BONFIGLIOLI Vectron Agile VABus/TCP Use and care manual

Agile

VABus/TCP

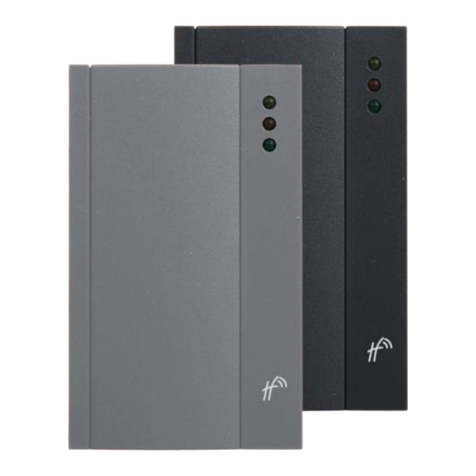

Communication module CM-VABus/TCP

Frequency inverter 230 V / 400 V

CONTENTS

1GENERAL INFORMATION ABOUT THE DOCUMENTATION 6

1.1 This document 6

1.2 Warranty and liability 7

1.3Obligation 7

1.4 Copyright 7

1.5 Storage 7

2GENERAL SAFETY INSTRUCTIONS AND INFORMATION ON USE 8

2.1 Terminology 8

2.2 Designated use 9

2.3 Misuse 9

2.3.1 Explosion protection 9

2.4 Residual risks 10

2.5 Safety and warning signs at frequency inverter 10

2.6 Warning information and symbols used in the user manual 11

2.6.1 Hazard classes 11

2.6.2 Hazard symbols 11

2.6.3 Prohibition signs 11

2.6.4 Personal safety equipment 11

2.6.5 Recycling 12

2.6.6 Grounding symbol 12

2.6.7 ESD symbol 12

2.6.8 Information signs 12

2.6.9 Font style in documentation 12

2.7 Directives and guidelines to be adhered to by the operator 12

2.8 Operator's general plant documentation 12

2.9 Operator's/operating staff's responsibilities 13

2.9.1 Selection and qualification of staff 13

2.9.2 General work safety 13

2.10 Organizational measures 13

2.10.1 General 13

2.10.2 Use in combination with third-party products 13

2.10.3 Transport and Storage 14

2.10.4 Handling and installation 14

2.10.5 Electrical connections 14

2.10.6 Safe operation 14

2.10.7 Maintenance and service/troubleshooting 15

2.10.8 Final decommissioning 16

12/13

Agile

VABus/TCP 3

3INTRODUCTION 17

3.1 Supported configurations 20

3.2 Initialization time 20

4FIRST COMMISSIONING 20

5COMMUNICATION OPTIONS 21

5.1 Control software VPlus: 21

6ASSEMBLY/DISASSEMBLY OF COMMUNICATION MODULE 22

6.1 Assembly 22

6.2 Disassembly 23

7VABUS/TCP INTERFACE 24

7.1 Communication modules 25

7.1.1 Installation instructions 25

7.2 Setup 26

7.3 TCP/IP address & subnet 26

7.3.1 Network without DHCP server: 26

7.3.2 Network with DHCP server: 26

7.4 TCP/IP configuration 27

7.4.1 TCP configurations tool 27

7.4.2 Parameter settings with VPlus 31

7.5 Operating behavior in the case of a communication error 33

8PROTOCOL 34

8.1 Telegram types 35

8.1.1 Data types 35

8.1.2 Send Request / Enquiry Telegram 36

8.1.3 Setting Request / Select Telegram 37

8.1.4 System bus Node-ID 38

8.2 Telegram check 40

8.3 Timeout control 41

8.4 Resetting errors 41

9PARAMETER ACCESS 42

9.1 Handling of datasets / cyclic writing of parameters 42

9.2 Handling index parameters / cyclic writing 43

9.2.1 Example: Writing of index parameters 43

9.2.2 Example: Reading of index parameters 44

4

Agile

VABus/TCP 12/13

10 EXAMPLE MESSAGES VABUS/TCP 45

10.1 Reading parameters 45

10.2 Writing parameters 46

11 CONTROL OF FREQUENCY INVERTER 49

11.1 Control via contacts/remote contacts 50

11.1.1 Device state machine 52

11.2 Control via state machine 53

11.2.1 Statemachine diagram 55

11.3 Behavior in the case of a quick stop 57

11.3.1 Behavior in the case of transition 5 (disable operation) 58

11.3.2 Reference value/actual value 59

11.3.3 Example sequence 60

12 ACTUAL VALUES 61

13 PARAMETER LIST 62

13.1 Actual values (Menu “Actual”) 62

13.2 Parameters (Menu “Para”) 63

14 APPENDIX 64

14.1 List of control words 64

14.2 List of status words 64

14.3 Warning messages 65

14.4 Application warning messages 66

14.5 Error messages 67

14.6 Conversions 67

14.6.1 Speed [1/min] into frequency [Hz] 67

14.6.2 Frequency [Hz] into speed [1/min] 67

14.7 ASCII table (0x00 – 0x7F) 68

INDEX 69

12/13

Agile

VABus/TCP 5

1General Information about the Documentation

For better clarity, the documentation of the frequency inverter is structured according to the custom-

er-specific requirements.

The present manual was created in the German language. The German manual is the original version.

Other language versions are translations.

Quick Start Guide

The “Quick Start Guide” describes the basic steps required for mechanical and electrical installation of

the frequency inverter. The guided commissioning supports you in the selection of necessary parame-

ters and the configuration of the software of the frequency inverter.

User manual

The user manual documents the complete functionality of the frequency inverter. The parameters

required for special purposes, for adjustment to the application and the numerous additional functions

are described in detail.

Separate user manuals are supplied for optional components for the frequency inverter. These manu-

als complement the operating instructions and the “Quick Start Guide” for the frequency inverter.

Application manual

The application manual complements the documentation to ensure goal-directed installation and

commissioning of the frequency inverter. Information on various topics in connection with the use of

the frequency inverter is described in context with the specific application.

1.1 This document

This document describes the communication via the VABus/TCP protocol with frequency inverters of

the

Agile

series of devices. Thanks to the modular hardware and software structure, the frequency

inverters can be customized to meet the customer's specific requirements, including applications re-

quiring high functionality and dynamism.

WARNING

Compliance with the documentation is required to ensure safe operation of the frequen-

cy inverter. BONFIGLIOLI VECTRON GmbH shall not be held liable for any damage

caused by any non-compliance with the documentation.

In case any problems occur which are not covered by the documentation sufficiently,

please contact the manufacturer.

6

Agile

VABus/TCP 12/13

1.2 Warranty and liability

BONFIGLIOLI VECTRON GmbH would like to point out that the contents of this user manual do not

form part of any previous or existing agreement, assurance or legal relationship. Neither are they

intended to supplement or replace such agreements, assurances or legal relationships. Any obligations

of the manufacturer shall solely be based on the relevant purchase agreement which also includes the

complete and solely valid warranty stipulations. These contractual warranty provisions are neither

extended nor limited by the specifications contained in this documentation.

The manufacturer reserves the right to correct or amend the specifications, product information and

omissions in these operating instructions without notice. The manufacturer shall not be liable for any

damage, injuries or costs which may be caused for the aforementioned reasons.

Furthermore, BONFIGLIOLI VECTRON GmbH excludes any warranty/liability claims for any personal

and/or material damage if such damage is due to one or more of the following causes:

•inappropriate use of the frequency inverter,

•non-compliance with the instructions, warnings and prohibitions contained in the documentation,

•unauthorized modifications of the frequency inverter,

•insufficient monitoring of parts of the machine/plant which are subject to wear,

•repair work at the machine/plant not carried out properly or in time,

•catastrophes by external impact and force majeure.

1.3 Obligation

This user manual must be read before commissioning and complied with. Anybody entrusted with

tasks in connection with the

•transport,

•assembly,

•installation of the frequency inverter and

•operation of the frequency inverter

must have read and understood the user manual and, in particular, the safety instructions in order to

prevent personal and material losses.

