JY817 Install and maintain instruction

IController display and operation

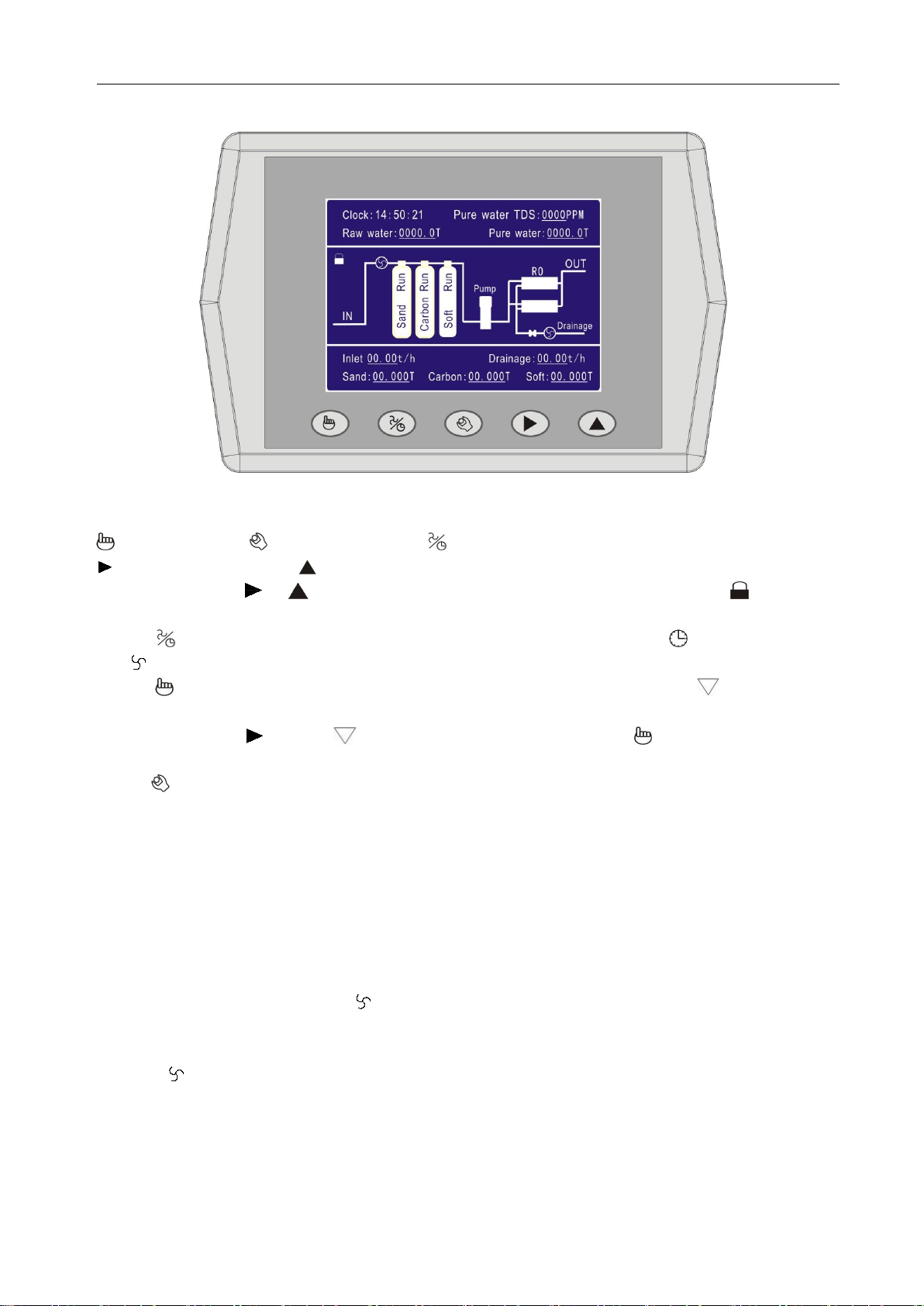

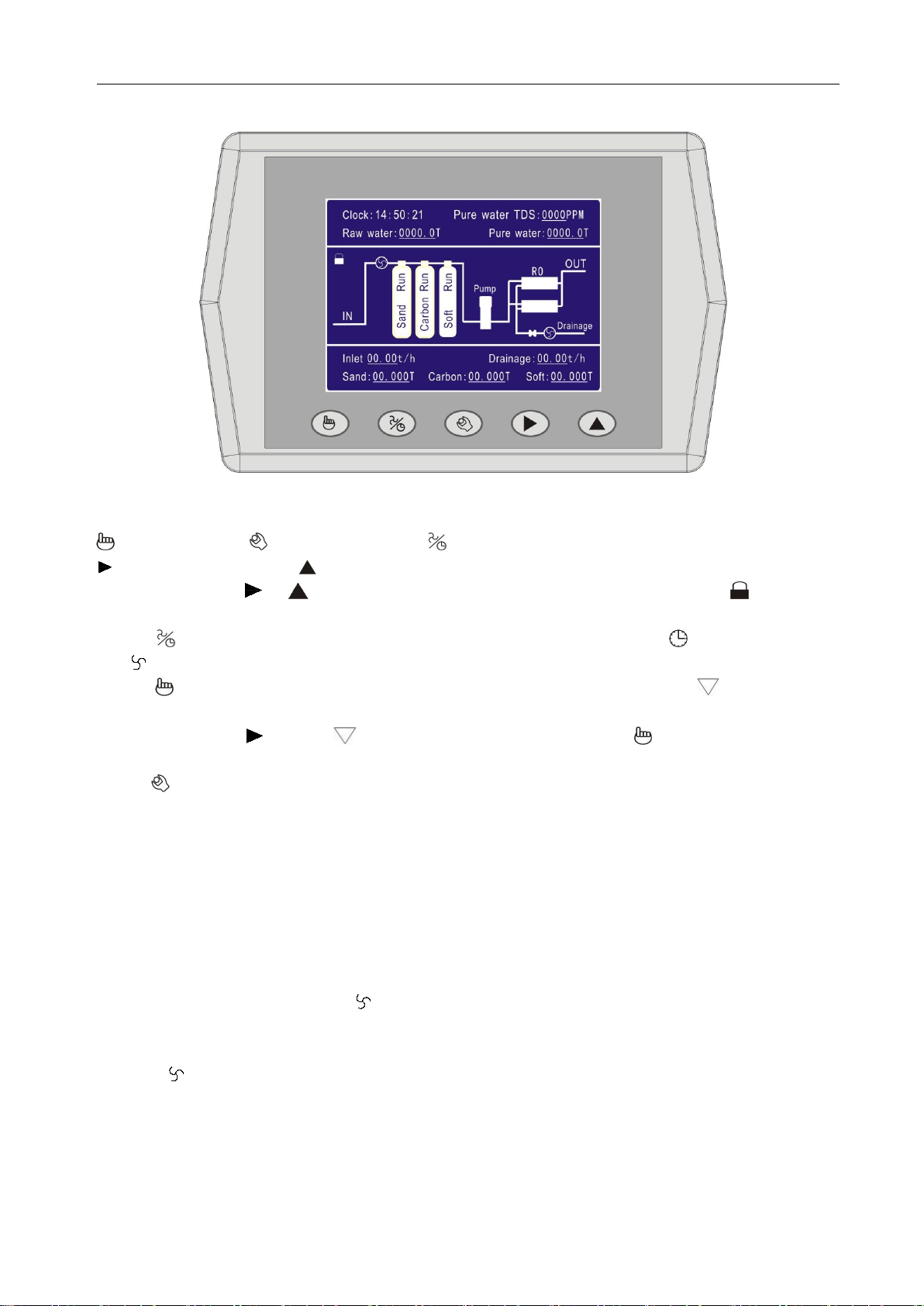

pic1:Control panel

The operation button:

:Manual switch; :Parameter setting; :Mode switch;

:Move to the next digit; :Plus 1

A、Unlock:Press “ ”&“ ” buttons at the same time,The key is unlocked,Displaying” ” disappear

B、Lock:Automatic lock after 3 minutes without any operation.

C、“ ” Mode switch:Unlock state, the operation button in time mode “ ” and meter Mode

“ ”display to switch between.

D、“ ”Manual switch:Unlock state, when pushing the button the valve(below )switch to next

station.As shown in the figure, the Sand Run (sand filter valve) enters the Sand B.wash →Sand

Wash. Press the " " button," "move to the Carbon Run, Press the " " ,switch the carbon filter

valve to enter the Carbon B.wash and Carbon B.wash . Cycle in turn.

E、“ ”Parameter setting:Unlock state, press the button and the screen will show the interface of

setting parameters.

(2) Service display:

A, Clock: 14:50:21: Delay backwash function must be set.

B, Pure water TDS: 0000 PPM Shows the salt content of pure water, unit PPM(the mass

concentration of total salt content of pure water per million)

C,Raw water: 0000.0T Measured by the water inlet flow meter, including all the softening water

flowing out of purifier,B.wash and wash drainage, subsequent RO membrane purified water and RO

drainage. Inlet flow meter symbol“ ”rotates when water flows through it.

D,Pure water: 0000.0T Total production of pure water, the unit is tons, by the inlet flow meter and

RO drainage flow meter measurement, by the program calculation and display. drainage flow meter

symbol“ ”rotates when water flows through it.

E, Inlet : 00.00t/h Flow rate of inlet water.

F. Drainage:00.00t/h ,RO drainage flow rate,it is adjusted by the drainage valve.

G,Sand: 00.000T; Carbon: 00.000T; Soft: 00.000T Respectively display the sand filter valve, carbon

filter valve, softening valve current station parameters, decline state, to "0" automatic to shift next

station.