PAGE 7

SERVICE INSTRUCTIONS

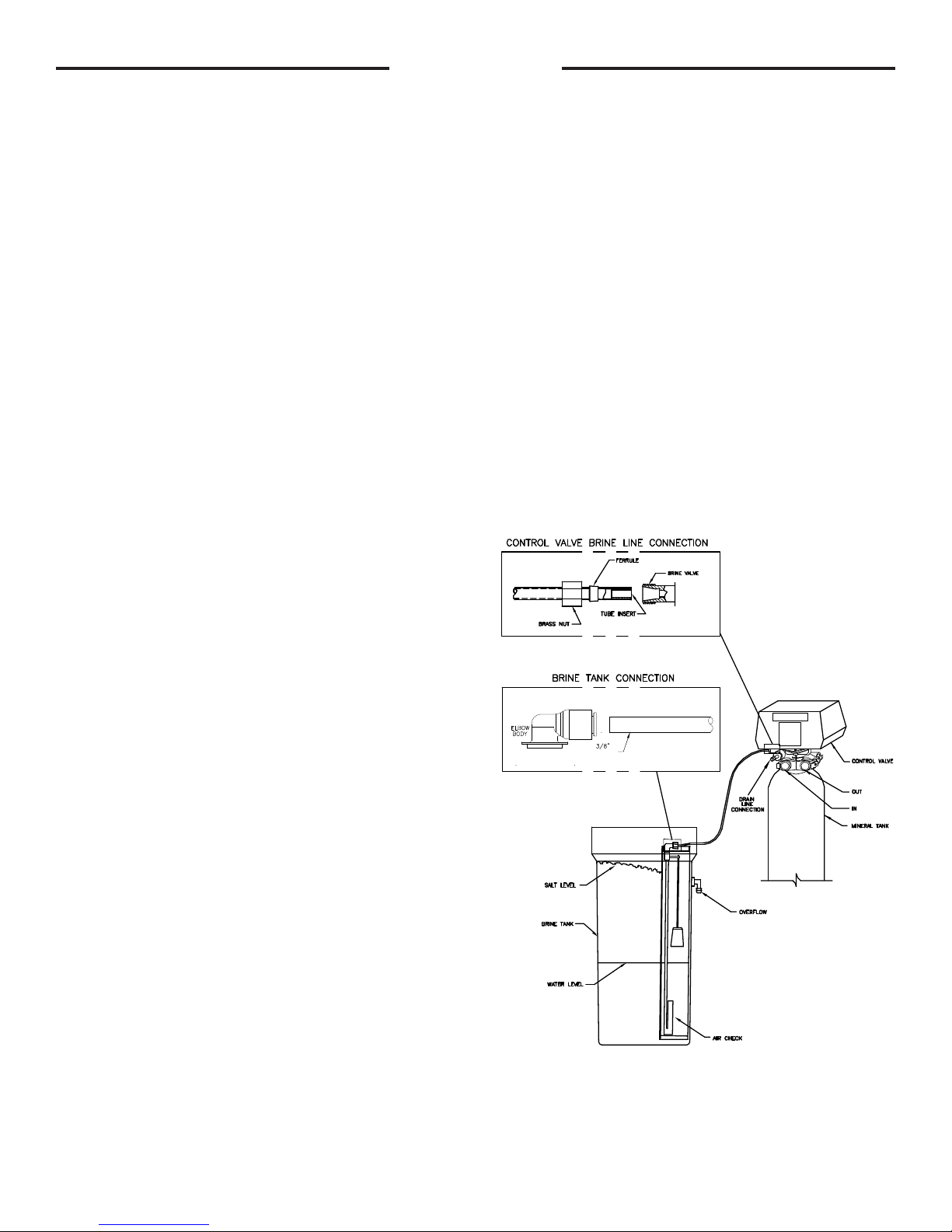

TO REPLACE BRINE VALVE, INJECTORS, AND SCREEN: Unplug electrical cord from outlet. Turn off water supply

to softener. Relieve water pressure in the softener by putting the control in the backwash position momentarily. Return the con-

trol to the service position. Disconnect brine tube and drain line connections at the injector body. Remove the two injector body

mounting screws. The injector and brine module can now be removed from the control valve. Remove and discard valve body

O-Rings.

TO REPLACE BRINE VALVE: Pull brine valve from injector body, also remove & discard O-Ring at bottom of brine

valve hole. Apply silicone lubricant to new O-Ring and reinstall at bottom of brine valve hole. Apply silicone lubricant to O-Ring

on new valve assembly and press into brine valve hole, shoulder on bushing should be ush with injector body.

