BORNEMANN SLH-5G User manual

Operating instructions

Screw pump

Type: SLH-5G

Translation of the original operating instructions

Hygiene application | non-Ex

Industriestr. 2 | 31683 Obernkirchen (Germany)

Telephone: +49-5724-390-0 | Fax: +49-5724-390-290

2

Type: SLH-5G

Hygiene application | non-Ex

Author: KME

Checker: BS/ML

22.09.2021.Rev.2, en_GB

©ITT Bornemann GmbH 2021

3

General information.

General information

This section contains some advance general information on using this manual, as well as the warranty conditions and

the contact data for customer service.

About this manual

This manual enables safe and ecient handling of the pump. The manual is an integral part of the pump and must be kept in the

immediate vicinity of the pump, accessible to personnel at all times.

The personnel must have carefully read and understood this manual before starting any work. A basic requirement for safe working is

the adherence to all safety and handling instructions in this manual. Furthermore, local accident prevention regulations and general

safety regulations apply to the area of application of the pump.

Illustrations in this manual are for general understanding and may dier from the actual combination.

Supplementary documents

In addition to this manual, you are receiving supplementary documents. These documents are part of the technical documentation of

the pump and familiarity with them is absolutely necessary for the safe operation of the pump. The documents with the necessary

information are listed in the following table.

Tab. 1: Supplementary documents

Document Content

Data sheet Technical data and operating conditions, output and operating

limits

Dimensional drawing Dimensions, weight, and connections

Supplementary document on lubricants and preservatives List of suitable lubricants and preservatives

Flushing sheet1) Operating and installation instructions for the use of a mechanical

seal

Operating & Installation Diagram1) Operating and installation instructions for the use of a seal supply

system, heating or cooling system

Documentation from suppliers1) Technical documentation for components, for which ITT Bornemann

GmbH is not the manufacturer

Spare parts list1) Sectional drawing and listing of spare parts

Safety data sheets for auxiliary and operating materials1) Information for the safe handling of auxiliary and operating mate‐

rials

1) Only included in the scope of supply if the pump has been ordered correspondingly.

General information

4

Technical terms

Tab. 2: Technical terms

Term Meaning

System Pump/pump assembly and all components connected by the operator

Component Part which makes a dened contribution to the function of a system

Pump assembly Pump, coupling and motor on base plate or prole frame

Pump system Pump assembly with pipelines, ttings and control components

Info boxes and special characters

These info boxes highlight tips and recommendations as well as information for an ecient and trouble-free operation.

At the beginning of individual chapters, these info boxes also contain references to supplementary documents that are

relevant for the respective chapter and must be taken into account.

The following special characters are used in this manual to highlight instructions, references and lists:

Tab. 3: Info boxes and special characters

Special characters Explanation

Instruction

Reference to sections of this manual

→Reference to supplementary documents

Listing without a dened order

Copyright

This manual is protected by copyright.

The transfer of these instructions to third parties, duplication in any kind and form – even as extracts, – as well as the utilisation and/or

communication of the contents are not permitted except for internal purposes without the written permission of ITT Bornemann GmbH

(hereinafter referred to as the manufacturer). Non-compliance will result in compensation for damages. The manufacturer reserves the

right to assert additional claims.

The copyright lies with the manufacturer:

© ITT Bornemann GmbH, Industriestr. 2, 31683 Obernkirchen, Germany

5

General information.

Warranty conditions

ITT Bornemann GmbH grants a warranty on the pump for 18 months after delivery or 12 months after commissioning, unless otherwise

stipulated in the contract.

The warranty will become void, if:

■damages occur due to non-compliance with this manual

■operating conditions from the data sheet are not observed

■unauthorised modications are made to the pump

Customer service

For questions about the pump, ordering spare parts and technical information, please contact ITT Bornemann GmbH using the following

contact details:

ITT Bornemann GmbH

Industriestr. 2 | 31683 Obernkirchen (Germany)

Telephone: +49 5724 390-100 | Fax: +49 5724 390-290

In addition, ITT Bornemann GmbH is always interested in information and experiences resulting from the use of our products which can

be valuable for making improvements to them.

