Booth TRM9HC User manual

Product Manual

TRM9HC

Water Cooler

Part Number 3B8108 Issue OR

2

Contents

Safety

The TRM9HC model uses a R290 (Care 40, Propane) refrigerant. Below are some

safety points which the end user must adopt to mitigate the risk of unsafe conditions

arising.

Service must only be carried out by a suitably qualified refrigeration engineer.

The unit must be isolated from the electricity supply before removal of the

covers.

Do not damage/puncture the refrigeration circuit.

This unit is not intended for use in lobbies or locations of egress, such as

hallways or public corridors.

Ventilation openings must be clear of obstructions.

There must be a gap of at least 100mm between the appliance and a wall or

other restriction.

Where components are replaced, the new component must be of the same

type.

Operate the unit within (ambient) operating temperatures; 16⁰C to 38⁰C.

Introduction

The TRM9HC is a dry block chiller designed to provide chilled still water by passing water

through a stainless steel water coil in the “cold block”. The TRM9HC in standard

configuration is designed as a single product chiller with an option of two depending on

targeted drink temperature.

Important: It is essential that the TRM9HC be turned off during cleaning to prevent

the cleaning fluid in the product line from freezing.

Section

Page

Section

Page

Safety, Introduction & Specification

2-3

Fault Finding

9

Installation &

Commissioning

4

Replacement Parts

10

Cleaning

5-6

Removal, Transportation

and Disposal

11

Schematics

7-8

Introduction and Specification

3

Specification

Dimensions

470mm(W)

425mm(D)

260mm(H)

Compressor

Cubigel

NLY12RAa

Dry Weight

27Kg

This product contains fluorinated

greenhouse gas with a GWP of 3 in an

hermetically sealed system

Supply

220-240Vac/50Hz

Climatic Class

N

Power

Consumption

168W

Refrigerant

290a 55g

(0.055Kg)

Introduction and Specification

4

1. The TRM9HC unit should be located on a firm level surface capable of holding the

weight, as close to the dispense point as possible, and orientated so that the on/off

switch and Eliwell control are accessible. Ensure at least 100mm of space is left all-

round the unit to allow adequate airflow for cooling.

2. Connect using John Guest fittings to “Product In” on the front of the cooler.

3. Connect using John Guest fittings to “Product Out” on the front of the cooler and feed

the insulated product line to the dispense tap.

Note: At this stage do not connect the unit to the electrical supply.

4. Connect the chiller to the water supply and open the mains supply isolation valve.

5. Activate the still water dispense until all air has been purged from the system.

6. Once all air has been purged from the system, connect the unit to the electrical supply

and turn on. After a short delay the compressor and fans will start.

7. After approximately 10 minutes, the compressor and fan will stop as the chiller has

reached its normal operating temperature. Note: The time taken for the chiller to

reach operating temperature will vary depending on ambient temperature,

humidity and the temperature of the incoming water supply.

8. Maintenance: Wipe occasionally with damp cloth.

9. If compressor or thermostat problems occur the control will shut the compressor off

and display an error code. This should be quoted when requesting assistance.

Product Connections

Connection

Connection Size/Type

Product In

1/2” John Guest Speed Fit

Chilled Product Out

1/2” John Guest Speed Fit

Installation and Commissioning

Product Out

Product In

5

Important:

The frequency of the following cleaning procedures should be

determined locally and may vary depending on machine usage and

environmental conditions.

Warm water should be no higher than 45°C.

After any cleaning procedure, dispense 1 litre of water from each tap to

ensure any cleaning residue is flushed out.

Routine Clean - Use the appropriate methods below.

Important: It is recommended that the routine clean procedure be performed at least

weekly.

Multi-Purpose Disposable Cloth.

Use the cloth to apply the cleaning agent. Submerge a clean cloth into the cleaning agent

(concentration recommended by manufacturer’s instructions). Remove the cloth and

remove excess water. Clean the dispense components wiping the cloth over the entire

area re-submerging the cloth as necessary. Rinse the cloth in clean warm water and wipe

off excess cleaning agent residue and soil. Dry using disposable paper towels, replace

dispense components.

Spraying on Cleaning Agent.

Remove all dispense components. Liberally spray the cleaning agent at the concentration

recommended by the manufacturer onto the dispense component ensuring that the whole

area has been covered. Finish the clean by exchanging the cleaning agent for warm water,

remove the soil with a multi-purpose disposable cleaning cloth and dry the component with

disposable paper towels.

