bonitron M3660REM User manual

Web: www.bonitron.com ● Tel: 615-244-2825 ● Email: info@bonitron.com

Model M3660REM

Regenerative Energy Monitor

Customer Reference Manual

Bonitron, Inc.

2

Bonitron, Inc.

Nashville, TN

An industry leader in providing solutions for AC drives.

ABOUT BONITRON

Bonitron designs and manufactures quality industrial electronics that improve the reliability of

processes and variable frequency drives worldwide. With products in numerous industries, and

an educated and experienced team of engineers, Bonitron has seen thousands of products

engineered since 1962 and welcomes custom applications.

With engineering, production, and testing all in the same facility, Bonitron is able to ensure its

products are of the utmost quality and ready to be applied to your application.

The Bonitron engineering team has the background and expertise necessary to design, develop,

and manufacture the quality industrial electronic systems demanded in today’s market. A strong

academic background supported by continuing education is complemented by many years of

hands-on field experience. A clear advantage Bonitron has over many competitors is combined

on-site engineering labs and manufacturing facilities, which allows the engineering team to have

immediate access to testing and manufacturing. This not only saves time during prototype

development, but also is essential to providing only the highest quality products.

The sales and marketing teams work closely with engineering to provide up-to-date information

and provide remarkable customer support to make sure you receive the best solution for your

application. Thanks to this combination of quality products and superior customer support,

Bonitron has products installed in critical applications worldwide.

Bonitron, Inc.

3

AC DRIVE OPTIONS

In 1975, Bonitron began working with AC inverter drive specialists at synthetic fiber plants to

develop speed control systems that could be interfaced with their plant process computers. Ever

since, Bonitron has developed AC drive options that solve application issues associated with

modern AC variable frequency drives and aid in reducing drive faults. Below is a sampling of

Bonitron’s current product offering.

WORLD CLASS PRODUCTS

Undervoltage Solutions

Overvoltage Solutions

Uninterruptible Power for Drives

(DC Bus Ride-Thru)

Voltage Regulators

Chargers and Dischargers

Energy Storage

Braking Transistors

Braking Resistors

Transistor/Resistor Combo

Line Regeneration

Dynamic Braking for Servo Drives

Common Bus Solutions

Portable Maintenance Solutions

Single Phase Power Supplies

3-Phase Power Supplies

Common Bus Diodes

Capacitor Formers

Capacitor Testers

Power Quality Solutions

Green Solutions

12 and 18 Pulse Kits

Line Regeneration

M3660REM

4

This page intentionally left blank.

Table of Contents

5

1. INTRODUCTION ..........................................................................................................................7

1.1. Who Should Use ........................................................................................................................... 7

1.2. Purpose and Scope ........................................................................................................................ 7

1.3. Manual Version and Change Record ............................................................................................ 7

Figure 1-1: M3660REM.............................................................................................................. 7

1.4. Symbol Conventions Used in this Manual and on Equipment ..................................................... 8

2. PRODUCT DESCRIPTION / FEATURES ........................................................................................9

2.1. Related Products ........................................................................................................................... 9

2.2. Part Number Breakdown ............................................................................................................ 10

Figure 2-1: Example of Part Number Breakdown .................................................................... 10

Table 2-1: System Voltage ........................................................................................................ 10

2.3. General Specifications ................................................................................................................ 11

Table 2-3: General Specifications Table ................................................................................... 11

2.4. General Precautions and Safety Warnings ................................................................................. 12

3. INSTALLATION INSTRUCTIONS ................................................................................................13

3.1. Environment ............................................................................................................................... 13

3.2. Wiring and Customer Connections ............................................................................................. 13

4. OPERATION ..............................................................................................................................15

4.1. Functional Description ............................................................................................................... 15

4.2. Features ....................................................................................................................................... 16

4.2.1. Hardware .............................................................................................................................. 16

Figure 4-1: Cables ..................................................................................................................... 16

4.2.2. Display ................................................................................................................................. 17

Figure 4-2: Front Panel ............................................................................................................. 17

4.2.3. Screens & Menu Navigation ................................................................................................ 18

Figure 4-3: Menu Tree .............................................................................................................. 19

5. TROUBLESHOOTING ................................................................................................................20

Table 5-1: Troubleshooting ....................................................................................................... 20

6. ENGINEERING DATA ................................................................................................................22

6.1. Ratings Chart .............................................................................................................................. 22

Table 6-1: Ratings Chart ........................................................................................................... 22

Table 6-2: Dimensions .............................................................................................................. 22

M3660REM

6

This page intentionally left blank.

User’s Manual

7

1. INTRODUCTION

1.1. WHO SHOULD USE

This manual is intended for use by trained personnel responsible for integrating,

installing, maintaining, troubleshooting, or using this equipment with any AC drive

system.

Please keep this manual for future reference.

1.2. PURPOSE AND SCOPE

This manual is a user’s guide for the model M3660REM. It will provide the user with

the necessary information to successfully connect and operate the M3660REM.

In the event of any conflict between this document and any publication and/or

documentation related to any associated hardware (capacitor bank, etc.), the latter

shall have precedence.

1.3. MANUAL VERSION AND CHANGE RECORD

The initial release for this module is Rev 00a.

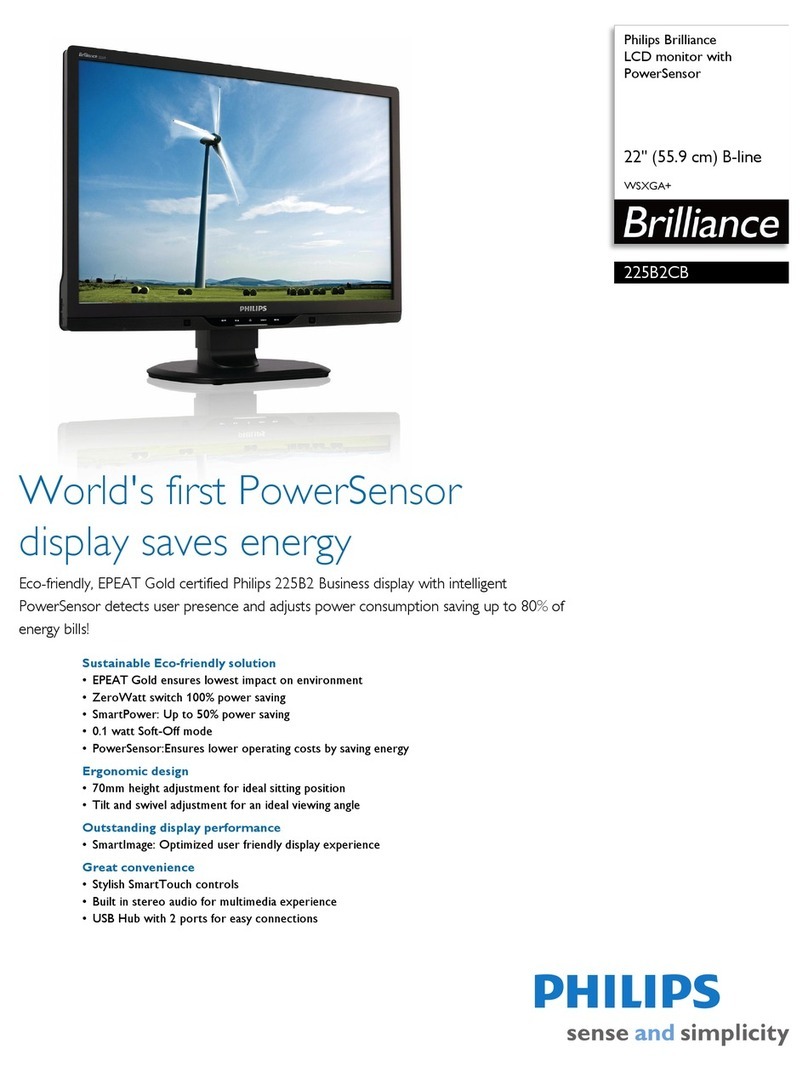

Figure 1-1: M3660REM

M3660REM

8

1.4. SYMBOL CONVENTIONS USED IN THIS MANUAL AND ON

EQUIPMENT

Earth Ground or Protective Earth

AC Voltage

DC Voltage

DANGER!

DANGER: Electrical hazard - Identifies a statement that indicates

a shock or electrocution hazard that must be avoided.

DANGER!

DANGER: Identifies information about practices or circumstances

that can lead to personal injury or death, property damage, or

economic loss.

CAUTION!

CAUTION: Identifies information about practices or circumstances

that can lead to property damage, or economic loss. Attentions

help you identify a potential hazard, avoid a hazard, and

recognize the consequences.

CAUTION!

CAUTION: Heat or burn hazard - Identifies a statement regarding

heat production or a burn hazard that should be avoided.

User’s Manual

9

2. PRODUCT DESCRIPTION / FEATURES

The Bonitron M3660 Regenerative Energy Monitor is a system analysis tool designed to

assist system integrators and end users in the proper sizing of their braking solution:

whether that’s optimizing an existing resistive solution or replacing it with a regenerative

one.

The M3660REM monitors the voltage and current seen by the load resistor; this allows it

to characterize a braking Event by measuring the peak and average currents as well as

calculating the total energy in the Event. This can be helpful information for system

engineers to verify that the braking chopper and/or load resistor are appropriately sized

and rated for the requirements of the application.

2.1. RELATED PRODUCTS

BRAKING TRANSISTORS

M3575T – Standard Duty Braking Transistor (up to 600A)

M3452 – Heavy Duty Braking Transistor (up to 1600A)

BRAKING RESISTORS

M3575R – Standard Duty Braking Resistors (up to 30A)

M3775R – Various Duty Load Banks (up to 1600A)

REGENERATIVE BRAKING

M3545 – Single or 3- Phase Line Regen (up to 15A)

M3645 – Three Phase Line Regen (up to 300A)

M3660REM

10

2.2. PART NUMBER BREAKDOWN

Figure 2-1: Example of Part Number Breakdown

BASE MODEL NUMBER

The base model number for all Regenerative Energy Monitors is M3660REM.

SYSTEM VOLTAGE RATING

The System Voltage rating indicates the maximum AC system voltage for which the

unit is designed to operate.

Table 2-1: System Voltage

RATING CODE SYSTEM VOLTAGE

C Up to 600VAC

MAX CURRENT RATING

The max current rating indicates the maximum DC load current the unit can measure.

M3660REM

C

BAS E MODE L NU MB E R

SYST E M VOL T A GE CO D E

MAX CURRE N T RAT I N G

2000

User’s Manual

11

2.3. GENERAL SPECIFICATIONS

Table 2-3: General Specifications Table

PARAMETER SPECIFICATION

System Voltage Up to 600 VAC

Braking Current 200A / 2000A DC

Controls Six display soft keys

Display Four line, eighty character LCD (4x20)

Unit Size (H x W x D) 13.4" x 11.6" x 6.0"

Weight 6 lbs.

Storage Temp -20°C to + 65°C

Humidity Below 90% non-condensing

Atmosphere Free of corrosive gas and conductive dust

M3660REM

12

2.4. GENERAL PRECAUTIONS AND SAFETY WARNINGS

ELECTROCUTION

HAZARD!

FOR USE BY QUALIFIED AND TRAINED PERSONNEL ONLY!

IMPROPER OPERATION OF THE PRODUCT OR

IGNORING THESE WARNINGS MAY RESULT IN

SERIOUS BODILY INJURY OR DEATH!

BEFORE CONNECTING THE M3660REM TO A

BRAKING

RESISTOR TERMINALS, ENSURE THAT THE SYSTEM IS

POWERED

OFF.

NEVER OPERATE THIS PRODUCT WITH THE E

NCLOSURE COVER

REMOVED.

DANGER!

NEVER ATTEMPT TO SERVICE THIS PRODUCT.

CERTAIN PARTS INSIDE THIS PRODUCT MAY GET HOT DU

RING

OPERATION.

BEFORE CONNECTING THIS DEVICE TO ANY OTHER PRODUCT,

BE

SURE TO REVIEW ALL DOCUMENTATION OF THAT PRODUCT

FOR

PERTINENT SAFETY PRECAUTIONS

.

ANY QUESTIONS AS TO APPLICATION, INSTALLATION, OR SERVICE

SAFETY SHOULD BE DIRECTED TO THE EQUIPMENT SUPPLIER.