1.4 Copyright

In accordance with applicable law against unfair competition, this user manual is a certificate. Any

copyrights relating to it shall remain with

BONFIGLIOLI VECTRON GmbH

Europark Fichtenhain B6

47807 Krefeld

Germany

This user manual is intended for the operator of the frequency inverter. Any disclosure or copying of

this document, exploitation and communication of its contents (as hardcopy or electronically) shall be

forbidden, unless permitted expressly.

Any non-compliance will constitute an offense against the copyright law dated 09 September 1965,

the law against unfair competition and the Civil Code and may result in claims for damages. All rights

relating to patent, utility model or design registration reserved.

1.5 Storage

The documentation form an integral part of the frequency inverter. It must be stored such that it is

accessible to operating staff at all times. If the frequency inverter is sold on to other users, then this

user manual must also be handed over.

12/13

Agile

VABus/TCP 7

2General safety instructions and information on use

The chapter "General safety instructions and information on use" contains general safety instructions

for the Operator and the Operating Staff. At the beginning of certain main chapters, some safety in-

structions are included which apply to all work described in the relevant chapter. Special work-specific

safety instructions are provided before each safety-relevant work step.

2.1 Terminology

According to the documentation, different activities must be performed by certain persons with certain

qualifications.

The groups of persons with the required qualification are defined as follows:

Operator

This is the entrepreneur/company who/which operates the frequency inverter and uses it as per the

specifications or has it operated by qualified and instructed staff.

Operating staff

The term Operating Staff covers persons instructed by the Operator of the frequency inverter and

assigned the task of operating the frequency inverter.

Skilled Personnel

The term Skilled Personnelcovers staff that are assigned special tasks by the Operator of the fre-

quency inverter, e.g. installation, maintenance and service/repair and troubleshooting. Based on their

qualification and/or know-how, Skilled Personnel must be capable of identifying defects and as-

sessing functions.

Qualified electrician

The term Qualified Electrician covers qualified and trained staff that have special technical know-how

and experience with electrical installations. In addition, Qualified Electricians must be familiar with the

applicable standards and regulations, they must be able to assess the assigned tasks properly and

identify and eliminate potential hazards.

Instructed person

The term Instructed Person covers staff that are instructed and trained about/in the assigned tasks

and the potential hazards that might result from inappropriate behavior. In addition, instructed per-

sons must have been instructed in the required protection provisions, protective measures, the appli-

cable directives, accident prevention regulations as well as the operating conditions and have their

qualification verified.

Expert

The term Expert covers qualified and trained staff that have special technical know-how and experi-

ence relating to the frequency inverter. Experts must be familiar with the applicable government work

safety directives, accident prevention regulations, guidelines and generally accepted rules of technolo-

gy in order to assess the operationally safe condition of the frequency inverter.

8

Agile

VABus/TCP 12/13

2.2 Designated use

The frequency inverter is designed according to the state of the art and recognized safety regula-

tions.

The frequency inverters are electrical drive components intended for installation in industrial plants or

machines. Commissioning and start of operation is not allowed until it has been verified that the ma-

chine meets the requirements of the EC Machinery Directive 2006/42/EC and DIN EN 60204-1.

The frequency inverters meet the requirements of the low voltage directive 2006/95/EEC and DIN

EN 61800-5-1. CE-labeling is based on these standards. Responsibility for compliance with the EMC

Directive 2004/108/EC lies with the operator. Frequency inverters are only available at specialized

dealers and are exclusively intended for commercial use as per EN 61000-3-2.

No capacitive loads may be connected to the frequency inverter.

The technical data, connection specifications and information on ambient conditions are indicated on

the rating plate and in the documentation and must be complied with at all times.

2.3 Misuse

Any use other than that described in "Designated use" shall not be permissible and shall be consid-

ered as misuse.

For, example, the machine/plant must not be operated

•by uninstructed staff,

•while it is not in perfect condition,

•without protection enclosure (e.g. covers),

•without safety equipment or with safety equipment deactivated.

The manufacturer shall not be held liable for any damage resulting from such misuse. The plant oper-

ator shall bear the sole risk.

