Booth EXL651 User manual

Product Manual

EXL651 Still and Carbonated

Water Cooler

Part Number 3B6220 Issue A (24/05/16)

2

Contents

Section Page

Section Page

Introduction & Specification 2 Fault Finding 8

Installation & Commissioning

3 Wiring Schematic 9

Spare Parts 7 Removal, Transportation

and Disposal

10

Introduction

The EXL651 is an ice-bank cooler designed for installation in a cupboard under a worktop,

and incorporates two water cooling coils. It can either be installed in conjunction with a

separate ambient carbonator, the EXL171, to provide still and carbonated water, or on its own

to provide still water only. The pack includes air duct components that must be installed if the

chiller is installed in an otherwise unventilated space.

Specification

Dimensions 330mm(W)

482mm(D)

522mm(H)

Compressor Cubigel

GL60TB

Dry Weight

32.5kg

This product contains fluorinated

greenhouse gas with a GWP of 1300

in an hermetically sealed system

Wet Weight 45.0kg

Supply

230Vac/50Hz

Refrigerant

R134a,

12

0

g

Rated Input 300W Climatic Class N

Rated Current 2A

Fuse Rating 5A Net cooling power

24°C ambient, during

recovery.

570W

IP Rating N/A Nominal ice bank 5kg

Contents

Introduction and Specification

3

Installation and Commissioning

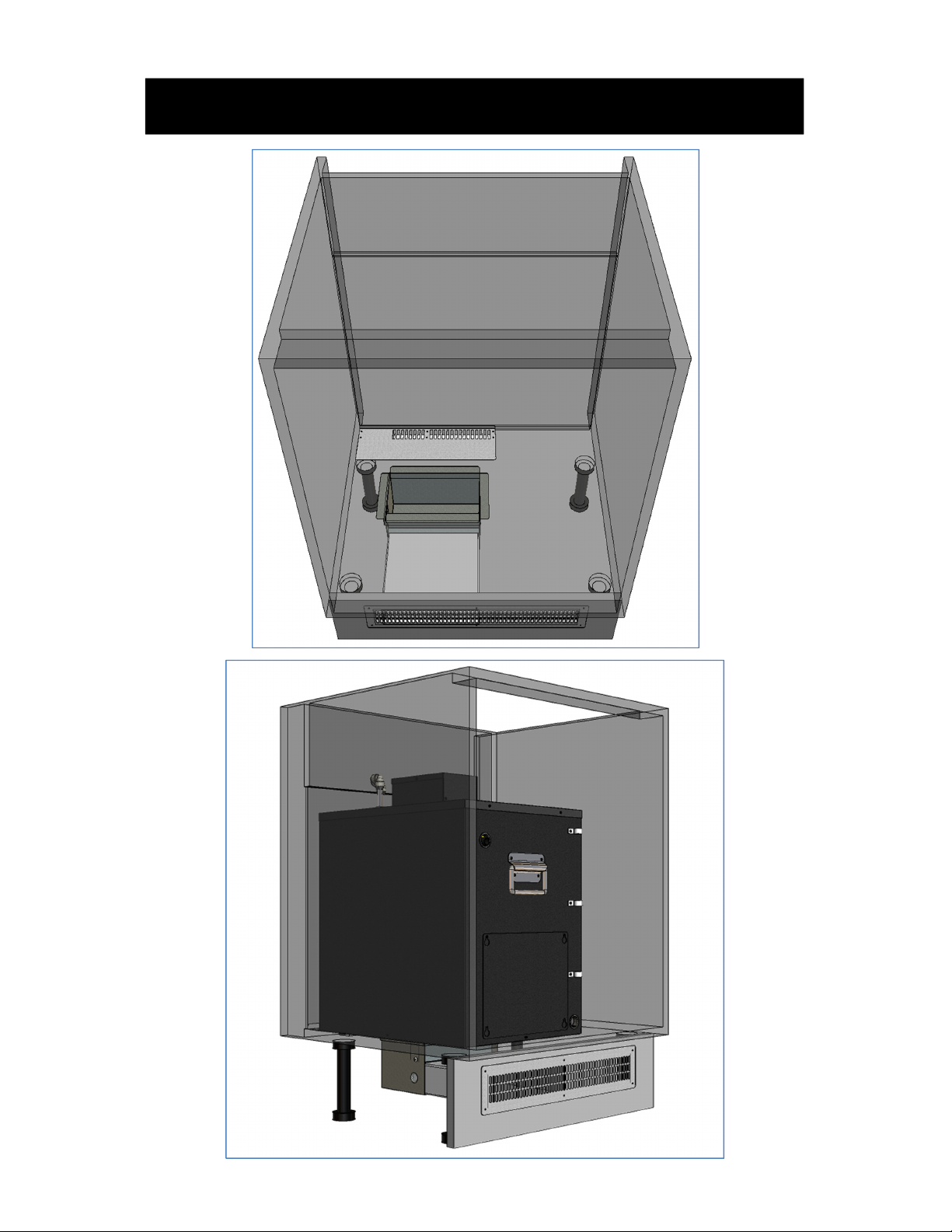

•The EXL651 is designed to be fitted in a cupboard under a worktop, and is supplied

with parts to ensure adequate ventilation is provided. It is essential that these be

used if the unit is to be fitted into an enclosed compartment, if not, this will

seriously affect the reliability of the fridge and will invalidate the warranty. It is

also possible that the heat generated by the fridge will distort the carcass of the

cupboard. The hot exhaust air is ducted down through the base of the cabinet, and

out of the front of the kick-space. Cooler air is drawn into the cupboard through a vent

at the rear, drawing air from the kick space. A facing grill is provided for the kick board

that provides for the location of the exhaust duct, and, if required, additional ventilation

for the kick-space. This additional ventilation will only be required if the kickboard is

sealed to the cabinets, in the majority of cases, there will be sufficient natural

ventilation.

