EN

3

IMPORTANT: BEFORE STARTING THE EQUIPMENT, READ THE CONTENTS OF THIS MANUAL,

WHICH MUST BE STORED IN A PLACE FAMILIAR TO ALL USERS FOR THE ENTIRE OPERATIVE

LIFE-SPAN OF THE MACHINE.

1. GENERAL SAFETY PRECAUTIONS

ELECTRIC SHOCK

• Electric shocks are hazardous and potentially may be fatal.

• Install and earth the welding machine according to the applicable regulations.

• Do not touch live electrical parts.

• Never operate the machine with the covers removed.

• Maintain the machine in a good, safe operating condition.

MOVING PARTS

• Moving parts can cause injury or catch loose clothing.

• Always ensure panels and covers are tted before operation or maintenance.

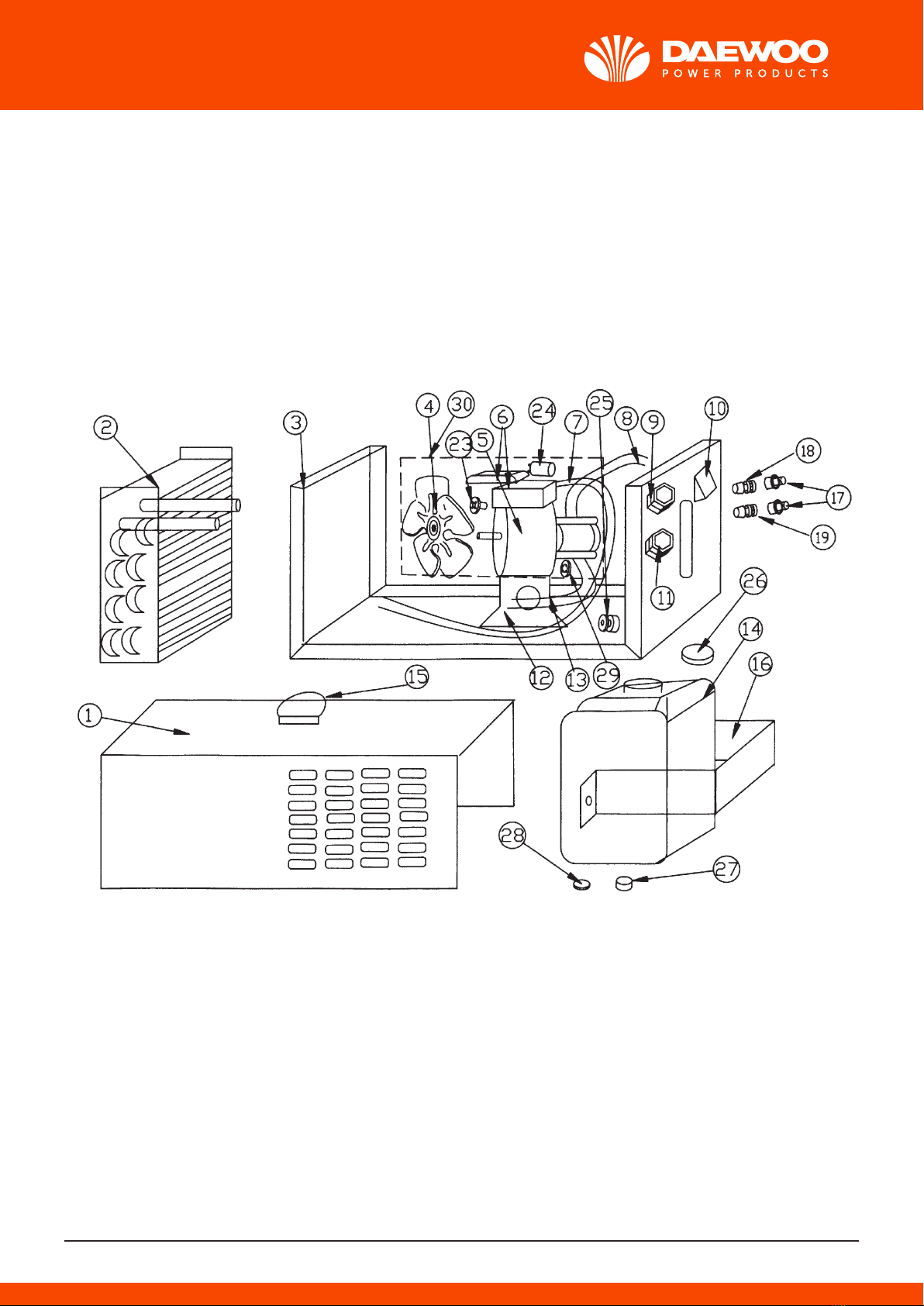

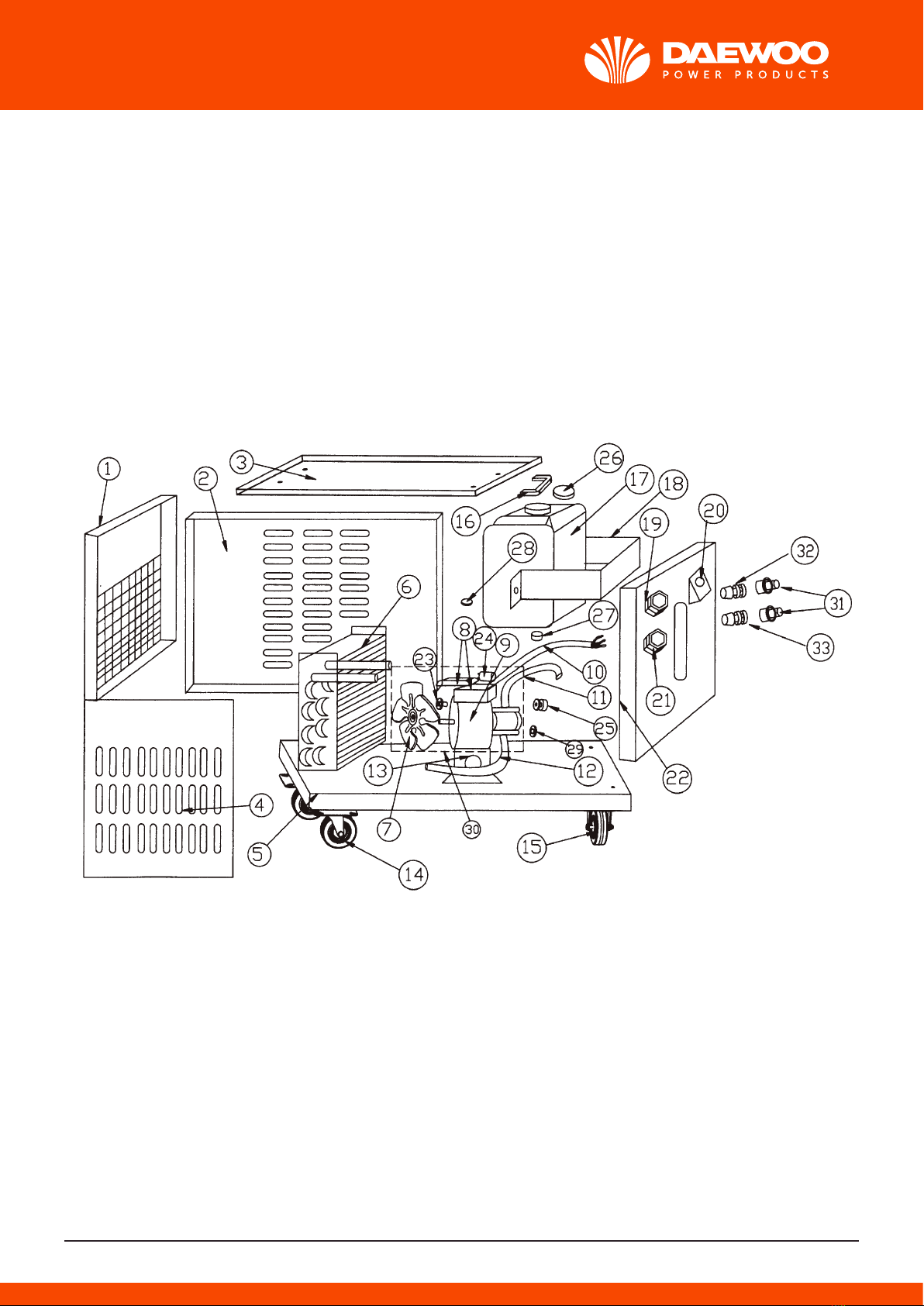

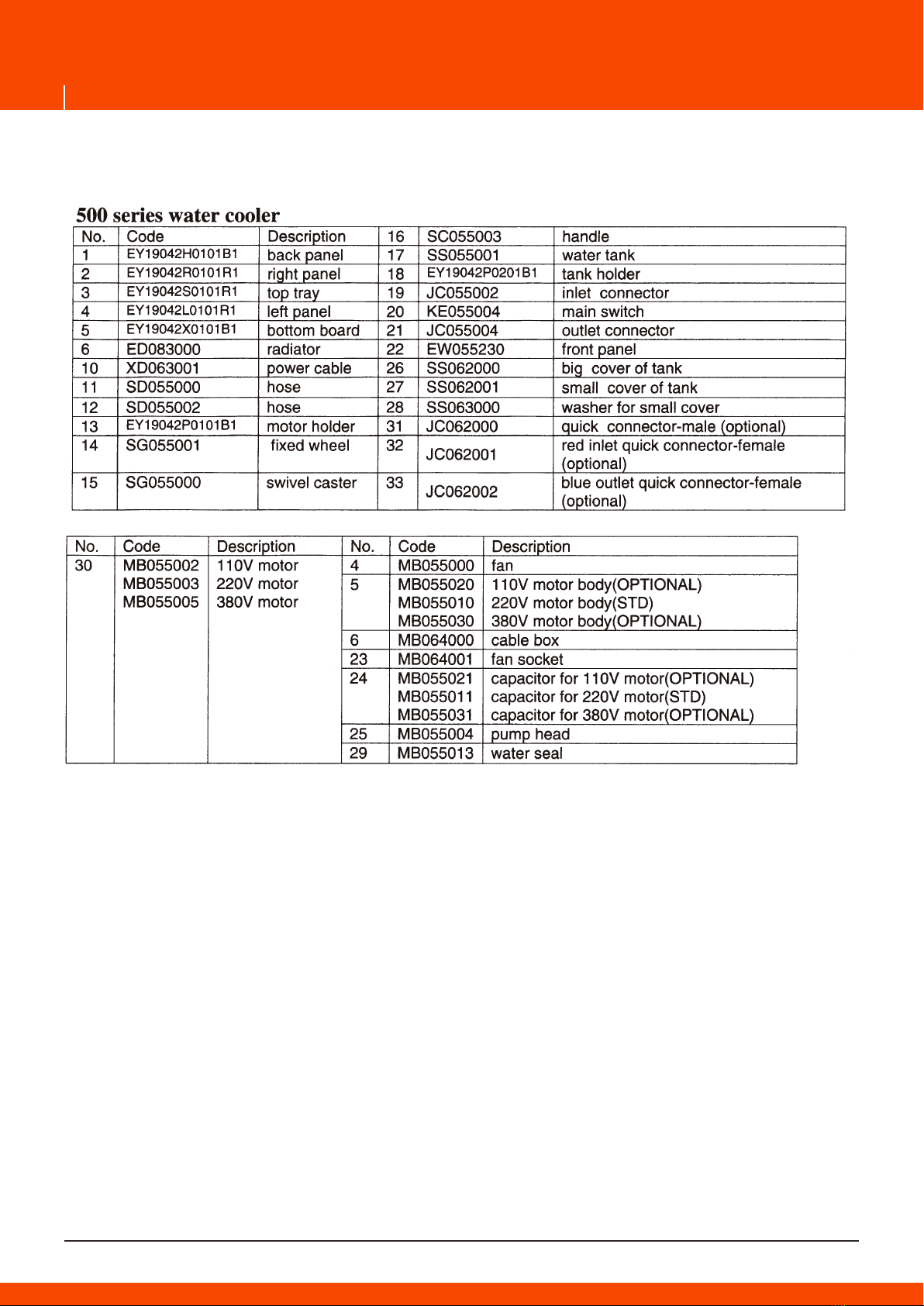

2. DESCRIPTION

This equipment is ideal for cooling torches and welding applications by means of water recirculation

via a closed system. The system comprises the following main parts:

• Single phase motor

• Brass pump for long life

• Coolant tank

• Radiator

• Mains switch

Some of the key features of the unit are:

• Corrosion free

• No priming required

• Quick ll and drain.

• Low and easy maintenance

3. PRECAUTIONS

1. For long time not using the cooler, Re-start the motor and make sure the water is pumped out to

prevent water cooling torch damaged.

2. Make sure the tank is lled with enough clean water and all the connectors is xed rmly.

Always sure the water tank is kept enough water over the safety line. Pump may be damaged while the

tank is without water.

3. Make sure the input voltage is correct. See the technical data. Or motor may be burn out!

4. If the motor works well (there is windy from the radiator), but the water draining is small or no

water, please pump in pressure air from compressor to inlet or outlet for 20seconds.

5. When the motor can't work:

a. The input voltage is too low, please change the electric supply.

b. When the starting capacitor is burn out, please change a new one.

c. The pump can't work if the motor stop long time. Please pump air into

the INPUT or OUTPUT for 20sec. Make the pump work again.

d. The motor has to be replaced if it is burnt out.

6. When this equipment incline too much, the water in tank may overow, the motor pump becomes

a short lifetime. Precautions against toppling-over, if the system shall be placed on a tilted plane.

7. This equipment is used for cooling the torch of welder, so that the torch doesn't burn-up for the

over high temperature. The cooling uid must be pure water or distilled water to avoid the torch or

cuprum walls up and burn-up the torch. Please add water upper warn line, when the water under the

warn line 3CM. If the water in tank has been used for a long time and very dirty, please open the cover

under the bottom of the tank and change the new water.

8. Because there is a motor in the equipment, the water cooler can't be used in the rain. No

water is allowed to come in the loop of the motor avoiding a shortage to burn-up the motor.

4 . I NS TALL ATI ON

1. Conrm the input voltage. (See the nameplate that on the machine. Incorrect input voltage will

damage the machine.)

2. Insert the OUTLET of the water cooler into the INLET of the welding machine

3. Insert the INLET of the water cooler into the OUTLET of the welding machine

4. The user is responsible for the installation and use of the equipment according to the instructions

provided in this manual. The equipment is designed for use in industrial environments.

The equipment is powered from a suitable power socket. Connect the outlet of the cooler unit to the

inlet of the welding unit. Connect the inlet of the cooler unit to the outlet of the welding unit.

IMPORTANT - The unit should be switched on at all times during welding to prevent damage

to torches and cables

Ensure the unit is lled with water and checked once the cables and hoses have been lled following

the start of the machine. If the unit is to be used in cold climates it is recommended that antifreeze

(glycol) is added to the water. Do not use antifreeze with propylene as this may cause the pump to

seize.

5. MAINTENANCE

Warning - Before carrying out any internal inspection disconnect the unit from the mains supply

• Don't use of unsuitable and conductive cooling uid

• Periodically check the level of the cooling uid

• Add uid when the level drops below the minimum level indicator

• Add antifreeze when the room temperature is below 10 °C .

• Make sure all the joints are tight and there are no leaks

• Periodically clean the radiator with clean dry air to eliminate blockages that may affect the efciency

IMPORTANT - Always use original spare parts which have been specially designed for the equipment.

The use of alternate parts may affect the performance of the unit.

• After long periods of not being used ensure the water is circulating freely through the system.

• The pump may be damaged if run with insufcient coolant

• Ensure the unit is connected to a suitable mains supply.

• The motor will not run if:

The mains voltage is to low

The start capacitor is defective

The motor is defective

The motor has not been used for a long period. This may be corrected bypumping compressed

air into the water inlet or outlet connection for 20sec.