean the oil cooler (air cooling)...... 62

Every 1,500 operating hours: Clean the oil cooler / air cooler

(water cooling) ................................................................................ 63

6.4 Maintenance work at fixed service intervals.............................. 63

Every 3,000 operating hours / once a year:

Change the suction filter cartridge.................................................. 64

Every 3,000 operating hours / once a year:

Have safety valve checked............................................................. 64

Contents

Page VI Operating instructions for S 40-3...S 150-3 series screw compressors

Every 3,000 operating hours / once a year:

Change the oil filter......................................................................... 64

Every 3,000 operating hours / once a year:

Change the oil separator ................................................................ 66

Every 3,000 operating hours / once a year: Check V-belt .............. 67

Every 9,000 operating hours: Change V-belt.................................. 68

Every 9,000 operating hours / every 2 years: Oil change............... 70

6.5 Special maintenance work........................................................... 73

Flush out oil circuit .......................................................................... 73

Drive motors with permanent lubrication ........................................ 73

Drive motors with lubrication device ............................................... 73

Drive motors with automatic lubricating equipment ........................ 74

Have proportional regulation checked

(Optional accessory for S series).................................................... 75

6.6 Spare parts and accessory equipment....................................... 76

List of spare and wear parts (for maintenance) .............................. 76

List of available accessory equipment ............................................ 76

Part 7:

Appendix

7.1 Flow chart...................................................................................... 77

Air cooled version, standard ........................................................... 78

Water cooled version, serial connection – parallel connection ....... 80

Air cooled version, frequency controlled......................................... 82

Water cooled version, serial connection – frequency controlled..... 84

BOGE Duotherm BPT plate heat exchanger .................................. 86

BOGE Duotherm-Plus BSW safety heat exchanger....................... 87

7.2 List of maintenance and service work........................................ 88

Operating instructions for S 40-3...S 150-3 series screw compressors Page 1

General information 1.1 General safety instructions

Part 1: General information

1.1 General safety instructions

Safety instructions for

compressor operation

1. Ensure that no commissioning and maintenance work on the compressor

is undertaken until these operating instructions have been read and under-

stood.

2. Only use the compressor for its intended use, as described in these oper-

ating instructions.

3. The owner must ensure,

– that only appropriately trained and authorised personnel work on this

compressor,

– that persons whose ability to react is restricted due to the misuse of

e.g. drugs, alcohol, medication etc., are prevented from working on

this compressor,

– that operating, maintenance and repair personnel is fully conversant

with all safety instructions, and that these safety instructions are ob-

served,

– that the compressor is only operated if it is in safe working order.

4. Avoid any way of working which may impair the safety of the compressor.

5. Always wear your compulsory personal protective equipment as protection

against injuries from sharp corners or edges when working on the com-

pressor.

6. To avoid dangers from debris or parts lying around, the working area of the

compressor must always be kept tidy and clean.

7. Always squat when working on components mounted at low height, never

stoop. When working on components mounted higher up, always stand up-

right and erect.

8. Do not exceed the limit value for the end of compression pressure specified

on the type plate.

9. Do not operate the compressor without the attendant protective equipment

and safety devices.

Do not dismantle any built-in safety devices or put them out of operation.

10.Ensure that all safety covers and doors are closed prior to commissioning/

starting up the compressor and that they are not opened during operation.

11.Place the compressor out of operation as described in these operating in-

structions, when dismantling the safety covers or safety devices for repair

or maintenance work. Reattach and close all covers and safety devices im-

mediately upon completion of the repair or maintenance work.

12.Operate the compressor only if any optional accessory equipment used is

recommended or authorised by the manufacturer.

WARNING!

Failure to observe the following safety instructions can lead to injuries and

damage to the compressor.

Observe the general safety and accident prevention regulations in addition

to the information in these operating instructions!

General information 1.1 General safety instructions

Page 2 Operating instructions for S 40-3...S 150-3 series screw compressors

13.Undertake conversions and modifications to the compressor only with the

prior approval of BOGE, and in compliance with all relevant safety regula-

tions. The manufacturer is not liable for damages resulting from unauthor-

ised modifications to the compressor.

14.Never start the compressor if one or more parts (e.g. cable, plug) are dam-

aged, or if the compressor is not in perfect working order, or if damage is

visible or suspected.

15.Observe all safety and danger signs attached to the compressor itself!

16.The compressed air/oil receiver is pressure equipment and requires testing

in accordance with national standards.

17.To avoid damage, special precautions must be taken during (re-)commis-

sioning of compressors with a frequency control if the frequency converter

has been disconnected from the power supply for a lengthy period of time

(> 12 months). In this case, please contact the BOGE's service department.

