Bolens 122-280R000 User manual

Other Bolens Lawn Mower manuals

Bolens

Bolens BL1740 User manual

Bolens

Bolens 546 User manual

Bolens

Bolens Bolens User manual

Bolens

Bolens 544 Series User manual

Bolens

Bolens 13000 Owner's manual

Bolens

Bolens 416 User manual

Bolens

Bolens 1058 User manual

Bolens

Bolens TRANSMATIC LAWN TRACTOR 660 User manual

Bolens

Bolens 111-050R304 User manual

Bolens

Bolens 11A-020W765 Guide

Bolens

Bolens 546 User manual

Bolens

Bolens V17 User manual

Bolens

Bolens 136 User manual

Bolens

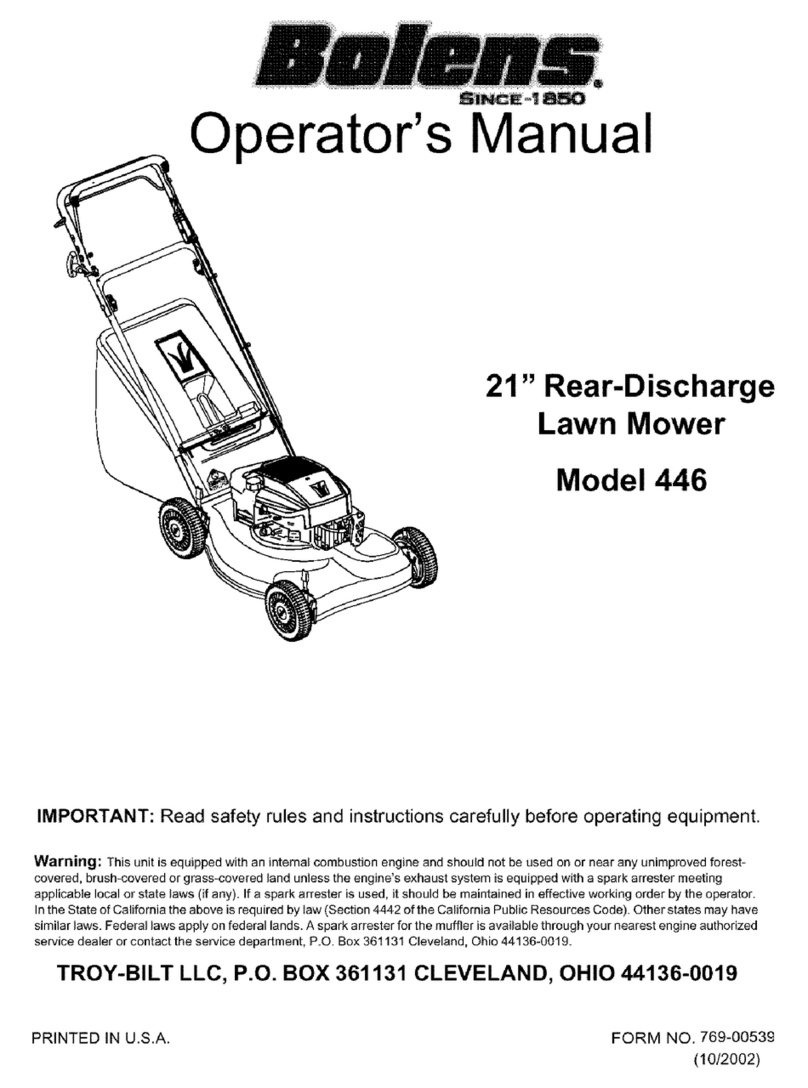

Bolens 446 User manual

Bolens

Bolens 526 User manual

Bolens

Bolens 660 - 688 User manual

Bolens

Bolens 112-400R000 User manual

Bolens

Bolens 717 User manual

Bolens

Bolens TRANSMATIC LAWN TRACTOR 660 User manual

Bolens

Bolens 264 User manual

Popular Lawn Mower manuals by other brands

TALEN TOOLS

TALEN TOOLS AVR HGM30 manual

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual