6

(STARTUP CONTINUED ON NEXT PAGE)

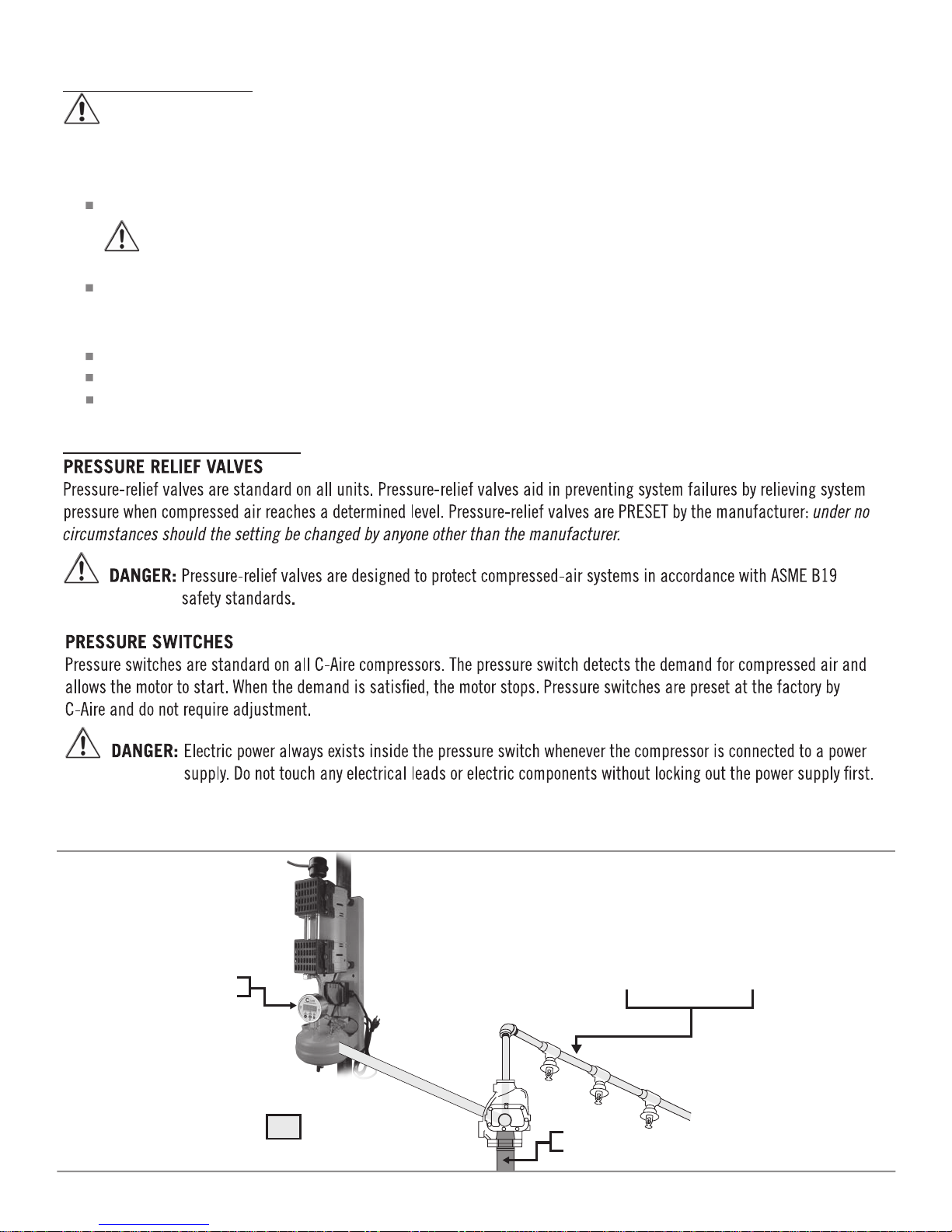

WIRING DIAGRAM

PRESSURE SWITCH

UNLOADER

UNLOADER

WIRE TO

POWER

SOURCE

WIRE TO

POWER

SOURCE

WIRE

TO

MOTOR

WIRE

TO

MOTOR

GROUND BLOCK

GROUND BLOCK

PRESSURE

SWITCH

PRESSURE

SWITCH

NOTE: There is no need to “break-in” your compressor. It has been tested and run at the factory by qualified personnel.