Special hazard warnings – Always wear your compulsory personal protective equipment when work-

ing on pressure pipes and connections!

– A protective grid serves to prevent you from accidentally reaching into the

impeller in the cooling fan.

– During operation, the compressor generates a high noise level which may

cause permanent hearing damage due to prolonged exposure. The com-

pressor must ALWAYS be operated with its housing closed! Wear addition-

al hearing protection at noise levels of over 80 dB(A)!

WARNING: Risk of injury!

Never operate the compressor with the protective grid removed! There is

constant danger of accidentally reaching into the impeller in the cooling fan!

Please note that the cooling fan may run on for a certain time even after the

compressor has been switched off!

Operating instructions for S 40-3...S 150-3 series screw compressors Page 3

General information 1.1 General safety instructions

Dangers of electricity

Obligations of the

operator

The operator is obliged to,

– operate the compressor only if it is in perfect technical working order,

– provide an automatic cutout device for disconnecting the electrical power

supply in the event of a fault to prevent hazards due to electricity.

– check the emergency stop device for the compressor regularly to ensure

that nothing is missing and that it works properly,

– assess the hazards of the machine workstations in his area of responsibility

and to issue specific user instructions on the basis of this,

– appoint a person who is responsible for the safe operation of the machine

as well as the coordination of all service work performed on it,

– avoid stress situations while operating the compressor by implementing

appropriate technological and organisational work preparation measures,

– ensure proper lighting at the compressor control panel in line with local

health and safety regulations,

– observe the safety data sheets for the lubricants used and make all infor-

mation specified by the data sheet accessible to personnel,

– provide the compulsory personal protective equipment and stipulate and

regularly check the wearing of this protective equipment,

– designate personnel responsible for the various types of work on the ma-

chine,

– instruct personnel on a regular basis about the extent of obligations to keep

the area around the compressor safe, tidy and in good order.

– in the event that the compressor requires to be dismantled, develop a safe

technical means of dismantling the structure, designate persons respon-

sible (for safety at work, supervision, completing the work), supervise the

dismantling work and monitor compliance with the safety precautions and

instructions drawn up,

DANGER: High voltage!

Persons working on the electrical equipment of the compressor are ex-

posed to mortal danger!

– Disconnect from the mains power supply before starting any work on the

compressor and use a padlock to prevent the power from being switched

on again.

– Only duly authorised professional electricians (e.g. plant electricians) are

permitted to carry out work on the electrical system of the machine.

– Inspect the electrical equipment of the compressor at regular intervals for

defects such as loose connections or scorched cables and have any de-

fects repaired immediately.

– Have all electrical equipment and fixed electrical installations checked by

a professional electrician at least every 4 years.

– Check all safety devices on the machine at regular intervals to ensure

they work properly.

– Only use original fuses.

General information 1.1 General safety instructions

Page 4 Operating instructions for S 40-3...S 150-3 series screw compressors

Personnel requirements Work on and with the compressor must only be carried out by personnel duly

authorised by the operator of the compressor.

The personnel working on the compressor must observe all industrial safety

regulations and user instructions, properly recognize responsibilities and have

read and understood the operating instructions. It is essential to wear the com-

pulsory personal protective equipment at all times when working on the com-

pressor!

Personal protective

equipment

During all work on the compressor,

– protective clothing,

– chemical resistant gloves,

– slip-resistant safety shoes and

– hearing protection, if applicable,

must be worn.

For special tasks,

– safety helmets (when operating lifting gear to transport equipment) and

– safety goggles (when working on the compressed air system and/or on the

pneumatic control system)

must be worn.

Before working with oils or greases, barrier cream must be applied to the skin.

After the work is finished, a skin care product must be applied.

Safety instructions for

maintenance and repair

of the compressor

– Ensure that maintenance work is carried out by suitably trained persons

only.

– Settings, fault rectification and repair work must be carried out by special-

ists or suitably trained persons only.

– Before carrying out any maintenance or repair work:

WARNING!

During repair and maintenance, use only original spare parts, compressor

oils and operating materials approved by BOGE.

DANGER: High voltage!

When working on the electrical system be aware of the constant danger of

contact with live parts!

To prevent danger, the mains connection must be equipped with an auto-

matic circuit breaker!

The automatic circuit breaker must comply with the requirements of national

regulations!

Operating instructions for S 40-3...S 150-3 series screw compressors Page 5

General information 1.1 General safety instructions

1. Switch off the compressor using the OFF button.

2. Press the emergency stop button.

3. Disconnect the compressor from all electric power sources using the circuit

breaker.

