BOSSCO ZON User manual

This document is to be used in conjunction with the full user guide available from the

manufacturer or to download at bossaccesstowers.com/literature.

Safe use

Please read this guide carefully. Please note that diagrams are for

illustrative purposes only.

• Check that all components are onsite, undamaged and that they are functioning

correctly - (refer to Checklist and Quantity Schedules in the user guide). Damaged

or incorrect components should not be used.

• Check ground on which tower is to be erected and moved is capable of supporting

the tower.

• The safe working load is 225kg (500lbs), per platform level, uniformly distributed

up to a maximum of 720kgs (1580lbs), per tower (including self-weight).

• Beware of horizontal forces (e.g. power tools) which could generate instability.

• Maximum horizontal force equals 30kg.

• Towers must only ever be climbed from the inside and using the rungs directly

below the trapdoor.

• It is recommended that towers should be tied to a solid structure when left

unattended.

• Only use the adjustable legs to level the tower and not to gain extra height.

Adjustable legs should only ever be extended to minimum amount required to

level the tower.

Lifting of equipment

• Tower components should be lifted using a reliable lifting material (e.g. strong

rope), employing a reliable knot (e.g. clove hitch), to ensure safe fastening and

always lift within the footprint of the tower.

• Assembled mobile towers should not be lifted with a crane or other lifting device.

• Ensure the safe working load of the supporting decks and the tower structure is

not exceeded.

Movement

• The tower should only be moved by manual effort, and only from the base.

• No person or materials should be on the tower during movement.

• Caution should be exercised when wheeling a tower over rough, uneven or

sloping ground, taking care to unlock and lock castors. If stabilisers are fitted,

they should only be lifted a maximum of 25mm above the ground to clear ground

obstructions.

• The overall height of the tower when being moved, should not exceed 2.5 times

the minimum base dimensions, or 4 metres overall height with stabilisers fitted in

the correct position (whichever is the smallest). If stabilisers are not fitted in the

standard position, the overall height of the tower should not exceed 2m.

• Before use, check the tower is still correct and complete.

• After every movement of the tower use a spirit level to check that it is vertical and

level to within 10mm/m and set the adjustable legs as required.

• Do not move the tower in wind speeds over 7.7 metres per second

(17 mph).

• Mobile access towers are not designed to be lifted or suspended.

NOTE: If the tower is moved, you MUST inspect prior to use.

Ties

For further information on tying-in a tower please contact your supplier or the

manufacturer.

Maintenance - storage - transport

All components and their parts should be regularly inspected to identify damage,

particularly to joints. Lost or broken parts should be replaced, and any tubing with

indentation greater than 5mm must not be used.

