Boreas Technologies BOS1211 User manual

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 1

BOS1211 Development Kit

1Features

•Plug and play development kit to experience

piezo haptic feedback

•Low-power BOS1211 integrated circuit, high

voltage driver with digital interface

•Easy generation of high-voltage waveforms

up to 120 V

•Enable sensing and emulate button behavior

using the actuator

•Three miniature PCB slots for scalable

BOS1211 driver boards

•Compatible with big piezoelectric actuators

such as TDK PowerHapTM

1

120 V models.

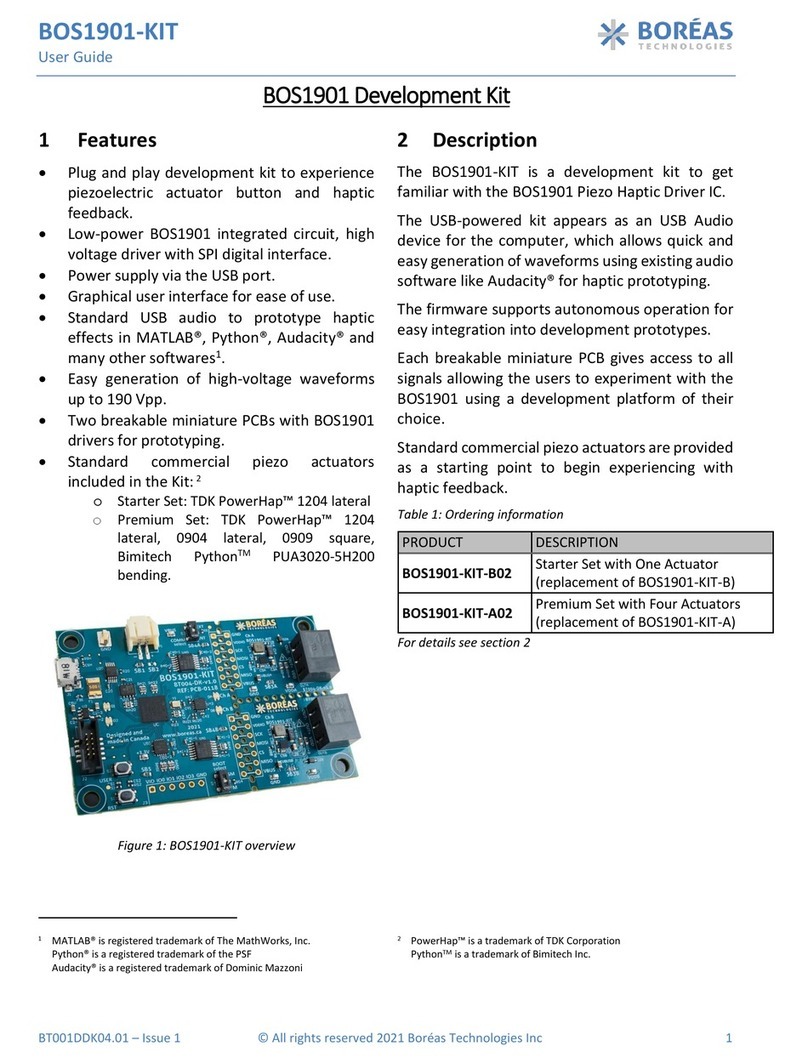

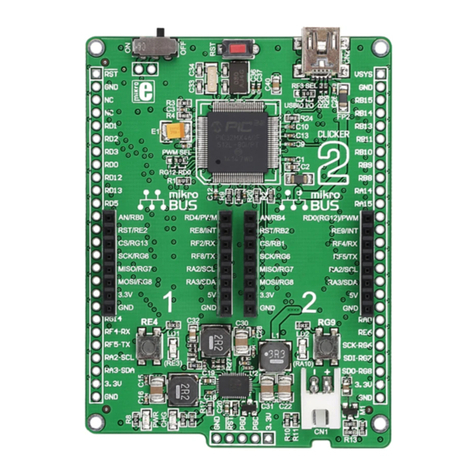

Figure 1: BOS1211-KIT Overview

2Description

The BOS1211-KIT is a Development Kit to help

users get familiar with the BOS1211 Piezo Haptic

Driver IC.

Miniature PCBs are interchangeable allowing the

users to experiment with the actuator sizes

adapted to their platform.

This kit connects to associated PC software over

USB for easy programming of the BOS1211 and

manual generation of waveforms on the

connected actuator.

The piezoelectric actuator sensing capability is

used to emulate a button behavior. The sensing

and feedback parameters can be changed using

the software.

Many GPIOs and hardware features are accessible

to ease prototype building.

Table 1: Ordering information

PRODUCT

DESCRIPTION

BOS1211-KIT-B

Starter Set with one actuator

For details see section 10.

1

PowerHap™ is a trademark of TDK Corporation.

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 2

3Quick-Start Guide

3.1 What's in the Box

The content of the BOS1211-KIT is given in the following table.

