4430 Gibsonia Rd. • Gibsonia, PA 15044 • USA • www.bontoo .com

SAFETY INSTRUCTIONS

Warning: When using electric tools always follow basic safety

precautions to reduce the risk of fire, electric shock and

personal injury.

1. KNOW YOUR POWER TOOL. Rea this manual carefully

an the rill manual associate with the rill use with this

Quickpoint Drill-Mate Mortar Gun.

2. Do not put han s in hopper while tool is plugge in.

3. Do not tighten or install parts while tool is plugge in.

4. Do not use the water hose to clean tool. (see cleaning

instructions)

5. In the event that tool plugs or jams, o not continue to

operate tool. See trouble shooting.

6. Before operating tool, be sure nozzle Key Allen Wrench is

inserte an lokcing nozzle in place.

7. Do not use this tool to ispense materials other than water

base cementacious mortars.

8. Do not overreach. Keep proper footing an balance at all

times.

9. Do not abuse power cor . Never carry tool by the rill

cor .

10. Keep han s away from all moving parts. (Install cam

guar before using)

11. Store i le tool. When not in use, store your tool in a ry

secure place. Keep out of the reach of chil ren.

ACCESSORIES

• 1 - Angle steel tip no. 552-A

• 1 - Wi e steel tip. 552

• 1 - Narrow steel tip no. 551

• 1 - Large steel tip no. 553

• 2 - “U” bla es

• 3 - Tip bla e sets

• 2 - 1/4- 28 x 1/4Stainless steel set screws

• 1 - Extra nozzle key Allen wrench

• 1 - 16 oz. Scoop no. 554

• 1 - 8 oz. Gibco’s - MRF

Tip bla es can be ma e from 1/8” electrician’s snake.

Ben with pliers an vice to contour below or sen for

replacement tips.

A set consists of one long, one short bla e an on “U” bla e.

<-- Insert this en in bla e coupling.

Caution: Protect eyes when cutting

har ene wire.

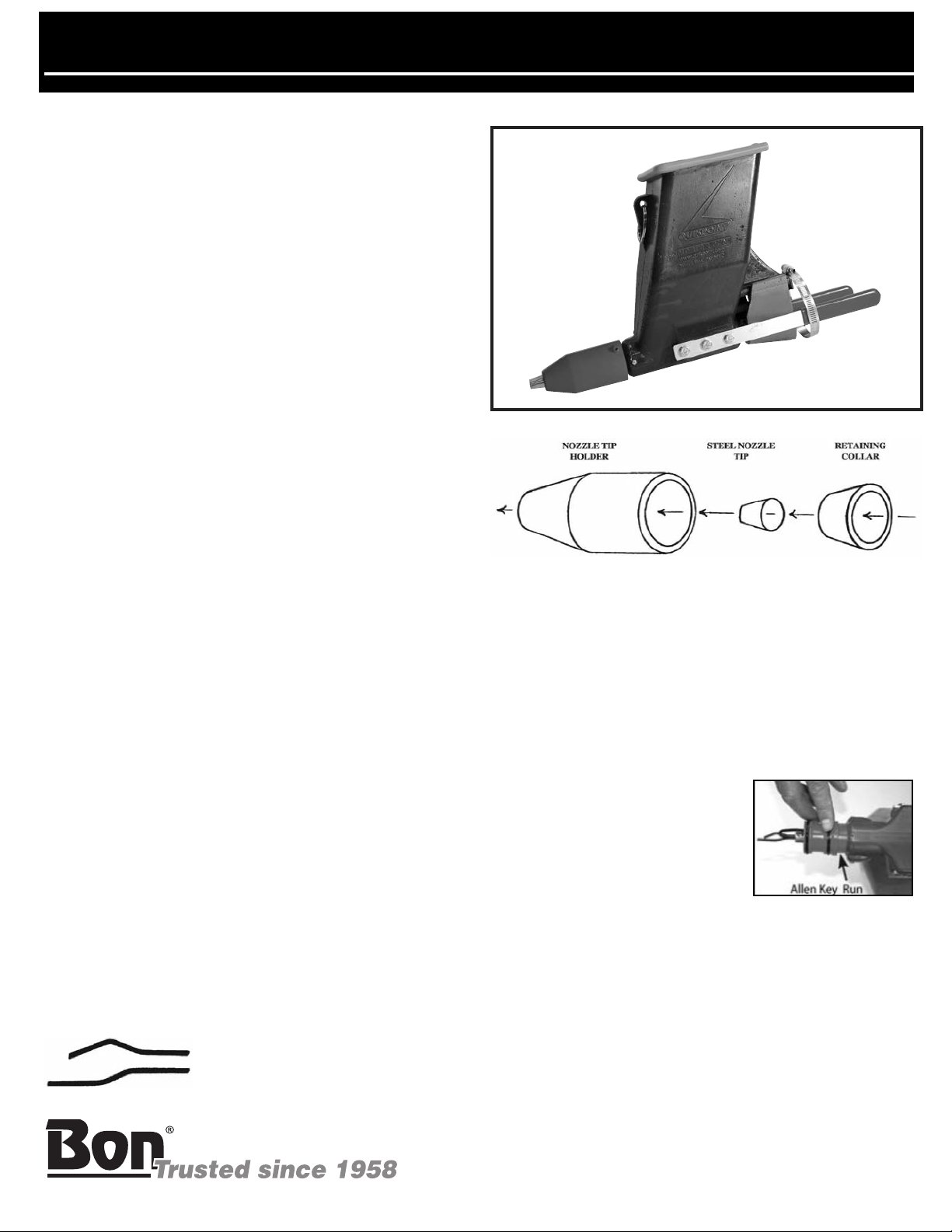

NOZZLE ASSEMBLY

1. Drop metal nozzle tip into nozzle tip hol er. Then insert

retaining collar as shown.