4. Take preventive action to prevent the current from being inadvertently

switched back on.

5. Check to ensure that all current-carrying parts are zero-potential.

6. Earth and short-circuit.

7. Cover or shield adjacent current-carrying parts.

8. Fix a warning label to the control and fill in the name of the person respon-

sible who is authorised to switch on the machine again.

9. Disconnect the compressor from the compressed air network (relieve or

block pressure lines).

– Exercise extreme caution during repair or maintenance work during which

the compressor needs to be operational.

Ensure that all persons are at a safe distance from the danger area.

– Ensure that work on electrical equipment is carried out by qualified electri-

cians only.

– Working on current-carrying parts and devices is prohibited. Exceptions

are governed by the appropriate national regulations.

– Before starting work on the electrical system, the power supply must be

switched off and a safeguard must be provided to prevent it from being un-

intentionally switched on again. Immediately after finishing the work, all dis-

mantled covers and safety devices must be refitted.

– The machine operator is responsible for inspecting the compressor daily

for externally visible damage and defects, and for immediately reporting

any changes (including in operational behaviour).

– When the automatic restart mode (auto-restart) is activated, the compres-

sor will start up automatically following a power failure. This is conditional

upon: The network pressure being lower than the set switch-on pressure.

Accident prevention

regulations

The operator of a compressor station is responsible for ensuring that it is prop-

erly installed, operated and maintained.

If the compressor system is operated outside the Federal Republic of Germa-

ny, the accident prevention regulations of the country where the compressor

is operated must be observed, in addition to the information contained in these

operating instructions. In the event that measures are required above and be-

yond the legal regulations specified in the Federal Republic of Germany or the

information contained in these operating instructions, then it is essential that

these are carried out prior to commissioning the compressor plant.

General information 1.2 Introduction

Page 6 Operating instructions for S 40-3...S 150-3 series screw compressors

1.2 Introduction

The purpose of these operating instructions is to familiarise the user with the

operation and all uses and features of the compressor.

These operating instructions contain important information on how to operate

the compressor safely, economically and according to its intended use. Ob-

serving these operating instructions will help to prevent danger, reduce repair

costs and downtimes and increase the reliability and service life of the com-

pressor. They contain important information on the necessary maintenance

and repair work, assists in the event of faults and contains information on spare

and wear parts.

These operating instructions must be available at all times to the compressor

operating personnel at the place of use.

The operating instructions must be carefully read and applied by all persons

authorised to undertake the following work on the compressor:

– Operation, including fault rectification and daily care

– Servicing (maintenance, inspection, repairs)

– Commissioning

– Transport

The compressor and its additional equipment must not be installed and com-

missioned until the operating instructions have been read and understood.

These operating instructions are intended to complement user instructions

based on existing national accident prevention and environmental protection

regulations.

In the illustrations, the compressor is shown in part without safety covers or

safety devices to provide a better view. However, operating the compressor

without these components is prohibited!

Operating instructions for S 40-3...S 150-3 series screw compressors Page 7

General information 1.2 Introduction

Symbols used In these operating instructions attention is drawn to important safety advice

and tips with the following symbols:

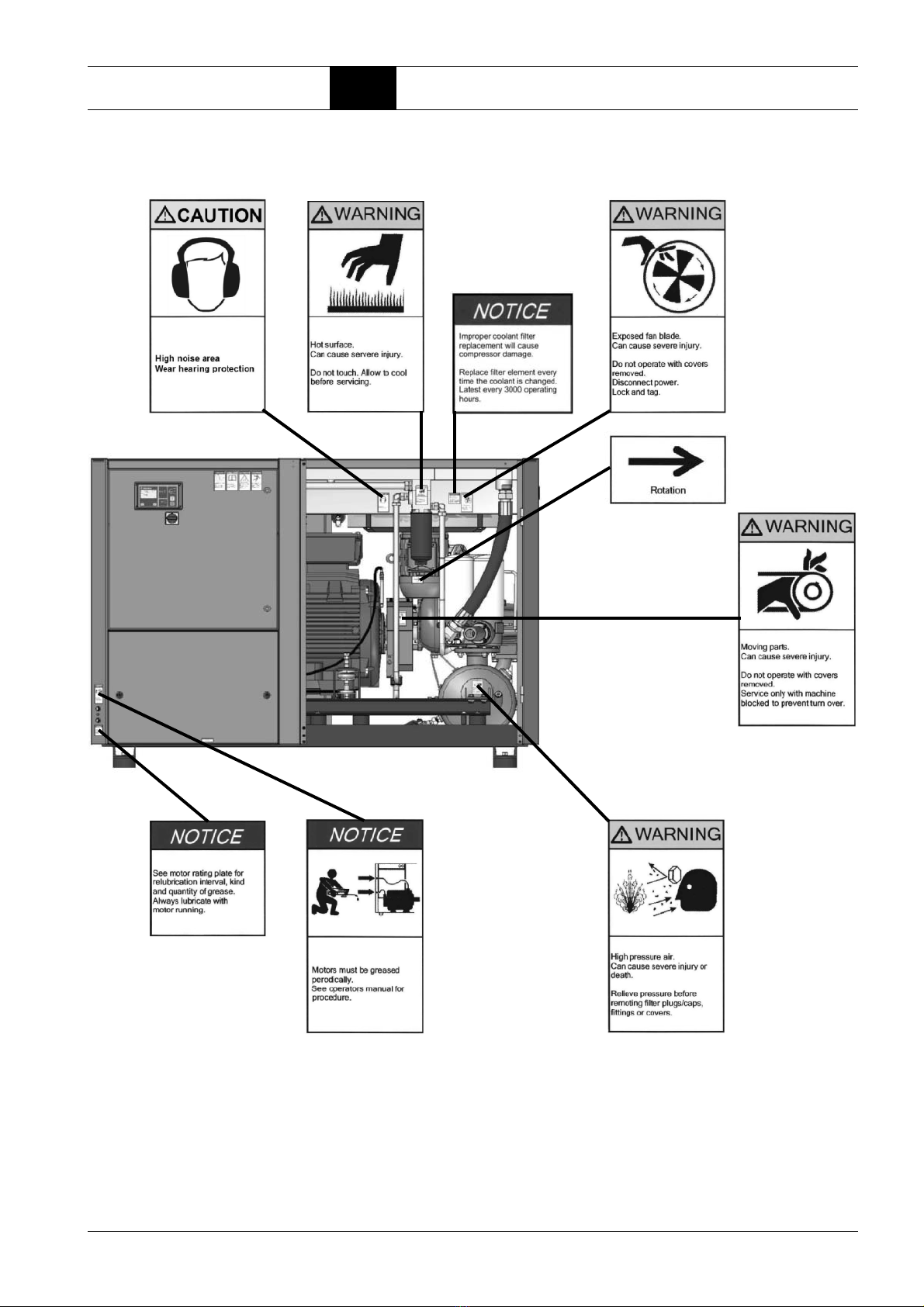

Warning signs on the

compressor

The following warning signs are fitted on the compressor:

WARNING: Risk of injury!

This symbol warns of danger to life and limb of the machine operator or other

persons.

WARNING!

This symbol warns of danger to life and limb of the machine operator or other

persons or dangers which might destroy or damage the compressor.

DANGER: High voltage!

This symbol warns of danger due to electricity.

This symbol indicates a warning of life-threatening electrical voltage levels.

It indicates work which must be performed by skilled electricians only.

NOTICE!

This symbol indicates information and tips on saving energy and prolonging

the life of the compressor through careful use.

NOTICE!

All warning signs on the compressor and in its surroundings must be kept in

a legible condition at all times. Missing or damaged signs must be replaced

at once!

