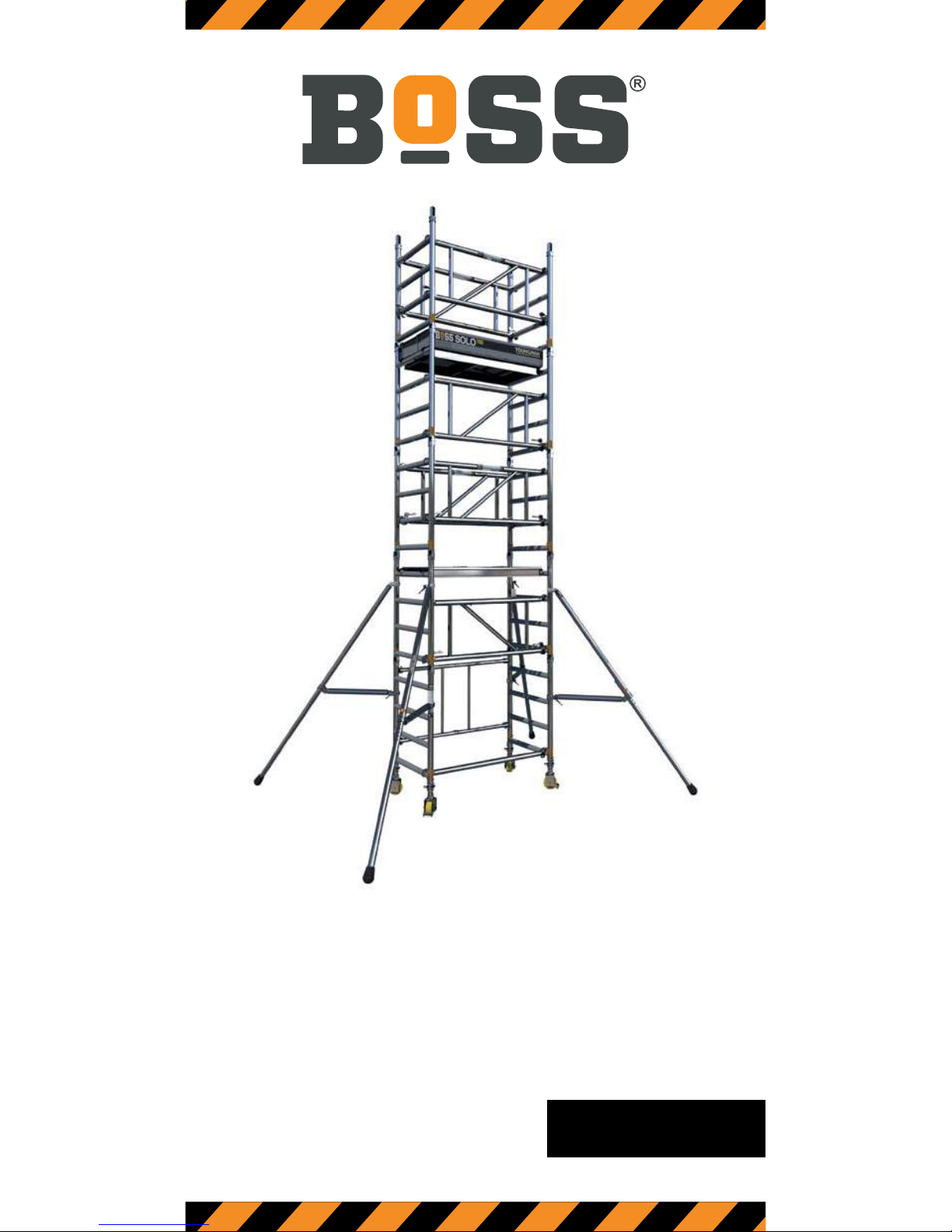

BOSSCO SOLO700 User manual

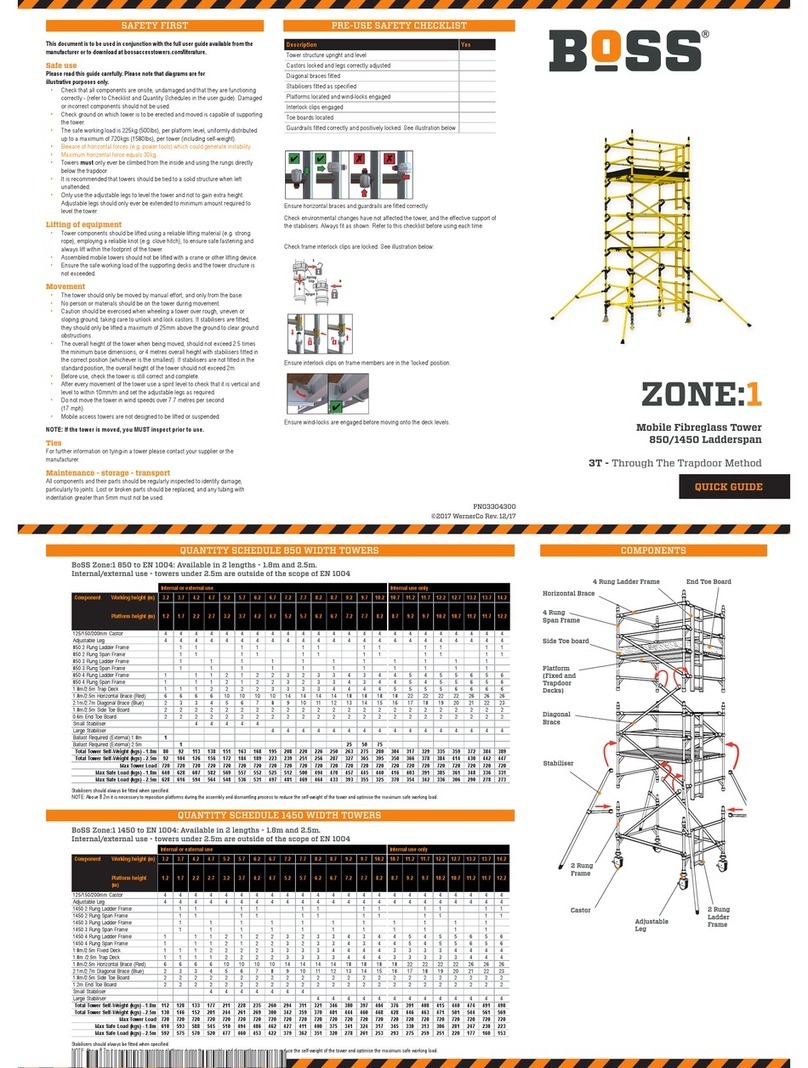

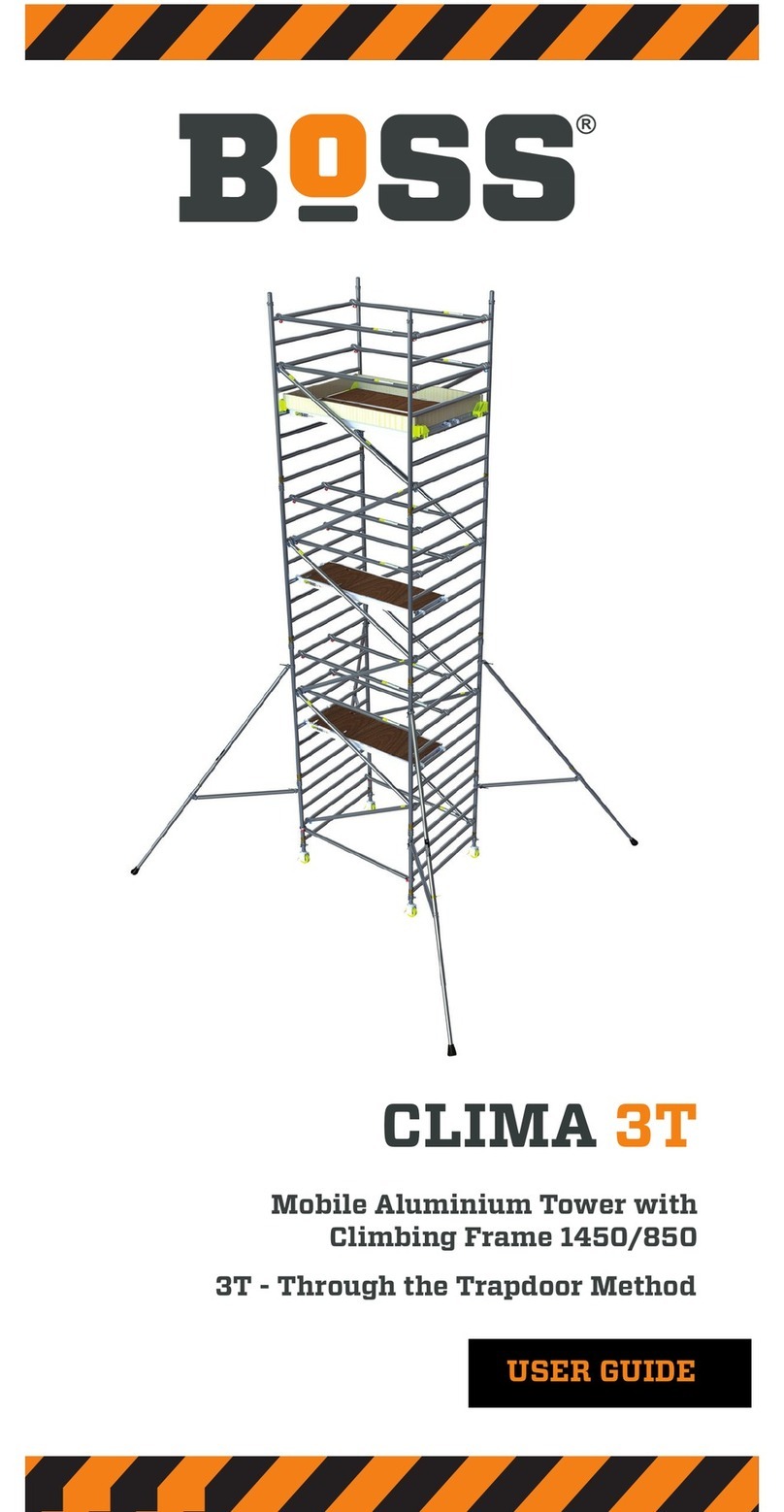