Table 2: Starter Set BOS1211-KIT-B development kit content

#

ITEM

DESCRIPTION

REFERENCE

1

Controller board

BOS1211-BRD-C controller evaluation board.

2

Driver board - Small

BOS1211-BRD-S driver board for smaller actuators.

3

Driver board –

Medium

BOS1211-BRD-M driver board for medium actuators.

4

Driver board - Large

BOS1211-BRD-L driver board for larger actuators.

5

USB Cable Micro

Type B

USB communication cable to connect the

LaunchPadTM to a computer.

Stewart Connector part number SC-2AMK001F

6

3 terminal block

connectors

Male connector used for interfacing the piezoelectric

actuator on the driver boards.

Molex part number 39510-0002

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 3

#

ITEM

DESCRIPTION

REFERENCE

7

TDK Piezo Actuator

TDK PowerHap™ 1919H021V120 (25G) Actuator

Ordering: Z63000Z2910Z 1Z43

Capacitance : 2.5 μF

Dim : 19.4 x 19.4 x 2.1 mm

8

12 V Power Supply

Power supply to provide 12 V to the Evaluation PCB.

CUI inc. part number SDI90-12-U-P5 with power chord

CUI inc. part number AC-C13 NA or equivalent.

9

Power adapter

European power adapter Ceptics model CT-9 or

equivalent

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 4

3.2 Board Overview

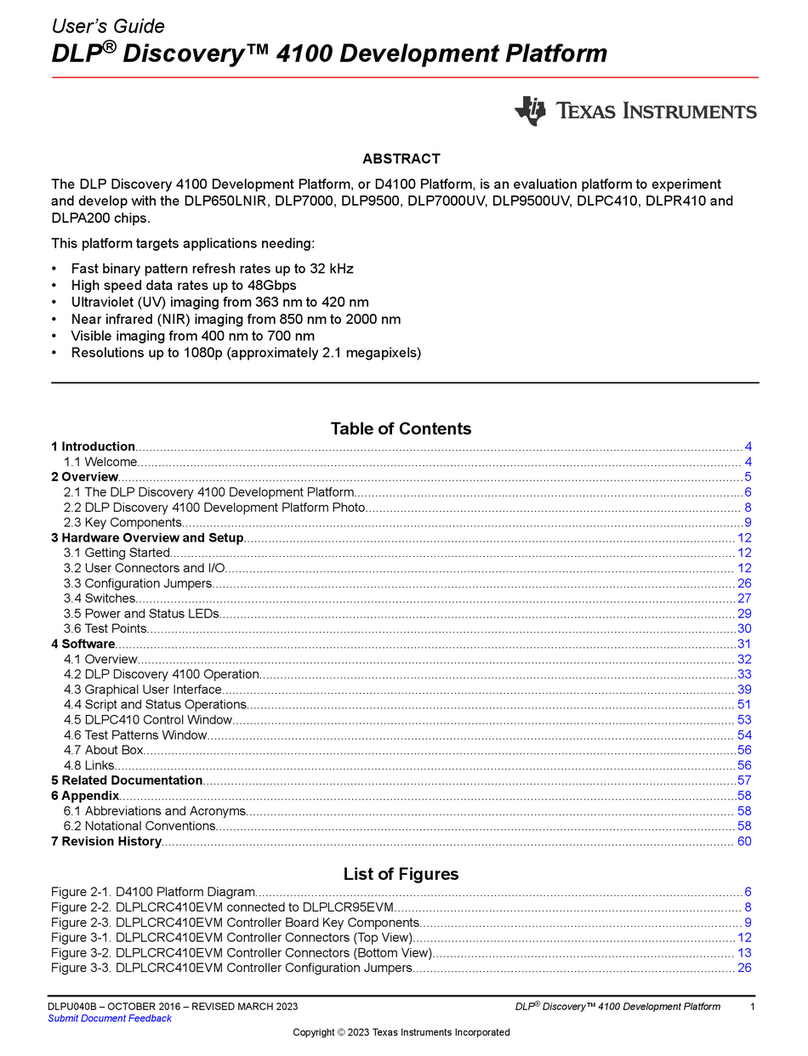

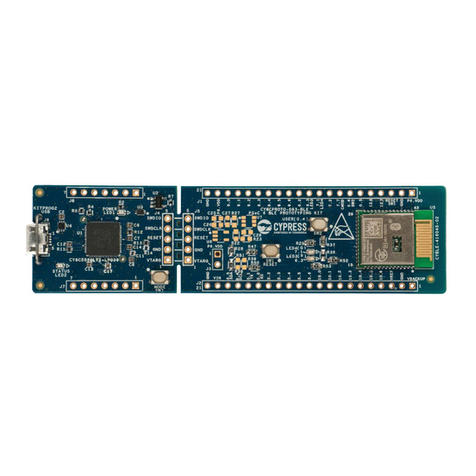

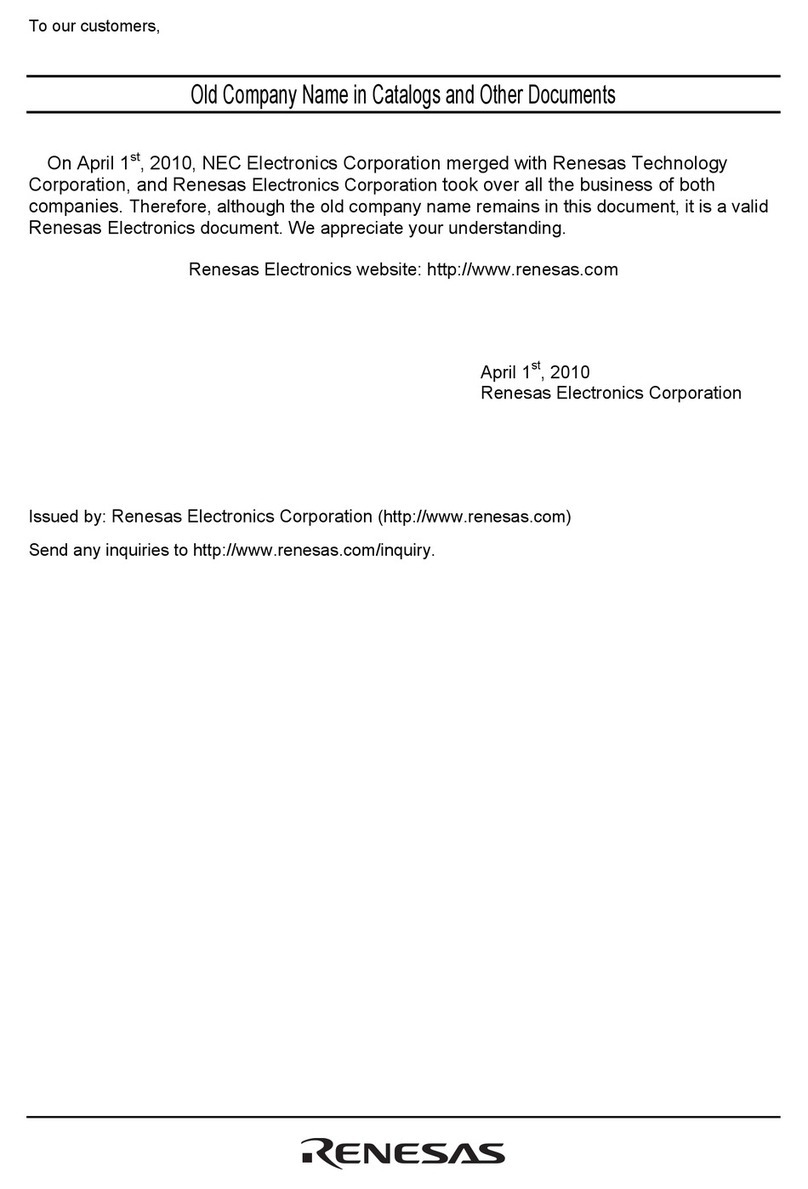

Figure 2: BOS1211-KIT-BRD-C controller board

