Boss Water Systems 021-4PC Installation and maintenance instructions

Boss Water Systems

Australia

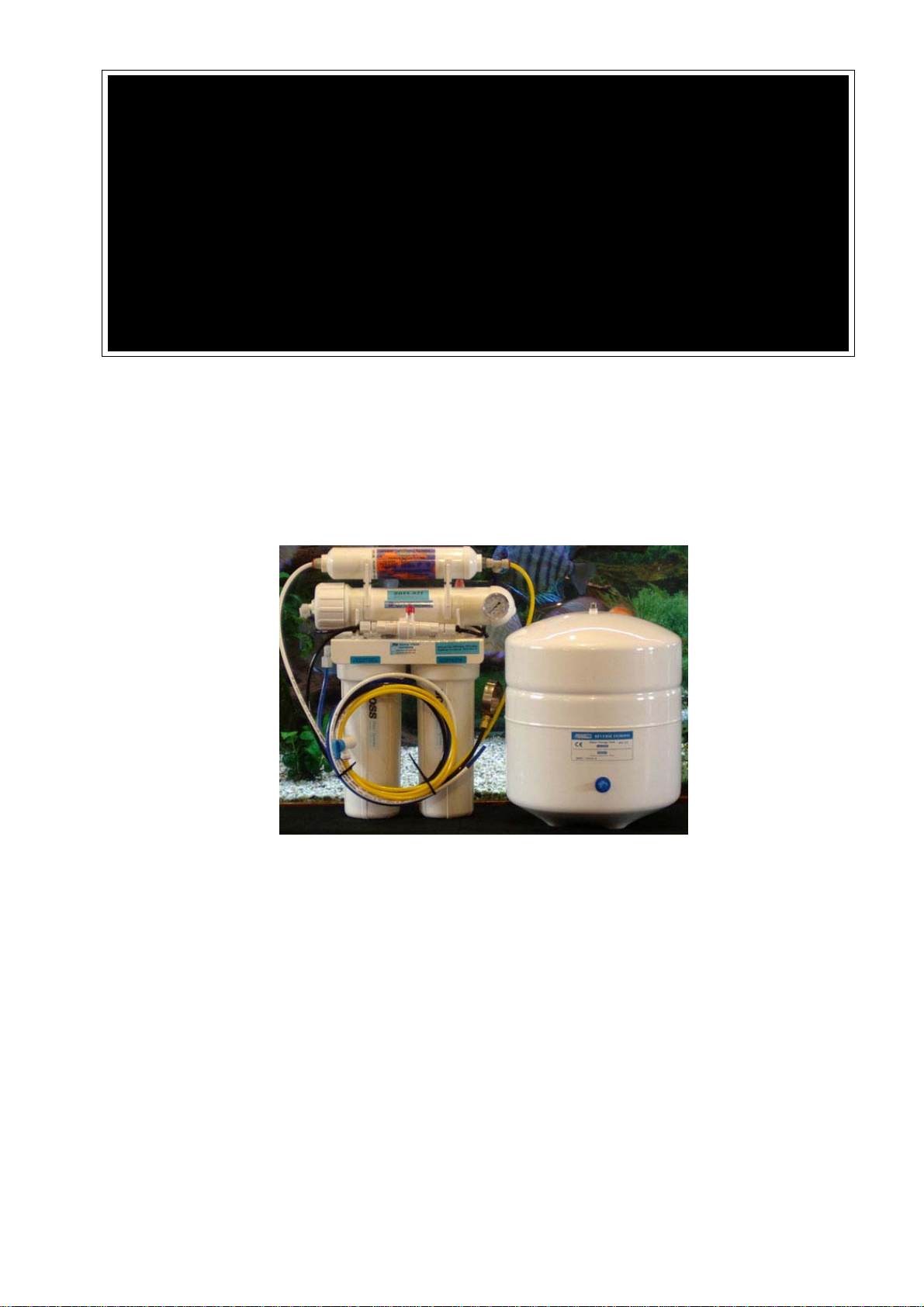

Reverse Osmosis System

Model – 021-4PC

Congratulations on your purchase of the

most advanced water purifier system

available!

Installation and Service Guide short web version,

this is not the instruction manual you will receive

with your purchase of a PSI-021-4PC but a shortened

version that is available on our web site, it is a

shorter version due to other suppliers likely to copy

this instruction manual as their own.