2. Slip the assembly over the front barrel of the gun. Pull the

nozzle assembly firmly against the front face of the gun

barrel until the metal nozzle tip is seate tightly in the

nozzle hol er.

3. Insert the allen wrench key into the holes at the back of the

nozzle assembly. The allen key, when properly place ,

will fit in the slot at the back of the secon o-ring.

Note: The nozzle assembly can now

be rotate for vertical or horizontal

applications. When assembling,

make sure all mating surfaces are

clean to insure proper seating. Put

lubricant such as Vaseline on o-ring

area an area where Allen Key runs.

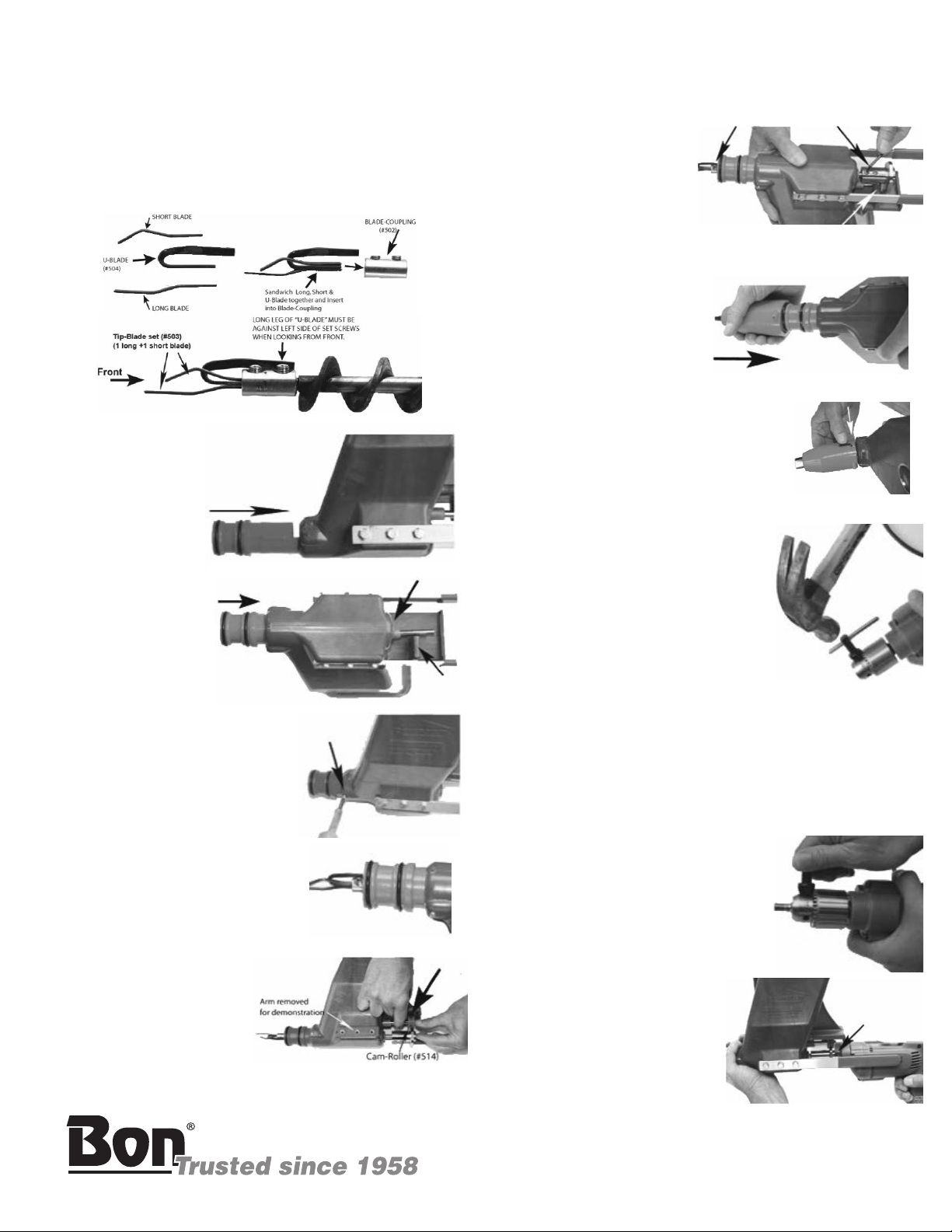

AUGER ASSEMBLY

1. Install the Bla e-Coupling (#502) on to the Auger by

tightening the Socket set screw on the flat of the auger

shaft.

2. The short leg of the U-Bla e (#504) is inserte between the

Tip-Bla e-Set (#503) with the short-bla e above (so that the

set screw tightens on this bla e first) an the long bla e

below.

1

INSTRUCTIONS

#14-188 Quickpoint

4430 Gibsonia Rd. • Gibsonia, PA 15044 • USA • www.bontoo .com

IS14188 08/09

PAGE 1 OF 4