Figure 3: BOS1211-KIT-BRD-C controller board overview

USB

USR

RST

µC

www.boreas.ca

BOS1211-KI T-

BRD-C

D1

Debug

port

USBUSB

D2

Digital

Inputs Digital

Outputs

ADC &

DAC

Ext.

I2CM

External

SPI Master

SPI

sel.

Mount

hole

Mount

hole

Mount

hole

Mount

hole

BOS1211

Expansion

Port

Slot Card A

Slot Card B

Slot Card C

12V

connector

Level

shifter

array

SPI

switch

array

TP

12V

TP

GND

TP

VSPI

TP

5V

TP

GND

TP

3.3V

TP

GND

D3C

D3B

D3A

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 5

3.3 Quick-Start Procedure

Important Note: this evaluation kit does not support hot swapping the driver boards in or out of the

controller board.

1. When shipped the BOS1211-KIT-BRD-C is already loaded with the appropriate firmware. If the

firmware needs updating, see section 5.4.

2. Install the PC GUI software. See section 6.1.

3. Launch the software application. See section 6.2.

4. Connect cables and the piezoelectric actuator. See section 4.1.

5. Select the appropriate USB Serial Device (COMxx) and click Connect to Port. See section 6.2.

6. Select parameters to play and click the Play button. Feel the feedback played on the actuator.

Warning: When measuring voltage signals on the actuator using an oscilloscope, use a separate probe

on each terminal of the actuator. Never connect the ground of a probe to one of these terminals. Doing

so might damage the BOS1211-KIT and/or your oscilloscope.

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 6

4Hardware

4.1 Kit Assembly Overview

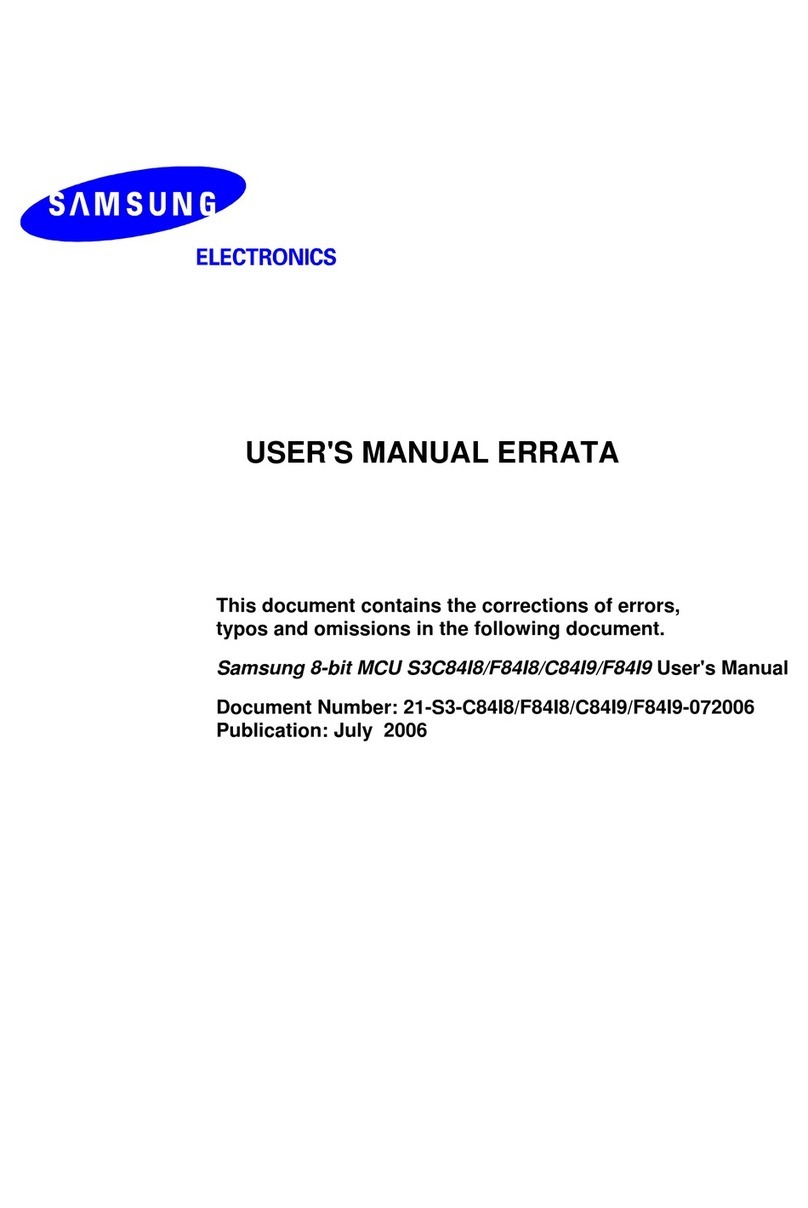

The kit is an assembly of many boards as shown in the figure below.

The larger BOS1211-KIT-BRD-C is the main controller board.

The smaller BOS1211-KIT-BRD-S, BOS1211-KIT-BRD-M and BOS1211-KIT-L driver boards must be inserted

in one of the three card sockets. They may be inserted in any order. Not all sockets need to be populated.

Use a terminal block to connect the actuator. Red wire must be connected at OUT pin, and black wire

must be connected at VIN pin. The provided terminal blocks are insertable in terminal block socket for

easy assembly and interchanging.

Connect the 12 V power supply to the controller board and connect the USB connector to a PC USB data

port to interface with the GUI software. It is possible to connect the USB cable to a USB charger port,

this limits the board behavior (see section 5.3.2).

Figure 4: BOS1211-KIT assembly overview

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 7

4.2 Changing the Miniature Driver Boards

BOS1211 board components can be scaled depending on the piezoelectric actuator used. Each driver

board (BOS1211-KIT-BRD-S, BOS1211-KIT-BRD-M and BOS1211-KIT-L) has been designed with

components to support various actuator sizes. The table below indicates which driver board is best

suited depending on the actuator capacitance.

Table 3 Board revisions and compatible software

PART NUMBER

DESCRIPTION

MAX PIEZO ACTUATOR

CAPACITANCE

(for 300 Hz, 120 V waveforms*)

COMPATIBLE TDK

POWERHAPTM ACTUATORS

BOS1211-KIT-BRD-S

Small layout driver board

with lower drive.

Up to 0.9 µF

1313H018V120

BOS1211-KIT-BRD-M

Medium layout driver

board with medium drive.

Up to 2.5 µF

1919H021V120

BOS1211-KIT-BRD-L

Larger layout driver board

with higher drive.