This system is designed to also remove ammonia which a normal reverse osmosis

system can’t do as the ammonia is introduced into the water as a gas not a liquid

REVERSE OSMOSIS WATER PURIFIERS

Of all the water purifier system types on the market by far the most superior is the reverse

osmosis process.

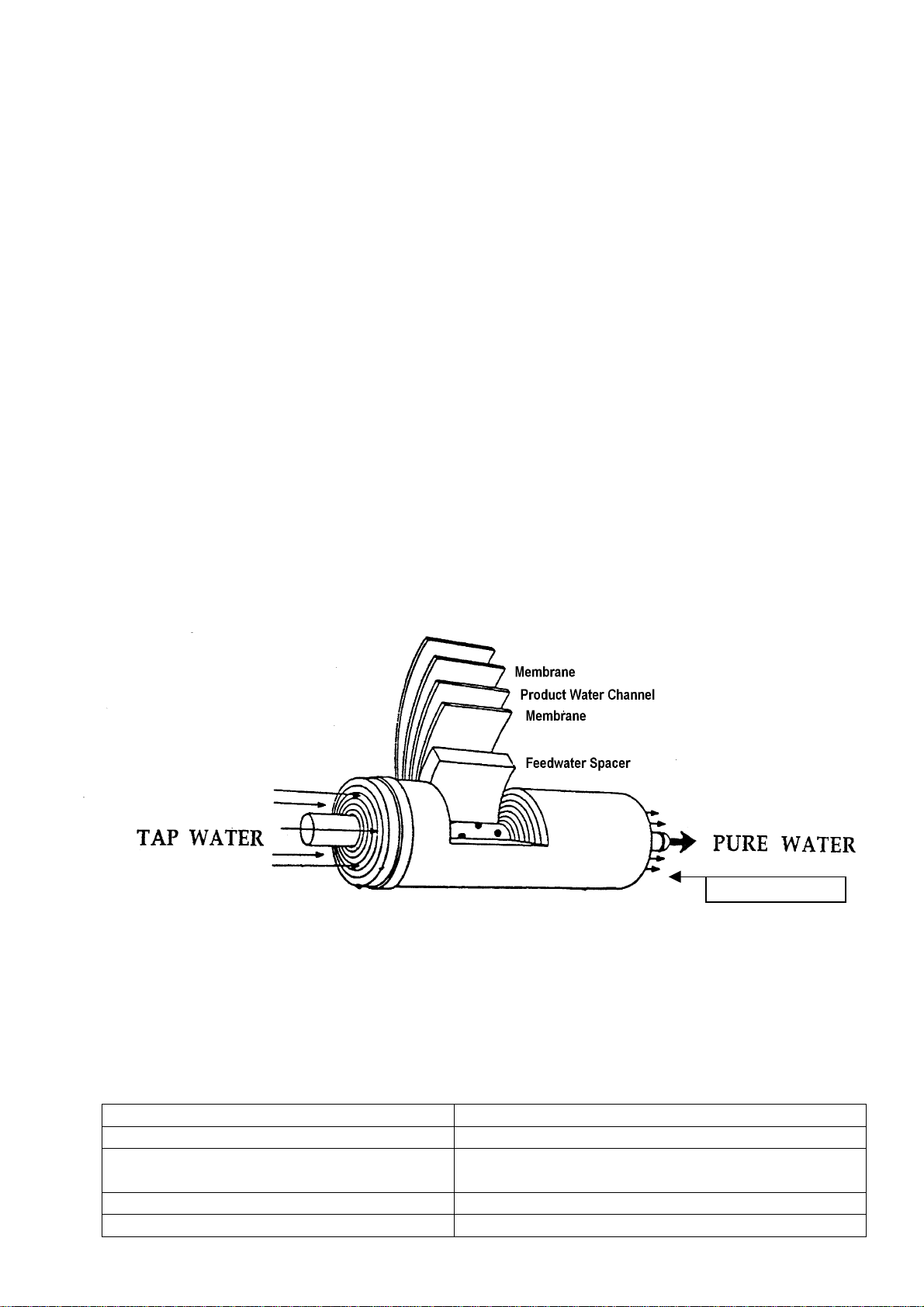

Reverse osmosis works by forcing water through a membrane, if the water molecule is

small enough it will pass across the membrane material and into the product line (pure

water). A water molecule is 2 parts hydrogen and 1 part oxygen (H2O) but if a molecule

had extra atoms attached the molecule is larger and won’t pass through the membrane

and is rejected, the contaminated molecule then goes into the waste line and is ejected

from the system.