When operating the compressor for the first time, do the following:

1. Perform an inspection of the compressor to ensure there are no obstructions that might interfere with moving parts.

2. Release any remaining tank pressure by slowly opening the manual drain valve.

3. Connect the compressor to the power source (the compressor will start).

START UP

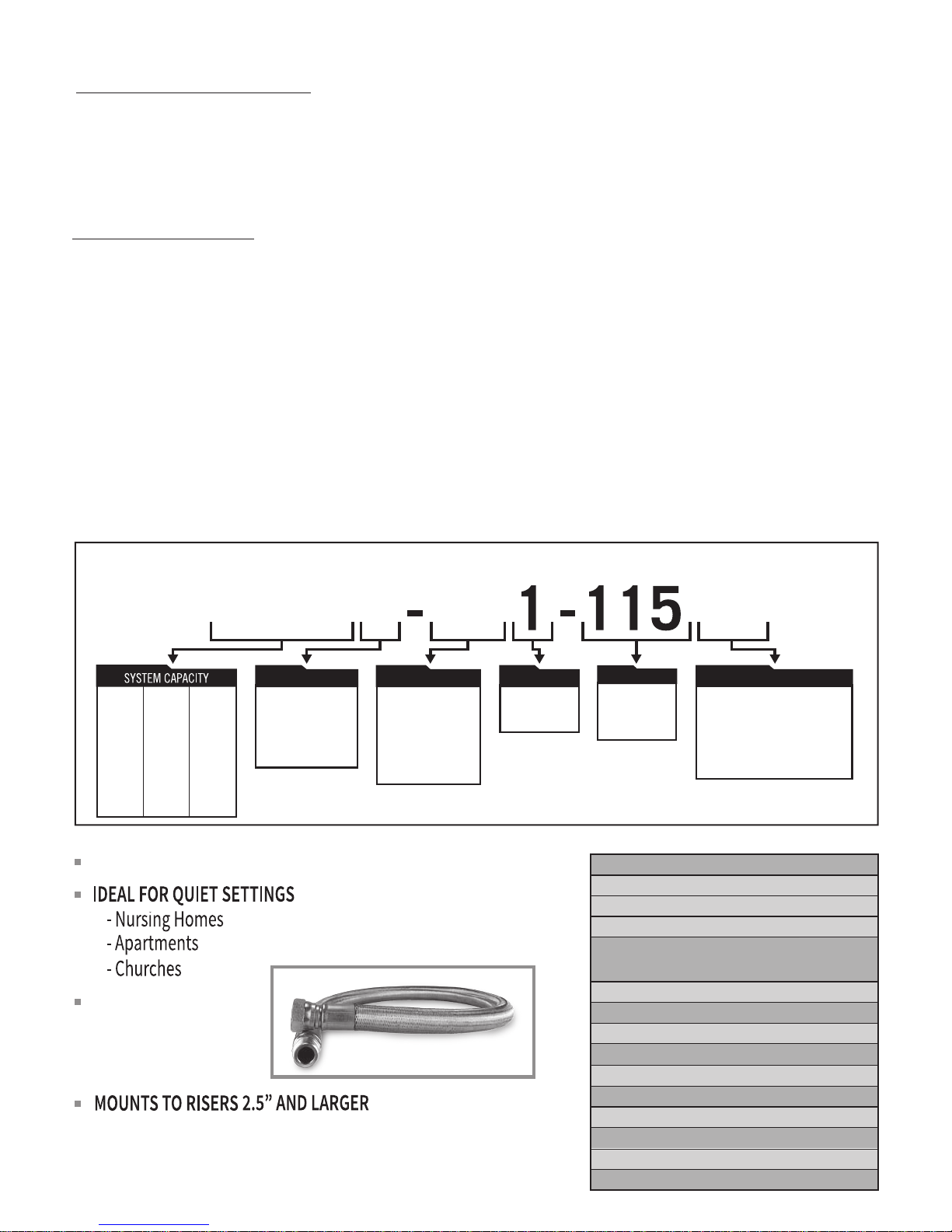

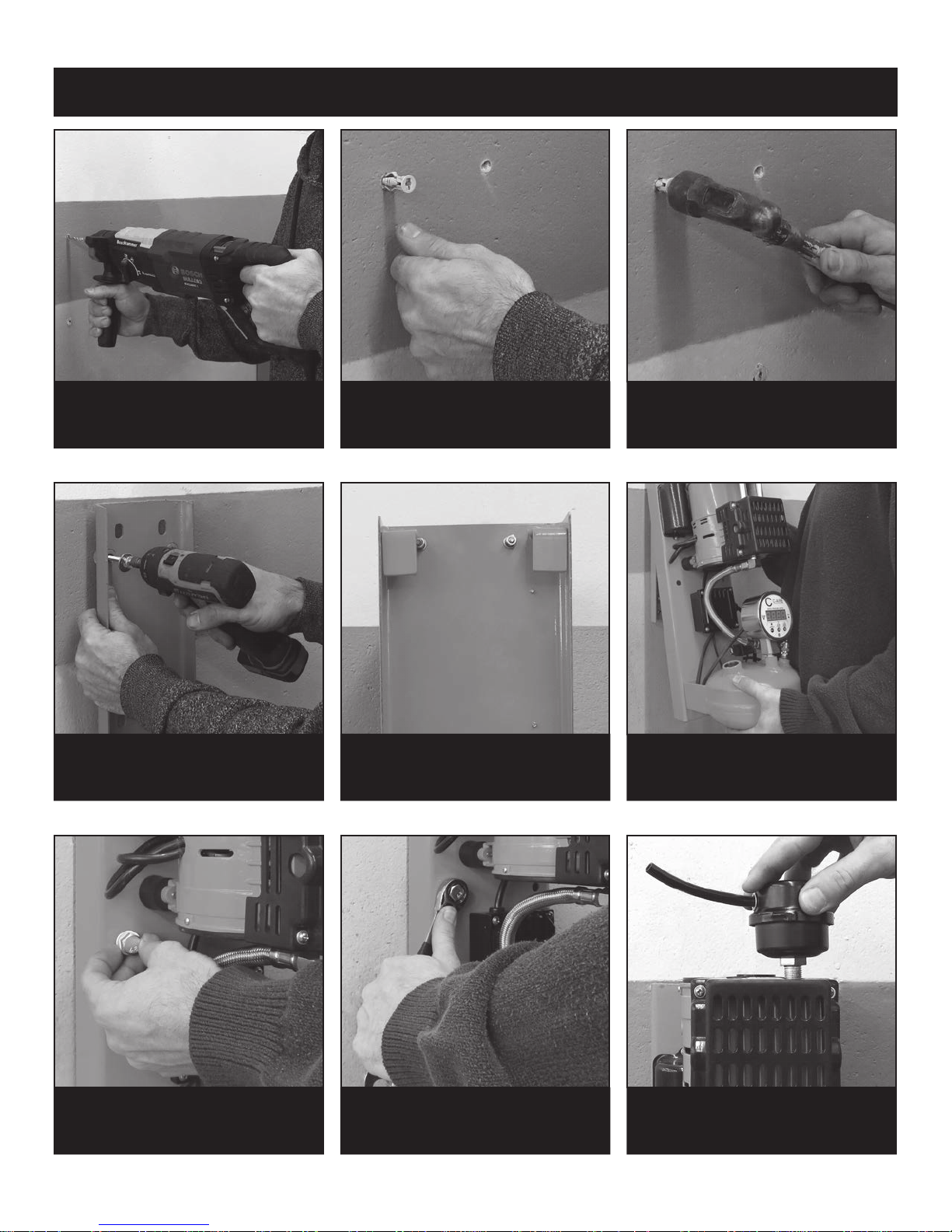

DIGITAL PRESSURE SWITCH PROGRAMMING AND INSTRUCTIONS

When the air compressor is first powered on, PSI light is illuminated, press the “MODE button.