2.3.1 Explosion protection

The frequency inverter is an IP 20 protection class device. For this reason, use of the device in explo-

sive atmospheres is not permitted.

12/13

Agile

VABus/TCP 9

2.4 Residual risks

Residual risks are special hazards involved in handling of the frequency inverter which cannot be elim-

inated despite the safety-compliant design of the device. Remaining hazards are not obvious and can

be a source of possible injury or health damage.

Typical residual hazards include:

Electrical hazard

Danger of contact with energized components due to a defect, opened covers or enclosures or im-

proper working on electrical equipment.

Danger of contact with energized components in frequency inverter if no external disconnection de-

vice was installed by the operator.

Electrostatic charging

Touching electronic components bears the risk of electrostatic discharges.

Thermal hazards

Risk of accidents by hot machine/plant surfaces, e.g. heat sink, transformer, fuse or sine filter.

Charged capacitors in DC link

The DC link may have dangerous voltage levels even up to three minutes after shutdown.

Danger of equipment falling down/over, e.g. during transport

Center of gravity is not the middle of the electric cabinet modules.

2.5 Safety and warning signs at frequency inverter

Comply with all safety instructions and danger information provided on the frequency inverter.

•Safety information and warnings on the frequency inverter must not be removed.

10

Agile

VABus/TCP 12/13

2.6 Warning information and symbols used in the user manual

2.6.1 Hazard classes

The following hazard identifications and symbols are used to mark particularly important information:

DANGER

Identification of immediate threat holding a high

risk of death or serious injury if not

avoided.

WARNING

Identification of immediate threat holding a medium

risk of death or serious injury if

not avoided.

CAUTION

Identification of immediate threat holding a low

risk of minor or moderate physical

injury if not avoided.

NOTE

Identification of a threat holding a risk of material damage if not avoided.

2.6.2 Hazard symbols

Symbol

Meaning

Symbol

Meaning

General hazard

Suspended load

Electrical voltage

Hot surfaces

2.6.3 Prohibition signs

Symbol

Meaning

No switching; it is forbidden to switch the ma-

chine/plant, assembly on

2.6.4 Personal safety equipment

Symbol

Meaning

Wear body protection

12/13

Agile

VABus/TCP 11

2.6.5 Recycling

Symbol

Meaning

Recycling,

to avoid waste, collect all materials for

reuse

2.6.6 Grounding symbol

Symbol

Meaning

Ground connection

2.6.7 ESD symbol

Symbol

Meaning

ESD: Electrostatic Discharge (can damage com-

ponents and assemblies)

2.6.8 Information signs

Symbol

Meaning

Tips and information making using the frequency

inverter easier.

2.6.9 Font style in documentation

Example

Font style

Use

1234

bold

Representation of parameter numbers

Parameter

italic, Font

Times New Roman

Representation of parameter names

P.1234

bold

Representation of parameter numbers without name, e.g. in

formulas

Q.1234

bold

Representation of source numbers

2.7 Directives and guidelines to be adhered to by the operator

The operator must follow the following directives and regulations:

•Ensure that the applicable workplace-related accident prevention regulations as well as other appli-

cable national regulation are accessible to the staff.

•An authorized person must ensure, before using the frequency inverter, that the device is used in

compliance with its designated use and that all safety requirements are met.

•Additionally, comply with the applicable laws, regulations and directives of the country in which the

frequency inverter is used.

Any additional guidelines and directives that may be required additionally shall be defined by the op-

erator of the machine/plant considering the operating environment.

2.8 Operator's general plant documentation

•In addition to the user manual, the operator should issue separate internal operating instructions

for the frequency inverter. The user manual of the frequency inverter must be included in the user

manual of the whole plant.

12

Agile

VABus/TCP 12/13

2.9 Operator's/operating staff's responsibilities

2.9.1 Selection and qualification of staff

•Any work on the frequency inverter may only be carried out by qualified technical staff. The staff

must not be under the influence of any drugs. Note the minimum age required by law. Define the

staff's responsibility in connection with all work on the frequency inverter clearly.

•Work on the electrical components may only be performed by a qualified electrician according to

the applicable rules of electrical engineering.

