Bosch Sensortec BNO055 User manual

Application Note

BNO055

Quick start guide

Bos ch Sensortec

Application note: BNO055 Quick start guide

Document revision 1.0

Document release date Mar.2015

Document number BS T-BNO055-AN007-00

Technical reference code 0 273 141 209

Notes

Data in this document are subject to change without notice.

P

roduct photos and pictures are for illustration purposes only and

m

ay differ from the real product’s appearance.

Application Note

BNO055 - Quick start guide

Page 2

BST-BNO055 -AN 00 7 -00| Versi on 1. 0 | Ma r ch 2015

Bosch Sensortec

© Bosch Sensort ec G mbH reserves all ri gh t s even in the event of i ndustrial property rig ht s. We reserv e all ri gh t s of di sposal such as copying and passing on to third

parti es. BOSCH and the sym bol are regi st ered trademarks of Robert Bosch GmbH, Germany.

Note: Speci fi cati on s wi thin thi s d ocu m ent are subj ect tochange wi t h out noti ce.

Contents

1. Introduction..........................................................................................................................3

2. Hardware design..................................................................................................................5

2.1 Schematics ......................................................................................................................5

3. Calibration ............................................................................................................................6

4. Sample codes ......................................................................................................................7

5Legal disclaimer.................................................................................................................8

5.1 Engineering samples .......................................................................................................8

5.2 Product use.....................................................................................................................8

5.3 Application examples and hints........................................................................................8

Application Note

BNO055 - Quick start guide

Page 3

BST-BNO055 -AN 00 7 -00| Versi on 1. 0 | Ma r ch 2015

Bosch Sensortec

© Bosch Sensort ec G mbH reserves all ri gh t s even in the event of i ndustrial property rig ht s. We reserv e all ri gh t s of di sposal such as copying and passing on to third

parti es. BOSCH and the sym bol are regi st ered trademarks of Robert Bosch GmbH, Germany.

Note: Speci fi cati on s wi thin thi s d ocu m ent are subj ect tochange wi t h out noti ce.

1. Introduction

The BNO055 is a system in package (SiP) chip that includes a 3-axis 14-bit accelerometer,

a 3-axis 16-bit gyr oscope, a 3-axis magnetometer and a 32-bit Cortex M0+ microcontroller

running the company’s BSX3.0 FusionLib software.

Besides giving access to the individual sensor signals such as acceleration, rotation,

and magnetic field strength, the sensor offers a total of five different sensor fusion modes. The

table below provides a quick overvie w of all the different fusion and non-fusion modes of the

sensor:

Operating Mode

Available sensor signals Fusion Data

Accel Mag Gyro

Relative

orientation

Absolute

orientation

CO NFI GM ODE

-

-

-

-

-

Non-fusionmodes

ACCONLY

X

-

-

-

-

MAGONLY

-

X

-

-

-

GYROONLY

-

-

X

-

-

ACCMAG

X

X

-

-

-

ACCGYRO

X

-

X

-

-

MAGGYRO

-

X

X

-

-

AMG X X X - -

Fusion modes

IMU

X

-

X

X

-

CO MP AS S

X

X

-

-

X

M4G

X

X

X*

X

-

NDOF_FMC_OFF

X

X

X

-

X

NDOF

X

X

X

-

X

* software simulated gyro signal

Fusion Modes:

IMU or Inertial Measurement Unit is a fusion of the accelerometer and the gyr oscope

Compass is a fusion of the accelerometer and magnetometer, also commonly known as a

tilt-compensated compass

M4G (Magnet for gyroscope) is a fusion of the accelerometer and the magnetometer but the

output data is similar to the IMU mode and hence the limitations of gyroscope is compensated

in this mode.

NDOF_FMC_OFF is a fusion of all three sensors – accelerometer, gyr oscope and the

magnetometer thereb y providing Nine Degrees of Freedom (NDOF). In this mode the ‘FMC

(Fast Magnetic Calibration)’ feature is disabled and thereb y the sensor needs a movement

similar to ‘figure 8 pattern’ to calibrate the magnetometer.

NDOF is also a fusion of all the three sensors, but with the feature ‘FMC’ enabled. By

enabling this feature, a quick movement (even an incomplete ‘figure 8 pattern’) will fully

calibrate the magnetometer.

Application Note

BNO055 - Quick start guide

Page 4

BST-BNO055 -AN 00 7 -00| Versi on 1. 0 | Ma r ch 2015

Bosch Sensortec

© Bosch Sensort ec G mbH reserves all ri gh t s even in the event of i ndustrial property rig ht s. We reserv e all ri gh t s of di sposal such as copying and passing on to third

parti es. BOSCH and the sym bol are regi st ered trademarks of Robert Bosch GmbH, Germany.

Note: Speci fi cati on s wi thin thi s d ocu m ent are subj ect tochange wi t h out noti ce.

Once the sensor is powered, it executes a power on self-test (POST) and stays in the

configuration (CONFIG) mode. After POR or soft reset, users need to wait at least 650ms

before talking to BNO055 through I2C interface. For the waiting time less than 650 ms, the I2C

communication does not respond. The hardware reset using h ardware RESET pin or writing to

the RST_SYS bit in the SYS_TRIGGER register (0x3F) have the same effect as the power on

rest (POR). Users can then change to one of the sensor operation modes by writing to the

OPR_MODE register (0x3D). Once the sensor is configured, it is ready to send the sensor

fusion results such as Quaternion, Euler angles, Linear acceleration and Gravity vector at

fixed output data rate. Users can then access the sensor fusion results from the BNO055

through I2C, UART or HID-over I2C interface.

The user can switch between Windows or the Android orientation format. By default however,

the sensor axes orientation of the sensor is of Android format as shown in Figure 1. The

Android rotation vector definition can be found at

http://developer.android.com/guide/topics/sensors/sensors_motion.html

Figure 1 BNO055 coordinate definition

•

Heading: rotation around the Z axis (0° <= heading < 360°). 0° = North, 90° = East,

180° = South, 270° = West. The heading value increases when you rotate around the Z

axis clo ckwise from top view of Figure 1.Pitch: rotation around the X axis (-180° <= pitch

<= 180°) with positive values increasing when the Z axis moves towards the Y axis.

•

Roll: rotation around the Y axis (-90° <= roll <= 90°) with positive values increasing when

the X

axis mo ves toward the Z axi s .

East

North

Application Note

BNO055 - Quick start guide

Page 5

BST-BNO055 -AN 00 7 -00| Versi on 1. 0 | Ma r ch 2015

Bosch Sensortec

© Bosch Sensort ec G mbH reserves all ri gh t s even in the event of i ndustrial property rig ht s. We reserv e all ri gh t s of di sposal such as copying and passing on to third

parti es. BOSCH and the sym bol are regi st ered trademarks of Robert Bosch GmbH, Germany.

Note: Speci fi cati on s wi thin thi s d ocu m ent are subj ect tochange wi t h out noti ce.

2. Hardware design

2.1 Schematics

BNO055 schematic is as shown in figure 2 with I2C interface to an external microcontroller

(MCU)1.

MCU

Figure 2 BNO055 schematics with I2C interface

Notes:

•

The external 32.768 kHz crystal is optional. Pin-26 (XOUT32) and Pin-27 (XIN32) can be

floating when the external crystal is not used.

•

Pin-5 (PS1) and Pin-6 (PS0) should be tied to GND directly o r through a zero Ohm resistor to

GND to select I2C interface protocol. Don’t use a pull-down resistor for these two pins.

•

The MCU GPIO1 can be used to select the BNO055 7-bit I2C slave address, which will be

0x29 when GPIO1 is high and 0x2 8 when low.

•

Pin-14 (INT) is push-pull and can be tied to MCU GPIO2 directly. This pin can be floating if

BNO055 interrupt is not used.

•

Pin-4 (nBOOT_LOAD_PIN) is pulled high through a 10K Ohms resistor. It is not necessary

to tie it to the other MCU GPIO pin.

1 Since majority of the application use I2C, the quick reference guide explains thi s commu nication protocol more in

detail.

VDD

S DA

SCL

GPIO1

GPIO2

Application Note

BNO055 - Quick start guide

Page 6

BST-BNO055 -AN 00 7 -00| Versi on 1. 0 | Ma r ch 2015

Bosch Sensortec

© Bosch Sensort ec G mbH reserves all ri gh t s even in the event of i ndustrial property rig ht s. We reserv e all ri gh t s of di sposal such as copying and passing on to third

parti es. BOSCH and the sym bol are regi st ered trademarks of Robert Bosch GmbH, Germany.

Note: Speci fi cati on s wi thin thi s d ocu m ent are subj ect tochange wi t h out noti ce.

3. Calibration

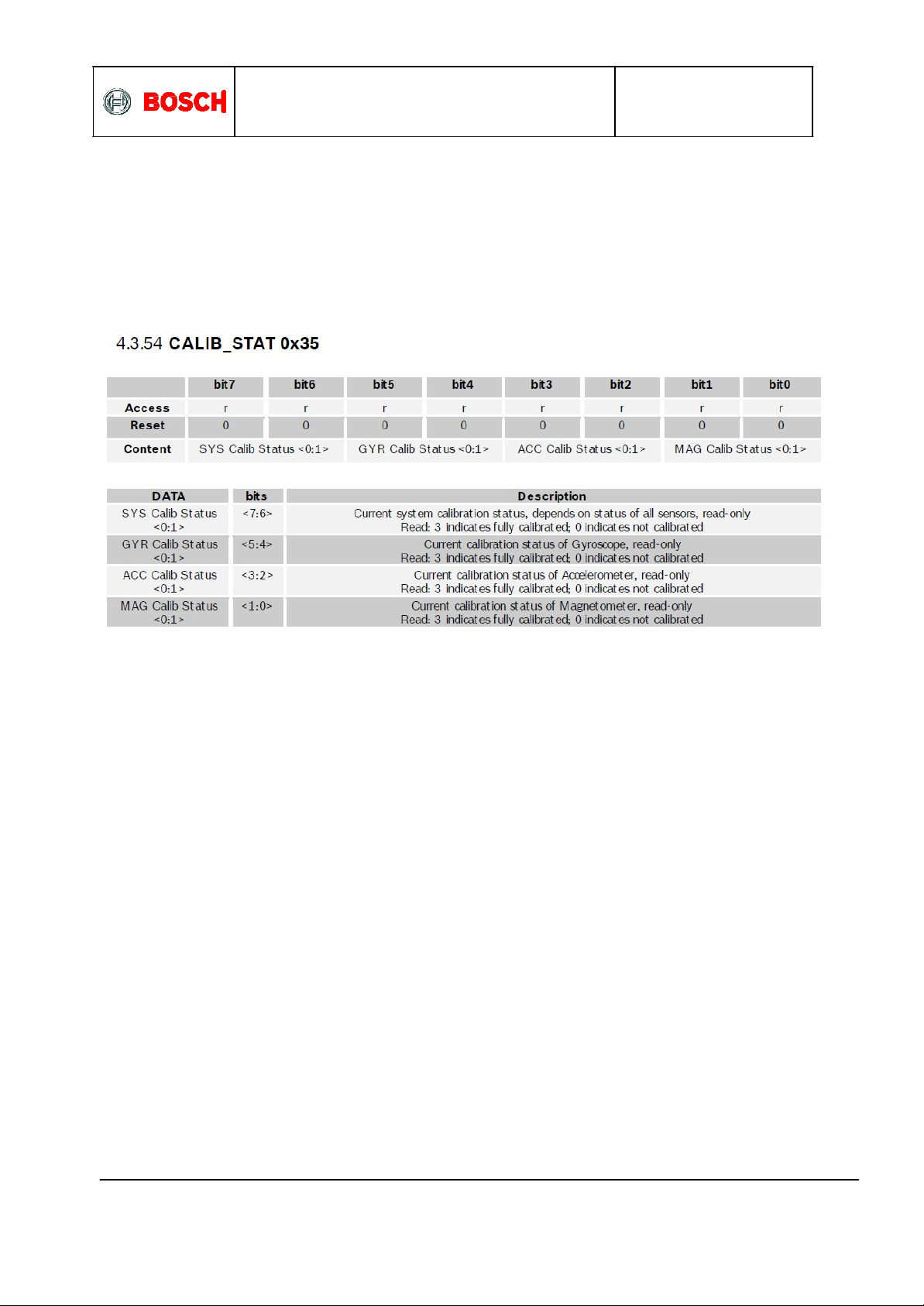

Calibration of the sensor plays a major role in the sensor fusion software. In the BNO055, the

calibration of the accelerometer, gyr oscope and the magnetometer runs in the background as

part of the sensor fusion software. The status of each sensor calibration is as shown in Figure 4.

Figure 4: BNO055 sensor calibration status register

The accelerometer and the gyr oscope are relative ly less susceptible to external disturbances,

as a result of which the offset is negligible. Moreover the accelerometer is factory

calibrated, and hence the calibration is not mandatory. For the gyr oscope however leaving the

BNO055 stationary for a few seconds at any time during the operation, will facilitate full