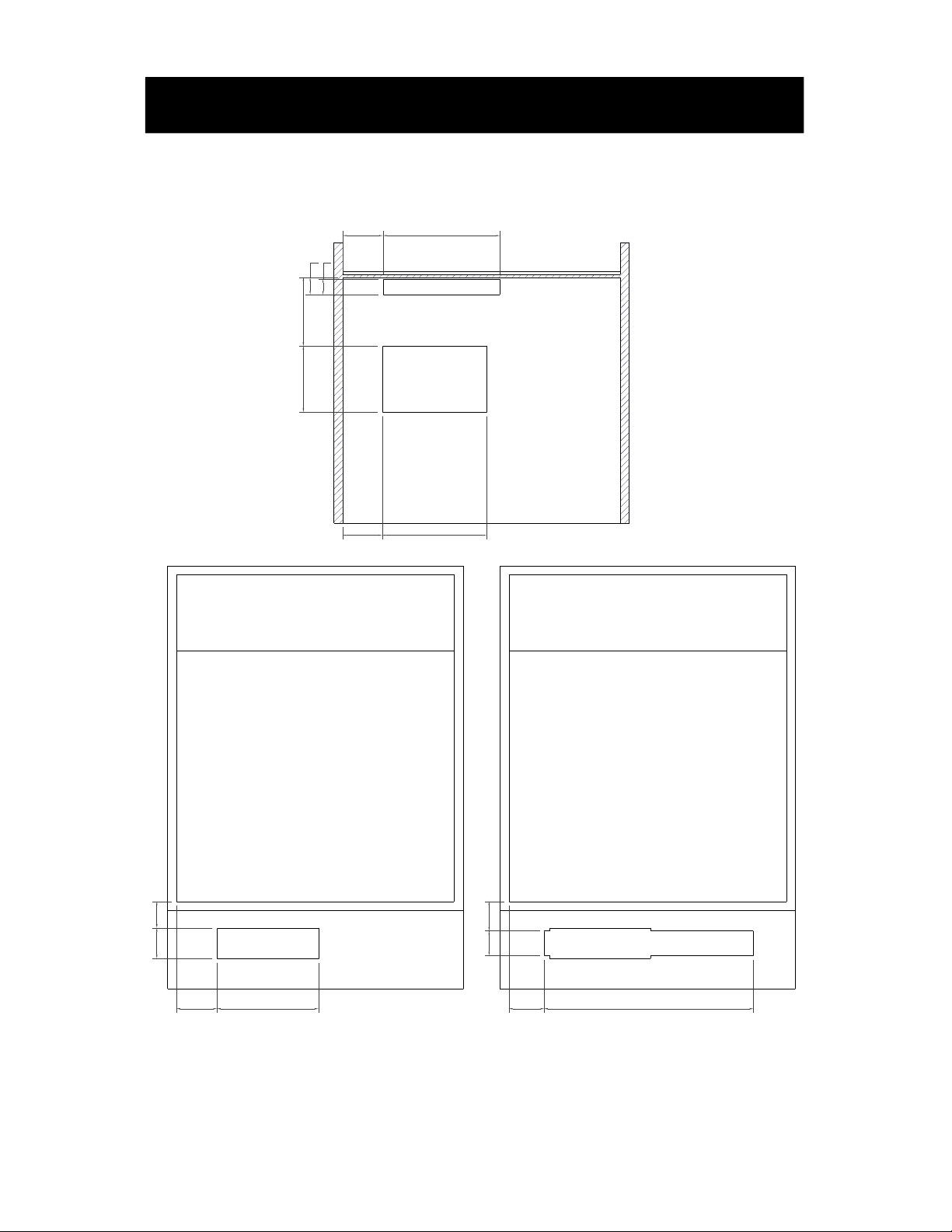

•Templates are provided to help in the location of ventilation openings that need to be

cut into the cabinet base, and kick space, and are designed to allow the EXL651 to be

installed against the left hand side of the cabinet, viewed from the front.

•Align template 3B4614 with the rear left hand side corner of the cabinet, and mark

through the corners of the two cut-outs. Cut out the openings taking care not to cut into

any pipes or cables that may be located under the cabinet.

•Align template 3B4615 with the top left corner of the kick board for the cabinet being

used. Again, mark through and cut-out the area for the exhaust duct, and mark the

fixing positions of the fixing holes.

NOTE: For additional dimension information on cut out sizes and positions please refer to

page 6 of this manual.

•Insert the right angled duct into the large hole in the base of the cabinet, and fix the

rear grill in position over the other gap cut previously.

•Insert the plastic air duct from the front, and ensure it is fully engaged with the right

angled duct. Mark the position on the plastic duct that aligns with the outside face of

the kick board, remove and cut to length.

•If the kick board is sealed to the cupboard and floor, additional ventilation will be

required. Offer up the front grill, aligning the fixing holes, and mark through the extent

of the ventilation openings. Now extend the opening, taking care that the height of this

part of the cut-out is less than that where the exhaust duct is located, this will ensure

the exhaust duct is held in position.

•Refit the exhaust duct, and fasten the front grill in position.

Installation and Commissioning

4

•Place the EXL651 into the cabinet with the rubber bump-stops to the rear, aligning the

left side to the left side of the cabinet. Push in until the bump stops contact the rear of

the cabinet. The exhaust grill on the bottom of the machine will now align with the cut-

out in the base of the cabinet.

•Place a suitable container under the bath overflow, a small plastic bottle is provided

for this purpose.

•Fill the bath with cold water through the opening on the top of the machine until water

is displaced from the over flow.

•Connect power to the machine and switch on. The fan and compressor will start, and

the machine will start to cool down.

•The machine can now be connected to the other components of the water system, and

once a full ice bank is produced, the fans and compressor will switch off, and the

machine is ready for use.

Installation and Commissioning

5

Installation and Commissioning

6

80 212

134 140

36 32

23882

82

54

206

62

Top View

Front View

Standard Cutout

72

60

425

50

Front View

Extended Cutout

All dimensions are based around a standard 600mm wide kitchen cabinet.