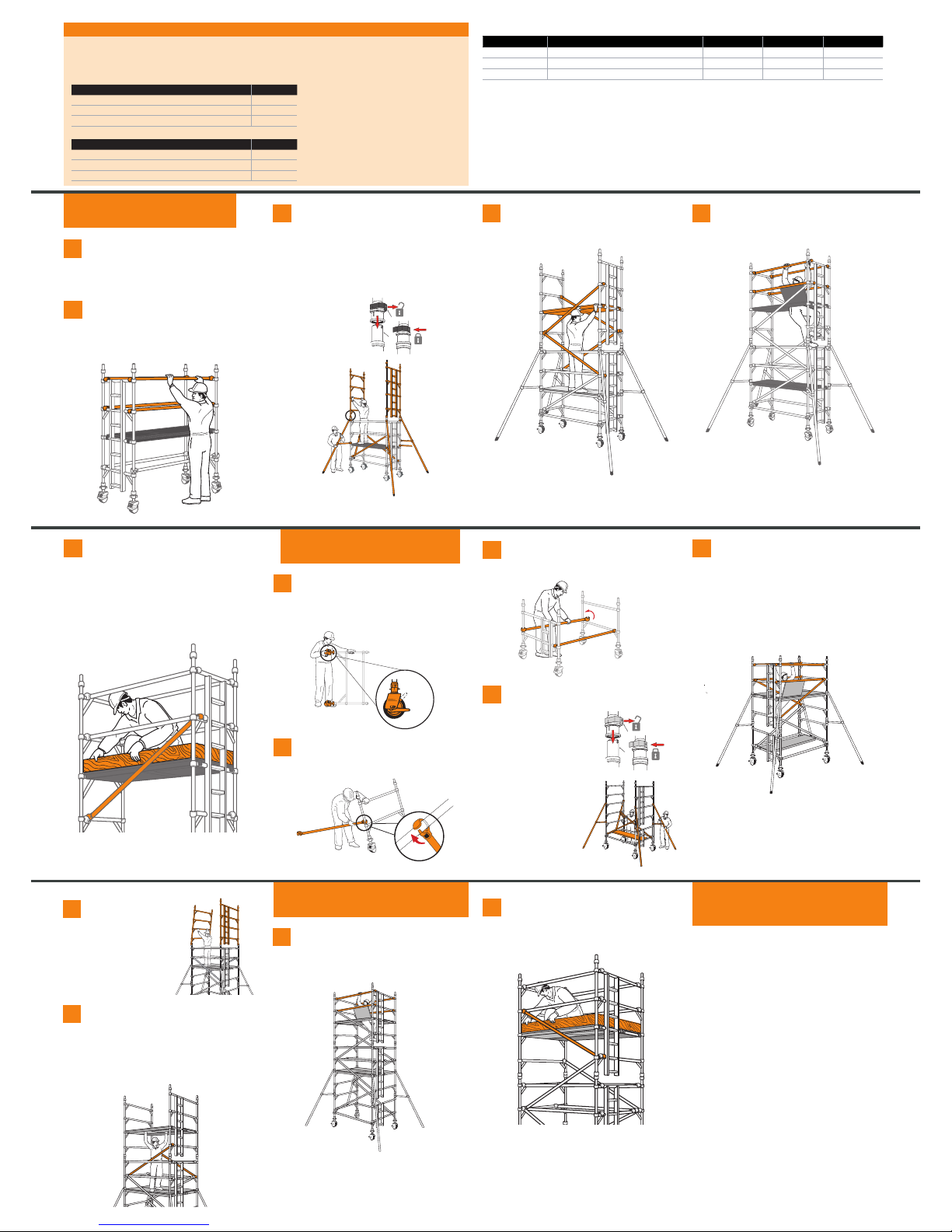

ZONE:1

PN03304300

4 Rung Ladder Frame

Horizontal Brace

4 Rung

Span Frame

Side Toe board

Platform

(Fixed and

Trapdoor

Decks)

Diagonal

Brace

Stabiliser

2 Rung

Frame

Castor

Adjustable

Leg

2 Rung

Ladder

Frame

End Toe Board

BoSS Zone:1 850 to EN 1004: Available in 2 lengths - 1.8m and 2.5m.

Internal/external use - towers under 2.5m are outside of the scope of EN 1004

Stabilisers should always be tted when specied.

NOTE: Above 8.2m it is necessary to reposition platforms during the assembly and dismantling process to reduce the self-weight of the tower and optimise the maximum safe working load.

Stabilisers should always be tted when specied.

NOTE: Above 8.2m it is necessary to reposition platforms during the assembly and dismantling process to reduce the self-weight of the tower and optimise the maximum safe working load.