calibration and thereby remove the zero rate offsets. Unlike the accelerometer and

gyr oscope, the magnetometer calibration is mandatory immediately after e ve r y ‘power on reset’

in order for sensor fusion to create accurate results.

Therefore, it is highly recommended to check the magnetometer calibration status periodically.

If the value of the two bits ‘MAG Calib Status’ is 3, then it means that the magnetometer is fully

calibrated and readyto go . If the value is 2, then the sensor fusion’s performance is still OK. If

the value is 1, then it is highly recommended to perform a Figure-8 motion to calibrate the

magnetometer. And if the value is 0, this means that the magnetometer just got disturbed by

the magnetic interference fields nearb y or the environment’s magnetic fields have just

changed. And therefore the magnetometer calibration must be performed. For further details

please refer section ‘3.10 Calibration’ in the datasheet.

Application Note

BNO055 - Quick start guide

Page 7

BST-BNO055 -AN 00 7 -00| Versi on 1. 0 | Ma r ch 2015

Bosch Sensortec

© Bosch Sensort ec G mbH reserves all ri gh t s even in the event of i ndustrial property rig ht s. We reserv e all ri gh t s of di sposal such as copying and passing on to third

parti es. BOSCH and the sym bol are regi st ered trademarks of Robert Bosch GmbH, Germany.

Note: Speci fi cati on s wi thin thi s d ocu m ent are subj ect tochange wi t h out noti ce.

