Bohle VETROCRAFT BO 5009337 User manual

Operating instructions

BO 5009337

Glass polisher VETROCRAFT

Operating Instructions Glass Polisher BO 5009337- Version 1.0 2

Dear customer,

Congratulations on your purchase of the BO 5009337 glass polisher.

Please read these operating instructions carefully before using the machine. The complete instruction manual should be

kept near the glass polisher at all times.

No part of these operating instructions may be reproduced in any form (print, photocopy, microfilm or any other process) or

processed, duplicated or distributed using electronic systems without the written consent of Bohle AG.

We reserve the right to make changes in the interest of technical progress.

© Bohle AG. All rights reserved.

1. Introduction

This glass polisher was designed for dry seaming and glass edge grinding in dry grinding.

2. EC Declaration of Conformity

We herewith declare that the VETROCRAFT Glass Polisher

in the delivered version complies with the relevant regulations:

EC Machinery Directive (2006/42/EU, Annex I)

Applied harmonised standards:

EN 55014-1:2006/+A1:2009/+A2:2011; EN 55014-2:2015; EN 61000-3-2:2014; EN 61000-3-3:2013; EN 60745-1:2009+A11:2010;

EN 60745-2-3:2011+A12:2013+A11:2014 +A12:2014+A13:2015; EK9-BE-88:2014

Bohle assumes no liability if:

•the glass polisher is not used as intended,

•the glass polisher is altered or changed without authorisation,

•components or spare parts from other manufacturers are used,

•the glass polisher is installed or handled incorrectly or by unauthorised or untrained persons,

•the glass polisher is not regularly maintained,

•warnings, instructions and regulations in these operating instructions are not observed.

Intended use

This glass polisher is only suitable for diamond dry grinding or polishing with paste polishing agents for glass and similar ceramic materi-

als. Any other use of this glass polisher is considered improper.

Haan, February 2023

Edgar Höhn

Technical Manager Machines, Authorised Representative for the compilation of technical documents