Up to 4.4 µF

2626H023V120

6005H070V120

6005H090V120

*If the voltage and/or bandwidth are different, the maximum capacitance in your application can be

approximated with the following equation.

𝐶𝑚𝑎𝑥 = 𝐶𝑡𝑎𝑏𝑙𝑒 ∗300 𝐻𝑧

𝑓

𝑢𝑠𝑒𝑟

∗𝑉𝑡𝑎𝑏𝑙𝑒

2

𝑉

𝑢𝑠𝑒𝑟

2

Important Note: this evaluation kit does not support hot swapping the driver boards in or out of the

controller board.

Before changing driver boards, first disconnect both the USB cable and the 12 V supply. Then disconnect

the insertable terminal block joining the actuator. Change the driver boards for the desired

configuration, then successively reconnect the terminal blocks, the 12 V supply and the USB cable.

Although one of each driver board is included in the development kit, it is possible to get additional

driver boards as needed. Therefore, it is possible to connect many identical boards on the same

controller board.

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 8

4.3 Identifying the Boards Revision Number

Each PCB board reference design and revision number (v#.#) are identified next to the “REF:” label. The

following table indicates compatibility with the firmware and Devkit Controller software.

Table 4 Compatible TDK PowerHapTM actuators for each driver board

REF NUMBER

COMPONENT

COMPATIBLE FIRMWARE

COMPATIBLE PC SOFTWARE

PCB-0069-BT002-DK-C-v1.1

BOS1211-KIT-BRD-C

Up to 1.7.x

Up to 2.7.x

PCB-0070-BT002-DK-S-v1.1

BOS1211-KIT-BRD-S

Up to 1.7.x

Up to 2.7.x

PCB-0070-BT002-DK-M-v1.1

BOS1211-KIT-BRD-M

PCB-0070-BT002-DK-L-v1.1

BOS1211-KIT-BRD-L

PCB-0089-BT002-DK-S-v1.3

BOS1211-KIT-BRD-S

Up to 1.7.x

Up to 2.7.x

PCB-0089-BT002-DK-M-v1.3

BOS1211-KIT-BRD-M

PCB-0089-BT002-DK-L-v1.3

BOS1211-KIT-BRD-L

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 9

4.4 BOS1211-KIT-BRD-C Other Hardware

The controller board has additional hardware features to expand the board functionally when testing

actuators and building prototypes. These features are described in this section.

4.4.1 Probe Hooks

Probe hooks have been inserted around the board to ease connection of instruments for measurement

of supplies when debugging.

4.4.2 Expansion Port

An expansion port is available to provide test point access to the SPI I/Os. This port is labeled TPSPI in

the BOS1211-KIT-BRD-C schematics. It is initially unpopulated but can be using a Sullins Connector

Solutions model number SBH11-NBPC-D12-SM-BK or equivalent.

4.4.3 GPIO

General-purpose inputs and outputs are provided to easier integration of the development kit in a

prototype. For example, digital inputs may be used as trigger inputs to fire the waveforms or to send

information from the system to the development kit.

Using these GPIOs implies to modify the firmware to support them. However, they are already physically

implemented and routed to the MCU. They only need to be activated in the firmware software code

project.

There are 8 inputs and 8 outputs available on header connectors at the bottom of the board. A jumper

is initially shorting VIO-IN and VIO-OUT with the board 3.3 V pin so they are referenced to the board

main 3.3 V supply. To use an external supply, remove the jumpers and connect the external voltage

supply to the VIO-IN and VIO-OUT pins. The external supply must be in the 1.65 to 5.5 V range. VIO-IN

and VIO-OUT may have different supply levels.

Refer to the board schematics in section 7.1 for MCU pins numbers corresponding to the inputs and

outputs used.

4.4.4 ADC and DAC Connections

One DAC and four ADC pins are made available to the user. These connections are buffered to protect

the controller board. These signals cannot exceed the board 3.3 V supply level.

Using these implies to modify the firmware to support them. However, they are already physically

implemented and routed to the MCU. They need to be activated in the firmware software code project.

4.4.5 External SPI Master

All BOS1211 actuator driver chips are controlled via the SPI interface using the PSoC6 MCU as master. It

is, however, possible to bypass the MCU and use an external SPI master. This can be useful when trying

to connect the BOS1211 ICs directly to an external system.

SCK, MISO and MOSI connections are shared by all BOS1211 on the driver boards. Three chip selects

(CSA, CSB and CSC) are required to access the chip select pin on each BOS1211 in the slots A, B and C.

By default, a jumper on 5 V and VSPI forces the internal 5 V supply to be used. To use an external voltage

domain, remove this jumper and connect VSPI to the external supply.

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 10

Finally, set the SPI Select switch to the EXT position to select the external SPI master, or leave it at the

INT position to use the MCU as the SPI master.