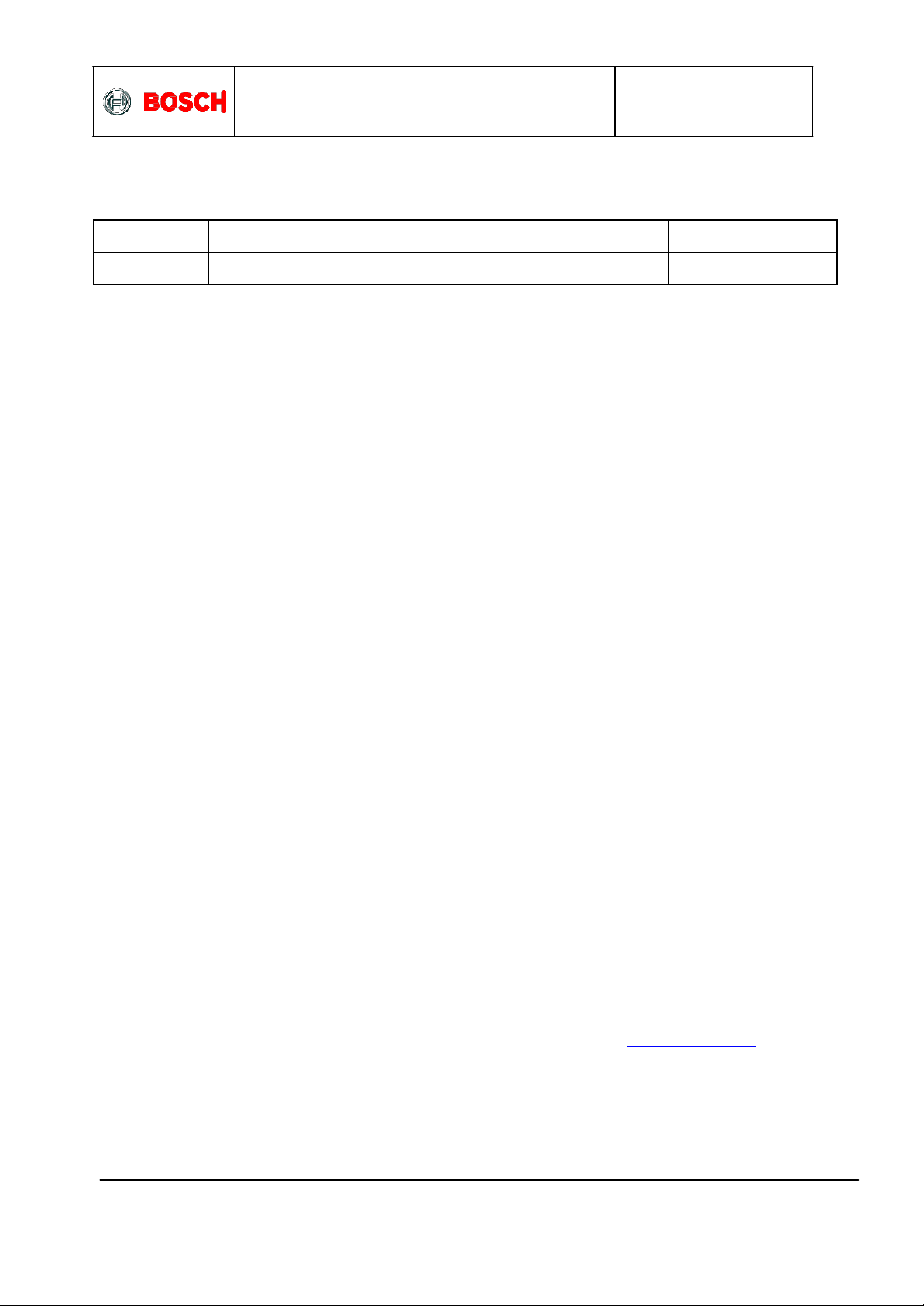

4. Sample codes

It is highly recommended to use the BNO055 standard APIs to ease the integration. The APIs

can be downloaded from https://github.com/BoschSensortec/BNO055_driver.

Below mentioned steps demonstrate how to get BNO055 up and running with few API calls.

Step

D e s c r ip t ion

Code snippet

1

Power on the BNO055

2

Create a structure to hold

device information

struct bno055_t myBNO;

3

Link the I2C driver functions

to the API communication

function pointer

myBNO.bus_read = BNO055_I2C_bus_read;

myBNO.bus_write = BNO055_I2C_bus_write;

myBNO.delay_msec = delay;

4

Set the correct I2C address

in the BNO055 API

myBNO.dev_addr = BNO055_I2C_ADDR1;

//myBNO.dev_addr = BNO055_I2C_ADDR2;

5

API initialization

bno055_init(&myBNO);

6

Change the operation

mode to NDOF

bno055_set_operation_mode

(OPERATION_MODE_NDOF);

7

Read Euler angles

struct bno055_euler_float_t eulerData;

bno055_convert_float_euler_hpr_deg(&eulerDa

ta);

8

Read calibration status

unsigned char accel_calib_status = 0;

unsigned char gyro_calib_status = 0;

unsigned char mag_calib_status = 0;

unsigned char sys_calib_status = 0;

bno055_get_accel_calib_stat(&accel_calib_st

atus);

bno055_get_mag_calib_stat(&mag_

calib_status);

bno055_get_gyro_calib_stat(&gyro_

calib_status);

bno055_get_sys_calib_stat(&sys_

calib_status);

Note: It is advisable to check the calibration status periodically and provide accuracy status to the user

for re-calibration.