SCREEN DISPLAY/SETTING PRESSURE

Use these three buttons to set maximum and minimum pressure:

A. MODE B. UP ARROW C. DOWN ARROW

STEP 1:

Press the “MODE” button once, the number “1” will display on the screen. You can now set the maximum pressure you would

like using the “UP ARROW” button or “DOWN ARROW” button. (with precision to 0.1 psi). The maximum pressure is

displayed on the screen. The setting range is: 10-90psi.

STEP 2:

Press the “MODE” button again, the number “2” will display on the screen. You can now set the minimum pressure you

would like using the “UP ARROW” button or “DOWN ARROW” button. (with precision to 0.1 psi). The minimum pressure is

displayed on the screen. The setting range is: 5-85psi.

There is a 5° differential on the settings so if you would like to change maximum/minimum pressure settings, change the

low or minimum pressure setting first and then set the high or maximum pressure. Otherwise the 5° differential will not

allow you to change the pressure settings.

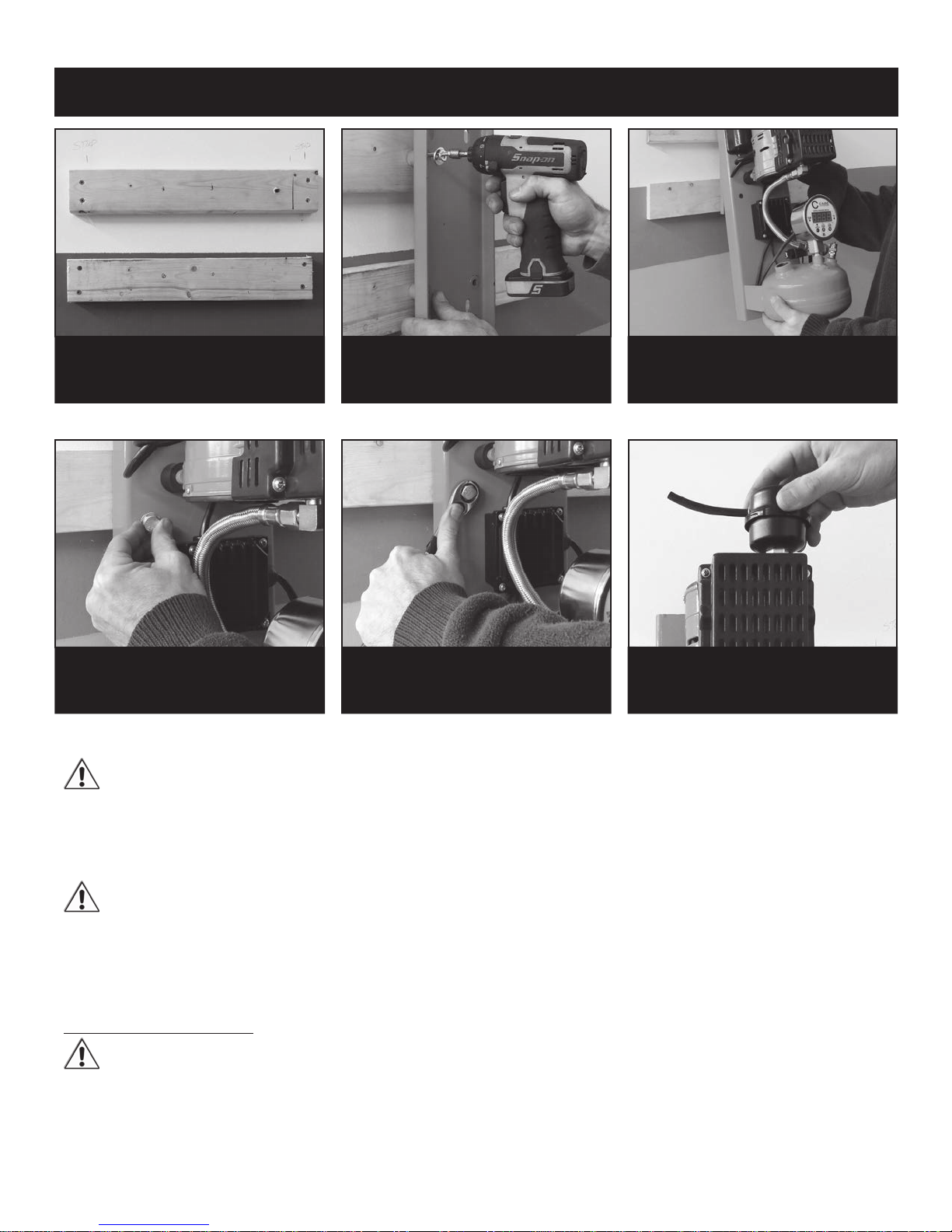

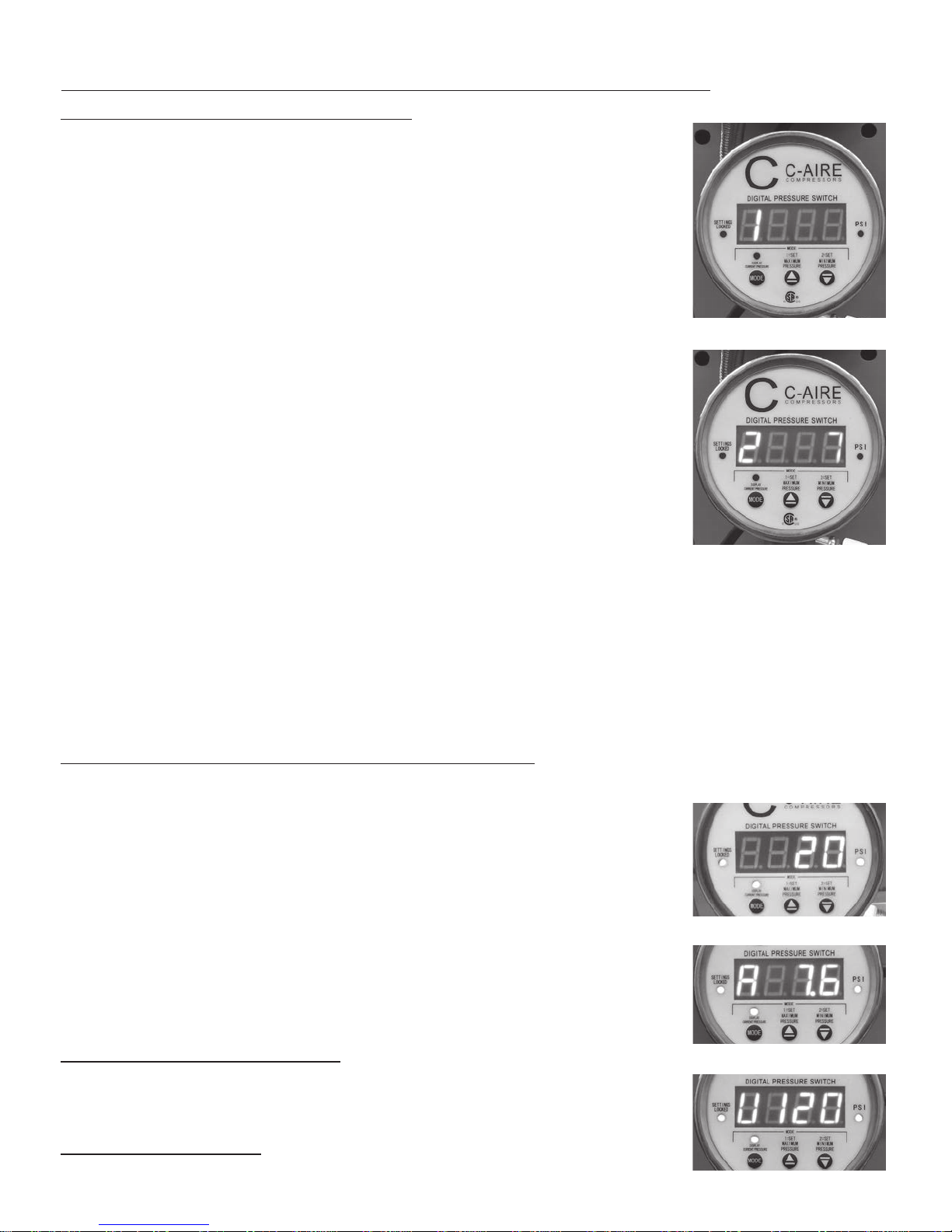

EXAMPLE:

The maximum pressure setting is set at 12psi and the minimum pressure is set at 7psi. You wish to change the maximum

pressure to 10 and minimum pressure to 5. Press the mode button until you see the minimum pressure of 7 on the screen.