Installation and Commissioning

7

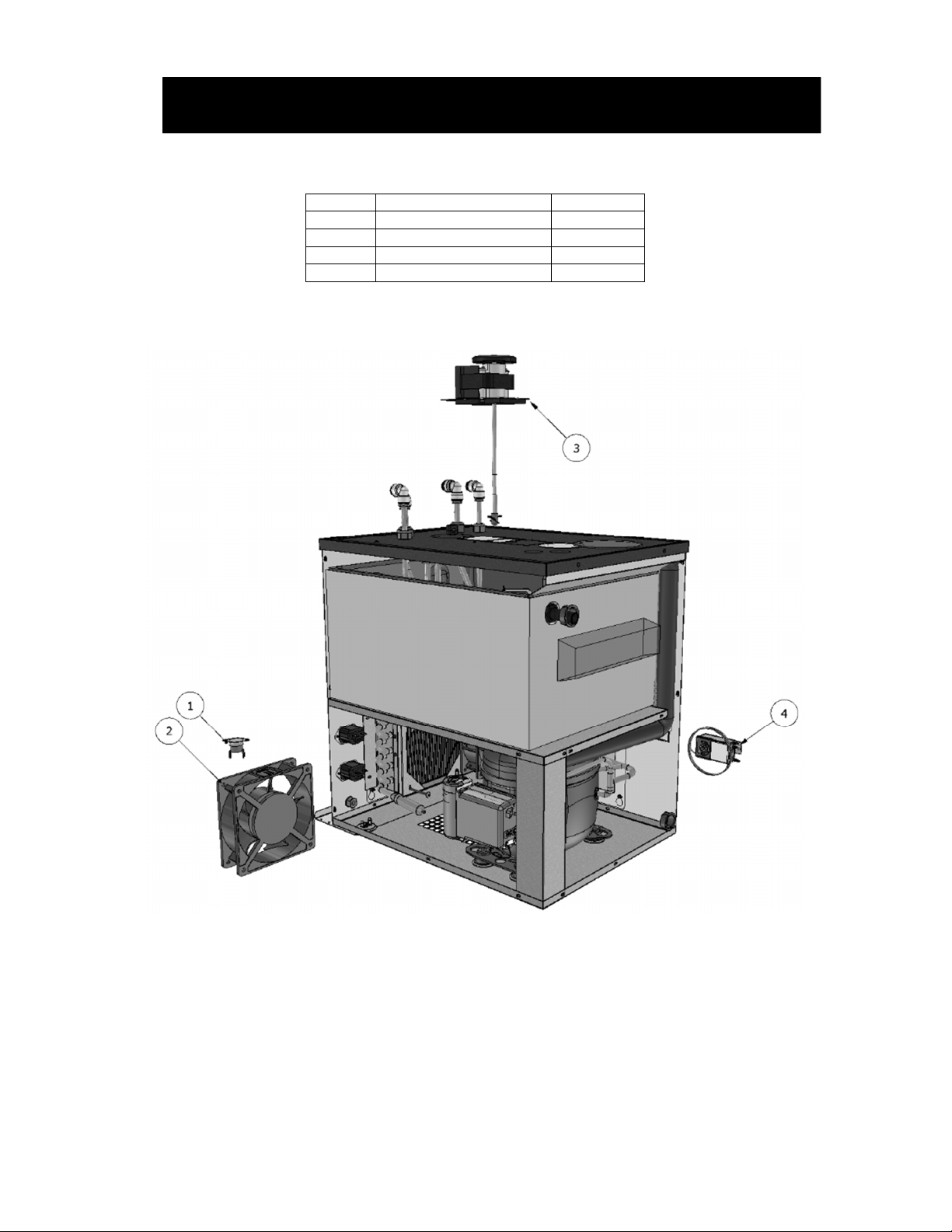

Item No

Description

Part No

1 High Side Protector 3B3963

2 Axial Fan 1B5514

3 Agitator Assembly 1A5237

4 Control Thermostat 1A4714

Spare Parts

8

Prior to any fault finding, please ensure all water connections to the chiller are sound and that the

incoming water supply is turned on. Also ensure that all electrical connections to the chiller and in

the chiller are secure and in good condition, the power is on and that the chiller has had adequate

time to reach operating temperature.

NOTE: When checking electrical connections ensure mains power is switched off.

No Drinks Water supply Check connections to water supply.

Check water supply is turned on.

Check system for blockages.

Frozen product coil Check thermostat probe is correctly located into the

bath probe well.

Check the agitator is running. If supply voltage is

present renew agitator assembly.

If agitator is running with no water agitation check

agitation blades.

Warm Drinks Insufficient air flow through

the fridge.

Check that the condenser is not blocked.

Check for blockages and obstructions to ventilation

grills.

If in enclosed cabinet check supplied ventilation kit

is fitted and can ventilate to cool air supply.

Cooling Fans Not running Check supply to cooling fans.

If supply present replace fans.

If supply not present check connections,

thermostat, high side protection and fuse.

Compressor not running Check supply to Compressor.

If supply present return for repair.

If supply not present check connections, thermostat,

high side protection and fuse.

Fridge failure If compressor & fan are running and there is no

cooling, return for repair.