Application Note

BNO055 - Quick start guide

Page 8

BST-BNO055 -AN 00 7 -00| Versi on 1. 0 | Ma r ch 2015

Bosch Sensortec

© Bosch Sensort ec G mbH reserves all ri gh t s even in the event of i ndustrial property rig ht s. We reserv e all ri gh t s of di sposal such as copying and passing on to third

parti es. BOSCH and the sym bol are regi st ered trademarks of Robert Bosch GmbH, Germany.

Note: Speci fi cati on s wi thin thi s d ocu m ent are subj ect tochange wi t h out noti ce.

5 Legal disclaimer

5.1 Engineering samples

Engineering Samples are marked with an asterisk (*) or (e). Samples may vary from the

valid technical specifications of the product series contained in this data sheet. They are

therefore not intended or fit for resale to third parties or for use in end products. Their sole

purpose is internal client testing. The testing of an engineering sample may in no way

replace the testing of a product series. Bosch Sensortec assumes no liability for the use of

engineering samples. The Purchaser shall indemnify Bosch Sensortec from all claims arising

from the use of engineering samples.

5.2 Product use

Bosch Sensortec products are developed for the consumer goods industry. They may only be

used within the parameters of this product data sheet. They are not fit for use in life-sustaining or

security sensitive s ys tems. Security sensitive s ys tems are those for which a malfunction is

expected to lead to bodily harm or significant property damage. In addition, they are not fit for

use in products which interact with motor vehicle s ys tems.

The resale and/or use of products are at the purchaser’s own risk and his own responsibility. The

examination of fitness for the intended use is the sole responsibility of the Purchaser.

The purchaser shall indemnify Bosch Sensortec from all third party claims arising from an y

product use not covered by the parameters of this product data sheet or not approved by Bosch

Sensortec and reimburse Bosch Sensortec for all costs in connection with such claims.

The purchaser must monitor the market for the purchased products, particularl y with regard to

product safety, and inform Bosch Sensortec without delay of all security rele van t incidents.

5.3 Application examples and hints

With respect to any examples or hints given herein, any typical values stated herein and/or any

information regarding the application of the device, Bosch Sensortec hereby disclaims any and

all warranties and liabilities of any kind, including without limitation warranties of non-infringement

of intellectual property rights or copyrights of any third party. The information given in this

document shall in no event be regarded as a guarantee of conditions or characteristics. They are

provided for illustrative purposes only and no evaluation regarding infringement of intellectual

property rights or copyrights or regarding functionality, performance or error has been made.

Application Note

BNO055 - Quick start guide

Page 9

BST-BNO055 -AN 00 7 -00| Versi on 1. 0 | Ma r ch 2015

Bosch Sensortec

© Bosch Sensort ec G mbH reserves all ri gh t s even in the event of i ndustrial property rig ht s. We reserv e all ri gh t s of di sposal such as copying and passing on to third

parti es. BOSCH and the sym bol are regi st ered trademarks of Robert Bosch GmbH, Germany.

Note: Speci fi cati on s wi thin thi s d ocu m ent are subj ect tochange wi t h out noti ce.

6 Document history and modification

Re v. No

Chapter

Description of modification/change s

Date

1.0

Document creation 04 March 2015

Bosch Sensortec GmbH

Gerhard- Kindler-Strasse 8

72770 Reutlingen/

Ge rm a ny

conta ct @bosch-sensortec.com

www.bosch-sensortec. com

Modifications reserved | Printed in G ermany

Specifications subject to cha nge without not ice

Document number: BST- BNO055-AN007- 00

Ve rsi o n _ 1. 0 _ 050315

Table of contents