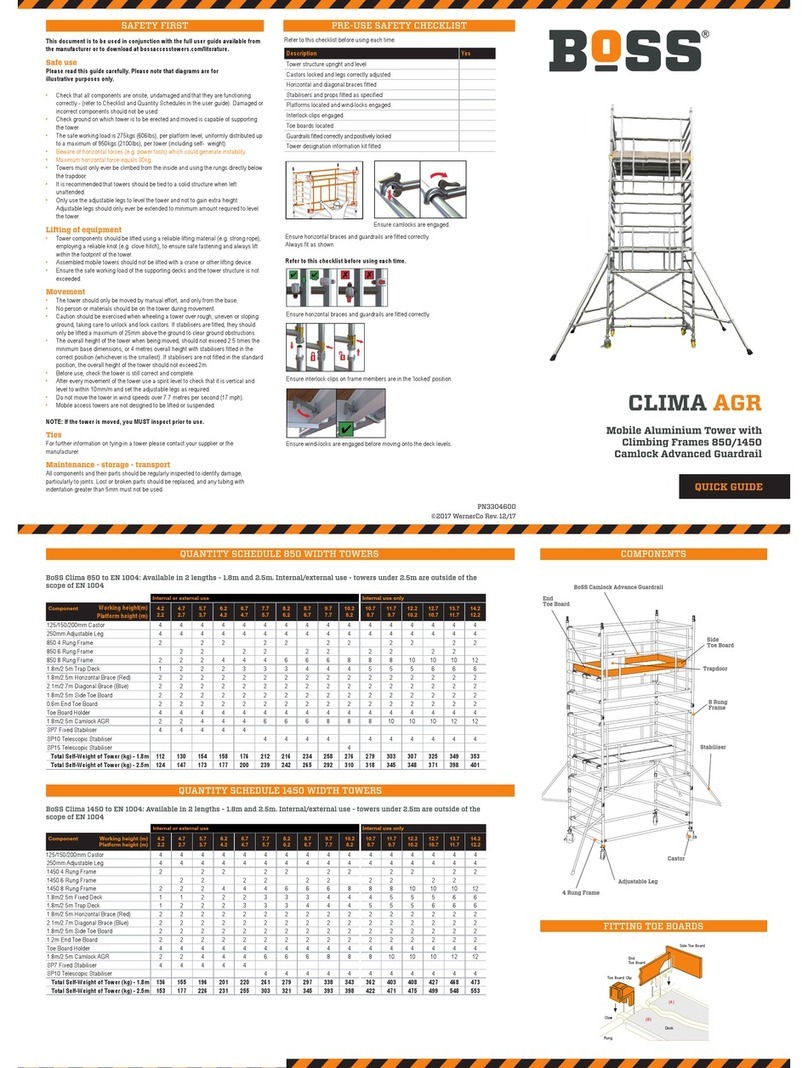

Description Yes

Tower structure upright and level

Castors locked and legs correctly adjusted

Diagonal braces tted

Stabilisers tted as specied

Platforms located and wind-locks engaged

Interlock clips engaged

Toe boards located

Guardrails tted correctly and positively locked. See illustration below

Llave de

resorte

Espita

Spring

Clip

Spigot

1

2

3

Check frame interlock clips are locked. See illustration below:

Check environmental changes have not affected the tower, and the effective support of

the stabilisers. Always t as shown. Refer to this checklist before using each time.

Ensure horizontal braces and guardrails are tted correctly.

Ensure interlock clips on frame members are in the ‘locked’ position.

Ensure wind-locks are engaged before moving onto the deck levels.

BoSS Zone:1 1450 to EN 1004: Available in 2 lengths - 1.8m and 2.5m.

