4

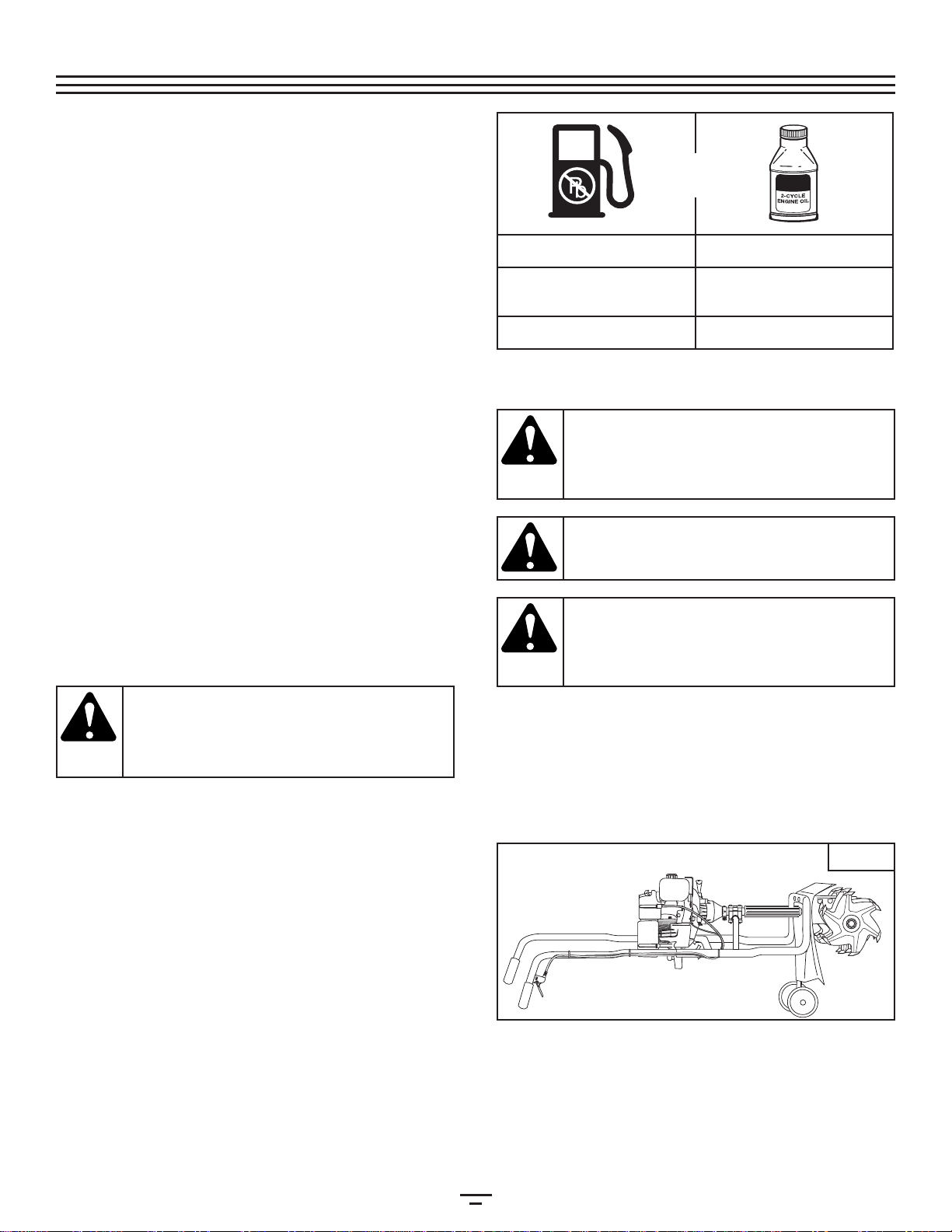

•Always stop the engine and allow it to cool before filling

the fuel tank. Never remove the cap of the fuel tank, or add

fuel, when the engine is hot. Never operate the unit with-

out the fuel cap securely in place. Loosen the fuel tank cap

slowlyto relieve any pressure in the tank.