•The operating staff must be trained for the relevant work to be performed.

2.9.2 General work safety

In addition to the user manual of the machine/plant, any applicable legal or other regulations

relating to accident prevention and environmental protection must be complied with. The staff

must be instructed accordingly.

Such regulations and/or requirements may include, for example, handling of hazardous media and

materials or provision/use of personal protective equipment.

In addition to this user manual, issue any additional directives that may be required to meet spe-

cific operating requirements, including supervision and reporting requirements, e.g. directives re-

lating to work organization, workflow and employed staff.

Unless approved of expressly by the manufacturer, do not modify the frequency inverter in any

way, including addition of attachments or retrofits.

Only use the frequency inverter if the rated connection and setup values specified by the manu-

facturer are met.

•Provide appropriate tools as may be required for performing all work on the frequency inverter

properly.

2.10 Organizational measures

2.10.1 General

Train your staff in the handling and use of the frequency inverter and the machine/plant as well

as the risks involved.

Use of any individual parts or components of the frequency inverter in other parts of the opera-

tor's machine/plant is prohibited.

•Optional components for the frequency inverter must be used in accordance with their designated

use and in compliance with the relevant documentation.

2.10.2 Use in combination with third-party products

•Please note that BONFIGLIOLI VECTRON GmbH will not accept any responsibility for compatibility

with third-party products (e.g. motors, cables or filters).

•In order to enable optimum system compatibility, BONFIGLIOLI VECTRON GmbH offers compo-

nents facilitating commissioning and providing optimum synchronization of the machine/plant

parts in operation.

•If you use the frequency inverter in combination with third-party products, you do this at your

own risk.

12/13

Agile

VABus/TCP 13

2.10.3 Transport and Storage

•The frequency inverters must be transported and stored in an appropriate way. During transport

and storage the devices must remain in their original packaging.

•The units may only be stored in dry rooms which are protected against dust and moisture and are

exposed to small temperature deviations only. The requirements of DIN EN 60721-3-1 for storage,

DIN EN 60721-3-2 for transport and labeling on the packaging must be met.

•The duration of storage without connection to the permissible nominal voltage may not exceed

one year.

2.10.4 Handling and installation

Do not commission any damaged or destroyed components.

Prevent any mechanical overloading of the frequency inverter. Do not bend any components and

never change the isolation distances.

Do not touch any electronic construction elements and contacts. The frequency inverter is

equipped with components which are sensitive to electrostatic energy and can be damaged if

handled improperly. Any use of damaged or destroyed components will endanger the ma-

chine/plant safety and shall be considered as a non-compliance with the applicable standards.

Only install the frequency inverter in a suitable operating environment. The frequency inverter is

exclusively designed for installation in industrial environments.

•If seals are removed from the case, this can result in the warranty becoming null and void.

2.10.5 Electrical connections

The five safety rules must be complied with.

Never touch live terminals. The DC link may have dangerous voltage levels even up to three

minutes after shutdown.

When performing any work on/with the frequency inverter, always comply with the applicable

national and international regulations/laws on work on electrical equipment/plants of the country

in which the frequency inverter is used.

The cables connected to the frequency inverters may not be subjected to high-voltage insulation

tests unless appropriate circuitry measures are taken before.

•Only connect the frequency inverter to suitable supply mains.

2.10.5.1 The five safety rules

When working on/in electrical plants, always follow the five safety rules:

1. Isolate

2. Take appropriate measures to prevent re-connection

3. Check isolation

4. Earth and short-circuit

5. Cover or shield neighboring live parts.

2.10.6 Safe operation

During operation of the frequency inverter, always comply with the applicable national and inter-

national regulations/laws on work on electrical equipment/plants.

Before commissioning and the start of the operation, make sure to fix all covers and check the

terminals. Check the additional monitoring and protective devices according to the applicable na-

tional and international safety directives.

During operation, never open the machine/plant

Do not connect/disconnect any components/equipment during operation.

The machine/plant holds high voltage levels during operation, is equipped with rotating parts

(fan) and has hot surfaces. Any unauthorized removal of covers, improper use, wrong installation

or operation may result in serious injuries or material damage.