4.4.6 External I2C Master

Connections are provided to allow for an External I2C Master to be used. This is useful to connect the

controller board to a system that requires I2C connectivity.

Initially, this function is not implemented in the firmware. The firmware source code must be modified

for the MCU to act as an I2C slave. However, the board makes it possible if needed and allows for an

external voltage domain to be used as well.

By default, a jumper on 3.3 V and VI2C forces the internal 3.3 V supply to be used. To use an external

voltage domain, remove this jumper and connect VI2C to the external supply. Note only a 3.3 V or 5 V

supply may be used.

4.4.7 RST and USER Push Buttons

RST push button forces a reset of the MCU and the firmware.

USER is not used by the current firmware.

4.4.8 LED

A total of 5 LEDs are present on the development kit BOS1211-KIT-BRD-C board.

D1 (green LED) and D2 (red LED) are located near the USB connector. They indicate firmware revision

during boot up and provide information on development kit operation. See sections 5.1 and 5.2 for

details.

D3A, D3B and D3C (orange LED) are located next to their associated channel slot card and are used to

indicate that channel current status (see section 5.2).

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 11

5Firmware

5.1 Identifying the Firmware Revision Number

When powering up the development kit, LEDs will show the firmware revision number and then the IC

revision.

After the 10-second bootload window while both LEDs are on (for firmware revisions below 1.5.0), the

green and red LEDs flash to indicate the firmware revision number. For a firmware revision X.Y.Z with

major revision X, minor revision Y and patch revision Z, the green LED will flash X times, then the red LED

will flash Y times and then both LEDs will flash Z times. The routine will execute twice. If no problem

were detected, the green LED will stay lit otherwise only the red LED will light up.

5.2 LED Indicators

The MCU continuously monitors the status of each channel. The status is then shown by the associated

LED (D3A, D3B, D3C). If an error occurs for a channel, the red LED (D2) will light up and the corresponding

channel orange LED will flash a number of times to indicate the error (see Table 5). The error will be

indicated in cycles until the issue is resolved. When no error is detected and a slot card is inserted, the

corresponding LED will stay lit.

Table 5: Channel LED flashing routine when in error

FLASHING

COUNT

ERROR DESCRIPTION (IC_STATUS FLAG)

0

No error.

1

Output voltage exceeded the maximum voltage allowed (OVV)

2

Overtemperature detected (OVT)

3

Maximum power reached; distortion is likely (MAX_POWER)

4

Problem with current detection (IDAC)

5

VDD too low (UVLO5)

6

VIN too low (UVLO12)

7

VIN too high (OVLO12)

8

Short-circuit detected between VOUT and VIN (SC)

For more information on the status error, please refer to the BOS1211 datasheet.

5.3 Modes of Operation

5.3.1 PC Connected

When the board is connected to a PC running the Boréas DevKit Controller software, it will communicate

with it and the user can control the board using the software interface.

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 12

5.3.2 Persistence Mode

When booting the BOS1211-BRD-C evaluation board, the firmware will enter the Persistence mode. In

this mode, the board will behave as programmed by its internal memory. The memory can be set from

the PC software to a specific feedback waveform and trigger mechanism. When using the external

trigger, a rising edge on the GPIO input pin 0 will trigger the waveform stored in memory. If sensing was

activated when programming the memory, sensing will be activated in the Persistence mode.

When the Boréas DevKit Controller software is connected, any configuration push to the board will

override this Persistence mode. The Persistence mode can be restored by rebooting the board, either by

pressing the RST button or by unplugging the USB cable.

This mode will operate whether the board is connected to a PC USB port or a charger port.

5.4 Firmware Installation/Update Procedure

5.4.1 Kits Shipped with Firmware Revision Prior to 1.5.0

The BOS1211-KIT is provided out of the box with a firmware for use as USB Serial Device.

This firmware can be changed and/or updated using the dfuh-tool.exe application available on Boréas