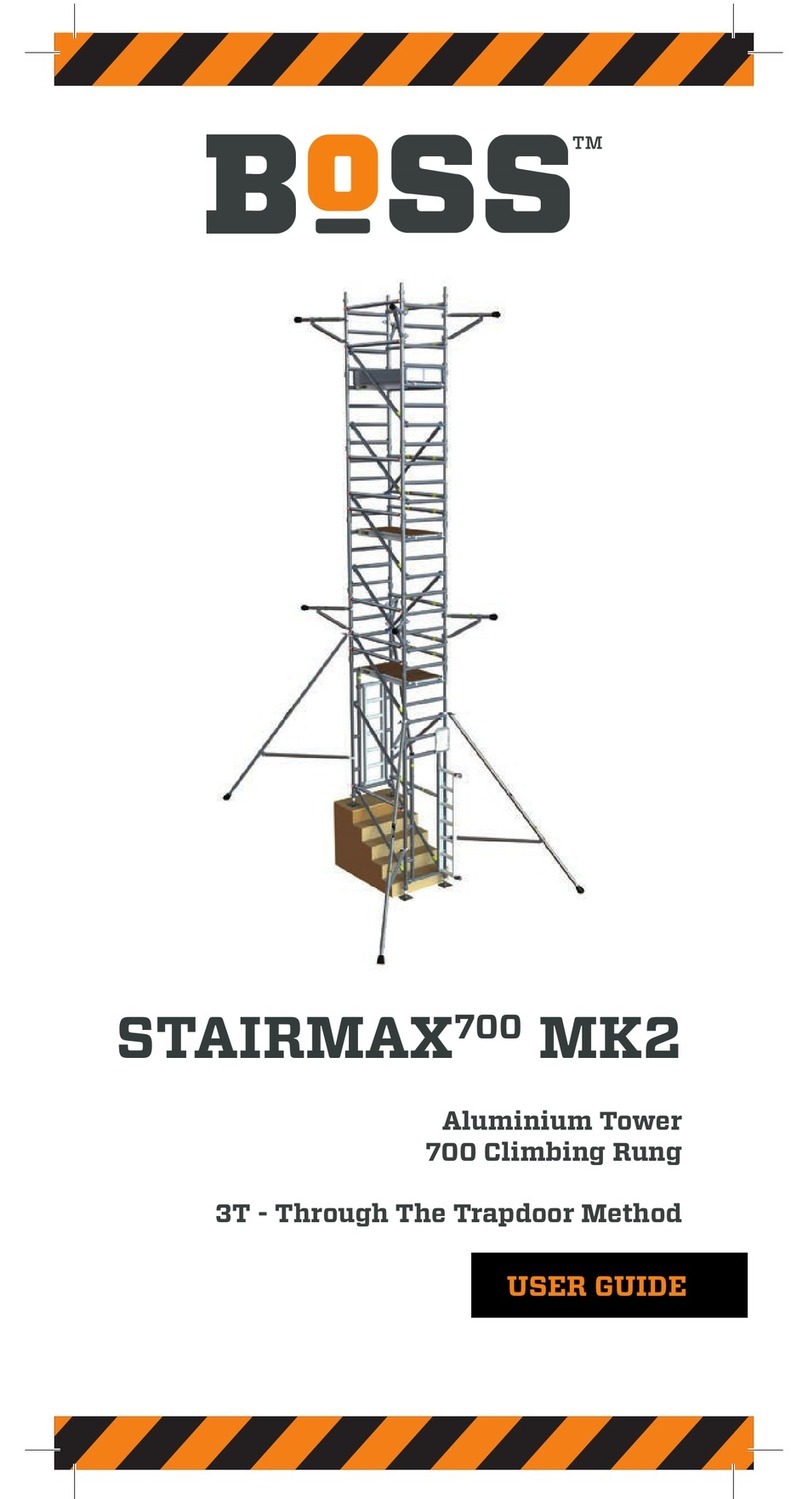

SOLO700

One Man Aluminium Tower

3T - Through the Trapdoor Method

USER GUIDE

1 BoSS SOLO700 User Guide

Safety First

Component Diagram

Quantity Schedules

Stabilisers

Build Method

Contents

2

7

9

10

11

2

bossaccesstowers.com

Safety First

Introduction

Please read this user guide carefully.