User’s Manual

13

3. INSTALLATION INSTRUCTIONS

3.1. ENVIRONMENT

While closed, the M3660REM is water, dust, and crush resistant. When open and in

operation, the unit should be used only in dry, clean areas. Ensure that the interior of

the unit casing is kept dry.

3.2. WIRING AND CUSTOMER CONNECTIONS

The M3660REM is not intended for permanent installation into a drive cabinet; it was

designed as a portable unit, to be used as needed. Therefore, it has no installation

wiring requirements.

M3660REM

14

This page intentionally left blank.

User’s Manual

15

4. OPERATION

4.1. FUNCTIONAL DESCRIPTION

The M3660REM is an analysis tool to help system designers get a better

understanding of the characteristics of their braking Events. It should be attached to

the load resistor terminals, not to the DC Bus directly; this way it only measures the

actual braking energy.

The REM records the following information about each braking Event it detects:

Date The Date that the Event occurred: YYYY:MM:DD

Time Time of Day when the Event occurred: HH:MM:SS

Length Duration of the Event: MM:SS.ms

Energy The total Energy dissipated during the Event (in kJ)

Avg Current The Average Current over the entire Event

Peak Current The Maximum Current reached during the Event

Note: the max save Length of a single saved Event is 30min; if an Event lasts longer

than this limit, it will automatically be split over multiple entries. For example, assume

a braking Event that lasted 42m, 27s. This will be saved as 2 Events: the first with a

Length of 30mins and the second with a Length of 12m, 27s.

In addition to the individual Event records, the Regen Monitor keeps some running

Lifetime Totals:

Number of Events

Total number of Events that have been recorded

Total Duration Total Duration of all recorded Events

Avg Duration Average Duration per Event, based on all recorded Events

Total Energy Total Energy from all recorded Events (in kJ)

Avg Energy Average Energy per Event, based on all recorded Events (in

kJ)

Peak Current Average of the Peak Current values from all recorded Events

Avg Current Average Current per Event, based on all recorded Events

M3660REM

16

4.2. FEATURES

4.2.1. HARDWARE

4.2.1.1. AC POWER INPUT CONNECTOR

The M3660REM is equipped with a standard IEC C14 connector for input

power. This connector mates with a standard C13 cable, commonly used

with desktop computers, to provide power to the unit.

4.2.1.2. VOLTAGE LEADS

The two voltage cables feature a large claw for easy connection to the

load terminals with a finger-safe, 4mm banana plug termination at the

unit.

4.2.1.3. CURRENT CLAMP

The provided Pico TA167 200A/2000A Current Probe connects to the

BNC terminal on the front panel of the unit.

Figure 4-1: Cables

User’s Manual

17

4.2.2. DISPLAY

The digital display presents the user with information about the present status

of the system, including the voltage and current. The display also presents

the user with options to control system operation.

4.2.2.1. DIRECTIONAL BUTTONS

Each of the four buttons corresponds to a direction: up, down, left or right.

Up and Down move the cursor among menu items. On screens where

numbers are input by the user, the Left and Right buttons move the

cursor, while the Up and Down buttons change the selected digits. On

some screens, certain buttons may have no function at all.

4.2.2.2. ENTER AND CANCEL BUTTON

The green Enter button selects menu options. On a menu screen, the red

Cancel button will return you to the previous menu.

