Index

Page IV BOGE Operating instructions for C 15 series screw compressors

Part 3:

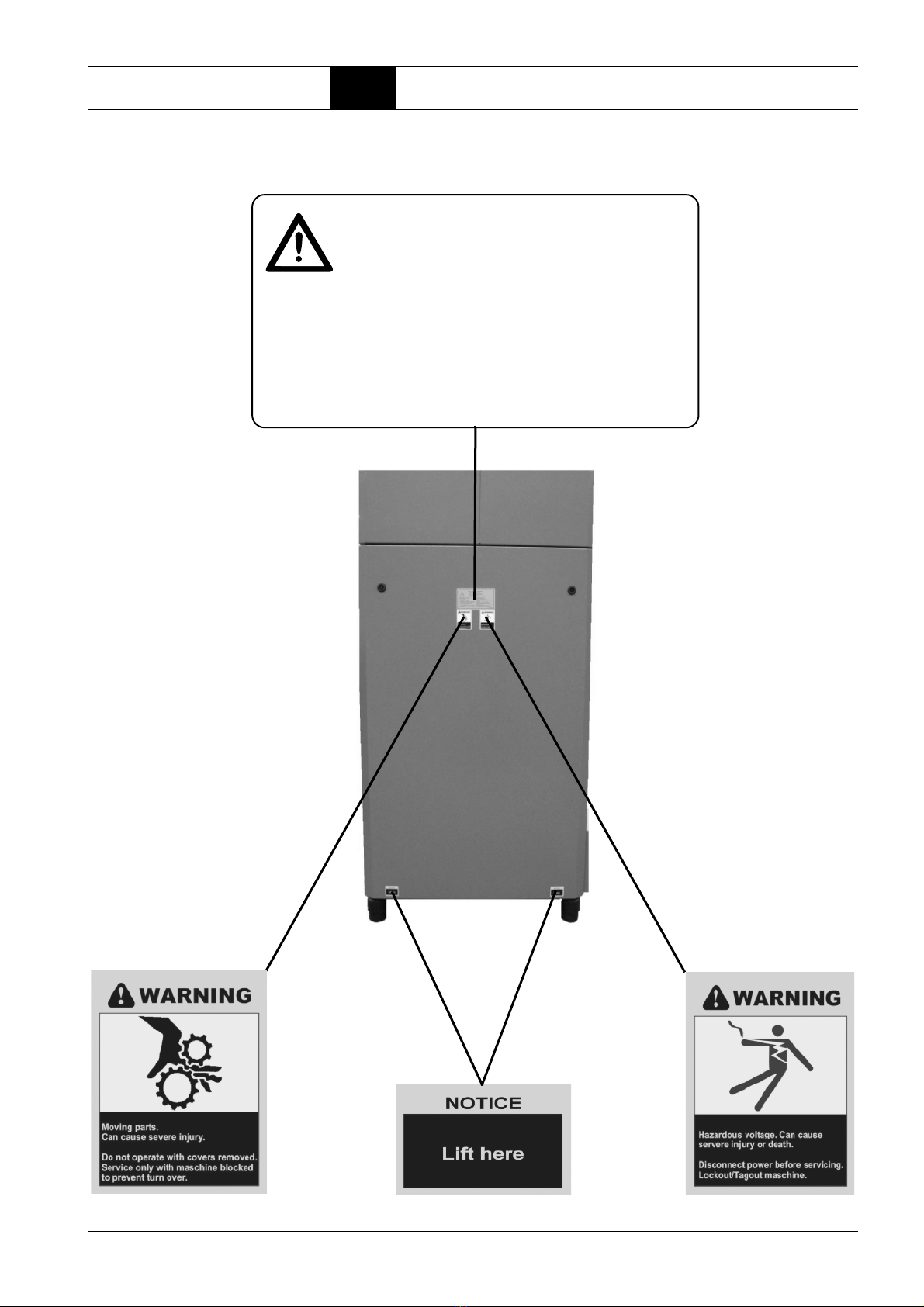

Installation

3.1 Transport and storage.................................................................. 23

General ........................................................................................... 23

Transport possibilities ..................................................................... 23

Intermediate storage....................................................................... 24

3.2 Compressor room......................................................................... 25

Installation conditions for separately arranged compressed air

receivers ......................................................................................... 25

Installation surface.......................................................................... 25

Fire protection................................................................................. 25

Sound protection............................................................................. 26

Admissible environmental influences.............................................. 26

Ventilation ....................................................................................... 26

Cooling air requirement .................................................................. 27

Ventilation possibilities.................................................................... 28

Condensate disposal ...................................................................... 28

3.3 Installation..................................................................................... 29

General ........................................................................................... 29

Checking the delivery scope........................................................... 29

Installing the compressor................................................................ 29

Connecting the compressor to the compressed air network........... 30

Remove cladding ............................................................................ 30

Activating the belt tensioning device............................................... 31

Checking the oil level...................................................................... 32

3.4 Electrical connection.................................................................... 32

3.5 Commissioning............................................................................. 34

Checking installation requirements ................................................. 34

Checking the rotational direction .................................................... 34

Checking compressed air outlet for tightness ................................. 35

Opening the stop valves ................................................................. 35

Checking for leaks .......................................................................... 36

Conducting trial run......................................................................... 36

Commissioning following extended stoppages............................... 36

3.6 Dismantling ................................................................................... 37

Part 4:

Optional equipment

4.1 BOGE-Duotherm BPT................................................................... 39

Function .......................................................................................... 39

Assembly ........................................................................................ 39

Commissioning ............................................................................... 39

Maintenance ................................................................................... 40

Part 5:

Faults

5.1 General .......................................................................................... 41

5.2 Faults – Compressor .................................................................... 41