Internal/external use - towers under 2.5m are outside of the scope of EN 1004

Internal or external use Internal use only

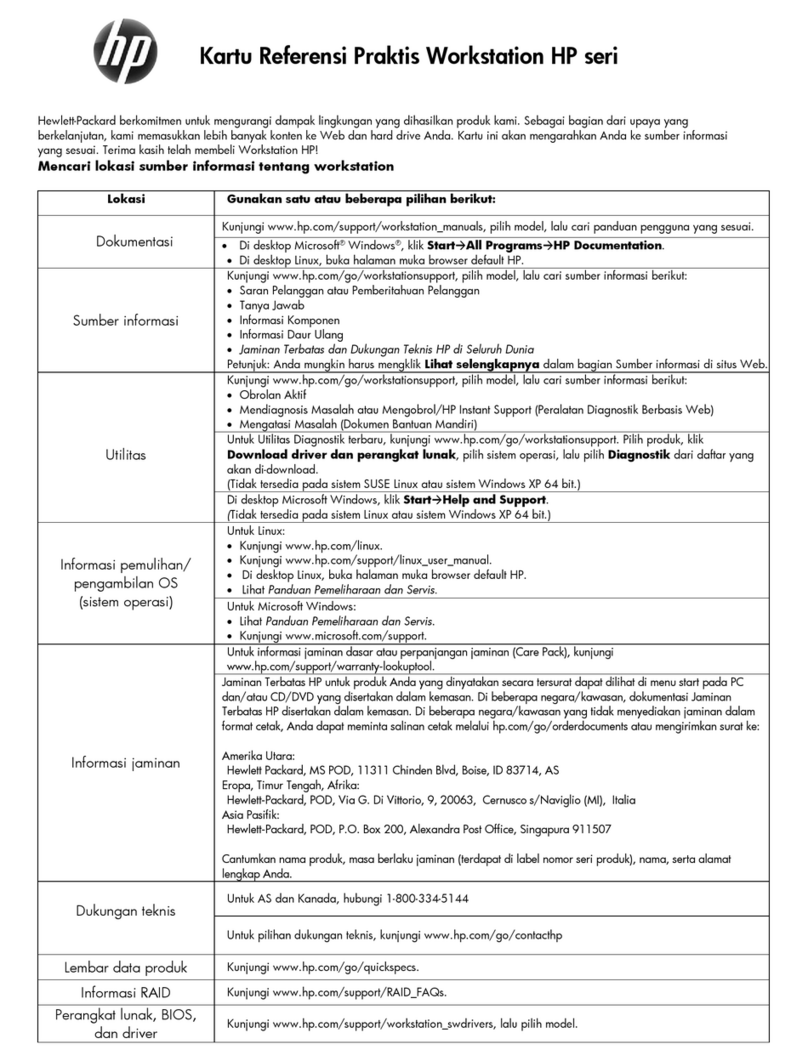

Component Working height (m) 3.2 3.7 4.2 4.7 5.2 5.7 6.2 6.7 7.2 7.7 8.2 8.7 9.2 9.7 10.2 10.7 11.2 11.7 12.2 12.7 13.2 13.7 14.2

1.2 1.7 2.2 2.7 3.2 3.7 4.2 4.7 5.2 5.7 6.2 6.7 7.2 7.7 8.2 8.7 9.2 9.7 10.2 10.7 11.2 11.7 12.2

Platform height (m)

125/150/200mm Castor 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

Adjustable Leg 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

850 2 Rung Ladder Frame 1 1 1 1 1 1 1 1 1 1 1 1

850 2 Rung Span Frame 1 1 1 1 1 1 1 1 1 1 1 1

850 3 Rung Ladder Frame 1 1 1 1 1 1 1 1 1 1 1

850 3 Rung Span Frame 1 1 1 1 1 1 1 1 1 1 1

850 4 Rung Ladder Frame 1 112122323343445455656

850 4 Rung Span Frame 1 112122323343445455656

1.8m/2.5m Trap Deck 11122223333444455556666

1.8m/2.5m Horizontal Brace (Red) 6 6 6 6 10 10 10 10 14 14 14 14 18 18 18 18 22 22 22 22 26 26 26

2.1m/2.7m Diagonal Brace (Blue) 2 3 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

1.8m/2.5m Side Toe Board 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

0.6m End Toe Board 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

Small Stabiliser 4 4 4 4 4

Large Stabiliser 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

Ballast Required (External) 1.8m 1

Ballast Required (External) 2.5m 1 25 50 75

Total Tower Self-Weight (kgs) - 1.8m 80 92 113 138 151 163 168 195 208 220 226 250 263 275 280 304 317 329 335 359 372 384 389

Total Tower Self-Weight (kgs) - 2.5m 92 104 126 156 172 184 189 223 239 251 256 287 327 365 395 350 366 378 384 414 430 442 447

Max Tower Load 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720

Max Safe Load (kgs) - 1.8m 640 628 607 582 569 557 552 525 512 500 494 470 457 445 440 416 403 391 385 361 348 336 331

Max Safe Load (kgs) - 2.5m 628 616 594 564 548 536 531 497 481 469 464 433 393 355 325 370 354 342 336 306 290 278 273

Internal or external use Internal use only

Component Working height (m) 3.2 3.7 4.2 4.7 5.2 5.7 6.2 6.7 7.2 7.7 8.2 8.7 9.2 9.7 10.2 10.7 11.2 11.7 12.2 12.7 13.2 13.7 14.2

1.2 1.7 2.2 2.7 3.2 3.7 4.2 4.7 5.2 5.7 6.2 6.7 7.2 7.7 8.2 8.7 9.2 9.7 10.2 10.7 11.2 11.7 12.2Platform height

(m)

125/150/200mm Castor 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

Adjustable Leg 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4

1450 2 Rung Ladder Frame 1 1 1 1 1 1 1 1 1 1 1 1

1450 2 Rung Span Frame 1 1 1 1 1 1 1 1 1 1 1 1

1450 3 Rung Ladder Frame 11111111111

1450 3 Rung Span Frame 11111111111

1450 4 Rung Ladder Frame 1 112122323343445455656

1450 4 Rung Span Frame 1 112122323343445455656

1.8m/2.5m Fixed Deck 1 1 1 2 2 2 2 3 3 3 3 4 4 4 4 3 3 3 3 4 4 4 4

1.8m /2.5m Trap Deck 1 1 1 1 2 2 2 2 3 3 3 3 4 4 4 3 3 3 3 3 4 4 4

1.8m/2.5m Horizontal Brace (Red) 6 6 6 6 10 10 10 10 14 14 14 14 18 18 18 18 22 22 22 22 26 26 26

