Bogen MO100A User manual

Other Bogen Amplifier manuals

Bogen

Bogen NYQUIST NQ-A4060 Quick start guide

Bogen

Bogen CC4052m Guide

Bogen

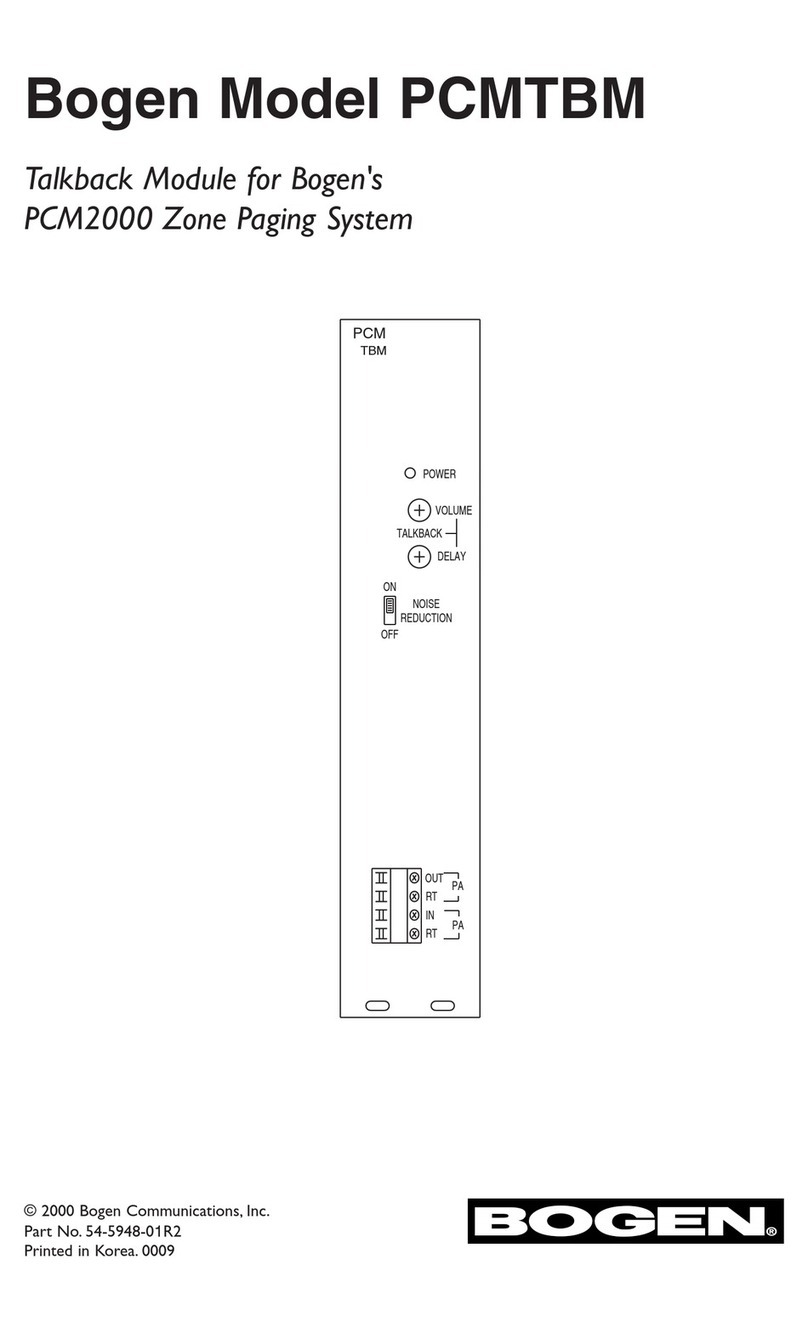

Bogen PCM2000 User manual

Bogen

Bogen WV100 Guide

Bogen