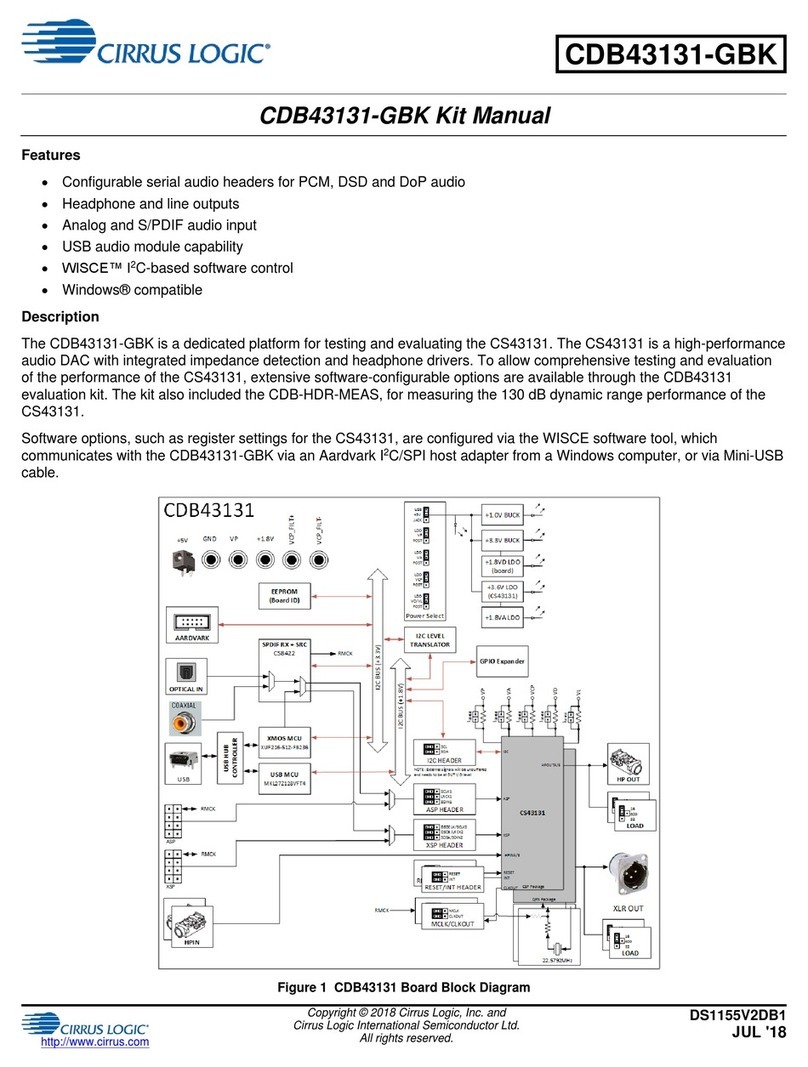

website. The procedure is the following (refer to the figure below for each step):

1. Load the appropriate *.cyacd2 file using the browse button next to the file selection text box.

2. Click the “Filters…” button and make sure only “Show UART ports”is checked.

3. Set UART settings to:

a. baud rate : 115200

b. data bits : 8

c. stop bits : 1

d. parity : None

4. Press and release the "RST" button on the evaluation PCB to set it to Device Firmware Update

(DFU) mode. A new “USB Serial Device –UART”item should appear in the ports text box. Select

this port then press on the program button. Note that upon reset this port will be connected

for only 10 seconds. Programming must be done within that time.

5. Wait for installation/update to finish. The "Log" field will inform of a successful firmware

installation.

6. Once the installation is complete, LEDs will go through the firmware identification sequence

given in the previous section, and end with green LED on and red LED off. If red LED does not

turn off, wait a couple of seconds then press and release "RST" again.

Once the firmware has been updated to version 1.5.0 or later, it can then be updated to a future revision

using the procedure in the next section.

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 13

Figure 5: dfuh-tool.exe for firmware installation/update

1

2

3

4

4

5

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 14

5.4.2 Kits with Firmware Revision Installed is 1.5.0 or later

The following procedure applies to kits shipped with firmware revision 1.5.0 or later installed. It will also

apply to previous kits once the firmware has been updated to revision 1.5.0 or later.

When running the PC software, upon connecting the kit to the software, if the firmware revision

detected on the board is not compatible with the current software, the user will be asked if he wants to

update the firmware or not.

After clicking Yes, the firmware update will be updated automatically.

Figure 6: Firmware update request window

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 15

6Boréas DevKit Controller PC Software

This User Guide is applicable to Boréas DevKit Controller software revisions starting with 2.7.x.

6.1 Installation

6.1.1 Software Installation

To install this application, please run the Boréas DevKit Controller installer executable file (Boreas-Dev-

Kit-Installer-2.7.x.exe). Follow the instructions given by the software. A shortcut on the desktop will be

created at the end of the installation.

6.1.2 Software Update

To update the application, download the latest installer and run it. The older version will automatically

be overwritten.

6.2 Using the Application

6.2.1 Overview

Boréas DevKit Controller is a graphical user interface (GUI) intended to ease evaluation of the BOS1211

IC. Using this application, users can easily trigger waveforms manually or using a system I/O, activate

sensing and monitor the IC state.

The following sections details the interface elements and how to use them.

6.2.2 Main Window

The main application window is separated into these sections:

1. Left panel

2. Mini-boards identification bar

3. Content tabs

When the board is not connected, only the left panel is visible.

Once the connection is established, the right panel will appear.

6.2.3 Left Panel

The left panel contains buttons that are always accessible. The upper section indicates the firmware of

the currently connected board.

USB Serial Device Dropdown List

This control lists the COM ports currently connected to the computer. The development board will

appear as a USB Serial Device with a dedicated COMxx name given by the system. Look for the one

appearing when physically connecting the board to know which label corresponds the board. Note the

board will also appear as a COM port during the initial bootloading sequence. Please wait for the green

LED before connecting to the board.