14

Agile

VABus/TCP 12/13

Some components, e.g. the heat sink or brake resistor, may be hot even some time after the ma-

chine/plant was shut down. Don't touch any surfaces directly after shutdown. Wear safety gloves

where necessary.

The frequency inverter may hold dangerous voltage levels until the capacitor in the DC link is dis-

charged. Wait for at least 3 minutes after shutdown before starting electrical or mechanical work

on the frequency inverter. Even after this waiting time, make sure that the equipment is deener-

gized in accordance with the safety rules before starting the work.

In order to avoid accidents or damage, only qualified staff and electricians may carry out the work

such as installation, commissioning or setup.

In the case of a defect of terminals and/or cables, immediately disconnect the frequency inverter

from mains supply.

Persons not familiar with the operation of frequency inverters must not have access to the fre-

quency inverter. Do not bypass nor decommission any protective facilities.

The frequency inverter may be connected to power supply every 60 s. This must be considered

when operating a mains contactor in jog operation mode. For commissioning or after an emer-

gency stop, a non-recurrent, direct restart is permissible.

After a failure and restoration of the power supply, the motor may start unexpectedly if the Auto-

Start function is activated.

If staff are endangered, a restart of the motor must be prevented by means of external circuitry.

Before commissioning and the start of the operation, make sure to fix all covers and check the

terminals. Check the additional monitoring and protective devices according to EN 60204 and ap-

plicable safety directives (e.g. Working Machines Act or Accident Prevention Directives).

2.10.7 Maintenance and service/troubleshooting

Visually inspect the frequency inverter when carrying out the required maintenance work and

inspections at the machine/plant.

Perform the maintenance work and inspections prescribed for the machine carefully, including the

specifications on parts/equipment replacement.

Work on the electrical components may only be performed by a qualified electrician according to

the applicable rules of electrical engineering. Only use original spare parts.

Unauthorized opening and improper interventions in the machine/plant can lead to personal injury

or material damage. Repairs on the frequency inverters may only be carried out by the manufac-

turer or persons authorized by the manufacturer. Check protective equipment regularly.

•Before performing any maintenance work, the machine/plant must be disconnected from mains

supply and secured against restarting. The five safety rules must be complied with.

12/13

Agile

VABus/TCP 15

2.10.8 Final decommissioning

Unless separate return or disposal agreements were made, recycle the disassembled frequency in-

verter components:

•Scrap metal materials

•Recycle plastic elements

•Sort and dispose of other component materials

Electric scrap, electronic components, lubricants and other utility materials must be

treated as special waste and may only be disposed of by specialized companies.

Always comply with any applicable national disposal regulations as regards environ-

mentally compatible disposal of the frequency inverter. For more details, contact the

competent local authorities.

16

Agile

VABus/TCP 12/13

3Introduction

The present document describes the VABus/TCP protocol for the CM-VABus/TCP and

CM-VABus/TCP-2P (switch function integrated) communication modules. After connecting VABus/TCP

to the PLC, you can use an additional logic connection from VABus/TCP to the VPlus software running

on a terminal connected via an Ethernet network.

For VABus/TCP connection, the frequency inverter must be equipped with the CM-VABus/TCP or CM-

VABus/TCP-2P communication module.

The CM-VABus/TCP and CM-VABus/TCP-2P communication modules are separate components and

must be attached to the frequency inverter. This is described in chapter 6.1 “Assembly”.

VABus/TCP communication (as described in this manual) requires software version 6.1.0 or higher.

This manual only describes the CM-VABus/TCP and CM-VABus/TCP-2P communication

modules. This manual is not to be understood as providing general/basic information on

Ethernet interfaces or frequency inverters.

General/basic knowledge of the methods and function of VABus/TCP interfaces and

VABus/TCP protocol are a prerequisite for understanding and implementing the instruc-

tions provided by this document.

In some chapters of these instructions, setting and display options via the PC software

VPlus are described as an alternative to the control unit. In this case, VPlus can use

−CM-VABus/TCP or CM-VABus/TCP-2P module or

−the serial interface

for communication with the frequency inverter.