•Add fuel in a clean, well-ventilated outdoor area where

there are no sparks or flames. Slowly remove the fuel cap

only after stopping engine. Do not smoke while fueling.

Wipeup any spilled fuel from the unit immediately.

•Move the unit at least 30 feet (9.1 m) from the fueling

source and site before starting the engine. Do not smoke.

Keep sparks and open flames from the area while adding

fuelor operating the unit.

WHILE OPERATING

•Never start or run the unit inside a closed room or build-

ing. Breathing exhaust fumes can be lethal. Operate this

unitonly in a well ventilated area outdoors.

•Wear safety glasses or goggles that are marked as meeting

ANSI Z87.1 standards, and ear/hearing protection when

operating this unit. Wear a face or dust mask if the opera-

tionis dusty.

•Wear heavy, long pants, boots, gloves and a long sleeve

shirt.Do not wear, short pants, sandals or go barefoot.

•To reduce the risk of injury associated with objects pulled

into rotating parts, do not wear loose clothing, jewelry,

scarves,etc. Secure hair above shoulder level.

•Usethe unit only in daylight or good artificial light.

•Keepoutside surfaces free from oil and fuel.

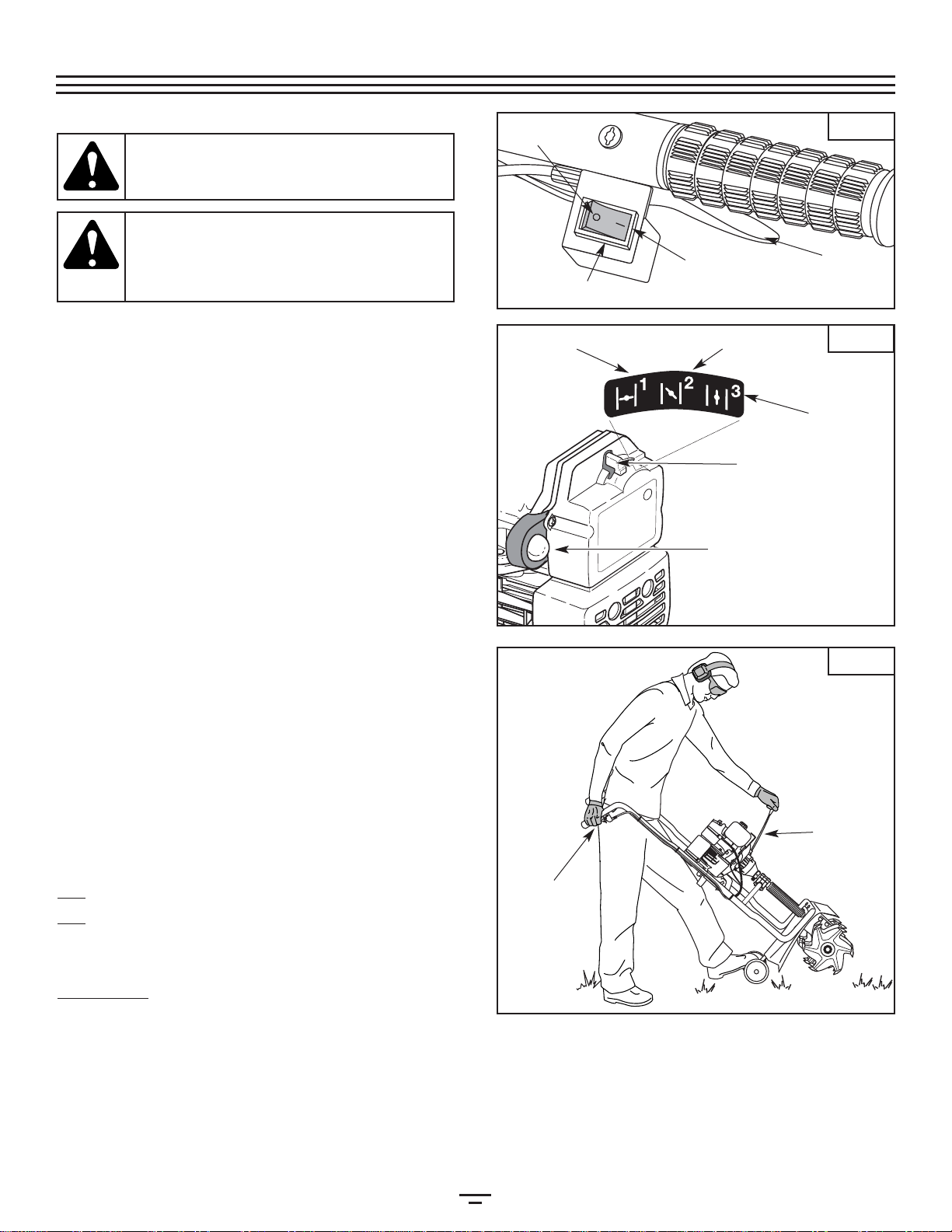

•This unit has a clutch. The tines remain stationary when

the engine is idling. If they do not, have the unit adjusted

byan authorized service technician.

•Be sure the tines are not in contact with anything before

startingthe unit.

•Avoid accidental starting. Be in the starting position when-

ever pulling the starter rope. The operator and unit must

be in a stable position while starting. Refer to the Starting/

StoppingInstructions.

•Usethe right tool. Only use this tool for the purpose intended

.

•Do not force the unit. It will do the job more effectively,

with a smaller chance of injury, if you use the unit for the

taskit was designed.