Bohle AG, Dieselstraße 10, D-42781 Haan

Operating Instructions Glass Polisher BO 5009337- Version 1.0 3

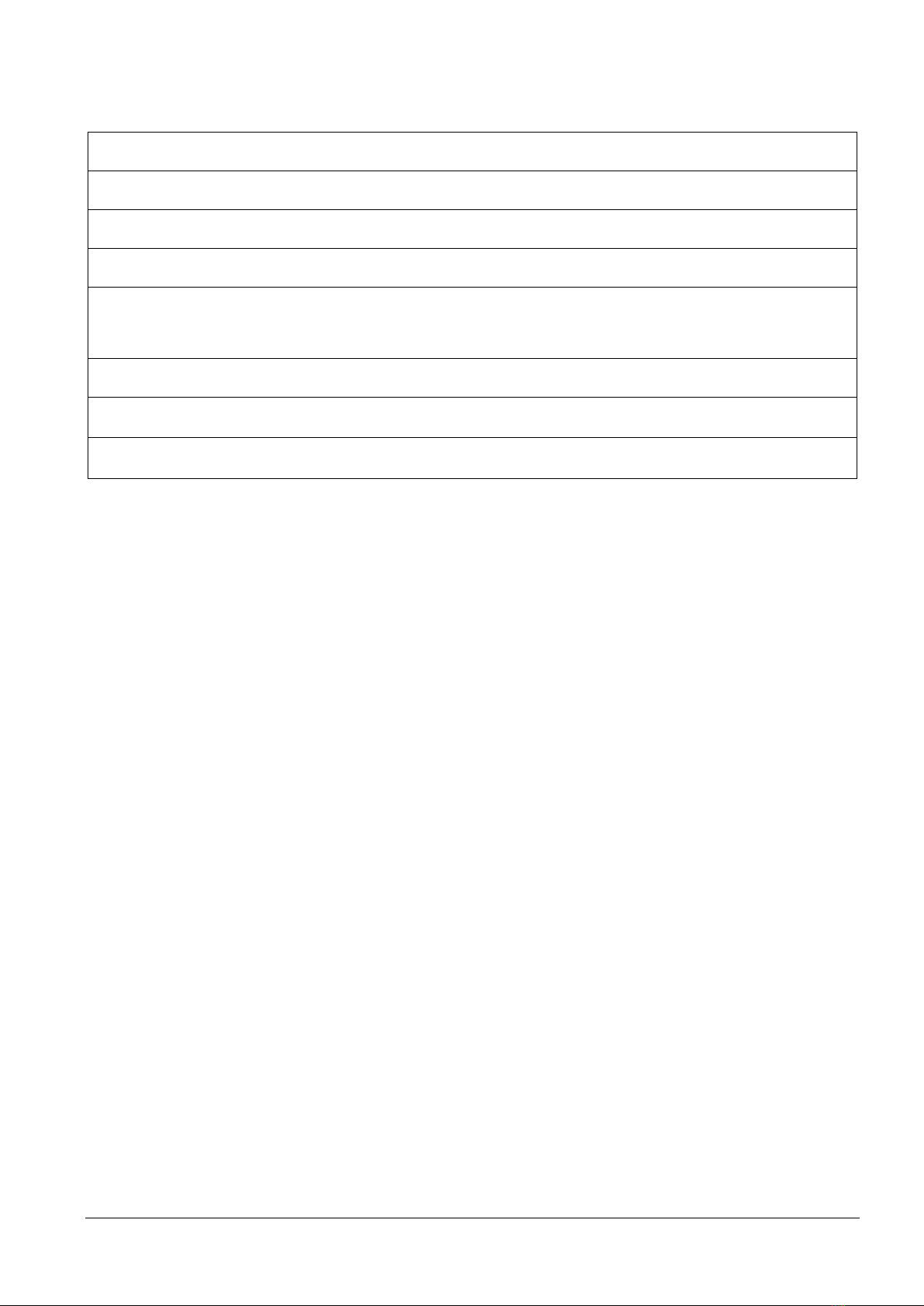

3. Technical data

Freewheel speed:

approx. 600 - 3,000 rpm (infinitely variable)

Velcro sanding disc:

Ø 115 mm

Felt plate:

Ø 125 mm

Machine weight:

approx. 3,230 g

Noise generation:

Sound power level max. 100 dB(A)

Sound pressure level max. 89 dB(A)

Electrical power:

1.300 W

Electrical connection:

220 - 240 V | 50 Hz

Working temperature range:

5 - 40°C

4. Safety instructions

4.1 General safety instructions

- Follow all safety rules, regulations and conditions when using the glass polisher.

- Disconnect the mains plug before carrying out any maintenance work.

- Always keep the glass polisher in good condition. Check that all moving parts can move freely.

- Always have damaged components replaced by a competent person and always use original parts.

- Always keep the glass polisher clean.

- Keep your work area clean and free of unused materials. Ensure that there is sufficient lighting.

- Avoid unintentional switching on of the glass polisher.

- Always wear approved closed-sided safety glasses, ear protection and gloves when using the glass polisher.

- Dry grinding of glass produces fine dusts. Wear a suitable dust mask.

- Avoid wearing loose clothing or jewellery and tie up long hair.

- Make sure the floor is not slippery and wear non-slip shoes.

- Keep children and unauthorised persons away from the work area.

- Do not operate the glass polisher if any parts are missing or defective. This can lead to failure and injury.

- Do not use the glass polisher until you have been instructed by a qualified person or have read the operating instruc-

tions.

- Do not operate the glass polisher in rooms where flammable gases, liquids or solids are present.

- Never leave the glass polisher unattended.

- Do not operate the glass polisher when you are tired or under the influence of alcohol, drugs or medication.

- Do not use the glass polisher in a damp environment.

- Store the glass polisher in a safe, dry place out of reach of children at a temperature not exceeding 40°C (104°F).

- The plug on the glass polisher must fit into the socket. Never modify a plug. Do not attach an adapter plug to the e-

arthed glass polisher. Original plugs and matching sockets reduce the risk of electric shock.

- Use the cable as directed. Never use the cable to carry, pull or disconnect the glass polisher from the power supply.

Keep the cable away from heat, oil, sharp edges or moving parts. Damaged or tangled cables increase the risk of

electric shock.

- When working outdoors, connect an extension cord approved for outdoor use. Using a cable suitable for outdoor use

reduces the risk of electric shock.

- If operation of the glass polisher in a damp place cannot be avoided, use a residual current circuit breaker. The use of a

residual current circuit breaker reduces the risk of electric shock.

Operating Instructions Glass Polisher BO 5009337- Version 1.0 4

- Remove all adjusting keys or spanners before switching on. Spanners stuck on rotating tool parts can cause injury.

- Do not lean over the tool. Always maintain a firm grip and balance. This makes it easier to control the power tool in un-

expected situations.

- Lay the power line at a sufficient distance from rotating parts. If you lose control of the glass polisher, the line may be

cut or strained and your hand or even arm may get caught in rotating parts.

- Never put the glass polisher down until all rotating parts have come to a complete standstill. Rotating parts can rub

against the supporting surface and make the power tool uncontrollable

- Do not leave the glass polisher in operation while you are carrying it by your side. In case of accidental contact, rotating

parts can get caught in your clothes and cause injury.