TO REPLACE INJECTORS AND SCREEN: Remove injector cap and screen, discard O-Ring. Unscrew injector nozzle

and throat from injector body. Screw in new injector throat and nozzle, be sure they are seated tightly. Install a new screen. Ap-

ply silicone lubricant to new O-Ring and install around oval extension on injector cap.

Apply silicone lubricant to the three new O-Rings and install over three bosses on injector body. Insert screws with washers

through injector cap and injector. Place this assembly through hole in timer housing and into mating holes in the valve body.

Tighten screws. Reconnect brine tube and drain line. Return bypass or inlet valving to normal service position. Water pressure

should now be applied to the softener. Check for leaks at all seal areas. Check drain seal with the control in the backwash

position. Plug electrical cord into outlet. Set time of day and cycle the control valve manually to assure proper function. Make

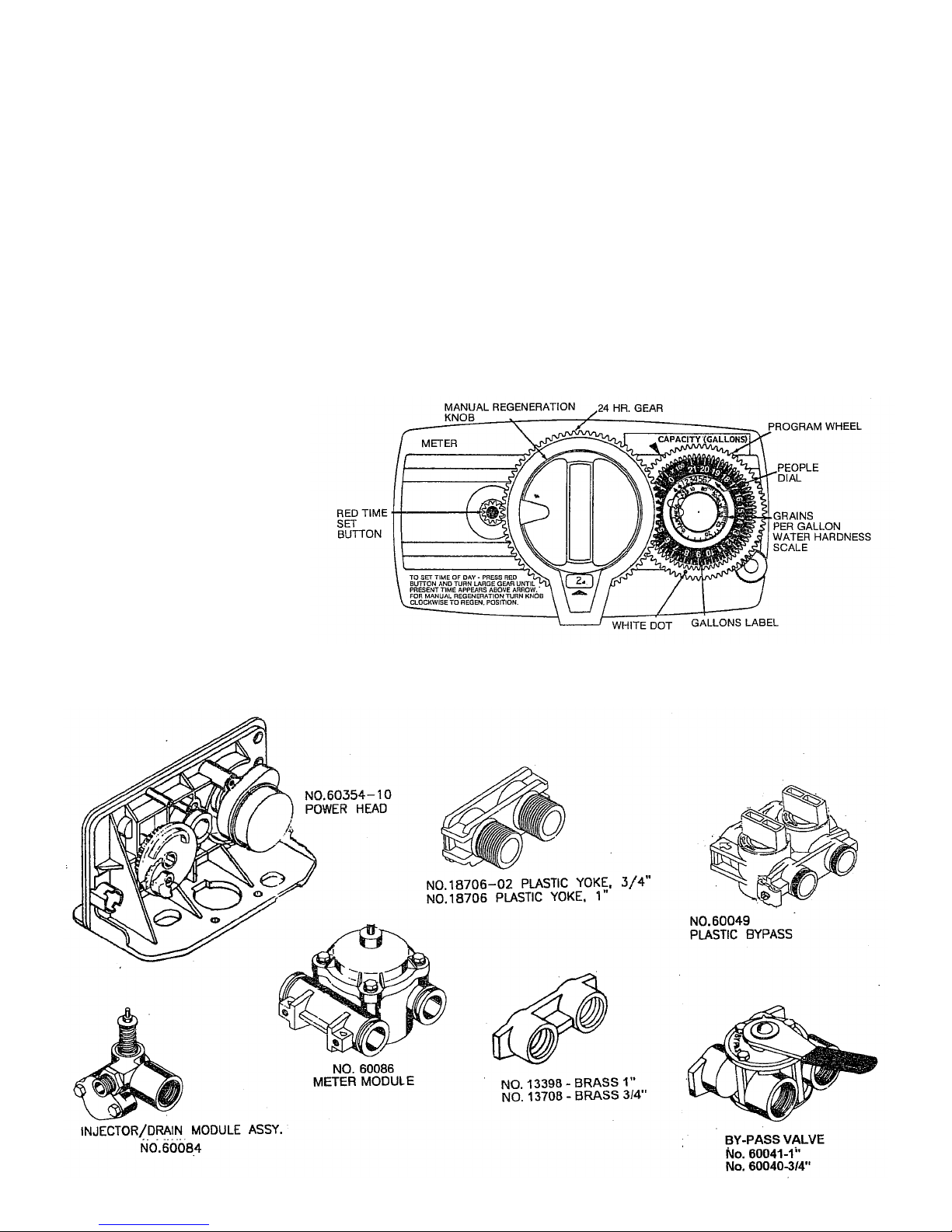

sure the control valve is returned to the service position. Make sure there is enough brine in the brine tank. Rotate program

wheel counter-clockwise until it stops at regeneration position. Start regeneration cycle manually if water is hard.