Food Grade Antibacterial Wipe.

Remove the dispense components, wipe the dispense component with the food grade

antibacterial wipe, remove all visible soil. Replace dispense component.

Important: It is recommended that the deep clean procedure be performed at least

monthly.

Remove dispense components, pre clean using a damp multi-purpose disposable cleaning

cloth soaked in warm water.

Soak cloth in cleaning agent solution, remove excess water and clean dispense

components. Using a brush, brush dispense head to dislodge any dried on soil. Remove

soil with the cloth.

Rinse dispense head with a new multi-purpose disposable cleaning cloth soaked in warm

water until all soil and cleaning agent residues have been removed.

Soak multi-purpose disposable cleaning cloth in disinfectant solution, apply to dispense

component, ensure that the whole area is wiped. Leave for 10 minutes. Rinse off

disinfectant using multi-purpose disposable cleaning cloth that has been soaked in clean

warm water. Dry dispense component with disposable paper towels. Refit all dispense

components.

Cleaning

6

General Cleaning - Parts not in contact with food products

Important: It is recommended that the procedure should be performed at least every

6 months.

Condenser. At regular intervals, determined by local environmental conditions, the

condenser should be thoroughly cleaned with a small stiff brush and/or a vacuum cleaner.

Do not use screwdrivers or other sharp implements which may puncture the fins.

Warning: Failure to clean the condenser can shorten the life of the compressor causing

premature failure of the unit.

Outer Panels. Clean the outside panels, pay particular attention to the edges of the panels

where spillage could have ingressed and the area around the base of the unit. If necessary,

remove the unit and thoroughly clean around the base and floor.

Sanitisation

Important: It is recommended that the procedure is performed during initial

installation and at least every 3 months.

Prepare the Unit

1. Disconnect the electrical power to the unit and isolate from the water supply.

2. Carefully follow the manufacturer’s instructions and prepare a solution of

proprietary sanitizing fluid.

Sanitize the Water System

3. Disconnect flexible water inlet tube from the water supply and place the end

into a container of sanitizing fluid. Flushing through of sanitising solution can

be achieved either using a pressurised container, or by using a syphon. In the

latter case, the sanitiser fluid needs to be held at a height sufficient to allow

fluid to flow through the chiller. Flush through approximately 0.5ltrs of water to

flood the chiller with sanitizing solution

Recommission the Unit

1. Restore the water supply to the unit and dispense approximately 1ltr of water

to flush the system of sanitizer.

2. Restore the electrical supply and allow the unit complete its cooling cycle.

Cleaning

7

Electrical Schematic

8

Water Schematic

9

Prior to any fault finding, please ensure all product connections to the chiller are sound

and that the incoming supply is turned on. Also ensure that all electrical

connections to the chiller and in the chiller are secure and in good condition, the power is

on and that the chiller has had adequate time to reach operating temperature.

NOTE: When checking electrical connections ensure mains power is switched off.

Symptom

Possible Cause

Corrective Action

No Water

Dispensing

Frozen block

Thermostat capillary not fully inserted into

chiller block.

Thermostat out of calibration or faulty.

Replace if necessary.

Warm Drinks

Insufficient air flow

through the fridge.

Check supply to cooling fans (220-240v AC).

If supply present replace fans.

If supply not present move on to the

compressor. (The supply to the fans and the

compressor are linked).

Compressor not running

Check the internal fuse and replace if

necessary.

Check for continuity across thermostat

contacts.

Fridge failure

If compressor & fan are running and there is

no cooling, return for repair.

Fault Finding

10

Spare Parts

1A6794

Eliwell Controller

3B7692

Fans

1B6430

Power Switch

11

Important: Before removal from the installation, ensure all electrical, product and

gas connections are disconnected.

Disposal of Scrap Units

It is illegal to simply scrap a refrigeration unit. Before a unit can be scrapped it must first

have the gas removed by a specialist using special equipment. Please contact Vero

Water for guidance.

Transportation

Important: This unit must be transported in an upright position

As with all refrigeration systems, irreparable damage can be caused by laying the unit on

its side or even transporting upside down. Where the unit is transported by a carrier, the

carton should always be marked in a conspicuous manner, the correct upright position

in which it must be handled.

If a unit has been transported incorrectly it should be placed in the correct upright position

and left for 24 hours before attempting to run the system.