Table of contents

6

Table of contents

1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Safety and warning information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Proper use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Improper use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Obligations of the operator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 Personnel qualications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6 Personal protective equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.7 Labelling on the pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.8 Special hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.9 Safety equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.10 Securing against restarting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.11 Environmental protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3Layout and function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Pump assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.1 Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.2 Coupling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.3 Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2 Sealing supply system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3 Other components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.1 Measuring devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.2 Frequency converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4Transportation and storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 Lifting and transporting the pump/pump assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Storing the pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5Preservative. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 Short-term preservation (up to maximum 3 months). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.2 Long-term preservation (from 3 months). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3 Removing the preservative. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6Set-up and connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 Preparing the pump assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1.1 Installing the heat insulation (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1.2 Install pump on prole frame or base plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7

Table of contents.

6.1.3 Installing the coupling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1.4 Assemble motor on prole frame or base plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.2 Preparing the installation site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3 Installing the pump assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.1 With machine feet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.2 With metal dowels (screwed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.3 With anchor bolt (cast). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4 Aligning the pump assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.5 Fitting the coupling guard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.6 Conguring the pipelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.7 Connecting the pipelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.8 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.1 Prepare the pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.2 Prepare sealing supply system (if provided). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3 Fill and bleed pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.4 Switching on at commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.1 Starting operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.2 Stopping operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.3 Cleaning/sterilising the pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.3.1 Cleaning/sterilising with CIP/SIP medium < 80 °C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.3.2 Cleaning/sterilising with CIP/SIP medium > 80 °C and pump with sealing supply system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.3.3 Cleaning/sterilising with CIP/SIP medium > 80 °C and pump without sealing supply system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.4 Provisions in the event of operational interruptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.5 Operating the pump as a stand-by pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.6 Winter operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.1 Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.2 Maintenance schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.3 Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.3.1 Lubrication points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.3.2 Lubricant quantity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.3.3 Relling the lubricating oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.3.4 Changing the lubricating oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table of contents

8

9.4 Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.4.1 Wearing parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.4.2 Ordering spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.4.3 Removing the pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.4.4 Sending the pump to the manufacturer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.5 Cleaning agent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11 Putting out of operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11.1 Emptying. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11.2 Clean. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

12 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

13 Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Noise level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Declaration of no objection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Declaration of incorporation in accordance with the EC machinery directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Declaration of conformity in accordance with the EC machinery directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

9

Overview.

1 Overview

This chapter contains an overview drawing of the pump and an example illustration of the type plate. For specications

regarding dimensions and weight →dimensional drawing.