TO REPLACE PISTON ASSEMBLY: Unplug electrical cord from outlet. Turn off water supply to softener. Relieve water

pressure in the softener by putting the control in the backwash position momentarily. Return the control to the service position.

Pull cable out of meter cover. Remove screw and washer at drive yoke. Remove timer mounting screws. The entire timer as-

sembly will now lift off easily. Remove end plug retainer plate. Pull upward on end of piston yoke until assembly is out of valve.

Inspect the inside of the valve to make sure that all spacers and seals are in place, and that there is no foreign matter that would

interfere with the valve operation. Take new piston assembly as furnished and push piston into valve by means of the end plug.

Twist yoke carefully in a clockwise direction to properly align it with drive gear. Replace end plug retainer plate. Place timer on

top of valve. Be sure drive pin on main gear engages slot in drive yoke (rotate control knob if necessary). Replace timer mount-

ing screws. Replace screw and washer at drive yoke. Return bypass or inlet valving to normal service position. Water pressure

should now be applied to the softener. Plug electrical cord into outlet. Set time of day. Cycle the control valve manually to assure

proper function. Make sure the control valve is returned to the service position. Be sure grommet at cable hole is in place. Make

sure there is enough brine in the brine tank. Rotate program wheel counter-clockwise until it stops at regeneration position. Start

regeneration cycle manually if water is hard. Plug cable into meter cover. Rotate cable to align drive at if necessary.

TO REPLACE SEALS AND SPACERS: Unplug electrical cord from outlet. Turn off water supply to conditioner. Relieve

water pressure in the softener by putting the control in the backwash position momentarily. Return the control to the service posi-

tion. Pull cable out of meter cover. Remove screw and washer at drive yoke. Remove timer mounting screws. The entire timer

assembly will now lift off easily. Remove end plug retainer plate. Pull upward on end of piston rod yoke until assembly is out of

valve. Remove and replace seals and spacers with ngers.

TO REPLACE METER: Unplug electrical cord from outlet. Turn off water supply to conditioner. Relieve water pressure in the

softener by putting the control in the backwash position momentarily. Return the control to the service position. Pull cable out of

meter cover. Remove two screws and clips at bypass valve or yoke. Pull resin tank away from plumbing connections. Remove

two screws and clips at control valve. Pull meter module out of control valve. Apply silicone lubricant to four new O-Rings and

assemble to four ports on new meter module. Assemble meter to control valve. Note, meter portion of module must be assem-

bled at valve outlet. Attach two clips and screws at control valve. Be sure clip legs are rmly engaged with lugs. Push resin tank

back to the plumbing connections and engage meter ports with bypass valve or yoke. Attach two clips and screws at bypass

valve or yoke. Be sure clip legs are rmly engaged with lugs. Return bypass or inlet valving to normal service position. Water

pressure should now be applied to the softener. Check for leaks at all seal areas. Plug electrical cord into outlet. Set time of day.

Make sure the control valve is in the service position. Rotate program wheel counter-clockwise until it stops at regeneration posi-

tion. Start regeneration cycle manually if water is hard. Plug cable into meter cover. Rotate cable to align drive at if necessary.

TO REPLACE METER COVER AND/OR IMPELLER: Unplug electrical cord from outlet. Turn off water supply to

softener. Relieve water pressure in the softener by putting the control in the backwash position momentarily. Return the control

to the service position. Pull cable out of meter cover. Remove four screws on cover. Lift cover off of meter module, discard O-

Ring. Remove and inspect impeller for gear or spindle damage, replace if necessary. Apply silicone lubricant to new O-Ring and

assemble to the smallest diameter on meter cover. Assemble cover to meter module. Be sure impeller spindle enters freely into

cover. Press rmly on cover and rotate if necessary to assist in assembly. Replace four screws and tighten. Return bypass or

inlet valving to normal service position. Water pressure should now be applied to the softener. Check for leaks at all seal areas.

Plug electrical cord into outlet. Set time of day. Make sure the control valve is in the service position. Rotate program wheel

counter-clockwise until it stops at regeneration position. Start regeneration cycle manually if water is hard. Plug cable into meter

cover. Rotate cable to align drive at if necessary.