Please note that diagrams are for illustrative purposes only.

User guides are also available to download from our website at

bossaccesstowers.com.

BoSS mobile aluminium towers are light-weight scaffold towers used

throughout the building and construction industry for both indoor

and outdoor access solutions where a stable and secure platform is

required. Ideal for maintenance and installation work or short-term

access, the highly versatile towers provide a strong working platform

for a variety of heights.

This user guide provides you with step by step instructions to ensure

your system is erected easily and safely, using the 3T (Through The

Trapdoor) method.

The law requires that personnel erecting, dismantling or altering

towers must be competent. Any person erecting a BoSS mobile

tower must have a copy of this user guide. For further information

on the use of mobile access and working towers consult the PASMA

operators code of practice.

If you need further information, design advice, additional user guides

or any other help with this product, please contact the manufacturer on

BoSS SOLO700 User Guide

3

Safety First

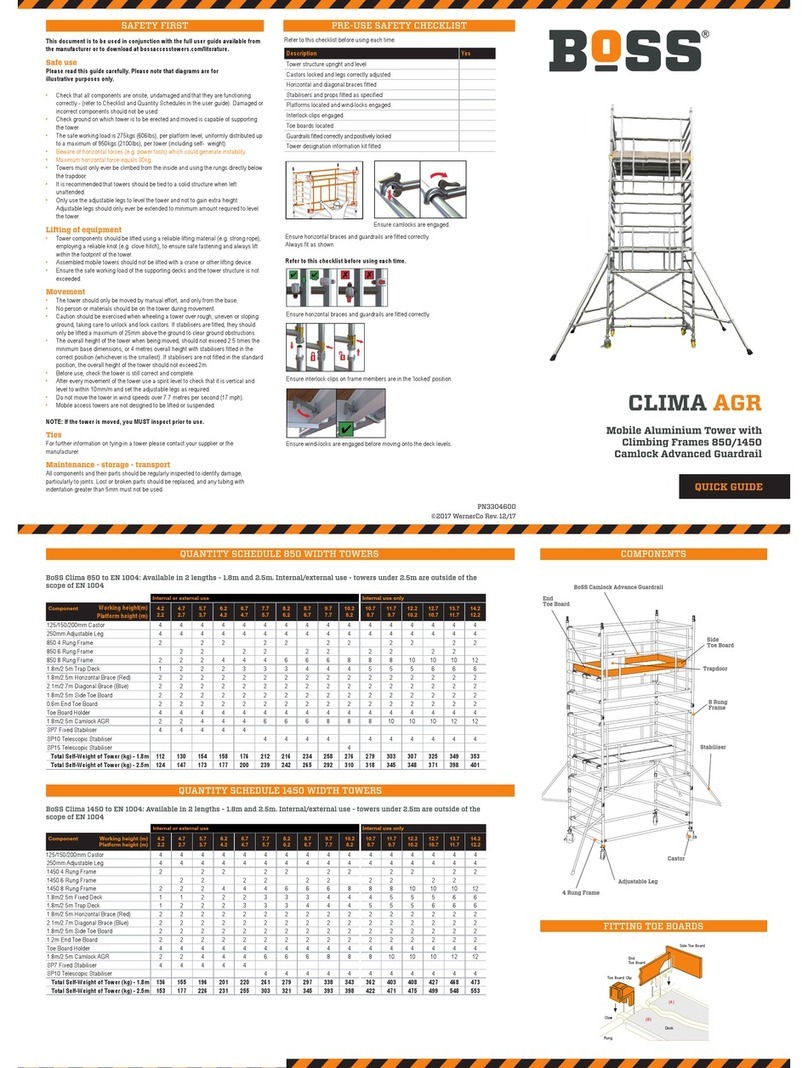

Safe use

Check that all components are onsite, undamaged and that they are

functioning correctly - (refer to Checklist and Quantity Schedules).

Damaged or incorrect components must never be used and must be

segregated for replacement, repair or destruction.

Ensure the ground on which the mobile access tower

is to be erected and moved is capable of supporting the tower.

The safe working load is 275kgs (675lbs), per platform level,

uniformly distributed up to a maximum of 550kgs (1213lbs) per

tower.

Adjustable legs should only be used for levelling.

Do not use ladders, steps, boxes or similar to gain additional

working height.

Mobile Access Towers are not designed to be lifted or suspended.