The term “waste water” is not a kind way of describing the contaminated (waste) water

that is rejected by the reverse osmosis as it is water that is contaminated in some way and

not simply waste as such, the reverse osmosis process is a selection process, if the water

molecule is pure it will pass into the pure water part, anything else is rejected.

The reverse osmosis process is the best water purity of any type of process and is similar

to Distillation but distilled water is almost devoid of oxygen and tastes flat and dead,

reverse osmosis water process actually adds oxygen to the water resulting in extremely

pure sweet tasting water with almost all the poisons and impurities removed.

Waste Water

The PSI-021-4PC is designed for simple installation and operation and is well within the

abilities of a home handyman to maintain, the filters should be changed at the

recommended service intervals to maintain continual un-troubled service life.

Operating parameters

System Pressure 300 to 600 kpa (40 to 87 psi)

PH range 3.0 to 11.0

Maximum Supply TDS level (low waste

units) 500 mg/L = 500 ppm TDS

Temperature 2 to 40 degrees

Turbidity <1.0 Net Turbidity (NTU)

Caution

This Reverse Osmosis system is designed for operation on microbiologically safe water

which is usually Chlorinated mains water supplies, this system is not suitable for

installation on Un-Chlorinated water supplies, contact your selling agent to have a UV

steriliser added for microbiologically unsafe water such as Tank, Dam or Bore water.

Sediment Filter

Stage 1

Reverse Osmosis

Membrane Stage 3

Pressurised Storage

Tank

Pressure gauge to read

p

ressure being applied to

the membrane

Membrane Flushing

Valve/ Flow Restrictor

Carbon Post Filter

stage 4

Chloramine Carbon

Filter Stage 2

Stage 1 Sediment pre-filter, this filter is a 1 micron polyspun sediment filter cartridge

for mechanical removal of Grit, dust, Rust, mud, algae ect. This cartridge is

normally replaced every 12 months but if dirty mains water is encounted more

frequent change may be required.

Stage 2 Carbon pre-filter, this filter is a high grade chloramine carbon cartridge to

protect the membrane from chlorine and ammonia which can damage a TFC

(thin film composite) membrane, this carbon cartridge will also assist the

membrane by removing THMs, TCEs, pesticides and other organic pollutants.

This cartridge is usually changed every 12 months unless very dirty from the

mains supply is encountered or very heavy usage.

Stage 3 This is the membrane which is the main filter in a reverse osmosis system, pore

size is less than 0.0005 micron, the membrane is a thin film composite, NSF stand

42, 53 and 58, normal replacement is usually between 3 to 5 years.

Stage 4 This is the carbon polishing post filter which provides final filtration to

provide superb tasting clean water. Normal replacement is 12 months.

Installation

Select a suitable location avoiding locations where the system could come into contact

with things like hot water pipes, also consider ease of maintenance.

Check where the faucet (tap) will be installed looking at things like possible damage to

pipes and electrical wires when drilling, choose a location that will be the most

convenient for use.

Choose a location for the storage tank, the tank can be more remote than the main filter

system, a back corner cupboard is often used, the tank tube line is 1.8 metres, try

to have as short a tube to the tank and faucet as practicable because the shorter

the tube the faster the flow will be.

All tube is colour coded for installation ease

Blue tube connects from the mains supply to the entry point of the unit.

Yellow tube connects the main filter unit to the storage tank.

The black line connects the main filter unit for waste to the sink drain, this waste

line can be run outside to be collected for use in the garden.

The white line connects the main filter unit to the faucet (tap)

The mains connection best suited to your installation will have been selected at the time

of ordering, separate instructions are supplied with the mains connection kit, use

the supplied plumbers thread tape on all threaded joints, connect to cold water

mains supply only.

Faucet Installation

The RO water faucet may be installed on any flat surface at up to 50 mm [2”] in

diameter. Check the underside of the location for interference.

Determine desired location for the faucet on your sink surface.

A. Place a piece of masking tape or duct tape on location where the hole is to be

drilled. Mark the centre of the hole on the tape.

B. Using a variable speed drill on the slowest speed, drill a 1/8” (3 mm) pilot

hole at the centre of the desired location.