2.1m/2.7m Diagonal Brace (Blue) 2 3 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23

1.8m/2.5m Side Toe Board 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

1.2m End Toe Board 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2 2

Small Stabiliser 4 4 4 4 4 4 4

Large Stabiliser 4 4 4 4 4 4 4 4 4 4 4 4 4

Total Tower Self-Weight (kgs) - 1.8m 112 128 133 177 211 228 235 260 294 311 321 346 380 397 404 376 391 408 415 440 474 491 498

Total Tower Self-Weight (kgs) - 2.5m 130 146 152 201 244 261 269 300 342 359 370 401 444 460 468 428 446 463 471 501 544 561 569

Max Tower Load 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720 720

Max Safe Load (kgs) - 1.8m 610 593 588 545 510 494 486 462 427 411 400 375 341 324 317 345 330 313 306 281 247 230 223

Max Safe Load (kgs) - 2.5m 592 575 570 520 477 460 453 422 379 362 351 320 278 261 253 293 275 259 251 220 177 160 153

©2017 WernerCo Rev. 12/17

QUICK GUIDE

PRE-USE SAFETY CHECKLISTSAFETY FIRST

Mobile Fibreglass Tower

850/1450 Ladderspan

3T -Through The Trapdoor Method

QUANTITY SCHEDULE 850 WIDTH TOWERS COMPONENTS

QUANTITY SCHEDULE 1450 WIDTH TOWERS

PN03304300 BoSS_DL_Folded_Zone1_Quick_Guide rev1217.indd 1 11/12/2017 15:32

The manufacturer recommends that two persons are used to build BoSS Towers. Above

4m height, it is essential that at least two persons are used. Only climb the tower from the

inside. Always start building with the smallest height frames at the base of the tower:

ASSEMBLY PRINCIPLES

Platform height in metres Frame at base

1.7, 2.2, 3.7, 4.2, 5.7, 6.2, 7.7, 8.2, 9.7, 10.2, 11.7, 12.2 2 rung

2.7, 4.7, 6.7, 8.7, 10.7 3 rung

1.2, 3.2, 5.2, 7.2, 9.2, 11.2 4 rung

1450 towers:

Platform height in metres Frame at base

1.7, 2.2, 3.7, 4.2, 5.7, 6.2, 7.7, 8.2, 9.7, 10.2, 11.7, 12.2 2 rung

2.7, 4.7, 6.7, 8.7, 10.7 3 rung

1.2, 3.2, 5.2, 7.2, 9.2, 11.2 4 rung

850 towers:

During use

Wind description Beaufort scale Beaufort no. Speed in mph Speed in m/sec

Medium breeze Raises dust and loose paper, twigs snap off 4 8 - 12 4 - 6

Strong breeze Large branches in motion, telegraph wires whistle 6 25 - 31 11 - 14

Gale force Walking is difcult 8 39 - 46 17 - 21

• Beware of high winds in exposed, gusty or medium breeze conditions. We recommend that in wind speeds over 7.7 metres per second

(17mph), cease working on the tower and do not attempt to move it. If the wind becomes a strong breeze, (expected to reach 11.3 metres per

second - 25 mph) tie the tower to a rigid structure. If the wind is likely to reach gale force, (over 18 metres per second - 40 mph) the tower

should be dismantled.

• Beware of open-ended buildings, which can cause a funnelling effect.

• Raising and lowering components, tools, and/or materials by rope should be conducted within the tower base. Ensure that the safe working

load of the supporting decks and the tower structure is not exceeded.

• The assembled tower is a working platform and should not be used as a means of access or egress to other structures.

• Beware of horizontal forces (e.g. power tools) which could generate instability. Maximum horizontal force 30kg.

• The stairway towers, featuring an inclined staircase access, are for frequent use by personnel carrying tools and/or materials.

• Do not use boxes or stepladders or other objects on the platform to gain extra height.

ASSEMBLY PROCEDURE

Assembly for 850 towers

Insert adjustable leg/castor assemblies into end

frames and lock the castors (see step 1 of the

1450 assembly). Base plates can be tted to the

adjustable legs if it is not necessary to move the tower.