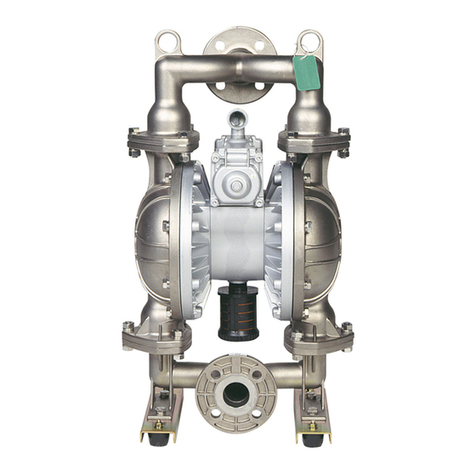

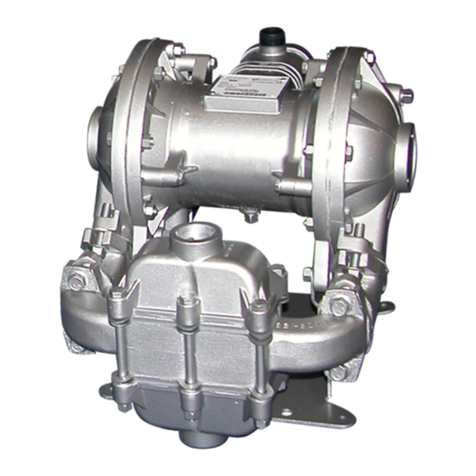

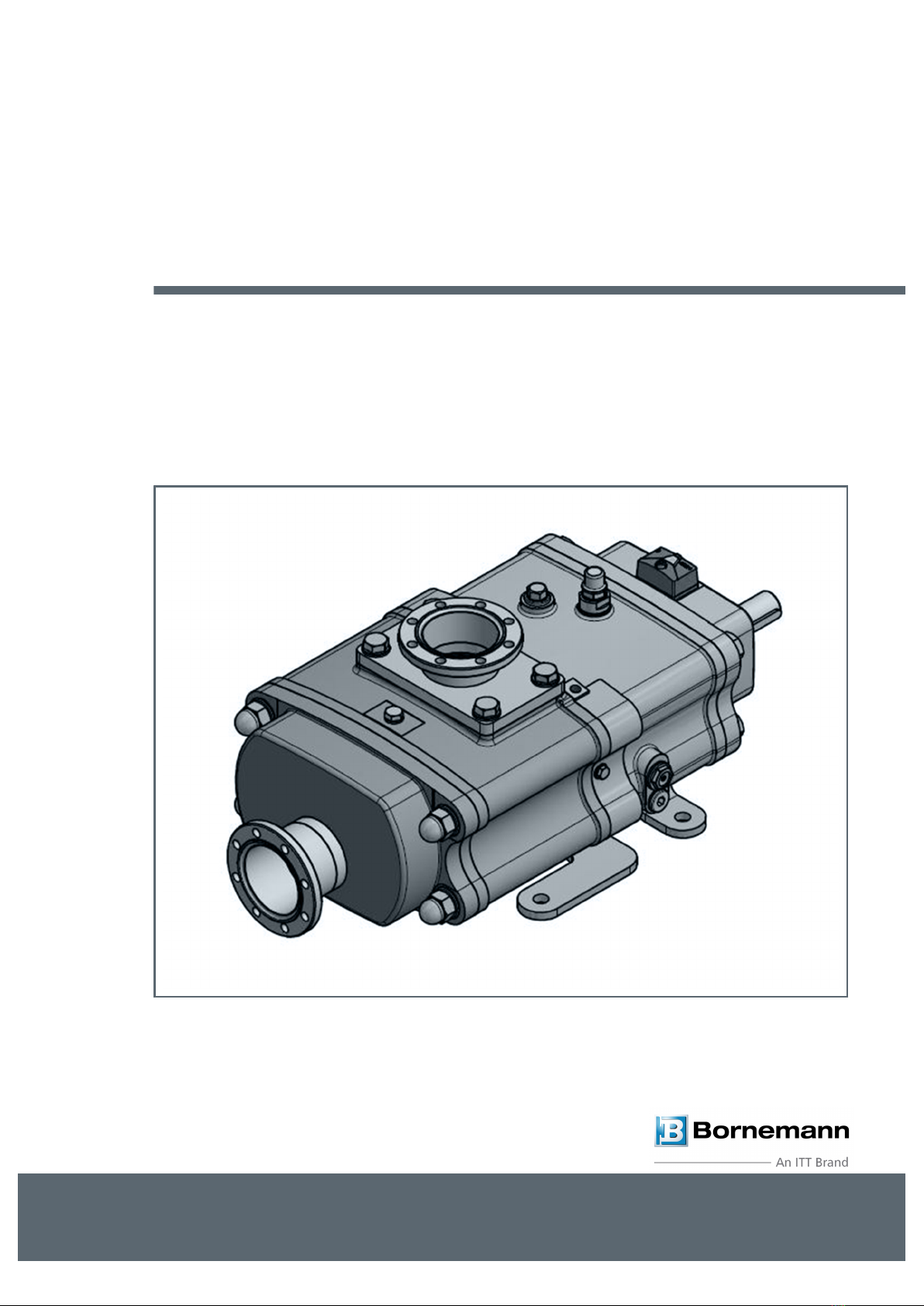

Screw pump SLH-5G

The following gure shows the pump only as an example and may dier from the pump supplied. For the order-specic

representation of the pump, in particular the position of inlet and outlet nozzles →dimensional drawing.

Fig. 1: SLH-5G

1 Outlet nozzle

2 Oil inlet

3 Ventilation lter

4 i-ALERT

5 Bearing casing

6 Pump casing

7 Inlet nozzle

8 Oil drain

9.10 Oil sight glass (on both sides)

Overview

10

Type plate on the pump (example)

The following gure shows the type plate on the pump only as an example. The type plate attached to the pump is

always decisive.