C. Enlarge the hole to ¼” (6 mm). Keep the drill speed on the slowest speed.

D. Enlarge the hole to 7/16th to ½” (11 to 13 mm) Keep the drill speed on the

slowest speed.

E. Pass the Escutcheon plate (chrome washer) and large black washer over the

threaded mounting tube at the base of the faucet.

F. From top of sink, slide the threaded mounting tube through the hole drilled

in the sink. Align the faucet body.

G. From under the sink, slide the smaller rubber washer on the threaded part of

the faucet first, then the plastic washer, locking washer and then the thin

threaded nut, Tighten with a spanner.

Holding the tube from the filter system, place the brass cup nut on first, then the nylon

olive and then insert the nylon thimble into the end of the tube as far as it will go.

Insert the tube into the base of the threaded part of the faucet, push it in firmly

(about ¼”) and slide nut up to thread and tighten firmly, do not over tighten.

Storage Tank

Place storage tank in a convenient position. Tank can be placed on its stand, either

upright or on its side.

Activating the System For the First Time

First open the Faucet, turn Feed Water Valve counter clockwise until fully open.

Check plumbing kit assembly for leakage.

Make sure all water supply/drain lines are secure and free from leakage.

Turn storage tank valve one quarter turn counter clockwise to open the valve [the

handle should be in line with the tubing as it enters the connection]

Let the water flow out the Faucet until all the air has been expelled from the system.

Water will be slightly discoloured [non-toxic carbon fines] and have some aeration.

This will take about 15 minutes.

Close the RO water faucet. In 15 minutes, check the connections for leaks and correct if

necessary.

Allow the tank to fill, this should take about 1 hour, open the faucet and drain the tank,

this process is repeated a second time. The membrane contains a food grade

preservative which prevents the membrane from bacteria in shipping and

storage, the process of draining the tank twice is only done when the system is

new or a new membrane is installed, this process expels the preservative.

Flush valve maintenance.

This unit is fitted with a membrane-flushing valve and is normally closed. About once a

month Turn the Faucet on and drain the tank, at the same time turn the small red

or blue valve at the front of the unit to the open position and leave it on for about

10 minutes to clear any possible build-up of particles, failure to do this will

shorten membrane life. This flush valve needs to be operated when the tank is

filling, if you open the valve and nothing happens the system is in shut down

mode, release some water from the faucet to start the unit filling again and open

the flushing valve again. Drain the tank as part of the membrane flushing

process. When this valve is in the closed position it operates as a flow restrictor.

As stated earlier this is a web version of our installation

instructions, a full printed version is supplied in

your system with more detail.

Table of contents

Other Boss Water Systems Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Oase