Fit two horizontal braces (red) to the 850 end frames as

shown in Steps 2 and 3 for the 1450 tower procedure.

1

Fit a trapdoor deck on the 2nd rung. Fix the

horizontal braces (red) as guardrails on the 3rd

and 4th rungs (2 and 4 rungs above the platform)

on both sides of the tower.

2

Fit two diagonal braces (blue) in opposing directions

between the 1st and 3rd rungs. Ensure that the frames are

vertical and level by checking with a spirit level and setting

the adjustable legs as necessary. Fit stabilisers. Fit the next pair of

end frames and check the frame interlock clips are engaged.

IMPORTANT. Only use the adjustment on the legs to level the

tower and not to gain extra height.

Fit two pairs of diagonal braces in opposing directions

between the 3rd and 5th rungs and the 5th and 7th rungs.

Locate a trapdoor deck on the 6th rung, with the trapdoor

next to the ladder.

4Climb up the inside of the tower and from the protected

position of the trapdoor, t guardrails to the 7th and 8th

rungs (in that order) on both sides of the tower.

5

Continue the procedure until the required working height is

reached, adding additional pairs of end frames, diagonal

braces and tting trapdoor platforms, as shown on previous steps.

At every platform level, add horizontal braces as guardrails from the

protected position within the trapdoor (as shown in Step 5).

Fit a single diagonal at the top of the tower as shown. Fit the toe

boards - see the component section for guidance on how to t.

The tower is now complete.

6ASSEMBLY PROCEDURE

Assembly for 1450 towers

Push castor into adjustable leg. Push castor/adjustable leg

assemblies into 2 rung span frame. Lock castors. Repeat

procedure with 2 rung ladder frame.

Note: Base plates can be tted to adjustable legs in lieu of

castors if it is not necessary to move the tower.

1

Fit one horizontal brace (red) onto the vertical of a span

frame, just above the bottom rung, with the claw facing

outwards. The frame will now be self supporting. NB: All locking

claws must be opening before tting.

2

Position the ladder frame as shown and t the other end

of the horizontal brace on to the vertical. Fit a second

horizontal brace on the other side of the frames to square the tower.

3Fit a trapdoor deck on the 4th rung (2.0m) with the trapdoor

next to the ladder. Ensure the trapdoor is positioned with the

hinges towards the outside of the tower as shown. Climb the ladder

and, from the protected trapdoor position, t guardrails on the 5th

and 6th rungs (in that order) on both sides of the platform.

Do not climb onto the deck until all guardrails are in place.

When horizontal braces are tted as guardrails, they should be

0.5m and 1.0m (1 and 2 rungs) above the platform level in all cases.

Remove the temporary deck from the lowest rung.

5

Unlocked

Locked

Locked

Fit two additional end frames,

ensuring the frame interlock

clips are engaged. Fit two diagonal

braces (blue) in opposing directions,

between the 1st and the 3rd rungs.

Ensure the frames are vertical and level

by checking with a spirit level and setting

the adjustable legs as required.

Fit a temporary deck on the lowest

rungs.

Fit stabilisers.

IMPORTANT - Only use the

adjustable legs to level the tower

and not to gain extra height.

4

Fit the next pair of diagonal

braces in opposing directions

between the 3rd and 5th

rungs. Add two additional end frames.

6

Add two more diagonal braces between the 5th and 7th

rungs. If nishing at this height (4.2m platform) reposition

the xed deck to the 8th rung on the tower. Fit a trapdoor deck

alongside it, with the hinges towards the outside of the tower, and the

trapdoor next to the ladder. Add a single diagonal between the 7th

and 9th rungs as shown. Climb up the ladder, and from the protected

trapdoor position, t the guardrails on the 9th and 10th rungs, in that

order, on both sides of the tower.

7

ASSEMBLY PROCEDURE

When building beyond

a 4.2m platform height

Continue to add pairs of end frames, diagonal braces and

t trapdoor decks as shown in the previous steps. Add

guardrails at 0.5m and 1.0m, (in that order), above the platform from

the protected trapdoor position.

Do not climb onto the deck until all guardrails are in place.

8

Fit the toe boards - see the component section for guidance

on how to t.

The tower is now complete.

9

Continue until the required height is reached.