Fault Finding

9

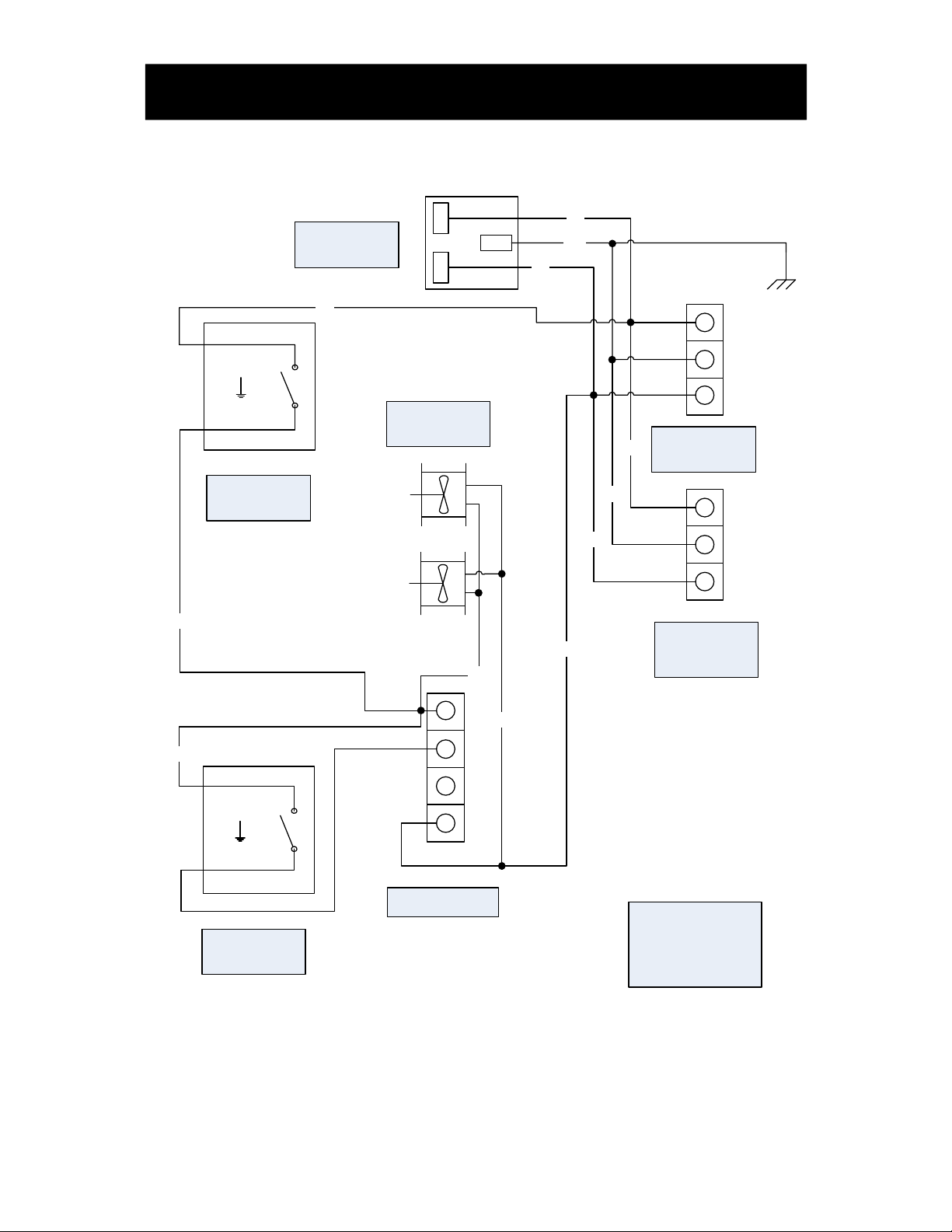

G/Y

BR

L

N

FUSED MAINS

PLUG

BU

BR

G/Y

BR

L

NC

E

N

WH

WH

YE

BU

BU

BU

AGITATOR IEC

CONNECTOR

CARBONATOR

IEC

CONNECTOR

CONDENSOR

FANS

COMPRESSOR

CONTROL

THERMOSTAT

HIGH SIDE

PROTECTOR

NOTE

SOME EARTH

CABLES (G/Y)

OMITTED FOR

CLARITY

Wiring Schematic

10

Important: Before removal from the installation, ensure all electrical, product and gas

connections are disconnected.

Disposal of Scrap Units

It is illegal to simply scrap a refrigeration unit. Before a unit can be scrapped it must first have the gas

removed by a specialist using special equipment. Please contact Booth Dispensers Ltd., who will be

happy to provide a quotation for disposal.