Oase FiltoSkim 3000 operating instructions

Aquadistri

Aquadistri SuperFish Aqua Pro Feeder quick start guide

Unilever

Unilever pureit UR5440 instruction manual

Grunbeck

Grunbeck AVRO 125 TS Operation manual

Design Filtration

Design Filtration DESIGN-AIRE DA2-2HSL-RSR-EC Installation and operation manual

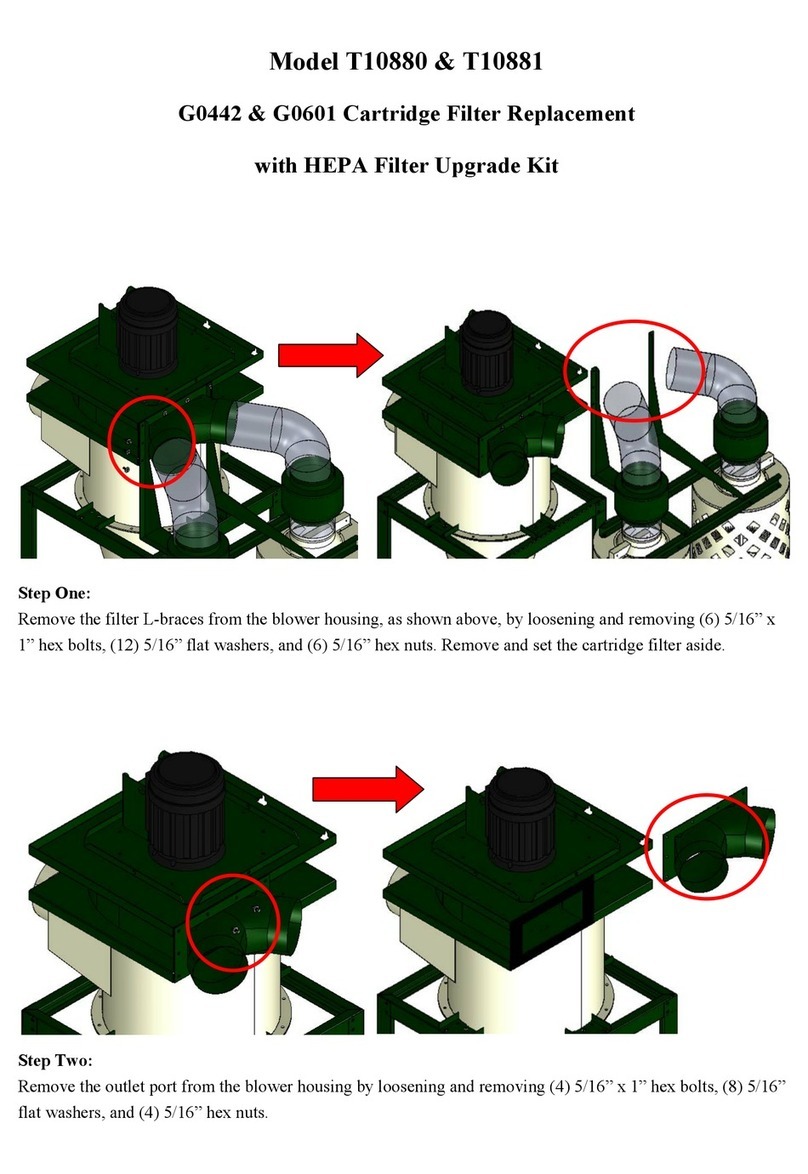

Grizzly

Grizzly T10880 manual

Allfyll