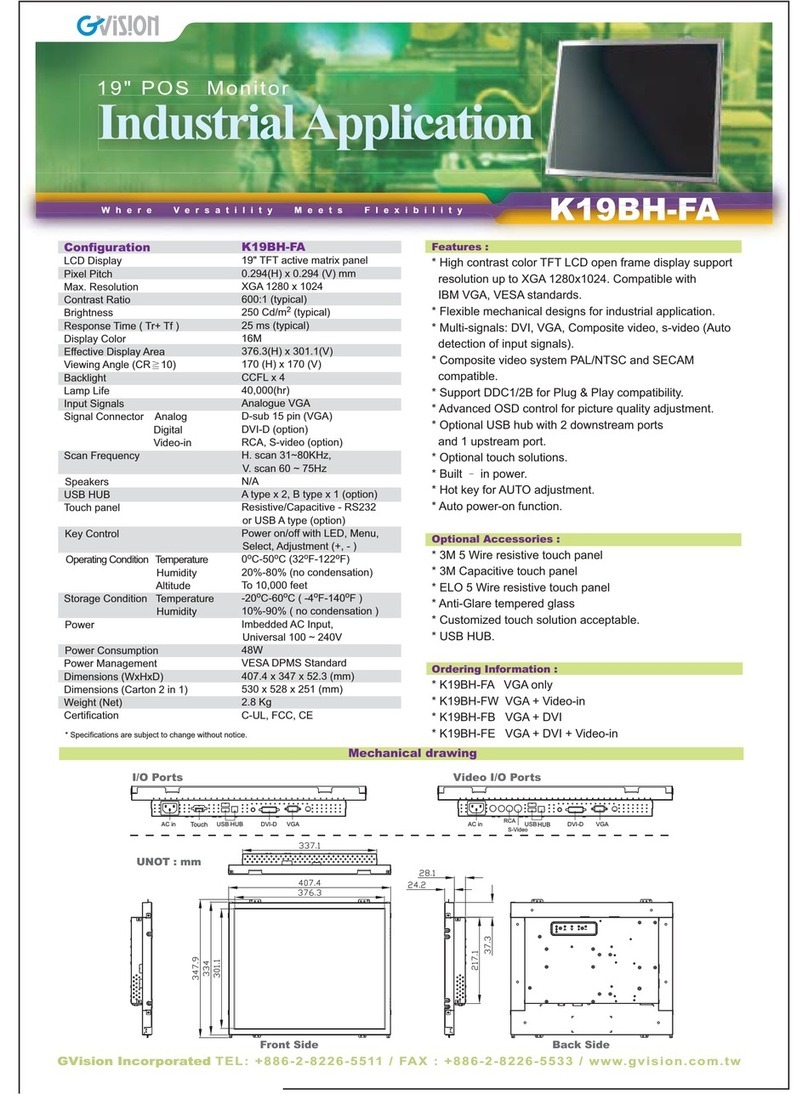

Figure 4-2: Front Panel

M3660REM

18

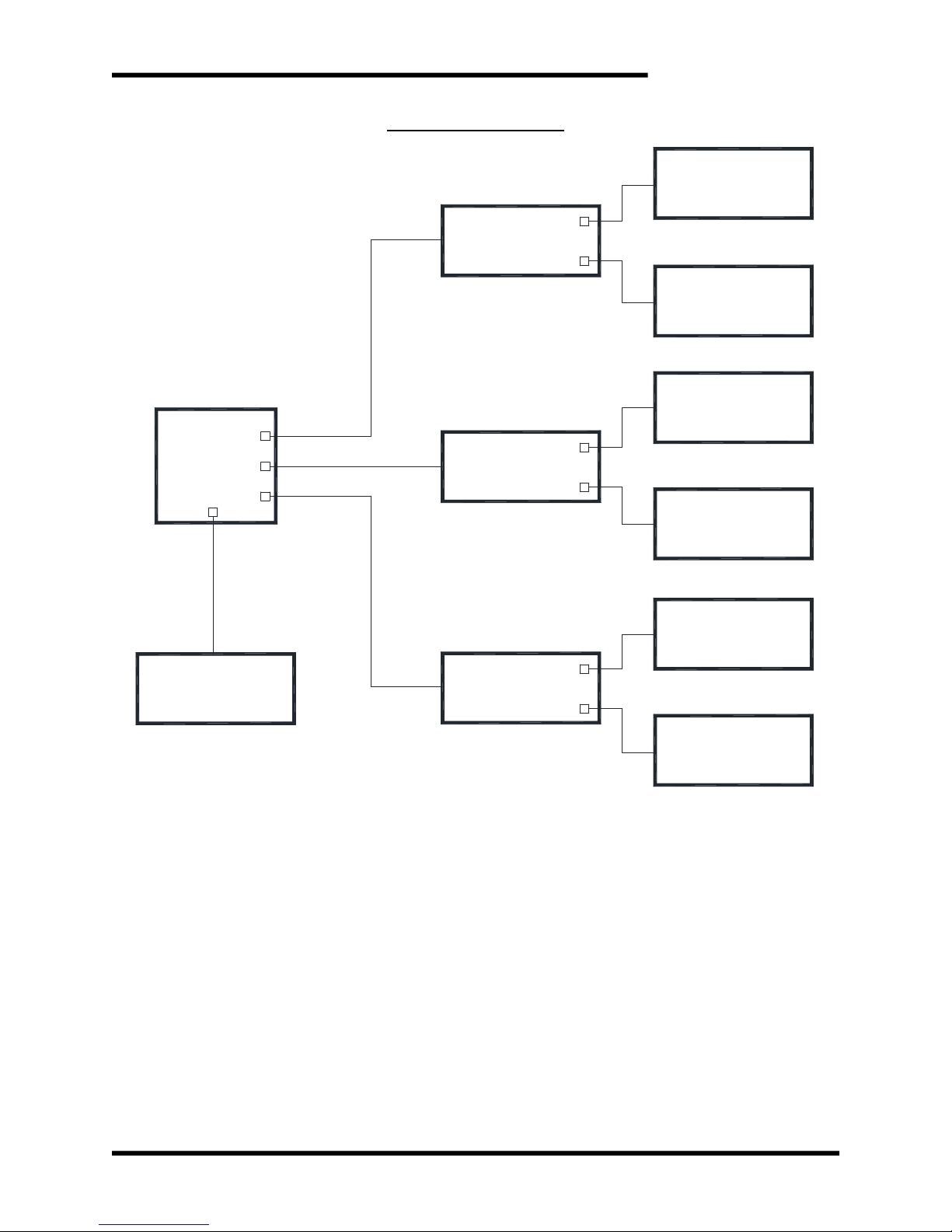

4.2.3. SCREENS & MENU NAVIGATION

Many screens are menus allowing access to other screens, or lists presenting

a number of options. The presently selected item on the menu is indicated by

a ‘>’ cursor. This selection indicator is moved using the Up and Down buttons.

If a line on the menu represents another screen, that screen is accessed with

the Enter button. The Cancel button will return the display to the parent

screen.

4.2.3.1. MAIN MENU

4.2.3.1.1. RECORDS

The Records Menu allows the user to view all saved Event

information. The Events page shows the most recent 50 Events in

chronological order. The Lifetime Stats page shows the

aggregated totals of all Events (since the last reset).

4.2.3.1.2. CONFIGURATION

The Configuration Menu contains all the settings that are user

adjustable.

Set Date/Time: The user can adjust the full timestamp (Year-

Month-Day, Hour-Minute-Seconds) if ever necessary.

Set Current Clamp: The user can swap between 200A and 2000A

settings.

Important

!

The Clamp setting in the unit MUST match the

Range selector on the Pico probe, otherwise the

Current and Energy calculations will be incorrect.

4.2.3.1.3. CLEAR RECORDS

The user can manually erase the saved Event data if desired.

Clear Event Records – This option will erase only the individual

Events list. The Lifetime Stats will remain unaffected.

Clear All Data – This will erase ALL Event data, both the individual

Events as well as the Lifetime totals.

4.2.3.2. STATUS

This screen shows the general status of the unit. While an Event is being

recorded, it will show live data: braking voltage & current and the percent

loading.

