Seko MSA Series User manual

SPR0136037 Rev. 1.5

EN

DE

ES

FR

IT

MECHANICAL DIAPHRAGM

MSA/MSV SERIES

INSTALLATION MANUAL

HANDBUCH

MANUAL DE INSTALACION

MANUEL D’INSTALLATION

MANUALE D’INSTALLAZIONE

SPR0136037 Rev. 1.5

SPR0136037 Rev. 1.5

Instruction Manual for Mechanical Diaphragm

MSA/MSV series

SPR0136037 Rev. 1.5

Before installation and use of this device, please read carefully this instructional manual, standard

constructor is not responsible for any loss caused by not following instructions contained. Standard

constructor remains the right to alter any contents without notice in advance.

Warranty and scope

[1] Upon receiving the pump, please check if the products are damaged, accessories and stand-by

are contact, if any damage happens during shipment, please immediately contact us.

[2] The warranty period is one and half a year starting from the date of delivery from our factory.

[3] During warranty period, under normal use, if some parts fall off or have defect due to improper

design and manufacturing, standard constructor will repair or replace those parts free of charge.

[4] The user must pay relevant charges in the following conditions:

The warranty is expired; the pump is wrongly used or stored; Customers use bad quality s

pare parts that are produced by manufacturers not recommended by standard constructor.

Any damage that is caused by maintenance done by workers not from standard constructor or not

designated by standard constructor.

Any damage that is caused by fire, earthquake or other natural disasters;

[5] Standard constructor is not responsible for products that are made from materials designated

by customers in accordance with standards of customers.

[6] Standard constructor is not responsible for any corruption to products caused by fluid chemical

reaction or directly by fluid to be dosed. The model recommendation from standard constructor is

only for suggestion and standard constructor is responsible for any results.

[7] Trouble or damage reason should be jointly confirmed by customer and our service engineer

after detailed discussion.

[8] Standard constructor is not responsible for fees incurred by disasters during pump operation.

Maintenance

During operation, if any abnormal situation is found, please immediately stop operation and check

if pump part fails to work (please refer to the instruction manual)

[1] Please contact Standard constructor or our authorized distributor for maintenance.

[2] Please read carefully the instruction manual to check the product before calling us or our

distributor for maintenance.

[3] If the pump needs to be returned to Standard constructor, please fill Service Sheet for our

reference and facilitate maintenance:

1. Model and series number

2. Ambient environment and service life

3. Details of trouble

3. Before returning pump to standard constructor, please make sure that residues remained in the

pump chamber are thoroughly cleaned.

SPR0136037 Rev. 1.5

Contents

1. Overview

1.1 Application and product identification

1.2 Operational principle of Mechanical Diaphragm pump

1.3 Adjustment of Stroke length

2. Installation

2.1 Installation dimension

2.2 Instructions for installation

2.3 Suction line

2.4 Discharge line

3. Start-up

4. Maintenance

4.1 Instruction for oil-filling

4.2 Sketch for pump head disassembly and installation

4.3 Instructions for motor operation

4.4 Notes

4.5 Recommended parts

5. Trouble shooting

6. Handling and storage

6.1 Handling

6.2 Storage

SPR0136037 Rev. 1.5

1

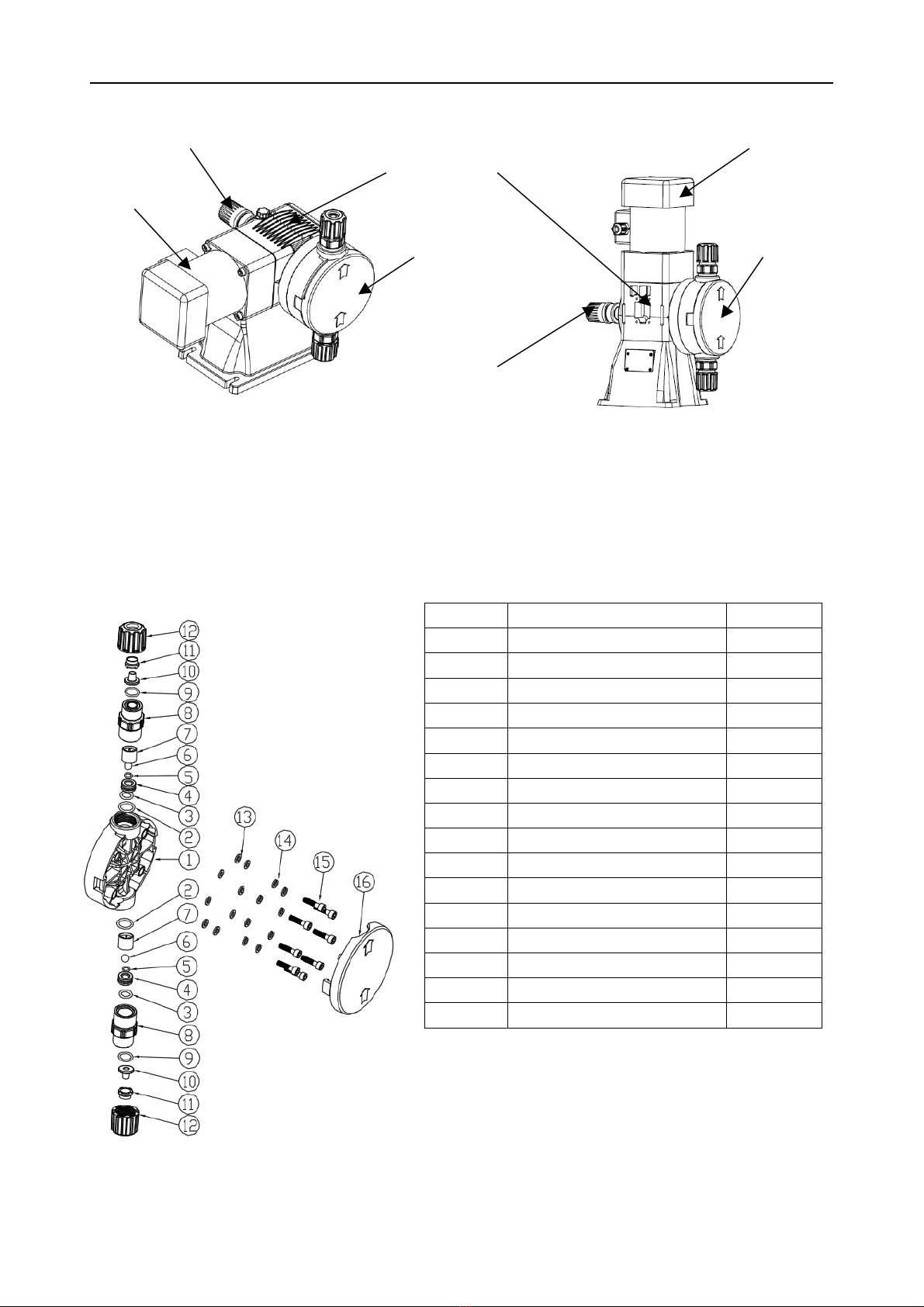

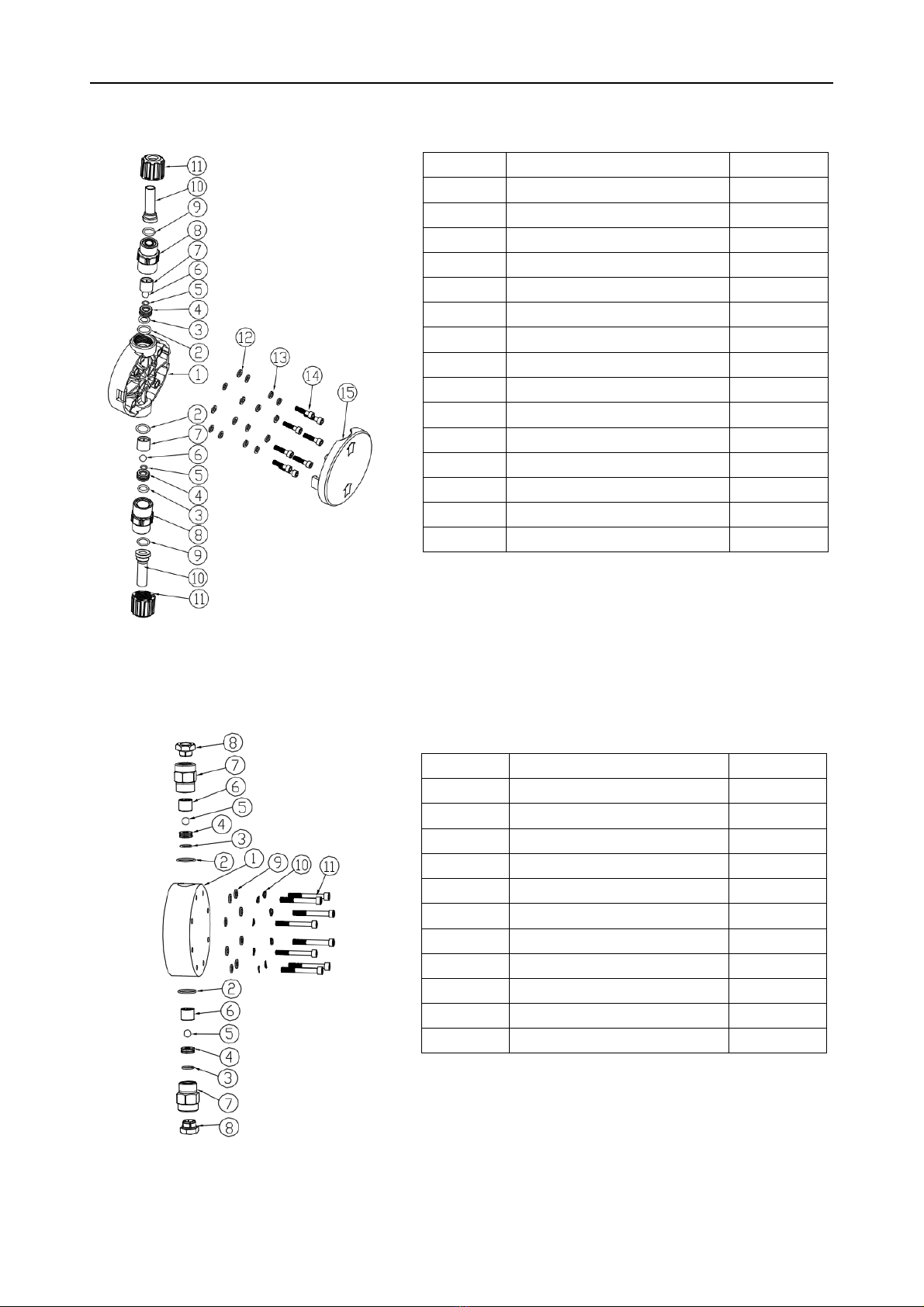

Structure of MSA/MSV series

Disassembly sketch of pump head

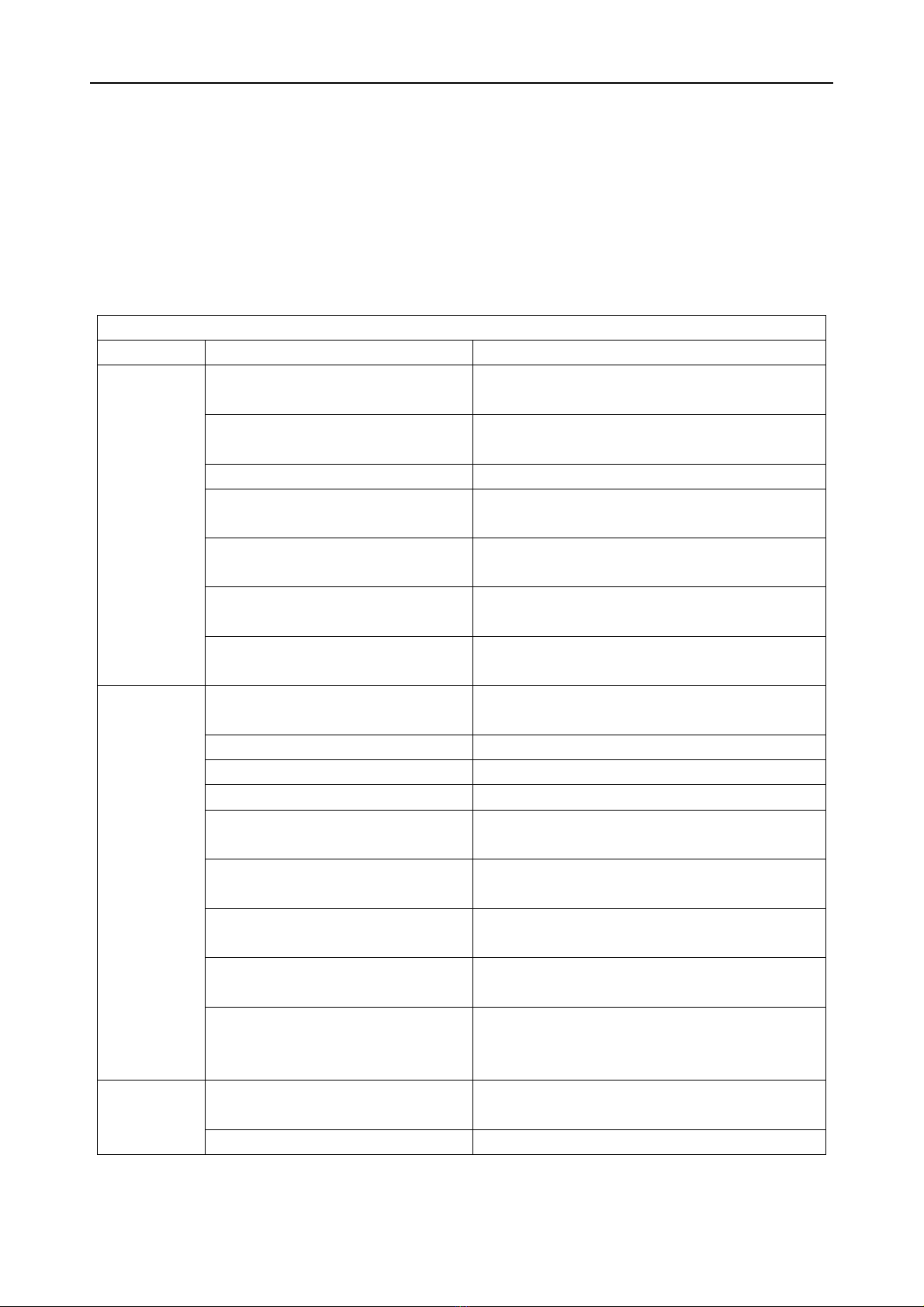

Table 1

PVDF pump head (standard)

Number

Description

Quantity

1

Pump head

1

2

Seal D18,72X2,62

2

3

Seal 14,48X2,69

2

4

Ball seat

2

5

Seal 7,65X1,78

2

6

Ball

2

7

Ball cage

2

8

Valve body

2

9

Seal 12,37 X T 2,62

2

10

Gasket

2

11

Clamp

2

12

Connecting nut PVDF

2

13

Gasket for M6 screw

8

14

Spring pad for M6 screw

8

15

M6x25 Hexagon screw

8

16

Cover for pump head

1

Adjustment knob of

stroke length

Adjustment knob of stroke length

Mechanism

Pump head

Motor

Motor

Pump head

SPR0136037 Rev. 1.5

2

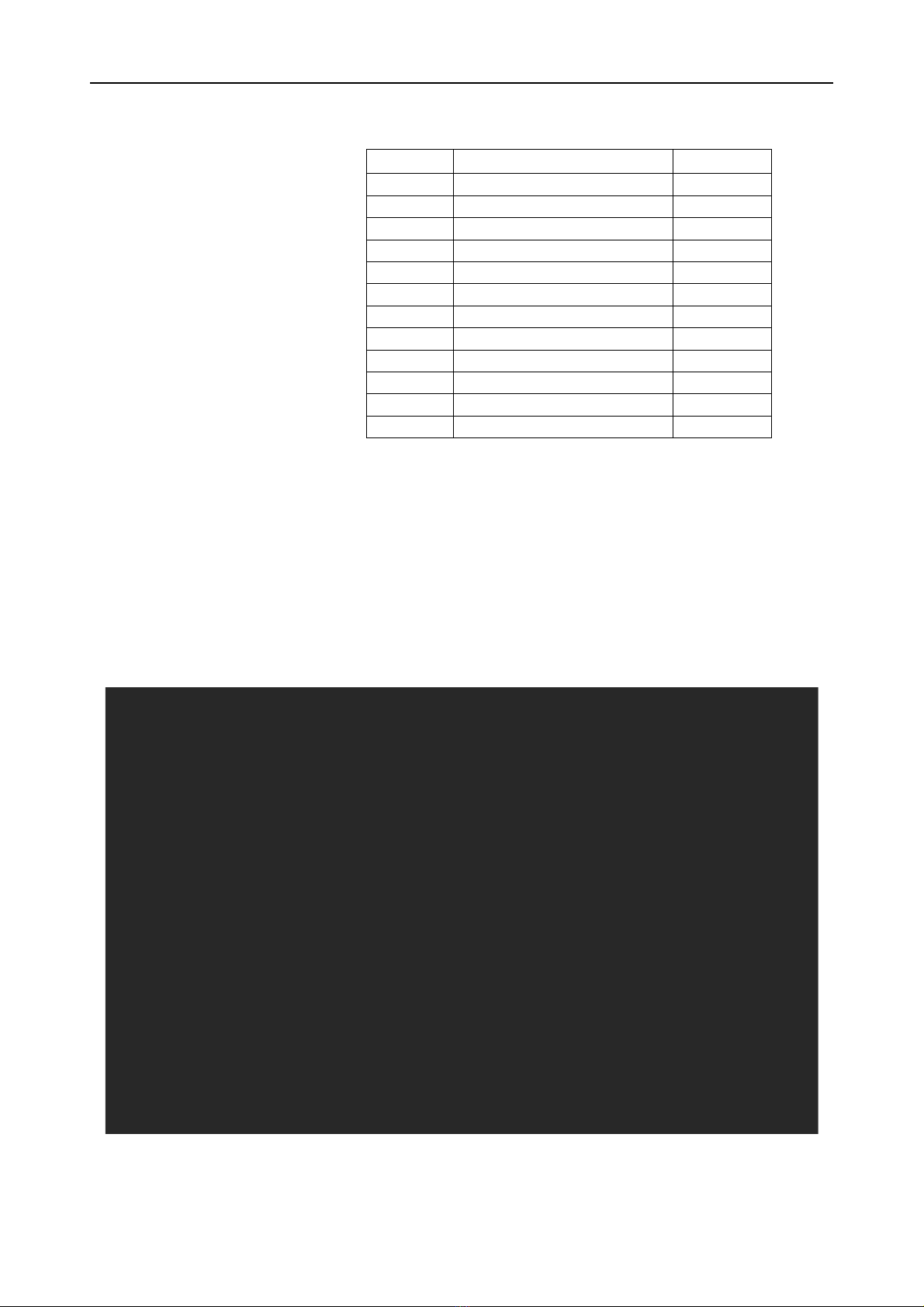

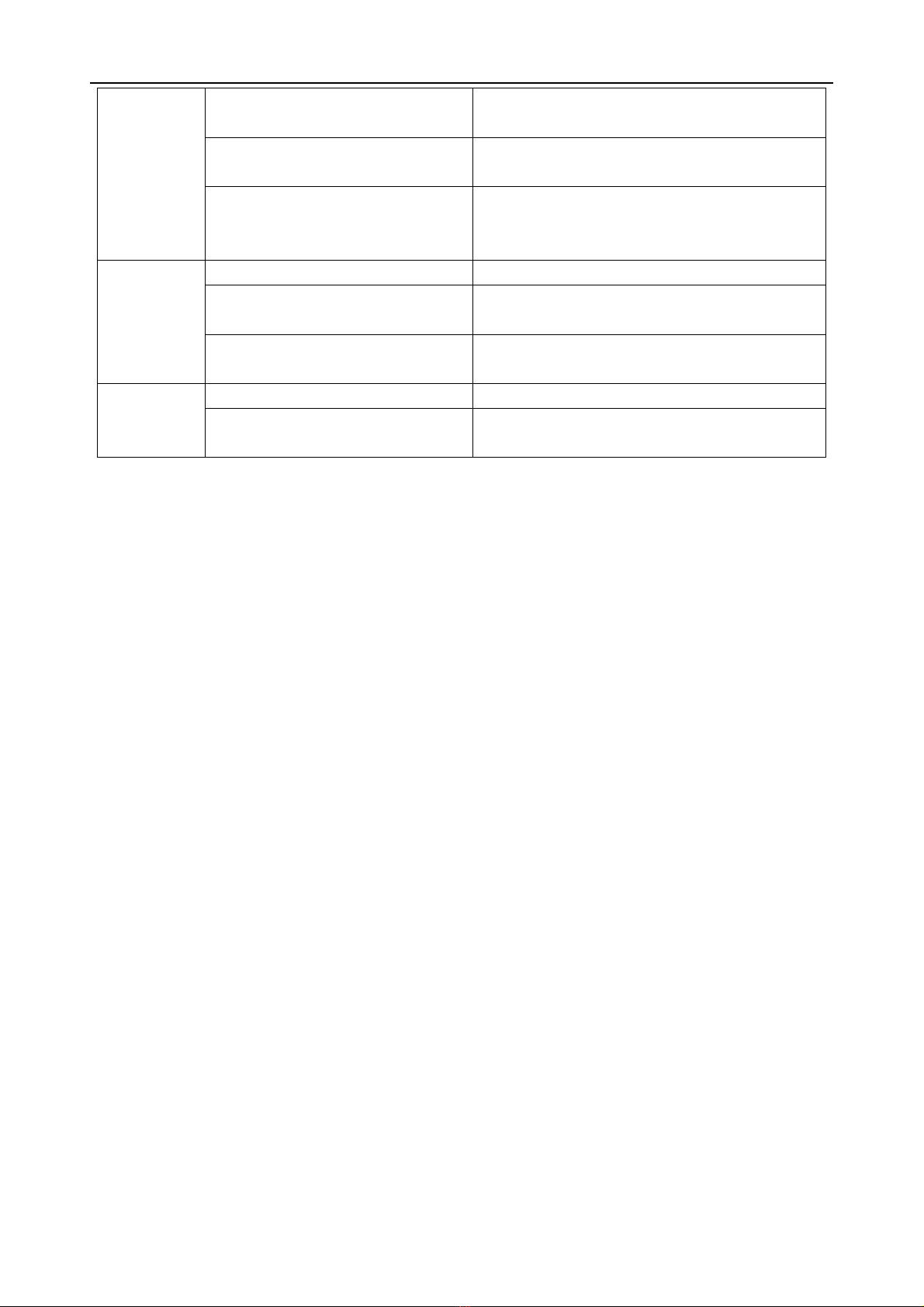

Table 2

PVDF pump head(with DN15 connector( number 10 and 11)

additional cost will be

charged)

Number

Description

Quantity

1

Pump head

1

2

Seal D18,72X2,62

2

3

Seal14,48X2,69

2

4

Ball seat

2

5

Seal7,65X1,78

2

6

Ball

2

7

Ball cage

2

8

Valve body

2

9

Seal 12,37 X T 2,62

2

10

Gasket

2

11

Connecting nut PVDF

2

12

Gasket for M6 screw

8

13

Spring pad for M6 screw

8

14

M6x25 Hexagon screw

8

15

Cover for pump head

1

Table 3

SS316L pump head

Number

Description

Quantity

1

Pump head

1

2

Ball

2

3

Ball cage

2

4

Ball seat

2

5

Valve body

2

6

Seal D12,42XT1,78

2

7

Seal D18,72X2,62

2

8

Valve cap

2

9

Washer for M6

8

10

Spring washer for M6

8

11

Screw M6x50

8

SPR0136037 Rev. 1.5

3

Table 4

Pump head connection with pipeline

Number

Description

Quantity

1

Injection point

1

2

Injection connector

1

3

Seal

2

4

Gasket

2

5

Tube clamp

2

6

Ring nut

4

7

Discharge tube

1

8

Discharge valve

1

9

Pump head

1

10

Suction valve

1

11

Suction tube

1

12

Foot filter

1

Disassembly sketch of mechanism

SPR0136037 Rev. 1.5

4

Number

Description

Quantity

1

Case for DOSY

1

2

Waterproof seal

1

3

Lateral cover

1

4

Screw for lateral cover

4

5

Propulsion shaft

1

6

Oiless bearing

1

7

Spring

1

8

Directional flange for propulsion shaft

1

9

Oil seal

1

10

Screw for directional flange

4

11

Propulsion board for membrane

1

12

Membrane

1

13

Small bearing for fixing eccentric shaft

1

14

Snap spring

3

15

Propulsion bearing for eccentric shaft

2

16

Eccentric shaft

1

17

Big bearing for fixing eccentric shaft

1

18

Fixing board for eccentric shaft bearing

1

19

Fixing screw

2

20

Gasket between motor and pump body

1

21

Motor

1

22

Base

1

23

Label

1

24

Adjustment rod

1

25

Seal for adjustment rod

1

26

Knob for adjustment rod

1

27

Graduation label

1

28

Protection ring for graduation label

1

29

Black cover for adjustment rod

1

30

Locking screw for adjustment rod

1

SPR0136037 Rev. 1.5

5

1. Overview

The metering pump is a reciprocating positive displacement pump; basic components are: the

motor, the gearbox, the mechanism, the stroke length adjustment and the liquid end (pump head)

Safety instruction

WARNING

Exceeding the maximum allowed operating pressure must be prevented

(e.g. by using a pressure relief valve)

Before starting to work on the metering pump verify carefully the following:

- The drive is disconnected from the power source

- Parts such as pump head and piping are depressurized

- Parts in contact with aggressive substances are washed before handling

- Personnel protection is carried out according to local regulations

1.1 Application and product identification

Metering pump is a process component capable to transfer defined volumes of liquid with high

accuracy; moreover it is possible to vary the flow rate by acting on integral devices.

To ob ta in th e be st pe rf o rm a n ce s, se le ct th e p um p co ns id e ri ng th e du ty re qu ire d an d th e

compatibility of the construction materials of the contact parts.

Before using a pump for a duty different from the original one, please contact us

for information.

Actual dimension of product identification

53x35mm

1. Model

2. Reference

3. Series number

4. Max pressure

5. Max flow rate

6. CE certificate

1.2 Operational principle of mechanical diaphragm pump

Mechanism is the device that permits to transform the electric motor rotary movement into

reciprocating movement by gearbox. The reciprocating movement draws membrane, making

the volume of pump chamber change to push the ball up and down to form vacuum adso

rption and squeezing for fluid transfer. The adjustment of flow rate is realized by regulating

the stroke length.

SPR0136037 Rev. 1.5

6

The operational principle is illustrated below:

1) As the membrane is drew back, the ball of discharge

valve drops on and cling to the valve seat , the ball of

suction valve is uplifted by vacuum formed between

membrane and pump head,correspondingly, the fluid is

also suctioned.

2

As the membrane is drew forward, the ball of suction

valve clings to valve seat ,so, the fluid can not pass

through, on the contrary, the ball of discharge valve is

uplifted by membrane’s forward movement.

To obtain high accuracy performances pump must

operate at ideal conditions: constant speed, pressure,

viscosity.

1.3 Adjustment of the stroke length

The adjustment of stroke length is realized by changing the stroke of membrane, and the

adjustment can only be done during pump operation.

MSA/MSV

The variation from 0 to 100% of the maximum flow rate is obtained by rotating the

adjustment knob counter clockwise; each revolution of the adjustment knob corresponds

to a variation of 1/4 of the maximum capacity. After adjustment, you need to lock the stroke

length.

SPR0136037 Rev. 1.5

7

2. Installation

2.1 Installation dimension

2.2 Safety precautions

To successfully install and use our products, please make sure you follow instructions contained in

6.1 and the following precautions:

1) don’t work alone

2) connect motor to grounding

3) When working on the pump verifies that electric motor or servomotor is not connected to

mains.

4) using electric tools in hazardous areas, pay attention to special regulations

SPR0136037 Rev. 1.5

8

5) keep available a first aid kit

6) observe local law safety regulations

7) Foundation height should be so as to facilitate maintenance operation, handling, oil refill and

drain, easy disassembling of pump head

8) Install the pump free of strain on its base, pump head connections and foundation

Precautions for electrical connection:

1) Electric motors and electrical components should be connected in accordance with local

regulations and by qualified personnel only.

2) Install overload protection or temperature sensor.

3) Check voltage, frequency, motor speed and power.

4) In hazardous areas special regulations must be applied.

For a good operation, the correct installation of the pump is fundamental:

Before carrying out hydraulic connections, make sure that the inside of pipes, tanks, etc. have

been thoroughly cleaned/washed. However we recommend the installation of a temporary filter

near to suction nozzle in order to stop plant residues and slags.

Connect pipes avoiding excessively stretching nozzles, or can install a pulse damper.

Install pipes correctly sized for the maximum flow rate of the pump, avoid necks and tortuosity

where air or gas could be entrapped.

Warning:

To prevent serious damages

the suction and discharge lines must be properly designed,

sized and connected to the pump.

2.3 Suction line

Install pipe as short as possible and avoid tortuous paths. The negative pressure situation (suction

uplift) should be avoided, because it will affect accuracy of metering. If the temperature of fluid to

be dosed reaches the boiling point, the enough suction head should be provided to prevent the

fluid from entering suction end during suction line and vaporizing.

The pipe diameter should be decided

in accordance with instantaneous ma

x flow rate (figure left), and the pipe

diameter should be equal to 1.5 the

diameters of the pump nozzles.

In case the pump needs to dose fluid with high viscosity, in order to reduce the loss of fluid, the

diameter of discharge tube must be 4 times as same as that of pump suction nozzle. If you can not

identify the dimension, please contact Standard constructor.

In order to prevent the impurities, do not close the tube to bottom of chemical tank. The suction line

must be airproof to ensure precise flow rate.

SPR0136037 Rev. 1.5

9

2.4 Discharge line

The discharge pressure should be larger than the max rated working pressure of pump.

It is very important to prevent the air entering into the discharge line.

The flow rate can be controlled only when the discharge pressure is larger than the suction

pressure.

Please observe the following instructions when pumping liquids that tend to crystallize or

suspensions that tend to sediment:

Keep suspension correctly agitated in order to prevent sedimentation

Avoid installation of vertical lines over the pump discharge nozzle

Before stopping the pump start a washing cycle of the pump and pipes

Designing suction and discharge lines should permit complete emptying

3. Start-up

Connect the motor to power supply.

Check the direction of rotation of the electric motor; an arrow on the electric motor shows the

correct direction of rotation

The electric motor should be connected by qualified personnel only!

WARNING:

Don’t start the pump with the suction and/or discharge check valves closed

Don’t close check valves while the pump is in operation

Before starting the pump check the following points:

• Check mechanism for the correct oil filling

• Check metering pump for overpressure protection (pressure relief valve installation)

• Verify that all hydraulic connections are correctly tight

• Position adjustment knob at “zero” flow rate

• Start the pump without discharge pressure and increase progressively the flow rate up to 100%

• Check if there is bubble in the pump chamber.

WARNING 1

DON’T EXCEED THE MAXIMUM PERFORMANCE STENCILLED ON THE PUMP LABEL, If no

pressure gauge is fitted on the plant, the installation of a temporary pressure gauge is

recommended in order to check that the actual pressure at the start-up doesn’t exceed the

maximum allowable pressure.

WARNING 2

If the pumped liquid is toxic, poisonous, aggressive, flammable or for any reason

dangerous, use particular care avoiding accidental leakages through gaskets or pipes

during start-up or maintenance operations.

Moreover

follow all the recommendations of the manufacturer for handling and the local

laws relevant to safety during handling and disposal of dangerous substances.

SPR0136037 Rev. 1.5

10

4. Maintenance

4.1 Instructions for oil-filling

Attention

The lubrication grease is filled as shipped from our factory.

Replace oil after 1500 operation hours and afterwards every 4000 hour

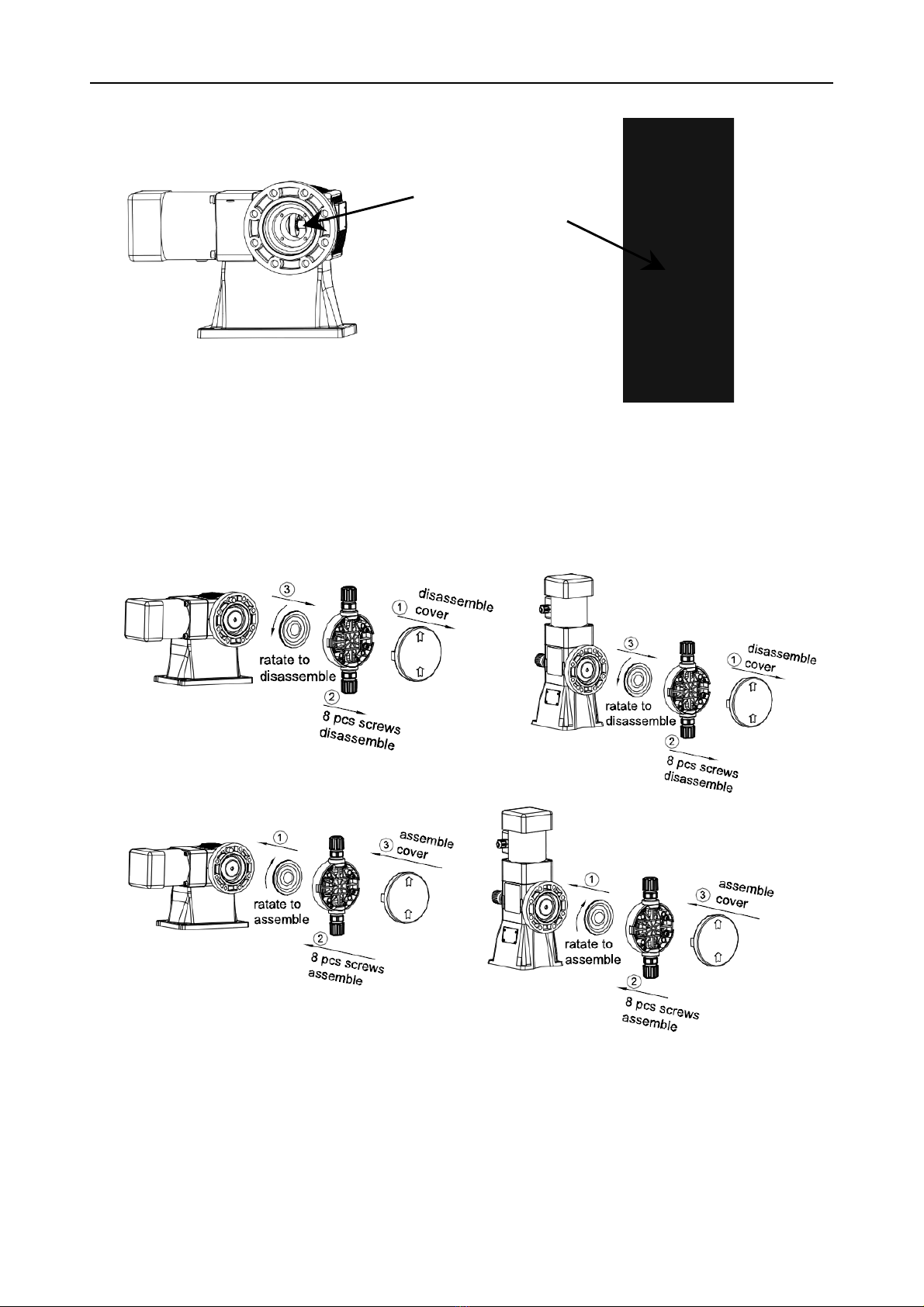

4.2 Disassembly and installation of pump head

1) Disassembly

2) Assembly

Attentions

1. Before disassembling the diaphragm, please position the knob at “ Zero” flow rate

2. The tightening torque for diaphragm is 4 N/m

3. After installation of diaphragm, the knob must be positioned at “ 100%” flow rate and

then install the pump head

Internal bearing and

adjustment rod shall

be lubricated

SPR0136037 Rev. 1.5

11

4.3 Instructions for motor operation

1. The ambient environment for motor is below 1000m, with temperature from -15°C to 40°C

2. The user should provide the power supply with stable voltage( single phase or

three-phase) corresponding to motor, especially for three-phase, every phase must be same

without failure, otherwise, the motor will be burned.

3. Wire connection

1) Connection for 110V and 220V: the yellow and green

wires are connected to the earth, and the black and red

wires are connected to the live line and the neutral line. The

rotation of motor has no effect on operation of pump.

2) Connection for 380V: the yellow and green wires are

connected to the earth, and the other three wires are

connected to the power supply wire. The rotation of motor

has no effect on operation of pump.

Connecting the motor to power supply, the user should

pay more attention to safetyand reliability of connection, no failure and wrong connection i

s allowed( especially for three-phase)

Virtual connection: the wire screw is not tightened or dropped.

Phase-losing connection: two phases are connection, the remaining phase is disconnected.

4. The motor should be installed at the dry place where is waterproof and dustproof with good

ventilation and heat dissipation condition.

5. Under normal working condition, the motor needs to be maintained at least one year, with main

maintenance on external cleaning of motor ( including internal fan cover, fan leaf surface and

surface of external housing ventilated rib), if the working condition is harsh ( outdoor or more dust),

the periodical maintenance time should be shortened( half an year, three month or even shorter)

6. The connecting wire between motor and power supply should be checked yearly for aging. In

terms of motor selection, under rated voltage, the torque should be corresponding to its related

equipment, not exceeding the rated torque; otherwise, the shaft of motor might be broken or

burned.

7. The motor must connect to grounding to avoid creepage, causing injury of person.

8. Handle and store carefully the motor.

9. The gearbox is closely connected to the motor, so the collision with motor can lead to loose

connection between motor and gearbox, which will reduce their life. Make sure good ventilation to

avoid overheating of motor.

10. Some simple solutions for motor troubles

The motor

can not start

but buzz

There is circuit

breaking, which

causes motor to

operate under single

phase condition

(very easy to burn

the motor)

1. Check if the connection between switch and stator

winding is correct

2. Check if the terminal is loose

3. Check if the wire is broken or has virtual connection,

use multimeter to check.

4. Check if starting device is connected correctly.

SPR0136037 Rev. 1.5

12

Low voltage

1.The power supply cable is too thin to burden huge

starting pressure, change into thick cable

2.The motor that should be connected by triangle

connection is wrongly connected by star connection, and

the motor is started with heavy-duty

The motor

temperature

is too high

and is smo

king

The voltage is too

low or with heavy

load; the pump stops

operation or bad

lubrication

1. Measure if the voltage is too low

2. Measure if the current is too big, if exceeding the

rated current, it might be overloaded, so it can

reduce the load

3. Solve the mechanical problem and fill lubrication oil

The motor suffers

from bad ventilation

or insolation

1. Check if the fan leaf is damaged or fixed

2. Check if the fan cover is jammed by dust

3. Remove articles affecting ventilation and heat

dissipation

4. Provide necessary shield for motor

The voltage is too

high or the wire

connection is wrong

1. If the voltage is too high, consider providing stable

power supply

2. The motor that should be done by triangle connection is

wrongly connected by star connection, so the phase

voltage is reduced and light load can be burdened, but for

heavy load, the motor heats and might be burned even.

3. The motor that should be done by star connection is

wrongly connected by triangle connection, so the phase

voltage is increased and immediately stop motor

operation, otherwise, the motor might be burned.

The motor is started

frequently or its

rotation direction is

changed very often

Reduce times of rotation direction change and start-up

Mutual friction

between stator and

rotor

1. The screw of motor cover is loose, forming gap

between cover and housing, the solution is to tighten the

screw

2. The rotor bearing block is too small or the bearing

chamber of motor cover is too big

The fuse is

burn or

tripped

Start under single

phase power supply

Check switch and fuse

There is short circuit

between switch and

motor

Check if there is short circuit between motor terminal and

if there is short circuit on the connecting wire between

motor and power supply

The stator winding is

not earthed or there

is short circuit on the

The motor should be earthed and insulate the short circuit

SPR0136037 Rev. 1.5

13

stator winding

The fuse is too thin

Replace the fuse with the one that corresponds to the rate

current of motor

The

Housing of

motor is

electriferous

The outgoing wire of

motor is broken and

contacts with the

housing

Open the wire box and tape the broken part with insulated

tape

The power supply

wire is broken and

contacts with the

housing

Tap e the p ow er s u p p ly w ire w ith i ns u la te d t ap e

The winding of stator

is aged and is

creepage

The winding of stator is aged and is creepage

The

insulation

resistance

of winding is

low

The working

condition of motor is

harsh, with moisture

and drop into the

motor, damaging the

insulation layer and

causing low

insulation layer

Use the megger to check and dry the stator

The insulation layer

is aged

The stator winding should be redipped for painting and

dried.

4.4 Notes

Before servicing pump or its related equipment verify that all electric connections (power and

control unit) have been disconnected from mainsDepressurize completely pump and pipes and

drain the section in which maintenance is required

Don’t pour in the ambient polluting substances such as pumped chemicals, hydraulic liquid,

lubricating oil, etc.

Before servicing pump or its related equipment, read carefully the technical specification of the

handled fluids with particular respect to the actions that must be done in case of accidental contact

with a dangerous fluid.

As minimum every six months, dismount the pump head as follows:

Disconnect suction and discharge pipes

Drain processed liquid in the pump head and pipes

Unscrew bolts fixing the pump head to mechanism

Dismount suction and discharge valves

SPR0136037 Rev. 1.5

14

4.5 Recommended spare parts

In order to face normal service problems and to avoid possible waste of time, we suggest to keep

in stock a small supply of the following spares:

One membrane

Two sets of plunger packing

One suction valve complete

One discharge valve complete

When ordering spares, please indicate always the model and the serial number of the pump

5. Trouble shooting

Trouble

Possible cause

Solution

Pump can

not work

The check valve is damaged or

polluted by fluid

Clean or replace new check valve

The chemical level in the tank is

too low

Inject more chemical

The discharge tube is jammed

Clean and dredge the tube

Disconnect motor from

power supply

Connect to power supply

The power supply cable

is disconnected

Find the disconnected part and repair

Position the knob at “zero” flow

rate

Readjust the knob

The voltage is not stable, burning

the motor

Measure and rectify the voltage, repair or

replace new motor

Low

flow rate

The chamber and tube remain

gas

Discharge the gas

The suction line is jammed

Clean the suction line

The suction head is too high

Relocate the pump to reduce suction head

The fluid temperature is too high

Cool the liquid

The fluid viscosity is too high

Reduce the viscosity( through heating or

dilution)

The check valve is too dirty

or damaged

Clean or replace check valve

The suction line is incorrectly si

zed

Check the length and diameter of suction line

The stroke length is wrongly

regulated

Check and readjust stroke length

The speed of pump is abnormal

Choose power supply and frequency that

corresponds to that of motor label

Excessively

big flow rate

The discharge pressure is lower

than suction pressure

Install back pressure valve

Wrong stroke length

Check and adjust stroke length

SPR0136037 Rev. 1.5

15

Motor

overheats

The discharge pressure is too

high

Check the setting of pressure relief valve

The discharge line is incorrectly

sized

Check the length and diameter of discharge

line

The power supply does not cor

respond the electronic specificat

ions

Make sure that the power supply

corresponds to motor

Work

with noise

Wrong electrical connections

Check and rectify connections

Lack of lubricant in the mechan

ism/gearbox

Refill with the correct lubricant

Excessive wear of the mechani

sm/gearbox

Overhaul mechanism/gearbox

The pipeline

vibrates

Pipe diameter too small

Enlarge pipe diameter

Pulsation damper out of operation

or too small

Repair or recalculate damper volume

6. Handling and storage

6.1 Handling

Here below is instructions for handling

- Do not sling, pull, push the pump head nozzles or flanges

- Do not sling, pull, push the adjustment knob

6.2 Storage

Precautions

During shipment and storage, the protection against rain, sand, dust, dirty and direct sunlight are

required.

Should the pump be stored for a long time, please store it in a dry and ventilated place.

Important Instruction for MSA/MSV Series

1) Please make sure that this instruction is attached to the pump

2) Make sure that the voltage and frequency is matched. Power supply: 380V/50Hz (or

220V/50Hz, refer to label for details), the motor temperature should be lower than 80 under

normal operation; It is strictly forbidden to operate without liquid for long time (not exceeding 3

minutes)

3) The pump is unable to work at the pressure exceeding its rated pressure (max working

pressure), and its rated pressure value is marked on the label, expressed by bar

(1bar=1kg/cc=10mlift). If the pump works overpressure, it might be damaged.

4) When the chemical to be dosed reacts to water, for example concentrated sulfuric acid, the

chamber must be cleaned and dried (some water drop might be left while testing at our factory)

5) When the adjustment knob is positioned below 100% graduation, the voice from internal

mechanism is relatively big, this is normal, in addition, we suggest you not to position below 30%

graduation.

6) Please make sure that the discharge/ suction line is installed correctly, and the suction line

(suction valve) is installed downward vertically; the discharge line (discharge valve) is installed

upward vertically; the discharge valve does not replace the suction valve each other. Loss of any

This manual suits for next models

1

Table of contents

Languages:

Other Seko Water Pump manuals

Seko

Seko KOMPACT DPT User manual

Seko

Seko KOMPACT AMC 200 User manual

Seko

Seko Tekna Evo TPG series User manual

Seko

Seko PULV User manual

Seko

Seko AKTUA ATR-05S Manual

Seko

Seko KRONOS 50 User manual

Seko

Seko PoolMatch pH User manual

Seko

Seko OPL Mini L Manual

Seko

Seko Maxima MPG User manual

Seko

Seko TDS Series User manual

Popular Water Pump manuals by other brands

Tallas Pumps

Tallas Pumps P1 300 Instruction for installation and maintenance

Westfalia

Westfalia 86 02 57 instruction manual

Wilo

Wilo Atmos GIGA-I Installation and operating instructions

MRC

MRC PP-D-720 Operation manual

Graco

Graco 231169 Instructions-parts list

Wilden

Wilden A2 Original Plastic Series manual