Failure to observe the above precautions could seriously damage the system, and would

void any warranty.

Removal, Transportation and Disposal

12

Booth Dispensers Ltd, Moor Park Avenue, Blackpool,

Lancashire, FY2 0LZ, UK

+44 1253 501800

Table of contents

Other Booth Water Dispenser manuals

Popular Water Dispenser manuals by other brands

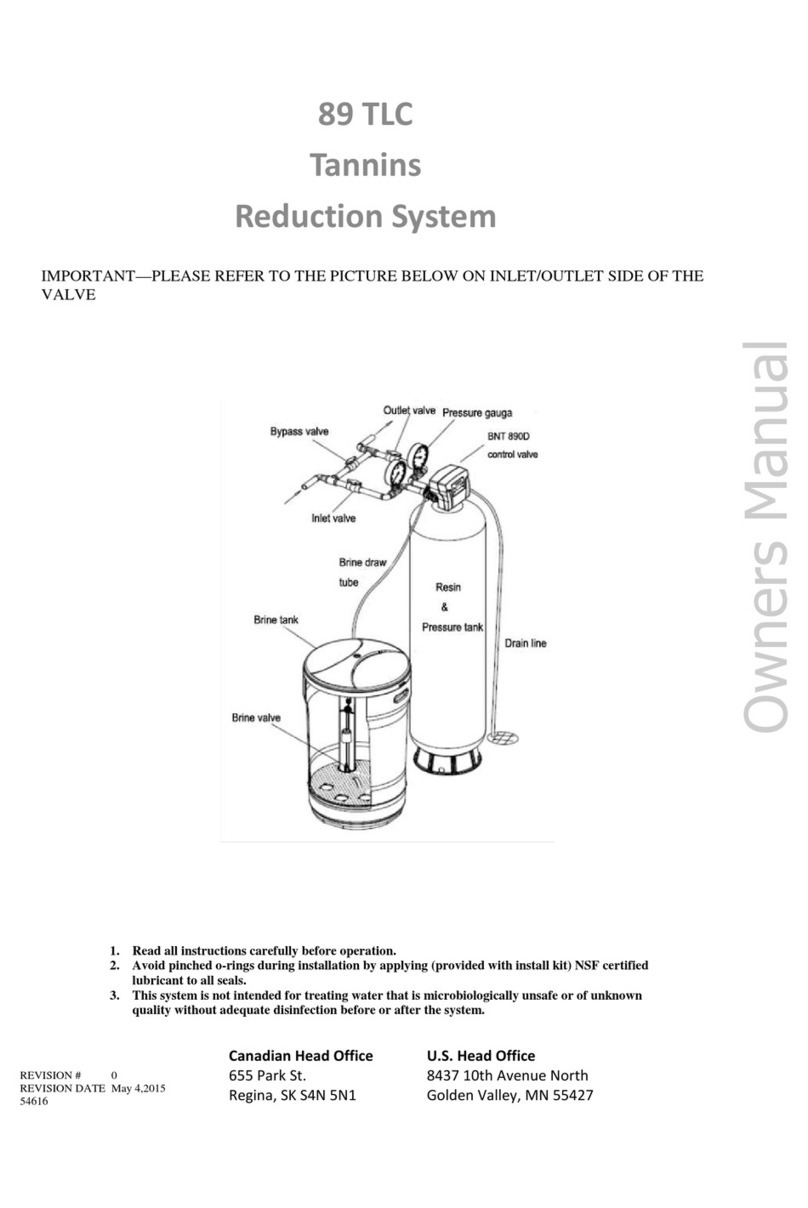

Canature WaterGroup

Canature WaterGroup Tannins 89 TLC owner's manual

Elkay

Elkay VRC Series Installation, care & use manual

Borg & Overstrom

Borg & Overstrom b4 quick start guide

Pelican

Pelican PAC3 owner's manual

Elkay

Elkay EZWS-ERPBM28K quick start guide

JCLASS

JCLASS SUPER HOT Installation, use and maintenance handbook

AFWFilters

AFWFilters 5600 Series installation instructions

Kenmore

Kenmore 350 Series owner's manual

InSinkErator

InSinkErator indulge Series owner's manual

Aqua Cooler

Aqua Cooler ODYSSEY Series Usage and Care Manual

BRIO

BRIO CLPOU720UVRO4X Setup manual

Morton

Morton MSS20B Installation and operation manual