Change the setting to 5 using “DOWN ARROW” button. Next press the “MODE” button once again to see the maximum

pressure of 12 on the screen. Use the “DOWN ARROW” button to change the setting to 10. If you try to set the maximum

pressure first the digital pressure switch will not allow you to change the number to 10 because that would cause the drop

to be below the 5° differential.

1. SCREEN DISPLAY/OPERATION

INLET AND DISCHARGE PIPING

CAUTION: Do not operate unit without inlet-air filtration.

If the air is dirty, pipe the filter to a source of clean air.

Do not install piping with a diameter lower than that of the pump intake.

CAUTION: Do not use PVC plastic in the discharge line.

Use hand-welded or threaded steel or copper pipes and cast-iron fittings that are safe for the discharge pressure and

temperature.

WARNING: Compressor installation must be performed by a qualified electrician in accordance with the National

Electrical Code (NEC) or the Canadian Electrical Code (CEC), the National Electrical Safety Code (NESC)

OSHA code, and/or any local or state codes having precedence.

Be sure of proper wire sizing and that the circuit breaker and the distance from the breaker is within suggested range.

Confirm your electrical-supply voltage matches what is required for the motor.

WARNING: The compressor must be grounded. Grounding reduces the risk of electric shock. Certain C-Aire models

are equipped with a cord that has a grounding wire with a grounding plug. The plug must be plugged

into an outlet that is installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper installation of the grounding plug will result in a risk of electric shock. When repair or

replacement of the cord or plug is required, do not connect the grounding wire to either flat-blade

terminal. The insulated wire with a green outer surface and yellow stripes is the grounding wire.

NOTE:

The installation, electric motor, wiring, and all electrical controls must be in accordance with NFPA 70-1996 National

Electric Code, National Electric Safety Code, and state and local codes.

Failure to abide by the national, state, and local codes

may result in physical harm and/or property damage.

DANGER: High voltage may cause personal injury or death. Disconnect and lockout/tagout, per OSHA regulation

1910.147, all electrical power supplies before opening the electrical enclosure or servicing.

DANGER: Never assume a compressor

is safe to work on if it is

not operating. It could

restart at any time.

Always disconnect/

lockout/tagout

before servicing.

CAUTION: Dry pipe sprinkler

compressor must be

wired to a reliable

power source to be

compliant with

NFPA 13.

RED

BLACK

WHITE

BROWN

BLACK

WHITE

BLACK

WHITE

BLACK

WHITE

WIRE

COLOR

CODE