Transportation

Important: This unit must be transported in an upright position

As with all refrigeration systems, irreparable damage can be caused by laying the unit on its side or

even transporting upside down. Where the unit is transported by a carrier, the carton should always

be marked in a conspicuous manner, the correct upright position in which it must be handled.

If a unit has been transported incorrectly it should be placed in the correct upright position and left for

24 hours before attempting to run the system.

Failure to observe the above precautions could seriously damage the system, and would void any

warranty.

Removal, Transportation and Disposal

Booth Dispensers Ltd, Moor Park Avenue, Blackpool,

Lancashire, FY2 0LZ, UK

+44 1253 501800

Table of contents

Other Booth Water Dispenser manuals

Popular Water Dispenser manuals by other brands

Kenmore

Kenmore 625.388180 owner's manual

Water Control Corporation

Water Control Corporation BrassMaster Installation & operation manual

Haws

Haws H1107.8 Installation, operation & maintenance instructions

Murdock

Murdock A171.8FGVR Series Installation & maintenance instructions

Lancaster

Lancaster 7-LMC56-75B Installation, operating and service manual

Daewoo

Daewoo DAWS-10L user manual

Elkay

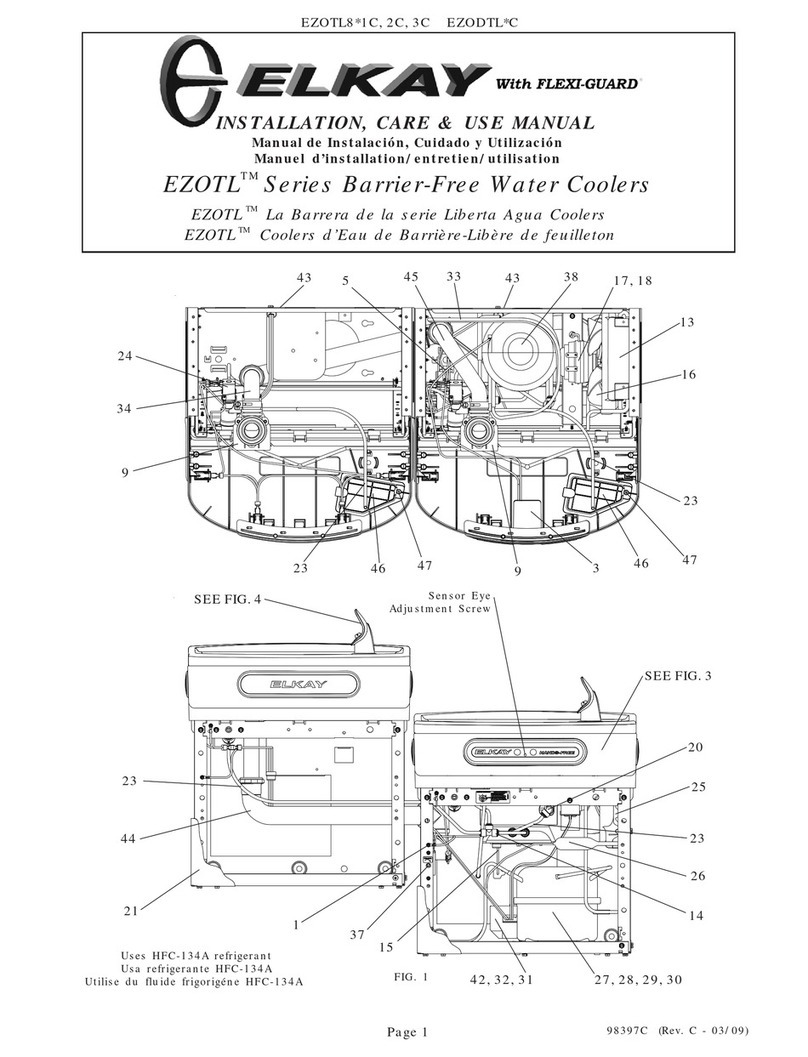

Elkay EZOTL FLEXI-GUARD Series Installation, care & use manual

Watts Premier

Watts Premier UC-2 Installation, operation and maintenance manual

IONICO

IONICO IQ Homeowner's manual

Hoshizaki

Hoshizaki DM-200B parts list

RAMTONS

RAMTONS RM/558 instruction manual

WaterLogic

WaterLogic WL400 Series Troubleshooting