Re-position the xed deck to the required platform height and t a

trapdoor deck alongside it as shown in Step 7. Fit a single diagonal

at the top of the tower as shown in Step 7. Fit the nal guardrails as

shown in Step 7.

DISMANTLING

PROCEDURE

To take down the tower reverse the building sequence. When

removing guardrail braces, unlock the four claws furthest from the

trapdoor and then return immediately to the protected position within

the trapdoor. You may then unlock the claws at the other ends of the

guardrails to remove them from the tower.

For a detailed user guide, please go to

bossaccesstowers.com/literature

3

Where all three frame heights

are used in a tower, start with

2 rung frames at the base, with

the 3 rung frames next and the 4

rung frames on the top. Refer to

the Quantity Schedules for detail.

The procedure illustrated shows

a 1450 tower starting with a 2

rung frame and a platform height

of 4.2m. If building an 850 tower,

the following method can be used

with single decks at all levels.

PN03304300 BoSS_DL_Folded_Zone1_Quick_Guide rev1217.indd 2 11/12/2017 15:32

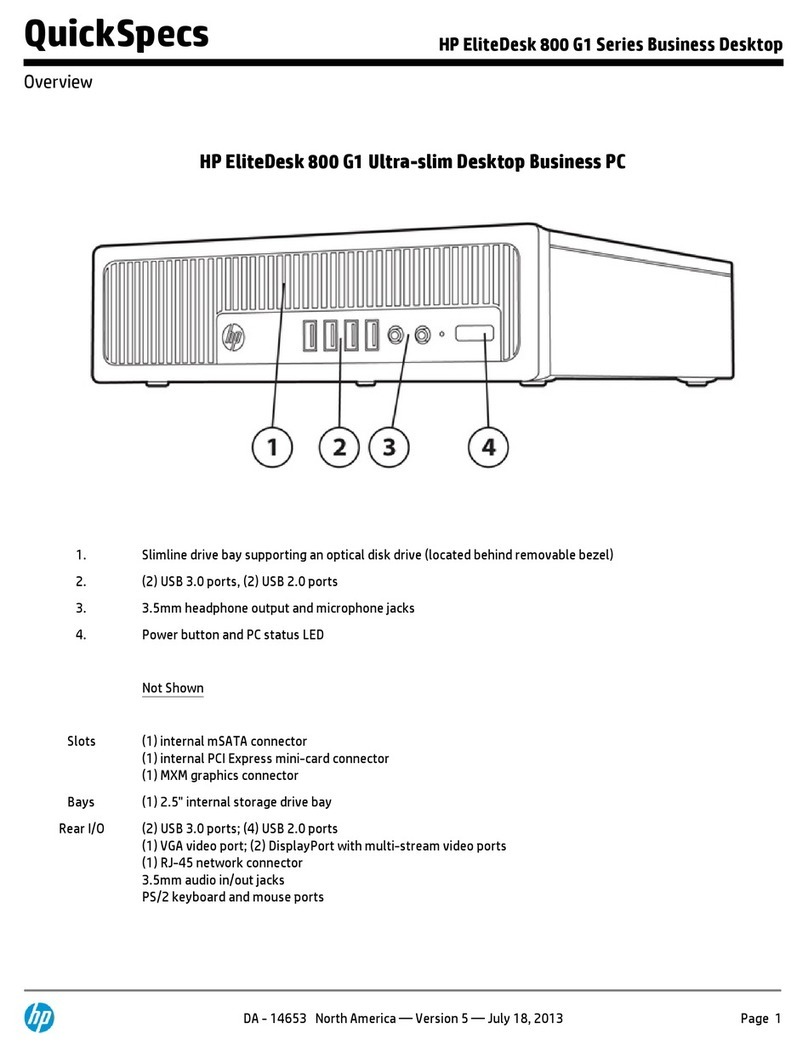

Other BOSSCO Desktop manuals

Popular Desktop manuals by other brands

HP

HP EliteDesk 800 G1 series Quickspecs

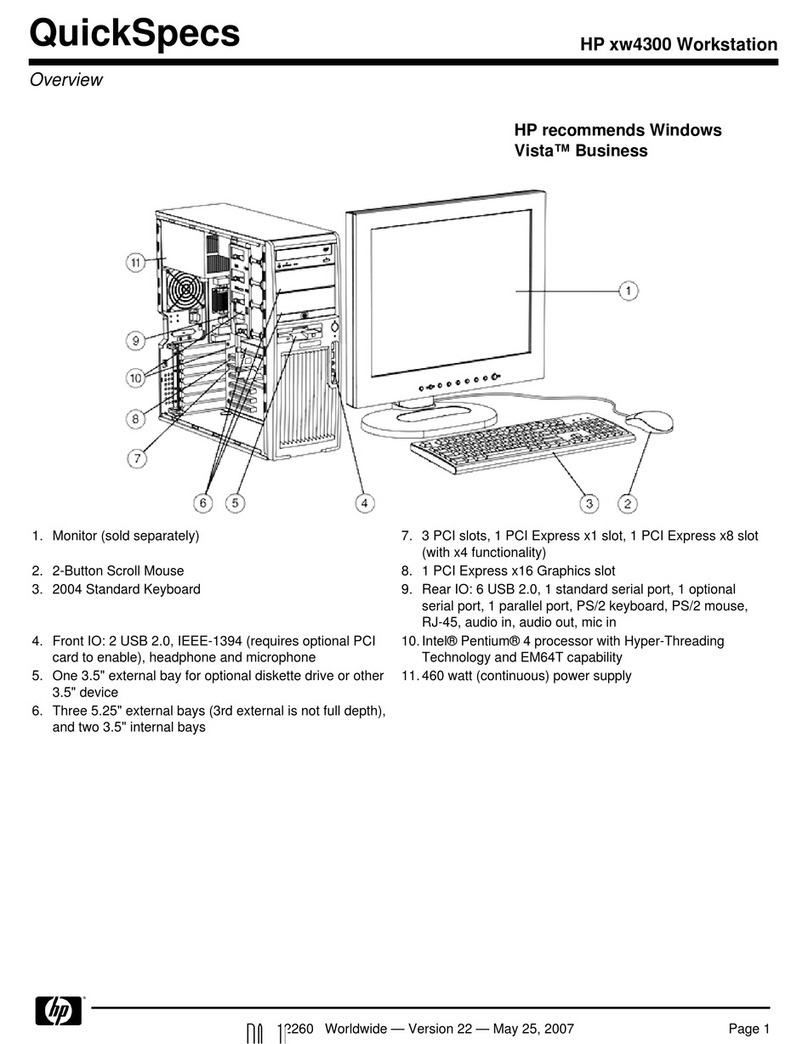

HP

HP Xw4300 - Workstation - 2 GB RAM Quickspecs

Lenovo

Lenovo ThinkCentre M75n Hardware Maintenance Manual

Mitsubishi Electric

Mitsubishi Electric apricot MS660 Owner's handbook

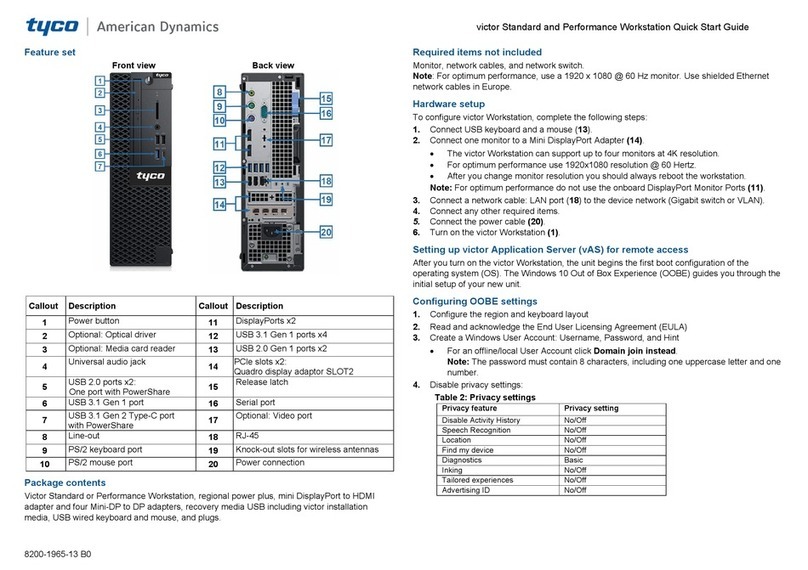

Johnson Controls

Johnson Controls tyco victor Standard Workstation quick start guide

ViewSonic

ViewSonic VOT530 Specifications