The manufacturer strongly advises against the mixing

of tower components because of the potential safety risks for

users, and their inability to rely upon the manufacturer’s Product

Liability Insurance in the event of an accident occurring as a result

of mixing components from different manufacturers.

It is recommended that towers should be tied to a solid structure

when left unattended.

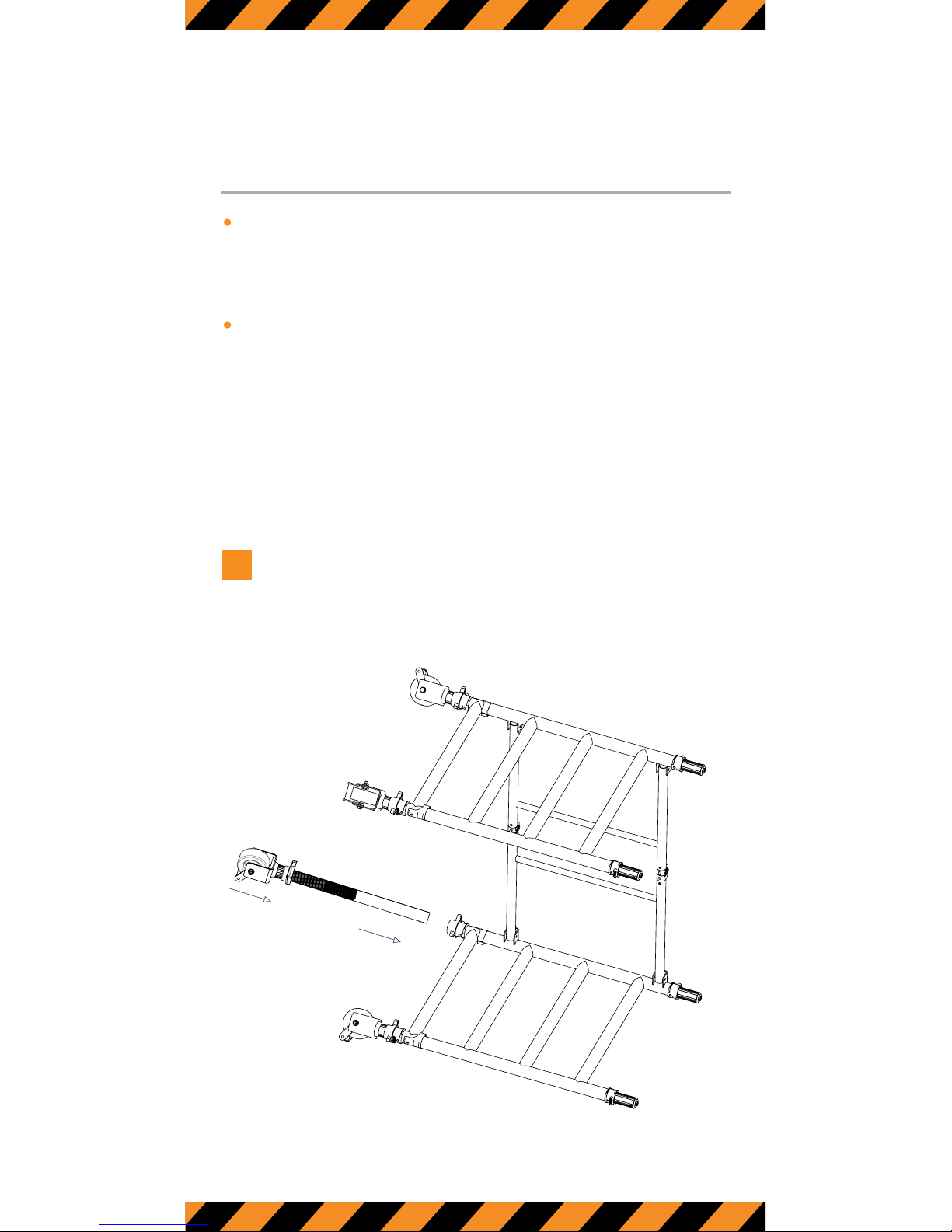

Lifting of individual tower components

Tower components should be lifted using the BoSS SOLO700

assembly bracket.

Raising and lowering components, tools and/or materials by rope

should be conducted within the tower base (i.e. within the area

bounded by the stabilisers). Ensure that the safe working load of

the supporting decks and the tower structure is not exceeded.

bossaccesstowers.com

4

Moving the tower

Towers should be moved with caution.

Before moving, check the suitability of the intended route to ensure

there are no obstructions, both at ground level and overhead. Wind

conditions must also be considered.

People and materials must be removed and the height of the tower

reduced to 4.0m.

The stabilisers should be left in position and raised no more than

25mm from the ground.

The tower must only be moved by applying manual effort at, or near,

the base of the tower and you should ensure there are sufcient

operatives on hand to control the movement of the structure.