User’s Manual

19

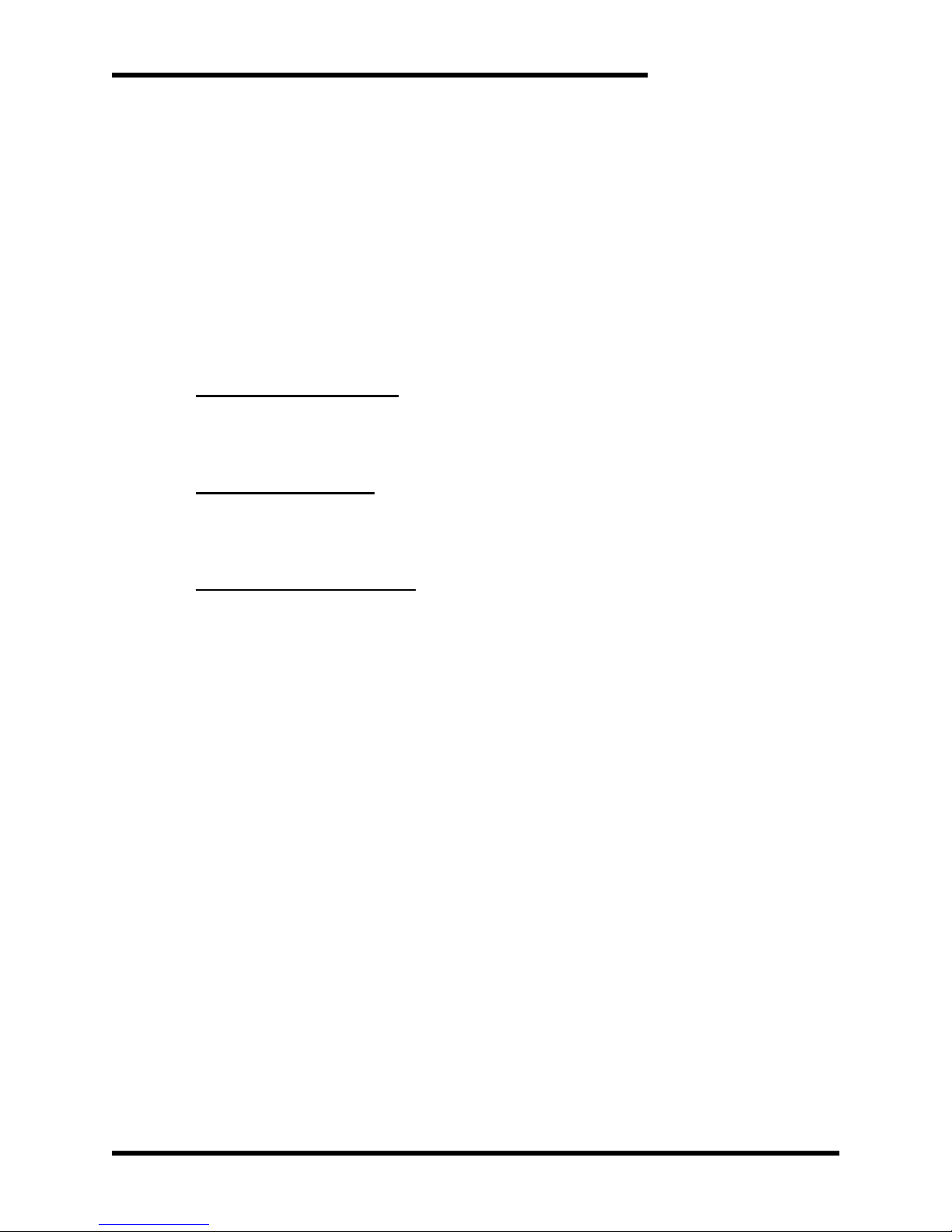

Figure 4-3: Menu Tree

Main

Menu

Clear

Records

Status

Configuration

Records

Individual

Events

Lifetime

Stats

Set

Date/Time

Set Current

Clamp

Clear Event

Records

Clear All

Data

M3660REM

20

5. TROUBLESHOOTING

If a problem occurs on start-up or during normal operation, refer to the problems described

below. If a problem persists after following the steps below, contact the product supplier

or your system integrator for assistance.

Repairs or modifications to this equipment are to be performed by Bonitron approved

personnel only. Any repair or modification to this equipment by personnel not approved

by Bonitron will void any warranty remaining on this unit.

Table 5-1: Troubleshooting

Display never comes on Ensure that the input power cable is connected firmly to the unit

and to a functioning power source at the correct voltage.

If both connections and the power supply are good, make sure

the input circuit breaker has not tripped.

Unit never goes ACTIVE

when a Braking Event occurs

Check the Voltage cables. Ensure they are firmly connected

between the unit and the load and that the polarity is correct.

Incorrect values for the Event

Currents and/or Energy are

being recorded

Check the Current Clamp. Verify that the twist-lock connector is

firmly seated on the front panel and Clamp’s jaws are closed

around the load wires.

Make sure the Current Clamp is powered ON and set to the

appropriate range.

Verify that the Current Clamp setting in the unit matches the range

selector on the Clamp.

Table of contents