Bogen GA2 Guide

Bogen

Bogen NYQUIST NQ-GA20P2 Quick start guide

Bogen

Bogen HAA20 User manual

Bogen

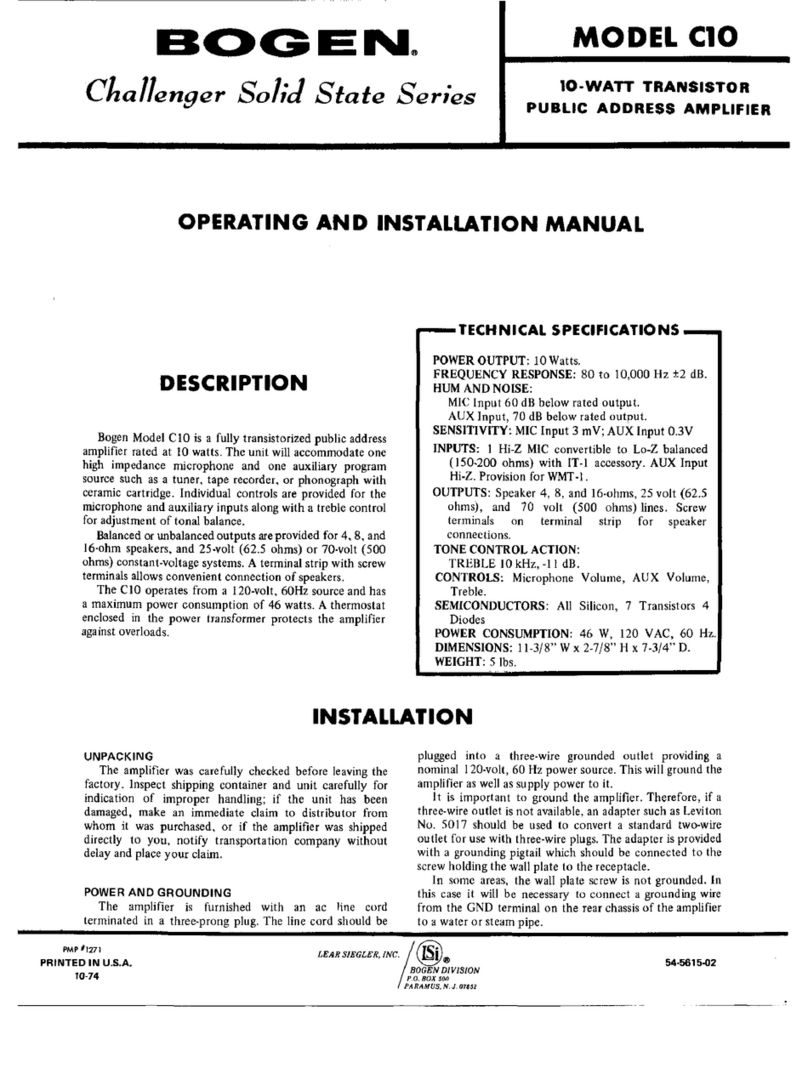

Bogen C10 User manual

Bogen

Bogen CAM User manual

Bogen

Bogen M-Class M300 User manual

Bogen