General information 1.2 Introduction

Page 8 Operating instructions for S 40-3...S 150-3 series screw compressors

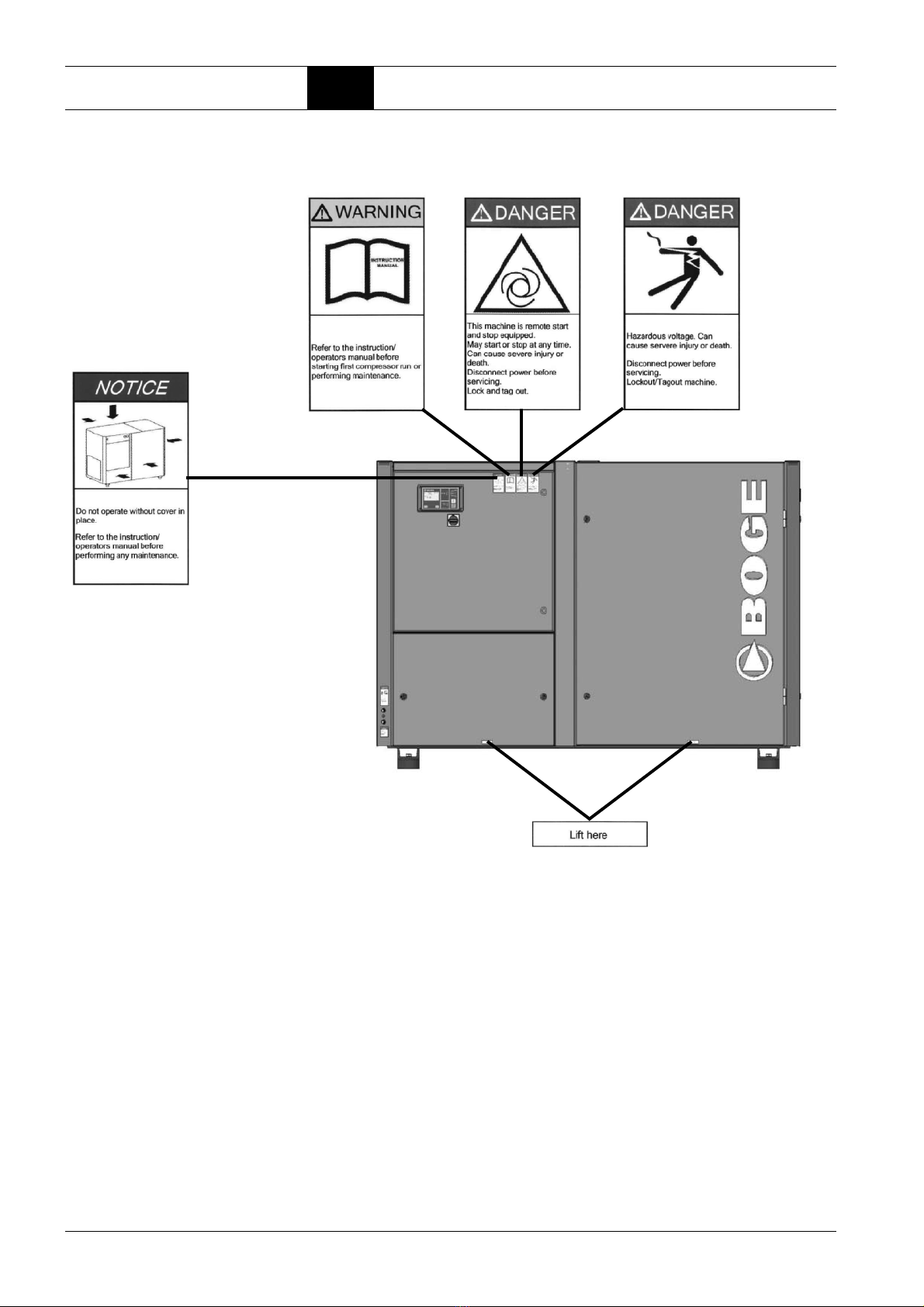

S 40-3...S 150-3, part 1, front (outside):

Operating instructions for S 40-3...S 150-3 series screw compressors Page 9

General information 1.2 Introduction

S 40-3...S 150-3, part 2, front (outside/inside):

General information 1.2 Introduction

Page 10 Operating instructions for S 40-3...S 150-3 series screw compressors

S 40-3...S 150-3, part 3, front (inside):

S 40-3...S 150-3, part 4, rear panel (outside/inside):

Operating instructions for S 40-3...S 150-3 series screw compressors Page 11

General information 1.2 Introduction

S 40-3...S 150-3, part 5 and 6, (inside/top):

General information 1.2 Introduction

Page 12 Operating instructions for S 40-3...S 150-3 series screw compressors

S 40-3...S 150-3, part 7 and 8, sides (outside/inside):

hidden

This manual suits for next models

18

Table of contents

Other Boge Air Compressor manuals

Popular Air Compressor manuals by other brands

Ingersoll-Rand

Ingersoll-Rand GHH RAND SILU CS80 Mounting instructions

Campbell Hausfeld

Campbell Hausfeld FP204100 Operating instructions and parts manual

Porter-Cable

Porter-Cable C2150 instruction manual

GÜDE

GÜDE 260/10/24 Original instructions

Ozito

Ozito MACP-015 instruction manual

Metabo

Metabo Mega 600 D Original operating instructions

Ronix

Ronix RC-2512 user manual

Sears

Sears Craftsman 919.166441 owner's manual

Ingersoll-Rand

Ingersoll-Rand 25/300 XHP1070AWCAT operating & maintenance manual

EINHELL

EINHELL TH-AC 200/24 OF Original operating instructions

C-Aire Compressors

C-Aire Compressors S261R-LD1-115PD owner's manual

KAESER

KAESER SK 19 Service manual