Fig. 2: Type plate on the pump

1 Order number

2 Serial number

3 Type

4 Year of manufacture

5 Pump capacity

6 Viscosity

7Dierential pressure

8 Inlet pressure

9 Output demand

10 Outlet pressure

11 Speed

12 Weight

Dimensions and weight

All detailed information on dimensions and weight are included in the dimensional drawing.

11

Safety.

Safety and warning information

2 Safety

This chapter contains important information that must be observed under all circumstances in order to use the pump

safely.

2.1 Safety and warning information

Safety and warning information is identied in this manual by warning signs and is introduced by signal words which indicate the

extent of the risk.

DANGER

This combination of warning sign and signal word indicates an impending, dangerous situation, which could lead to death or serious

injury if it is not avoided.

WARNING

This combination of warning sign and signal word indicates a potentially dangerous situation, which could lead to death or serious

injury if it is not avoided.

CAUTION

This combination of warning sign and signal word indicates a potentially dangerous situation, which could lead to slight or minor

injuries if it is not avoided.

NOTICE

This combination of warning sign and signal word indicates a potentially dangerous situation, which could lead to property damage

if it is not avoided.

ENVIRONMENT

This combination of warning sign and signal word indicates possible dangers for the environment.

Safety

Improper use

12

2.2 Proper use

The pump has an anticipated service life of 20 years.

■Only use the pump in compliance with this manual and all supplementary documents (⮫ ‘Supplementary documents’ on page 3).

■Have all work on the pump performed only by specialist personnel.

■Only operate the pump in technically perfect condition.

■Use pump exclusively for pumping the agreed pumped medium (→data sheet).

■Observe the operating limits of the pump (→data sheet).

■The pump is designed for a limited number of load cycles (N) between the pressureless state and the maximum permissible

pressure according to the data sheet (N=1000, see AD 2000 leaet S1, section 1.4 for this). During operation, any number of

pressure uctuations are permitted, as long as the load range of these does not exceed 10 % of the maximum permissible pressure.

■When pumping liquids containing solids: Comply with the limit values for the proportion of solids and grain size (→data sheet).

■When pumping liquids containing gas: Observe the limit values for the gas contents (→data sheet).

■Only operate the pump if the inlet and outlet lines are properly connected in the direction of ow (→dimensional drawing).

■Avoid dry running: Only put the pump into operation with pumped medium and do not operate without pumped medium

■Avoid cavitation:

–Fully open the inlet side valve (if available) during pump operation and do not use to regulate the pump capacity.

–Fully open the outlet side valve (if available) during pump operation and do not use to regulate the pump capacity.

■Only operate the pump with suitable non-return protection.

■Only operate the pump with suitable dierential pressure monitoring.

■Only operate the pump with suitable operating pressure limiting.

2.3 Improper use

Any use other than uses detailed under⮫ Chapter 2.2 ‘Proper use’ on page 12 shall be considered improper and is impermissible, for

example:

■Operating if safety devices are removed or defective

■Operating if the inlet valve (if available) is not opened completely

■Operating if the outlet valve (if available) is not opened completely

■Throttling the outlet side

■Operating without suitable non-return protection

■Operating without suitable dierential pressure monitoring

■Operating without suitable dierential pressure limiting

■Using pressure safety valves to regulate the ow rate and the pressure

■Filling the pump while hot

■Filling the pump during operation

■Pumping acids or other corrosive liquids without approval from ITT Bornemann GmbH

■Pumping pure gases

■The pumping of explosive media as well as explosive mixtures, which could arise under certain operating conditions

■Installation and operation of the pump in an Ex-area

■Reversing the permissible pumping direction

13

Safety.

Obligations of the operator

■Spraying the pump with high-pressure jets or re extinguishing equipment

■Failure to undertake measurements and checks for early damage detection

■Failure to observe the maintenance intervals

■Impermissible exchange of wearing parts

■Maintenance work was not carried out correctly

■Repair work was not carried out correctly

■Unauthorised modications to the pump without approval from ITT Bornemann GmbH

2.4 Obligations of the operator

The pump is used in the commercial sector. The operator of the pump is therefore subject to the statutory occupational safety

obligations.

In addition to the safety instructions in this manual, the safety, occupational safety and environmental protection regulations applicable

to the area of application of the pump must be observed.

In particular, the following shall apply:

■The operator must inform himself/herself about the applicable occupational health and safety regulations and identify additional

hazards arising from the special working conditions at the place of pump installation in a risk assessment,. This must be

implemented in the form of operating instructions for the operation of the pump.

■During the entire operating time of the pump, the operator must check whether the operating instructions drawn up by him/her

correspond to the current status of the regulations and, if necessary, adapt them.

■The operator must clearly regulate and dene the responsibilities for installation, operation, troubleshooting, maintenance and

cleaning.

■The operator must ensure that all persons using the pump have read and understood this manual. In addition, he/she must

regularly train the personnel and inform them about the dangers.

■The operator must provide the personnel with the necessary protective equipment and instruct them to wear the necessary

protective equipment.

Furthermore, the operator is responsible for ensuring that the pump is always in perfect technical condition. Therefore the following

shall apply:

■The operator must ensure that the maintenance intervals described in this manual are adhered to.

■The operator must have all safety devices checked regularly for functionality and completeness.

Hygiene-protected areas

The operator must comply with and implement further obligations arising from the hygiene regulations for the food industry if the

pump is used in such an area.

The following applies here:

■The operator must provide the necessary protective equipment for all employees who enter hygiene-protected areas.

■The operator must ensure that all employees put on the necessary protective equipment before entering hygiene-protected areas

and take this o before entering common rooms and dining areas.

■The operator must provide separate storage facilities for worn protective equipment and other clothing.

■The operator must ensure that the protective equipment is cleaned, disinfected and maintained.

Safety

Personnel qualications

14

2.5 Personnel qualications

WARNING

Risk of injury if the personnel is not suciently qualied!

If unqualied personnel carry out work on the pump/pump assembly or are in the danger area of the pump, dangers arise which can

cause serious injuries and considerable damage to the system.

−All activities must be carried out only by qualied personnel.

−Keep unqualied personnel away from danger areas.

Only persons who are expected to perform their work reliably may be permitted to be personnel. Persons whose

reactions are aected, e. g. by drugs, alcohol or medication, are not permitted.

When selecting personnel, observe the age and occupation-specic regulations applicable at the site of operation.

This manual lists the qualications of the personnel listed below for the various elds of activity:

Supervisor

The supervisor is a person authorised by the operator, who supervises assembly and repair work as well as operation (commissioning

and decommissioning) and gives instructions regarding technical processes and mechanical work. The supervisor has been instructed by

the operator and knows the residual risks arising from the system.

The supervisor is also able to carry out the tasks assigned to him/her on the basis of his/her knowledge and experience as well as

knowledge of the relevant regulations, and can recognise and avoid possible dangers independently.

Transport specialist

The transport specialist is trained to carry out transport work using a crane or forklift truck. He/she is able to select suitable lifting

equipment in accordance with the transport requirements and use it properly. For transport with a forklift truck, the transport specialist

is trained on the device and is able to guide it.

The transport specialist is specially trained for the working environment in which he/she works and knows the relevant regulations.

Qualied mechanic

The qualied mechanic is trained to carry out installation, testing, maintenance and repair work on hydraulic and mechanical machines

and systems. He/she is able to read, evaluate and use instructions and technical specications to carry out work properly.

The qualied mechanic is specially trained for the working environment in which he/she works and knows the relevant standards and

regulations. He/she is trained in the use of the product and can carry out the assigned tasks safely and without damaging the product.

He/she also has knowledge of pneumatics and hydraulics in order to assess and avert the dangers posed by pneumatic and hydraulic

systems as well as the reactions of the systems.

Qualied electrician

The qualied electrician is trained to carry out installation, testing, maintenance and repair work on electrical installations. He/she is

able to read, evaluate and use instructions, circuit diagrams and technical specications to carry out work properly.

The qualied electrician is specially trained for the working environment in which he/she works and knows the relevant standards and

regulations.

15

Safety.

Personal protective equipment

2.6 Personal protective equipment

Personal protective equipment is used to protect people from health and safety impairments at work. Personnel must wear appropriate

personal protective equipment during all work on the pump/pump assembly.

The following explains the personal protective equipment:

Protective work clothing

Protective work clothing protects the torso, arms and legs from dangers such as:

■Abrasion and grazing

■Risk of injury due to moving parts

■Burns due to hot surfaces or hot liquids

■Scalds due to hot vapours

■Injuries due to coming into contact with chemicals

The type of protective work clothing must be selected according to the area of application.

Safety shoes

Safety shoes protect the feet from bruising, falling parts and pointy or sharp objects. They also

protect against slipping on slippery surfaces.

Industrial safety helmet

An industrial safety helmet protects the head against falling objects, swinging loads and

impacts on stationary objects.

Safety goggles

Safety goggles protect the eyes from ying parts and liquid splashes.

Hearing protection

Hearing protection protects against hearing damage caused by exposure to noise.

Protective gloves

Protective gloves protect the hands from abrasion and grazing, punctures or deeper injuries, as

well as from contact with hot surfaces.

Chemical-resistant protective gloves protect hands from aggressive chemicals.

The type of protective gloves must be selected according to the area of application.

Safety

Special hazards

16

2.7 Labelling on the pump

WARNING

Danger from illegible signs!

In the course of time, stickers and signs may become dirty or otherwise unrecognisable, so that dangers cannot be recognised and

necessary operating instructions cannot be followed. This results in a risk of injury.

−Keep all safety, warning and operating instructions in a clearly legible condition at all times.

−Immediately replace damaged signs or stickers.

The following symbols are located in the work area. They refer to the immediate environment in which they are installed.

Hot surface

Hot surfaces, such as hot machine parts, containers or materials, but also hot liquids, are not

always noticeable. Do not touch them without heat-resistant protective gloves.

2.8 Special hazards

The pump/pump assembly has been designed in accordance with state-of-the-art and current safety regulations. However, special

hazards remain that require careful action. These hazards and the resulting behaviours and provisions are listed below.

Electrical current

DANGER

Risk of death due to electrical current!

In case of contact with live parts, there is an immediate risk of death due to electric shock. Damage to the insulation or individual

components can be life-threatening.

−Only allow work to be carried out on the electrical systems by qualied electricians.

−If the insulation is damaged, immediately switch o the power supply and arrange for a repair.

−Before starting work on active parts of electrical systems and equipment, ensure that they are in a voltage-free state and that

they remain so for the duration of the work. Observe the 5 safety rules:

−Switch o.

−Secure against being switched back on.

−Determine that there is no current.

−Earth and short-circuit.

−Cover or isolate neighbouring live parts.

−Never bridge fuses or put them out of service. When replacing fuses, observe the correct current rating.

−Keep moisture away from live parts. This can lead to a short circuit.

17

Safety.

Special hazards

Hot pumped medium

WARNING

Risk of scalding due to hot pumped medium!

Pumped medium can exhibit high temperatures. Contact with escaping pumped medium can cause severe scalding.

−Always wear heat-resistant protective work clothing, safety footwear, safety goggles and protective gloves during all work.

−Before all work on the pump: Switch o the pump, close the shut-o valves and wait until the pump has cooled down and the

pressurised components of the pump are depressurised.

Hot surfaces

WARNING

Risk of injury due to hot surfaces!

The pumped media, the streamed-through components and the drive can exhibit high temperatures. Skin contact with hot surfaces

causes severe burns.

−Always wear heat-resistant protective work clothing and protective gloves when working near hot surfaces.

−Before all work on the pump: Switch o the pump, close the shut-o valves and wait until the pump has cooled down.

High operating pressure

WARNING

Risk of injury from media under pressure!

The pump can be used to pump pumped media at high pressures. By opening pressurised components and through leakages, media

can escape under high pressure and cause injuries.

−Wear personal protective equipment: Protective clothing, safety footwear, safety goggles, chemical-resistant protective gloves.

−Only allow work to be carried out on the system by qualied personnel.

−Do not disassemble any components during operation.

−Before working on components under pressure: Relieve components of pressure completely in the safe area and ensure this

condition for the duration of the work.