Bogen Gold Seal GS100 User manual

Bogen

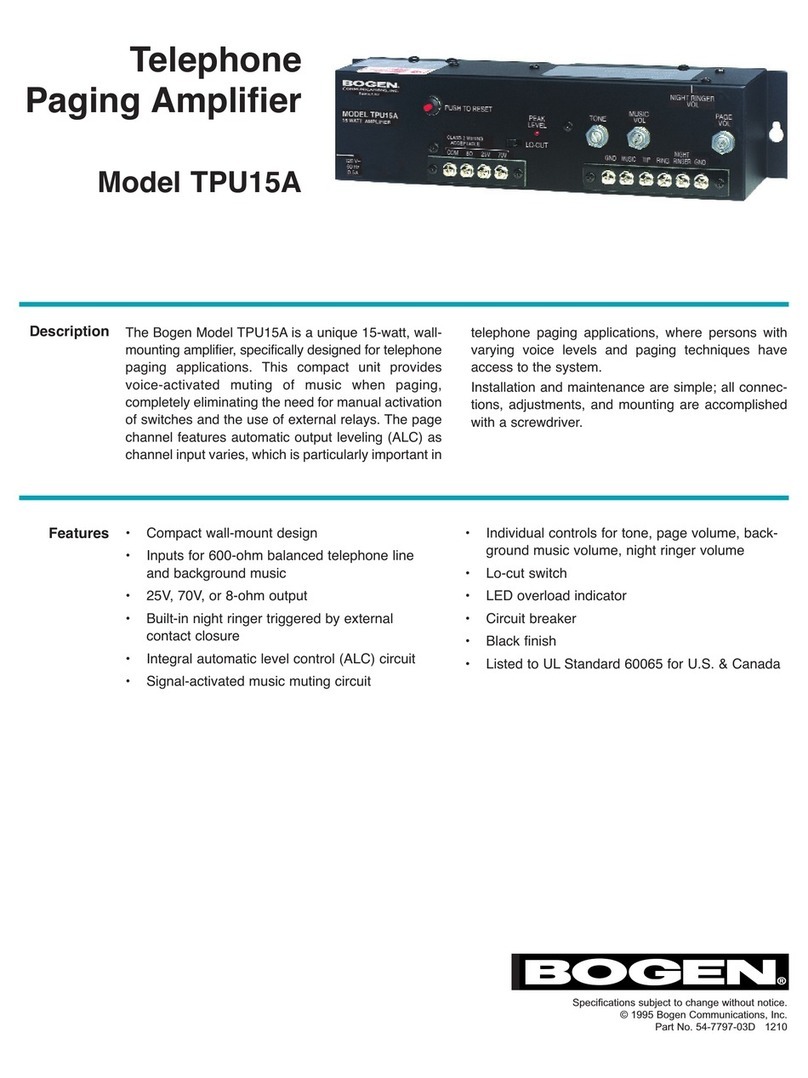

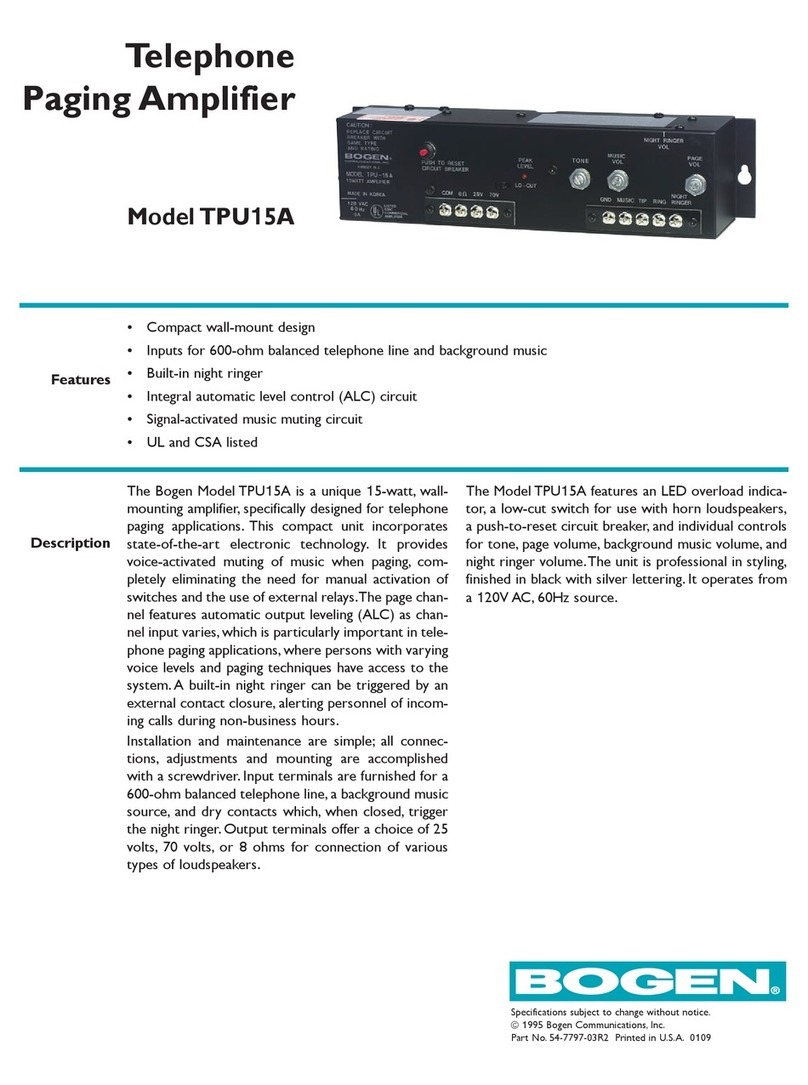

Bogen TPU-15A User manual

Bogen

Bogen NYQUIST NQ-A4060 Instruction sheet

Bogen

Bogen TPU-15A User manual

Bogen