5. Operation

5.1 After use

5.1.1. Switch off the motor before putting down the glass polisher. All moving parts must be at a complete standstill.

5.1.2. After switching off, never brake the rotation of moving parts by applying an opposing force.

5.2 Preparation

5.2.1. Attach the handle to the machine in an upright position using the two hexagon socket head screws supplied and

the 6 mm Allen key.

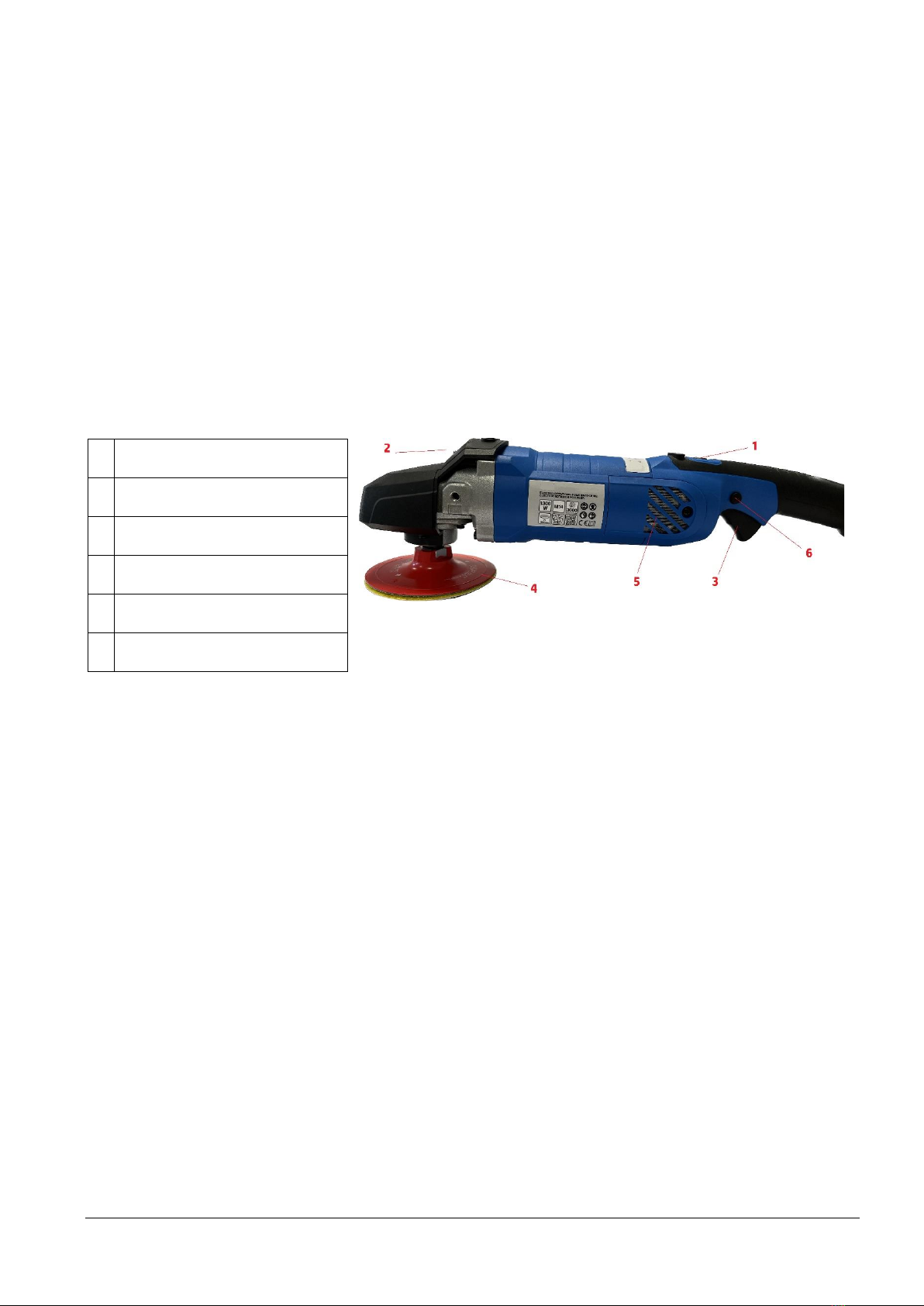

5.2.2. Press the button (2) to lock the main shaft.

5.2.3. Turn the hook and loop disc clockwise onto the external thread of the drive shaft and hand-tighten the hook and

loop disc.

5.3. USING THE MACHINE

5.3.1. Polishing/abrasive connection

o Disconnect the unit from the mains

o Select the required polishing or diamond Velcro disc and place it centrally on the Velcro disc 4.

o To remove the polish/abrasive, proceed in reverse order

5.3.2. Before using the tool

o All accessories must be correctly mounted and tightly tightened

o Check the Velcro pad for free movement by turning it by hand.

o Make a test run of at least 30 s at the highest idling speed in a safe position.