After moving and before use, check that the tower is still correct and

complete. Use a spirit level to ensure that it is vertical and level, then

adjust the legs as required.

Do not move the tower in wind speeds over 7.7 metres per second

(17mph).

Safety First

Maintenance - storage - transport

All components and their parts should be regularly inspected to identify

damage, particularly to joints. Lost or broken parts should be replaced

and any tubing with indentation greater than 5mm should not be used

and put to one side for repair by the manufacturer. Adjustable leg threads

should be cleaned and lightly lubricated to keep them free running.

Brace claws, frame interlock clips, trapdoor latches, camlocks, claw

mechanisms and platform wind-locks should be regularly checked to

ensure they lock correctly.

Refer to the BoSS Inspection Guidance poster for detailed inspection

and maintenance advice:

bossaccesstowers.com/literature.

Components should be stored in clean, dry conditions with due care to

prevent damage.

Ensure components are not damaged by excessive strapping forces

when transported.

BoSS SOLO700 User Guide

5

Safety First

Preparation and inspection

Inspect the equipment before use to ensure that it is not damaged

and that it functions properly. Damaged, incorrect or incompatible

components must not be used.

During assembly, use and dismantling

Complete towers, in accordance with EN1004, should be stable in

a free standing condition in a wind speed that equates to 28mph

or Beaufort force 6. If the wind speed exceeds 17mph, you should

cease work upon the tower. If the wind speed is expected to

reach 25mph, the tower should be tied into a rigid structure. If it is

expected to reach 40mph the tower should be dismantled.

The effect of onsite wind conditions must be considered prior to

the assembly of a tower.

Sheets, tarpaulins, cladding or similar, must not be attached to the

tower as these will signicantly increase any side loads from wind

and will potentially make the tower unstable.

Wind conditions from funnelling effects, such as open-ended

buildings, hangers or unclad buildings, must also be considered

prior to use as these wind effects can be much greater.

Wind

description

Beaufort

scale

Beaufort

no.

Speed in

mph

Speed in

m/sec

Medium

Breeze

Raises dust and

loose paper,

twigs snap off

4 8-12 4-6

Strong Breeze

Large branches

in motion,

telegraph wires

whistle

6 25-31 11-14

Gale Force Walking is difcult 8 39-46 17-21

Excessive side loads from working on the tower, i.e. drilling or

pulling may also make a tower unstable. The maximum allowable

side load on a tower is 20kg.

Do not abuse equipment. Damaged, incorrect or incompatible

components should not be used.

bossaccesstowers.com

6

Safety First

Ties

You should tie in towers of all heights wherever possible, as it is

safe practice to do so. However, where towers are left unattended

or are to be located in particularly exposed conditions, wind forces

will almost certainly affect stability. In these circumstances ensure

that the tower is adequately tied in or restrained from blowing over

and that the platforms are securely xed or alternatively the tower

dismantled.