Bogen Classic C35 Owner's manual

Bogen

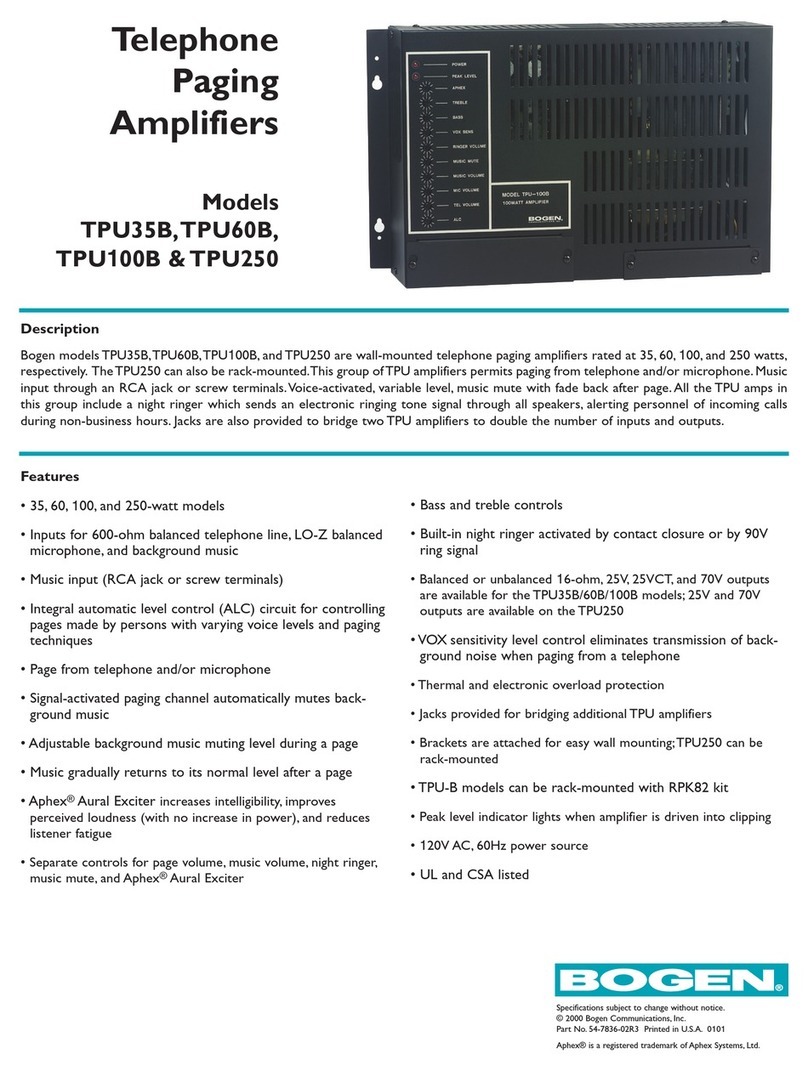

Bogen TPU-35B User manual

Bogen

Bogen C10 Specification sheet

Bogen

Bogen CC4021 Guide

Bogen

Bogen Wall Mount Modular Amplifier WMA80 User manual

Bogen

Bogen C10 User manual