Connect to port/Disconnect from port

Once the appropriate port has been selected, click Connect to port to establish the communication with

the development board. Click Disconnect from port before unplugging the board. If the firmware revision

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 16

is not compatible with the PC software, the user will have the opportunity to automatically update the

firmware.

About

This button opens the About box giving information about the application.

Exit

This button closes the application.

Figure 7 Main application window when not connected

6.2.4 Mini-boards identification bar

The top of the right panel provides information about the mini-boards connected to the controller

board. For each of the mini-boards inserted in slots A, B and C, the associated chip ID will appear. Slots

used will be marked as Connected, unused slots are indicated as Not connected.

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 17

6.2.5 Basic Tab

For the selected mini-board tab, the Basic tab is used to send waveforms to the evaluation board. This

section describes each parameter and control.

Sync/Desync All Button

When pressed, all connected boards will play the same waveform using BOS1211 SYNC feature.

Depress the button to play waveforms on individual boards.

Save in Memory

This button will save the current configuration to the MCU internal memory. This configuration will be

automatically loaded when the board is booted, whether it is connected to a USB port or USB charger.

See Persistence mode at section 5.3.2.

Load from Memory

This button will load the Persistence mode configuration from the MCU internal memory.

Reset

Press the red reset button to return parameters in the board memory to their default values.

Amplitude

This value is the amplitude in volt of the waveform played. The waveform will be played between 0 V

and this value. Value is valid between 20 and 120 V.

Frequency

This value is the frequency in Hertz of the waveform played. Value is valid between 100 and 300 Hz.

Cycle

This value is the number of sine cycles played. The minimum valid value is 1 cycle. The maximum value

when playing half-waves is 10 cycles. The maximum value when playing full sine waves is 16711425.

Stabilization Time

This value determines the time the piezo creep will be stabilized after playing a waveform. The valid

range is from 0 to 1000 ms.

Half-Wave

When unchecked, each waveform cycle will correspond to a full sine cycle (0 to 2π).

When checked, each waveform cycle will correspond a sine half-cycle (0 to π).

Play Button

This button manually triggers a waveform to be played as defined by the above parameters.

Enable GPIO Interrupt

When checked, a pulse on GPIO input pin 0 will trigger the waveform as defined by the above

parameters. The pulse is debounced by the firmware. Its width must be at least 5 ms. Note that the

parameters must have been sent from the GUI to the device first.

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 18

Figure 8 Main application window when connected - Basic tab

Sensing

When checked, the actuator will behave like a button, playing the waveform when pressed and released.

The release waveform amplitude is set to 75% of the press waveform amplitude. This box must first be

checked to adjust the sensing parameters.

Piezo Config

Selecting a specific piezoelectric actuator PowerHapTM model sets the default parameter profile for this

actuator. Individual parameters can then be adjusted.

Press/Release Settings

Sensing parameters are set separately for the press and release detection events.

Threshold

Value the piezo voltage must be over or below for a detection to be successful. Using TDK PowerHapTM

actuators, the threshold of a press event should be positive and that of a release event should be

negative.

Hold Time

Time the voltage must be above or below the threshold for the detection to be successful.

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 19

Direction

Direction the voltage is crossing the threshold for a detection to be successful. Using TDK PowerHapTM

actuators, the direction of a press event should be upward and that of a release event should be

downward.

Figure 9 Main application window when connected - Basic tab - Sensing

BOS1211-KIT CONFIDENTIAL

User Guide –Preliminary

BT002BDK01.05 –Issue 5 © All rights reserved 2020 Boréas Technologies Inc 20

6.2.6 Registers Tab

The Registers Tab allows to monitor the register content of the selected connected mini-board. It also

allows to write specific values to any writeable registers on the driver IC by clicking the Send button next

to that register. Before editing any register, it is recommended to first click Load All. Be aware data will

be overwritten on the IC, even if not previously loaded.

The registers are displayed, one per line. The register label is given on the left, then the register address,

then the parameters for this register are given (MSB on the left, LSB on the right), and then there is Send

button to send the parameter values to the board IC if the register is writeable. When using this button,

and only the associated register for the selected channel is written.

When selecting a parameter box, the information for that parameter is given on the right side of the

screen. Information includes parameter name, its current value, the number of bits of that parameter

(Length), the minimum and maximum possible values, and a short description.

Figure 10 Main application window when connected - Registers tab

Table of contents

Other Boreas Technologies Microcontroller manuals

Popular Microcontroller manuals by other brands

Atmel

Atmel AVR2103 quick start guide

mikroElektronika

mikroElektronika CLICKER2 FOR PIC32MX manual

Renesas

Renesas mPD179327 Subseries user manual

Toshiba

Toshiba TLCS-870/C1 Series manual

Littelfuse

Littelfuse Zilog Z8 Encore! XP F3224 Series user manual

Texas Instruments

Texas Instruments MSP430FG461x series manual