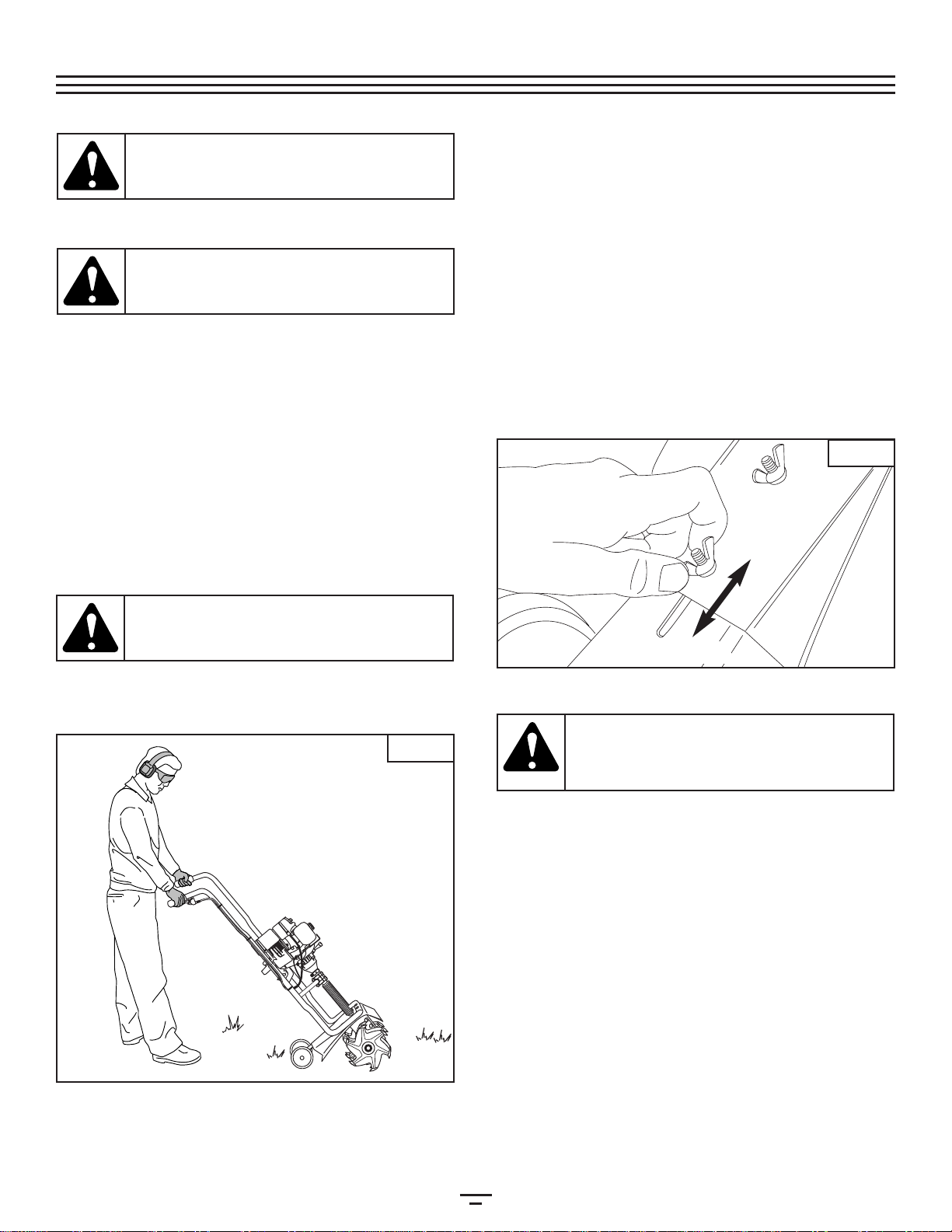

•Use extreme caution when reversing or pulling the unit

towardsyou.

•Do not overreach. Take extra care when working on steep

slopesor inclines. Always keep proper footing and balance.

•Always hold the unit with both hands when operating.

Keepa firm grip on the handlebar grips.

•Keep hands, face and feet at a distance from all moving

parts. Do not touch or try to stop the tines when they are

rotating.Do not operate without guards in place.

•Do not touch the engine, muffler or gearbox. These parts

get extremely hot from operation. When turned off they

remainhot for a short time.

•Do not operate the engine faster than the speed needed

to do the job. Do not run the engine at high speed when

notin use.

•Always stop the engine during suspended or delayed

operation,or when you walk from one location to another.

•Stop the engine for maintenance, repair or to install or

remove the tines. To avoid injury, stop the unit and make

surethe tines no longer turn.

•The tines become very sharp from use. Always wear heavy

gloves when handling, removing, installing or cleaning the

tines.

•Use only Genuine Factory Parts™ replacement parts and

accessories for this unit. These are available from your

authorized service dealer. Use of any non original factory

parts or accessories could lead to serious injury to the user,

ordamage to the unit, and void your warranty.

•Keep the unit clean of vegetation and other materials. They

maybecome lodged between the tines and gearbox or guard.

•To reduce the risk of fire, replace a faulty muffler and spark

arrestor. Keep the engine and muffler free from grass,

leaves,excessive grease or carbon build up.

OTHER SAFETYWARNINGS

•Never store the unit, with fuel in the tank, inside a building

wherefumes may reach an open flame or spark.

•Allow the engine to cool before storing or transporting. Be

sureto secure the unit while transporting.

•Store the unit in a dry place, either locked up or up high to

prevent unauthorized use or damage. Keep out of the

reachof children.

•Clean the tines with a hose and water. Wipe the tines with

alight machine oil to prevent rust.

•Never douse or squirt the engine with water or any other liq-

uid. Keep handles dry, clean and free from debris. Clean after

each use, as described in the CleaningandStorage section.

•Keep these instructions. Refer to them often and use them

to instruct other users. If you loan someone this unit, also

loanthem these instructions.

SAVETHESE INSTRUCTIONS

• IMPORTANT SAFETY INFORMATION •

RULESFORSAFEOPERATION