Content

1.

General Information............................................................................4

1.1

Measurements..................................................................................................................................

4

1.2

External appearance..................................................................................................................

4

1.3

Nomenclature.........................................................................................................................

4

2.

Combo Type Heat Pump Water Heater....................................................5

2.1

Features.......................................................................................................................

5

2.2

Refrigerant circuit ....................................................................................................................

6

2.3

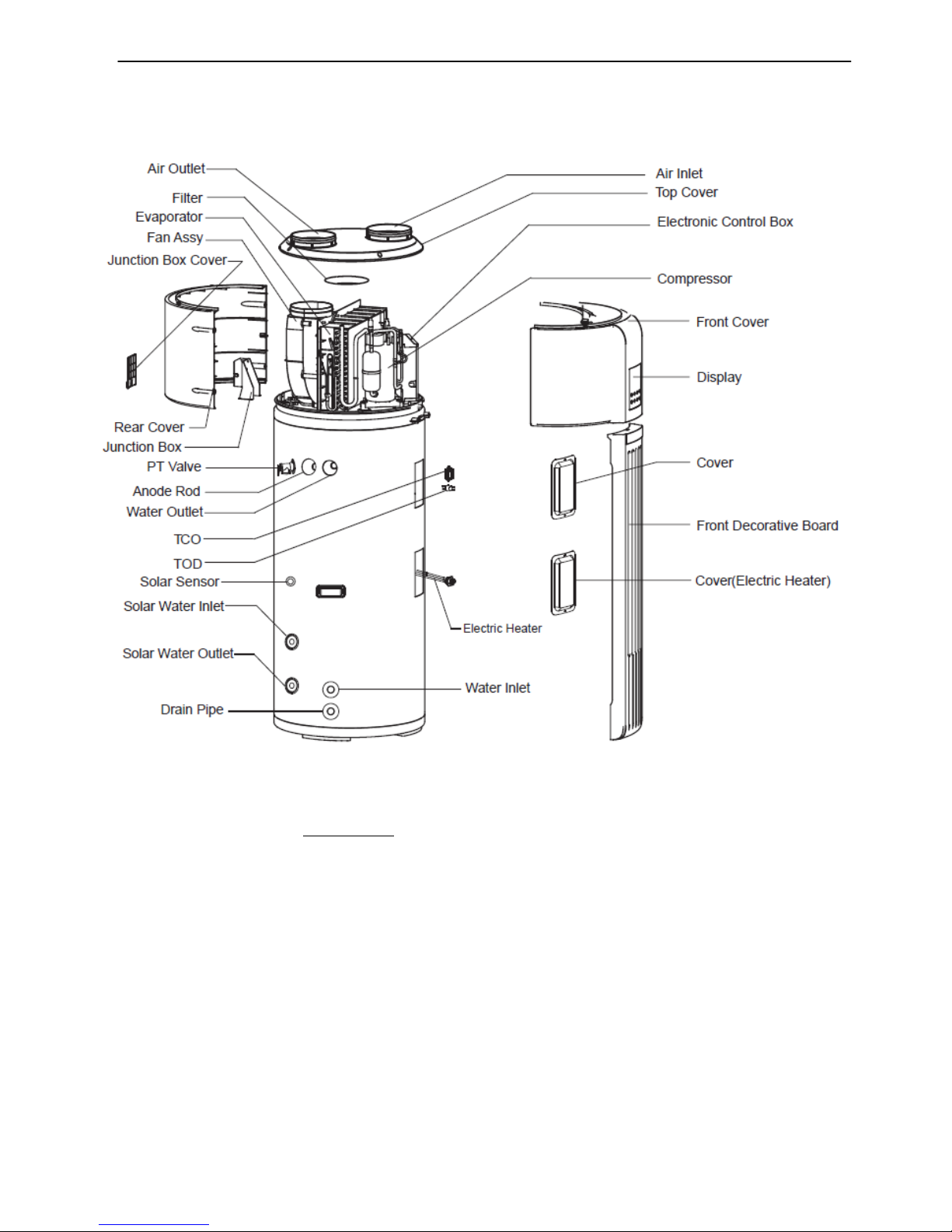

Unit structure...............................................................................................................................

7

2.4

Specifications..............................................................................................................................

8

2.5

Dimension

.................................................................................................................................11

2.6

Performance diagram........................................................................................................

12

2.7

Wiring diagram..........................................................................................................

13

2.8

Installation ...............................................................................................................................

14

2.9

Water affusion and effusion...................................................................................................

22

2.10

Trial run .........................................................................................................................................

23

2.11

Maintenance..................................................................................................................................

24

2.12

Trouble shooting.....................................................................................................................

25

2.13

Function ........................................................................................................................

29

2.14

Frequently Asked Questions............................................................................................

30

2.15

Operation............................................................................................................................

38

2.16

Accessories...................................................................................................................................

32

2.17

Exploded view

....................................................................................................................39

2.18

Typical applications in cooling and purification of air

..........................................................41

2.19

Running logic

......................................................................................................................44