−Regularly check pressurised components for awless condition.

Safety

Safety equipment

18

Moving parts

WARNING

Risk of death due to moving parts!

When working near moving parts, e. g. the drive spindle, hair may be drawn in, body parts may be crushed or other serious injuries

may be caused.

−Do not interfere with moving parts during operation and do not handle moving parts.

−Before performing tasks, switch o moving components and secure them against being switched on again.

−Keep covers closed during operation.

−Pay attention to the stopping time: Before opening the covers, ensure that all parts are stationary.

Noise

WARNING

Risk of injury from noise!

In the area of the pump and drive, the noise level may exceed the permissible limit value and cause permanent hearing damage.

−When working in the immediate vicinity, always wear hearing protection.

Slippery surfaces

CAUTION

Risk of injury due to slippery surfaces!

Leaks can occur in the area of the pump. This can cause slippery surfaces and lead to falls and injuries.

−Regularly clean accessible surfaces to remove slippery deposits and leaks.

2.9 Safety equipment

WARNING

Risk of death due to malfunctioning safety equipment!

In the case of safety equipment that is not functioning or has been disabled, there is a risk of serious injury or death.

−Before starting work, check that all safety equipment is in working order and properly installed.

−Never disable or override safety equipment.

−Ensure that all safety equipment is accessible at all times.

19

Safety.

Securing against restarting

Providing safety equipment

■Ensure that contact protection is provided for hot, cold and moving parts.

■Ensure that sucient earthing and potential equalisation are guaranteed.

■For maintenance and repair work: Provide electrical disconnection devices.

■Provide a suitable non-return device in the system, which prevents uncontrolled back-ow of the pumped medium when the

pump is at a standstill.

■Provide suitable operating pressure limiting, which reliably prevents the maximum permissible operating pressure of the system

from being exceeded.

■Provide a suitable dierential pressure monitoring system for the pump.

Safe handling of EMERGENCY STOP buttons

■If necessary, include EMERGENCY STOP buttons for switching o the system at a sucient safety distance from the system.

■Remember the positions of all EMERGENCY STOP buttons, in order to be able to react quickly in an emergency.

■Always keep all EMERGENCY STOP buttons freely accessible.

■Only reset the EMERGENCY STOP once the danger has been rectied.

2.10 Securing against restarting

WARNING

Risk of death due to unauthorised or uncontrolled restart!

Unauthorised or uncontrolled restarting can result in serious injuries or even death.

−During all work on the system: Ensure that the system is secured against unauthorised or uncontrolled restarting.

−After completion of work on the system: Ensure that no persons are left in the danger zone before the system is switched on

again.

The following provisions can be implemented to secure the system against being switched back on:

■Keep removed circuit breakers or fuse links in a safe place and replace them with suitable locking plugs or dummy elements.

■Lock the circuit breaker, switch cabinet or fuse box and keep the lock key in a safe place.

■Attach suitable switching prohibited signs or warning signs.

Safety

Environmental protection

20

2.11 Environmental protection

ENVIRONMENT

Danger to the environment from incorrect handling of environmentally hazardous substances!

Incorrect handling of environmentally hazardous substances, especially incorrect disposal, can cause considerable damage to the

environment.

−Always observe the information below regarding the handling of environmentally hazardous substances and their disposal.

−If environmentally hazardous substances accidentally enter the environment, take appropriate provisions immediately. If in

doubt, inform the relevant local authority of the damage and ask for appropriate provisions to be implemented.

Lubricants

Lubricants such as oils contain toxic substances. They must not get into the environment. Disposal must be carried out by a specialist

disposal company.

Pumping medium

In order to ensure proper disposal, local regulations, laws and technical regulations must be observed and complied with if applicable.

Cleaning agent

Cleaning agents are irritants and contain toxic substances. They must not get into the environment.

In order to ensure proper disposal, local regulations, laws, technical regulations, etc. and the safety data sheets for the respective

substances must be observed and complied with.

Preservative agents

Preservatives are irritants and contain toxic substances. They must not get into the environment.

In order to ensure proper disposal, local regulations, laws, technical regulations, etc. and the safety data sheets for the respective

substances must be observed and complied with.

Table of contents