1

Cruise control

2

Main shaft locking device

3

On/Off switch

4

Velcro sanding disc

5

Ventilation slots

6

Locking button On/Off switch

Operating Instructions Glass Polisher BO 5009337- Version 1.0 5

o In case of strong vibrations or other defects, stop the glass polisher immediately and determine the cause

5.3.3. Switch on/off

o The glass polisher is switched on and off by pressing/releasing the on/off switch 3

5.3.4. Soft electronic start-up

o Ensures that the set speed is reached smoothly when the glass polisher is switched on without an abrupt jolt

5.3.5. Switch interlock for continuous use, unlocking

o Press the on/off switch 3

o Press the locking button with your thumb 6

o Unlock the locking knob by pressing the on/off switch 3 again and then releasing it

5.3.6. Speed control

o The speed can be set from low (600 rpm) to high (3,000 rpm) via controller 1.

o Start the appliance with control 1 in position 600 rpm (lower speed).

o Increase the speed as needed while the unit is running

5.3.7. Operating the glass polisher

o First switch on the glass polisher, place it completely on the surface to be polished and move it evenly on individual sections

o Before you switch off the glass polisher, you should lift it off the workpiece

o The hook and loop disc continues to rotate for a short time after it is switched off.

5.3.8. Holding and guiding the glass polisher

o Always hold the glass polisher by both handle areas when working

o Always hold it with both hands so that you always keep it under control

o Ensure a safe standing position

o Do not apply so much pressure to the glass polisher that it jams

o Keep the ventilation slots 5 free

6. Care

6.1 Maintenance/ servicing

Protect the glass polisher from impacts, shocks and grease

- Always keep glass polishers and cables clean (especially ventilation slots 5)

o Disconnect the mains plug before cleaning.

o Do not attempt to clean ventilation slots by inserting pointed objects

Clean the glass polisher only with a damp cloth.

Never use solvents for cleaning.

For all other service, repair and maintenance work, please contact a competent person.

Operating Instructions Glass Polisher BO 5009337- Version 1.0 6

7. Disposal

Recycle unwanted materials instead of disposing of them as waste. Sort all tools, accessories and packaging, take them to

a recycling centre and dispose of them in an environmentally friendly way.

At the end of its service life, dispose of this product in accordance with the EU Directive on Waste Electrical and Electronic

Equipment. Check with your local waste authority about recycling measures or give the product to Bohle AG or a specialist

electrical dealer for disposal.

8. Accessories

Velcro backing pad KGS® Swiflex® M QRS M14 Ø 115 mm

The Velcro disc is compatible with KGS® Swiflex® metal-bonded discs with Velcro fastener. This special Velcro fastener

guarantees a secure connection for metal discs. The disc has an M14 connection.

ART. NO.

BO 5310081

Diamond grinding wheels KGS Swiflex® 115 mm Ø

With Velcro fastener, to be used only in conjunction with the mounting plate BO 5310081!

Diameter 115 mm ・Centre hole 15 mm

CORPORATION COLOUR ART. NO.

60 green BO 5010081T

120 black BO 5010082T

220 red BO 5010083T

400 yellow BO 5010084T

Felt plate with threaded flange M14, Ø 125 mm

The felt plate with fibre backing is suitable for removing small hair scratches, blind areas or stubborn dirt from glass

surfaces.

ART. NO.

BO 5300811

Replacement felt with fibre backing Ø 125 mm

ART. NO.

BO 5300810

Operating Instructions Glass Polisher BO 5009337- Version 1.0 7

Polishing Fluid 3M™Glass Polishing Compound 60150

This polishing fluid has been specially developed for applications on glass surfaces to remove small and minute scratches,

swirls and haze.

The polishing liquid is particularly suitable for polishing up light imperfections such as streaks, burns, lime and silicone resi-

dues on glass.

1. use sufficient polishing liquid to keep the repairing surface moist during polishing.

Wet the polishing medium evenly and completely with the polishing liquid before starting the machine.

Start the machine with the polishing medium on and begin the polishing process with high pressure.

Reduce the pressure in the last 2 -3 seconds of polishing and stop the process as soon as the imperfections are polished out. Do not allow the polishing

liquid to dry on.

Remove the residue with a soft and dry cloth.

ART. NO.

BO 5300806

Cerium polishing powder white (decolourised)

The white (decolourised) cerium polishing powder is used in conjunction with a polishing felt to remove small hairline scrat-

ches or "blind" areas in the glass.

Mix the polishing powder with water to a paste and apply the paste to the surface to be treated. Then polish carefully with

the polishing felt.

ART. NO.

BO CE2601 (1 kg container)

BO CE2601 (20 kg container)

Table of contents