BoSS SOLO700 User Guide

7

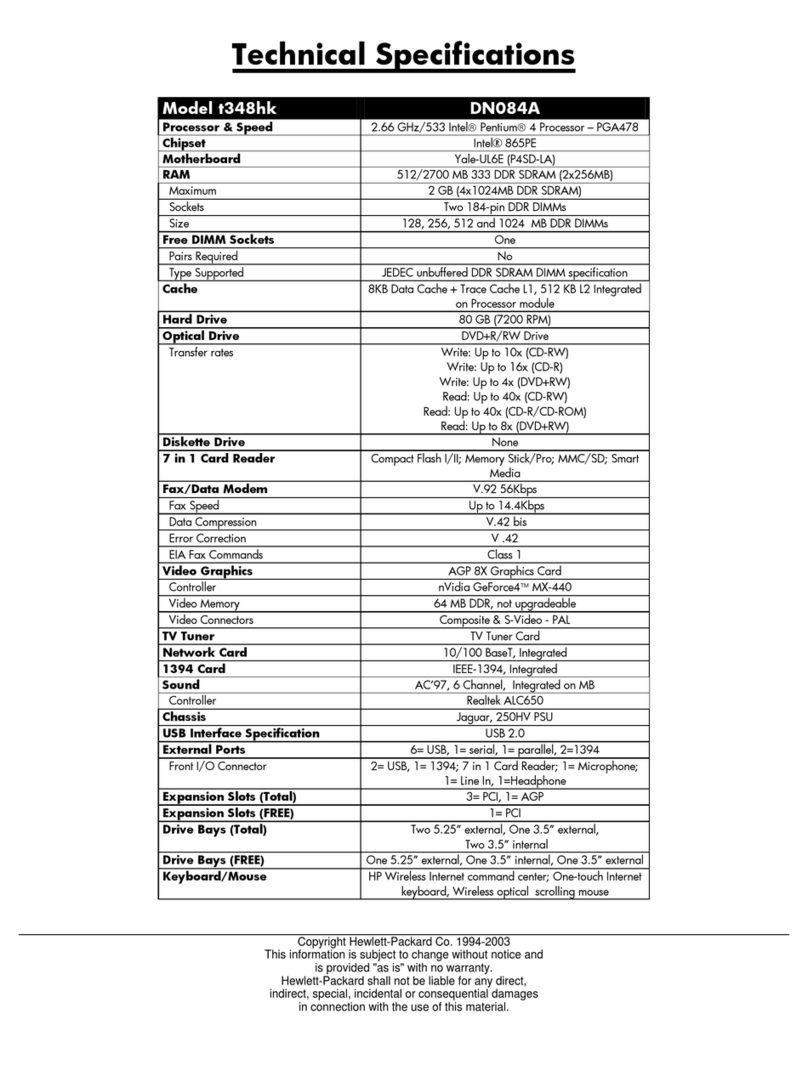

Component Diagram

Camlock

Guardrail

Frame

1m End

Frame

Folding

Aluminium

Toe Board Set

Assembly

Bracket

1.3m

Trapdoor

Deck

SP4

Stabiliser

Horizontal

Brace

Adjustable

Leg and

Castor

Folding Base

Unit

bossaccesstowers.com

8

Safety Checklist

Mobile Towers - 3T Method

Pre-assembly checklist

Ensure all components are present

(see quantity schedule on page 9)

Inspect components prior to assembly

Ensure all brace claws, camlocks and adjustable

legs operate correctly

Ensure castors rotate freely and brakes lock

Full inspection guidance can be found here at

www.bossaccesstowers.com/literature

Pre-use checklist

Inspect tower prior to use

Tower is vertical and level, using a spirit level,

and adjust legs if necessary

Castors are locked

Correct stabilisers are tted correctly

Platforms are tted correctly and wind-locks

engaged

Toe Boards are tted correctly

Guardrails are tted correctly, see illustrations below

Re-inspect the tower every 7 days or less

BoSS SOLO700 User Guide

9

Quantity Schedule

Number of working platforms allowed

The MAXIMUM SAFE WORKING LOAD (the combined weight of the

users, tools and materials) that may be placed on the tower is 550kg.

Platform loading

The maximum safe working load (the combined weight of the users,

tools and materials) that may be placed on a platform is 275kg. This

must be evenly distributed over the whole platform level.

The quantity schedules shown in this user guide will enable the tower

to be built safely and therefore comply with the requirements of the

‘Work at Height Regulations’. Folding toe boards will need to be

added if any levels are used as working platforms, or for storage of

materials.

This tower system has been developed in accordance with EN1004

for single person use. If the tower is to be used with two people,

SP10 stabilisers must be tted in place of SP4 stabilisers.

BoSS Solo 700 - 1.3m x 0.7m

3T Method Internal or external use

Working Height (m)

Component Platform Height (m)

4.2 5.2 6.2

2.2 3.2 4.2

Castor 4 4 4

Adjustable Leg 4 4 4

4 Rung End Frame (1.0m high x 0.7m wide) 4 6 8

Folding Base Unit 1 1 1

1.3m Camlock Guardrail Frame 3 5 6

1.3m Trapdoor Deck 1 2 2

1.3m Horizontal Brace 1 1 1

Aluminium Folding Toe Board 1 1 1

Assembly Bracket 2 2 2

SP4 Telescopic Stabiliser 4 4 4

Total Self Weight of Tower (kg) 93 121 134

bossaccesstowers.com

10

Quantity Schedule

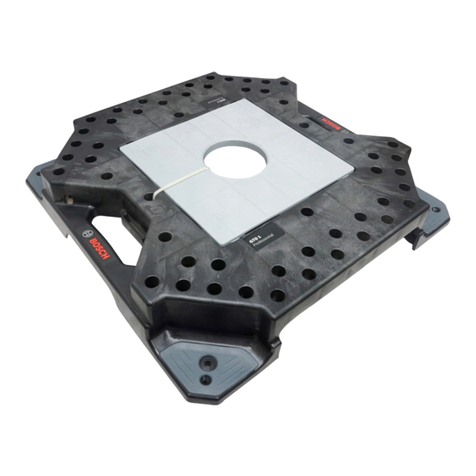

Stabilisers

Stabilisers should always be tted when specied.

To improve stability, larger stabilisers can be used at a lower level

than shown in the quantity schedules.

Attach one stabiliser to each corner of the tower as shown.

Ensure stabiliser feet are equally spaced to form a square.

SP4 and SP10 telescopic stabilisers must always be fully

extended.

Position the lower clamp so that the lower arm is as close to

horizontal as possible. Adjust the position of the top clamp to

ensure the stabiliser foot is in contact with the ground. Ensure

clamps are secure.