Allfyll Series N instruction manual

Oase

Oase Filtral 3000 UVC Operating instruction

AFRISO

AFRISO WAF 04 R - G3/4 operating instructions

JY

JY JY817 manual

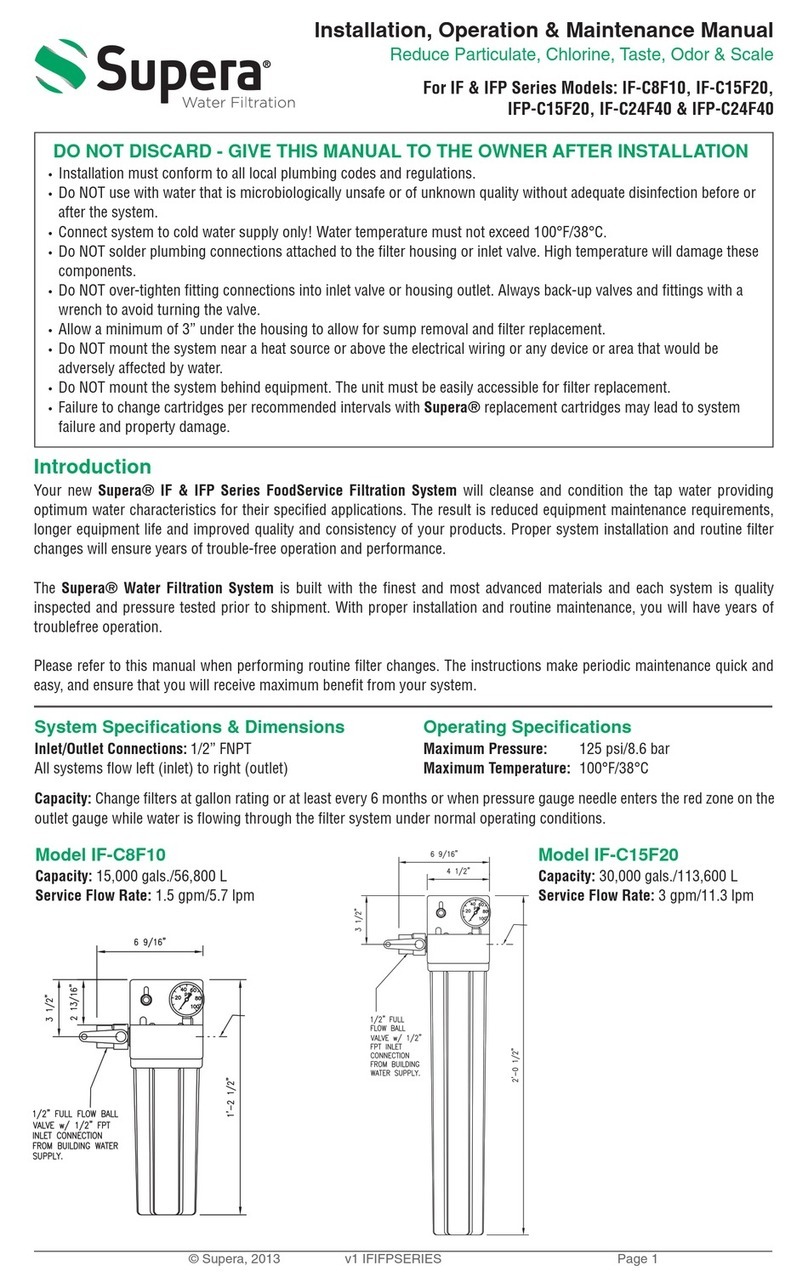

Supera

Supera IF-C8F10 Installation, operation & maintenance manual

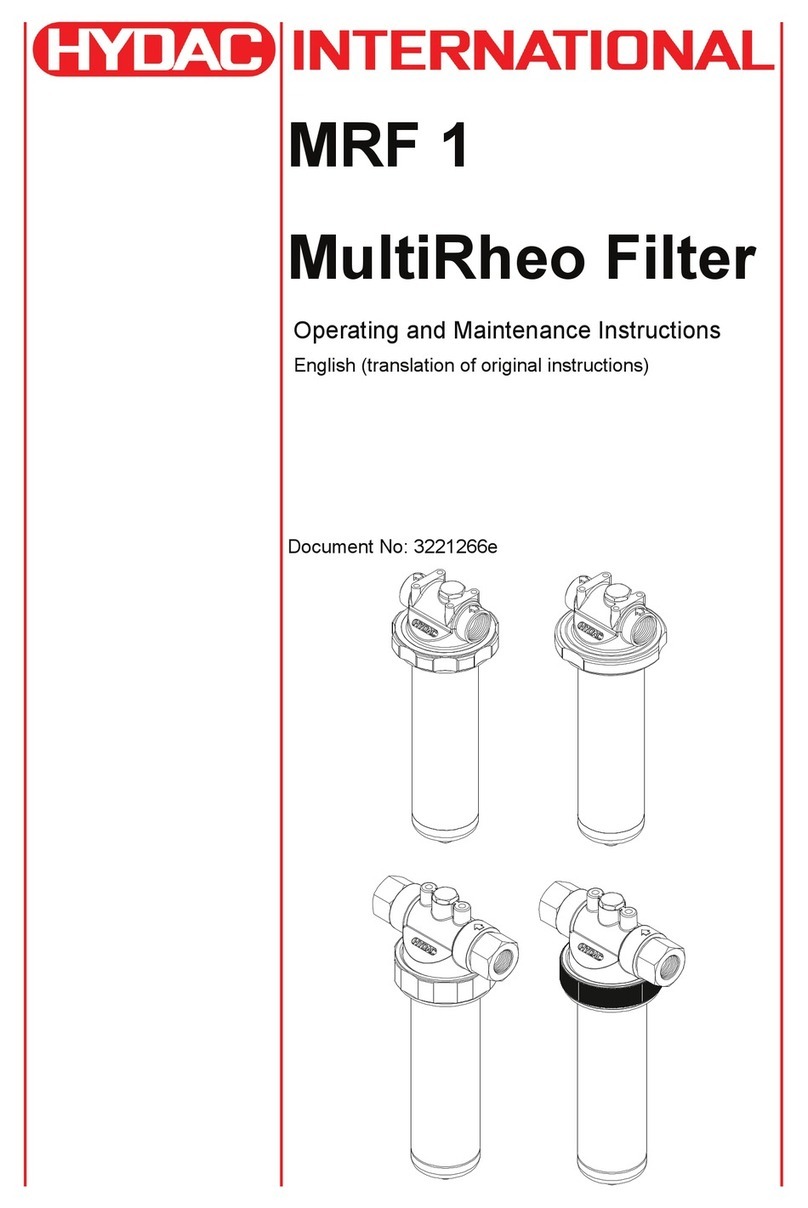

HYDAC International

HYDAC International MRF 1 Operating and maintenance instructions