66 720 606 692 (02.05)

4.4 Maintenance

When it has been in service for a year, the appliance

should be inspected, thoroughly cleaned and, if

necessary, descaled.

Servicing m y only be c rried out by n uthorised person.

Before c rrying out m inten nce work of ny kind, the g s

nd cold w ter isol ting cocks must be turned off.

Heat Exchanger body

Cle n the flue side of the he t exch nger block. Check

he t exch nger body nd connecting pipes for sc le nd if

necess ry desc le with propriet ry desc ler ccording to

m nuf cturers instructions.

The desc ling is done only to the he t exch nger, the

chemic ls used d m ge the HDG nd other p rts.

Test for le ks t m x. 2000 kP .

Use new g sket when re- ssembling.

Burner

Unscrew burner nd cle n in so p solution if necess ry.

Pilot burner

The fl me should he t the fl me-f ilure electrode (di gr m

3, item 4). If the fl me is too sm ll, cle n pilot burner.

Slow ignition valve

After unscrewing the v lve, cle n out ny dirty p rticles.

The b ll inside the v lve must move freely (check by sh king).

Inspect the O-ring nd repl ce if necess ry. Screw the slow

ignition v lve b ck in. Check ll connections for le ks.

Checking the vacuum chamber

- Push the sliding g s control to the right nd dr w off hot

w ter.

- Disconnect green le d from the servo g s v lve (di gr m

3, item 1). The m in burner should go out nd the pilot

burner rem ins lit. Disconnect the red le d from the pilot

g s v lve (di gr m 3, item 3) - the pilot fl me should

then go out.

- Re-connect red le d, pilot burner should re-ignite.

- Re-connect green le d, m in burner should re-ignite.

Functional Test (does not pply to first time commissioning).

Switch off ppli nce. When hot w ter t p is turned on,

the burner should come on full within 5 seconds. When the

hot w ter t p is turned off, the burner should go out within

pproxim tely 2 seconds.

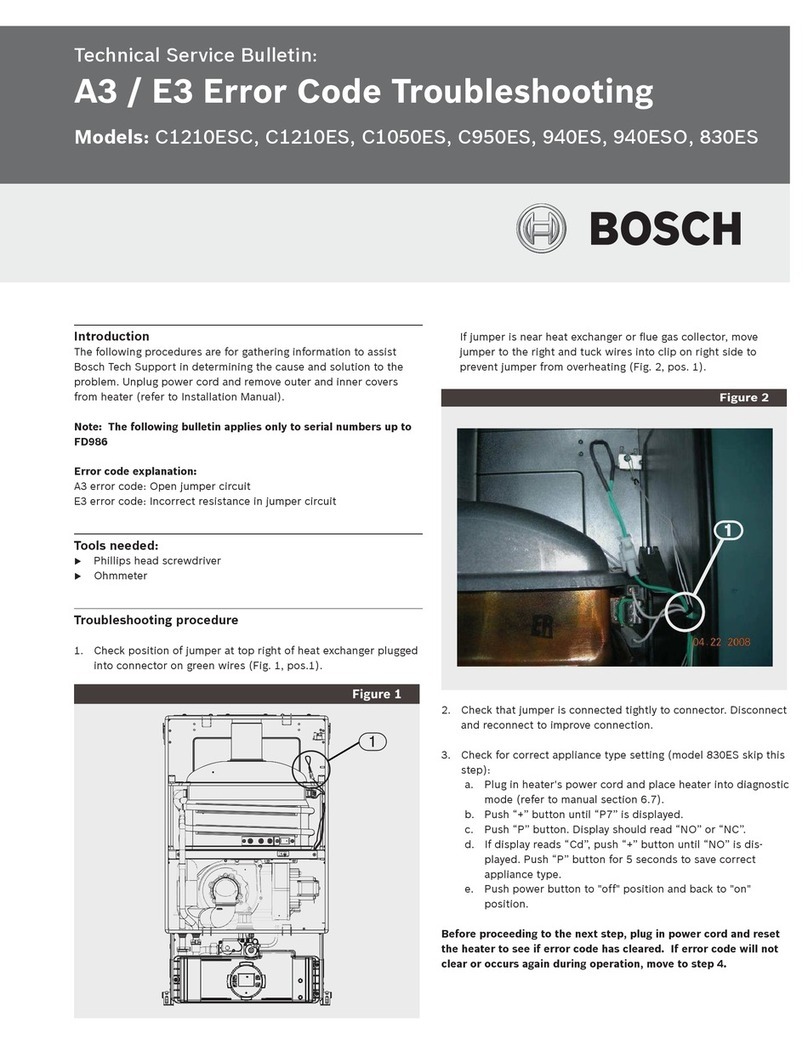

Diagram 7

G661_009

G661_016

Diagram 6

4.3 Conversion to ther Gases

nly use conversion kits supplied by the manufacturer.

This oper tion must be c rried out by qu lified fitter.

1. Cut off the g s supply by closing the g s isol ting v lve,

nd remove the front cover of the ppli nce;

2. Remove the burner nd repl ce the injectors (di gr m 7,

item 1);

3. Repl ce the pilot g s injector (di g. 7, item 3);

4. Repl ce the v cuum ch mber if converting from LP to

NG. Pressure regul tor lso required.

5. Repl ce the m in poppet v lve he d (di g.2, item 27);

6. Tighten the g s v lve nd check for possible le ks;

7. Note the new type of g s on the ppli nce's r ting pl te;

8. Fin lly, djust the minimum g s flow of the ppli nce

using suit ble method, the most common one being

described below:

) Select m nometer with mb r or mm (H2O) sc le;

b) Loosen se ling screw D in the burner pressure t p-off

point (di gr m 5) nd connect the m nometer;

c) Open the g s isol ting v lve;

d) St rt up the ppli nce with the output slide control t

the minimum output position;

e) Adjust the pressure using screw C (di gr m 6), in

compli nce with Section 2 Technic l D t , p ge 4.

G662_042

Diagram 5

Gas burner pressure adjustment for minimum output

(see clause 4.3, section 8)

Gas inlet pressure adjustment

1. Turn off g s supply.

2. Remove inlet test point screw A.

3. Att ch U tube m nometer.

4. Turn on g s supply nd st rt up ppli nce in ccord nce

with oper ting instructions.

5. Check inlet g s pressure while ppli nce is oper ting.

6. For n tur l g s ppli nces djust pressure t ppli nce

regul tor.

No djustment for LP ppli nces, check cylinder

regul tor nd pipe size.

7. Turn off g s supply, remove m nometer, repl ce se ling

screw, turn on g s supply nd test for le ks.