The module enables using VABus/TCP via a PLC and VPlus via the VABus/TCP protocol

at the same time.

WARNING

With CM-VABus/TCP or CM-VABus/TCP-2P, controllers can access all

parameters of the

frequency inverter.

Changing parameters the function of which is unknown can result in malfunction of the

frequency inverter and dangerous situations in the plant.

Ethernet properties:

•10/100 MB (10Base-T/100Base-T)

•Automatic identification (Autonegotiation)

•MDI/MDIX

12/13

Agile

VABus/TCP 17

Ports:

The module supports two logic TCP/IP ports for VABus/TCP communication. Each port can be used for

establishing one logic connection:

•Port #17220: Connection for PLC communication

•Port VPlus: Connection for VPlus

When a PLC starts communicating with a frequency inverter, it creates a TCP/IP source port to send

data to target port #17220 of the frequency inverter. The response of the frequency inverter is sent

by 17220 to this port of the PLC.

VPlus is the software for configuration and maintenance of BONFIGLIOLI VECTRON frequency invert-

ers. It can connect with a frequency inverter while it is communicating with a PLC. VPlus can establish

connections to any type of industrial Ethernet CM modules.

Module variants:

There are two VABus/TCP variants.

CM-VABus/TCP provides a physical interface for communication via VABus/TCP. A star-type network

topology can be used. An external switch is the star point.

CM-VABus/TCP-2P provides two physical interfaces for communication via VABus/TCP. The following

network topologies are possible:

•Star-type (like in CM-VABus/TCP)

•Line

18

Agile

VABus/TCP 12/13

[1] PLC

[2] PC for commissioning or diagnosis (connected temporarily or permanently)

[3] AGL with CM-VABus/TCP or CM-VABus/TCP-2P (2nd port not connected)

[4] AGL with CM-VABus/TCP-2P

12/13

Agile

VABus/TCP 19

3.1 Supported configurations

Agile

frequency inverters support various types of control and reference point input:

•Contacts or remote contacts

•State machine

Contacts or remote contacts

Required settings: Local/Remote 412 = (remote) contacts

Control (start, stop, frequency changeover, etc.) is typically performed through

odigital contacts.

oRemote contacts via field bus.

Reference values depend on the selected function. Typical:

oReference speed/reference frequency:

Analog input.

Fixed values from parameters.

oReference percentage for technology controller or torque control

Analog input.

Fixed values from parameters.

See Chapter 11 “Control of frequency inverter”.

State machine:

Required settings: Local/Remote 412 = 1 – State machine

Control (start, stop, change of mode, etc.) is performed via

Control word

410

.

Reference values depend on the selected function. Typical:

oReference speed/reference frequency:

Analog input.

Fixed values from parameters.

oReference percentage for technology controller or torque control

Analog input.

Fixed values from parameters.

3.2 Initialization time

When the frequency inverter is turned on, the communication module must be initialized in addition to

the frequency inverter. The initialization can take up to 20 seconds.

Wait until the initialization phase is complete before starting the communication (RUN

LED).

4First commissioning

For first commissioning, you should be familiar with the followings steps and the de-

scribed functions:

•Installation of module

Chapter

6.1

•Selection of device control Local/Remote 412

Chapter

11

•Commissioning of device functions via PLC

oFault Reaction

Chapter

7.5

Fault reset

Chapter

8.4

•Setting reference values:

oReference Frequency

Chapter

11.3.2

•Diagnosis:

Chapter

13.1 and 14.1

20

Agile

VABus/TCP 12/13

Table of contents

Other BONFIGLIOLI Vectron Control Unit manuals

Popular Control Unit manuals by other brands

USR IOT

USR IOT USR-TCP232-E2 Hardware manual

B meters

B meters RFM-TX1.1 manual

Multitech

Multitech MultiConnect Dragonfly MTQ-EV3 Series Device guide

Bosch

Bosch DS7432 installation manual

TECH FASS

TECH FASS APS mini Plus MREM 65 Series user guide

Qcells

Qcells Q.PEAK DUO ML-G10.X Series Installation and operation manual