When moving the tower, adjust the top clamps or the telescopic

leg in order to lift the four stabiliser feet a maximum of 25mm off

the ground and unlock the castor brakes. After moving, ensure

all four stabiliser feet are repositioned in rm contact with the

ground.

X

X

90%

PLAN OF

TOWER

Free Standing Tower In a Corner

Against a Wall

PLAN OF

TOWER

PLAN OF

TOWER

BoSS SOLO700 User Guide

11

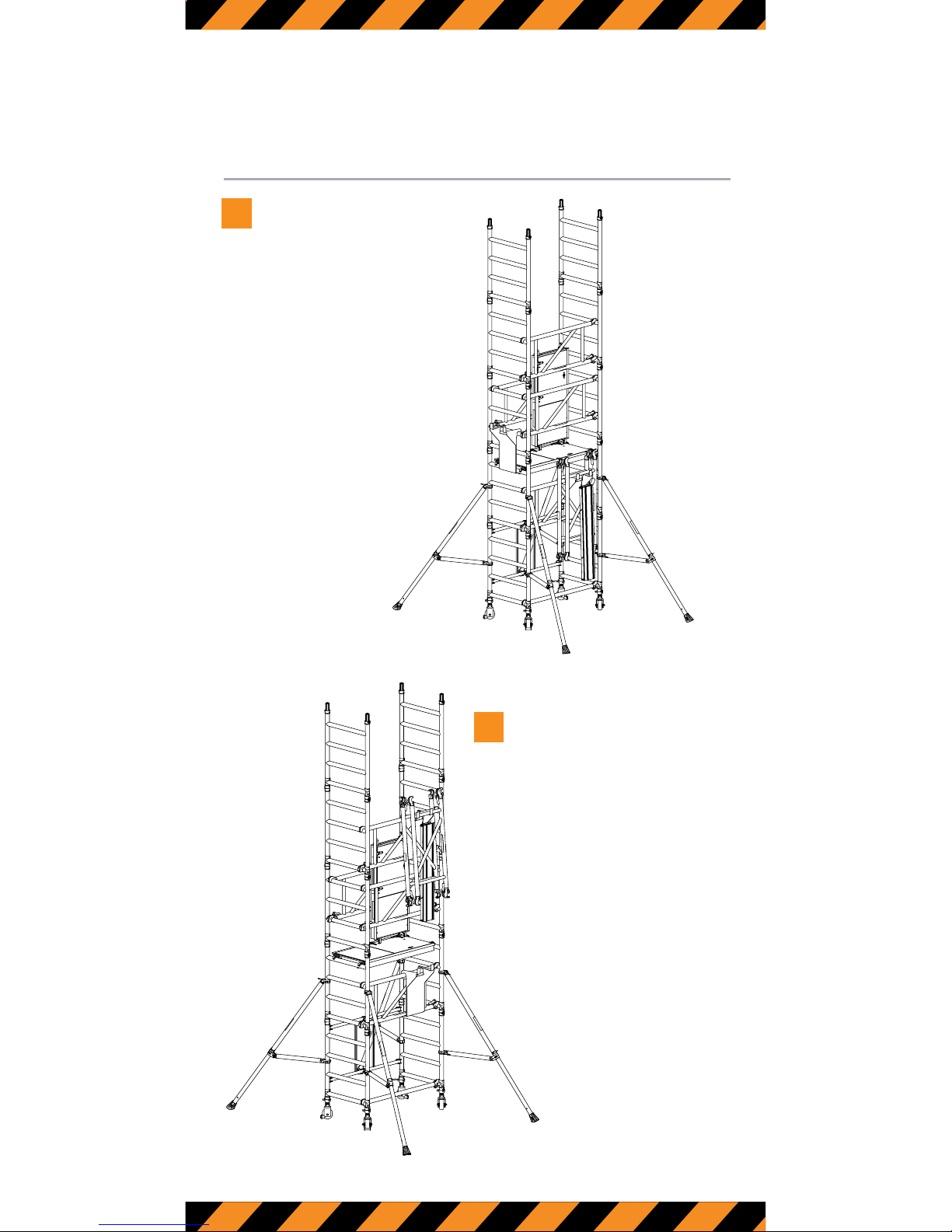

To comply with the ‘Work at Height Regulations’, we show

assembly procedures with platforms every 2 metres in height and

the locating of guardrails (in advance of climbing onto a platform)

to increase safety and reduce the risk of a fall.

Never stand on an unguarded platform positioned above the rst

rung of a tower. If your risk assessment shows it necessary, you

may also need to add guardrail platforms at this level.

The procedure illustrated shows a 6.2m working height tower.

The BoSS SOLO700 system has been developed so that a

single person can safely build the tower to a platform height

of 4.2m.

Build Method

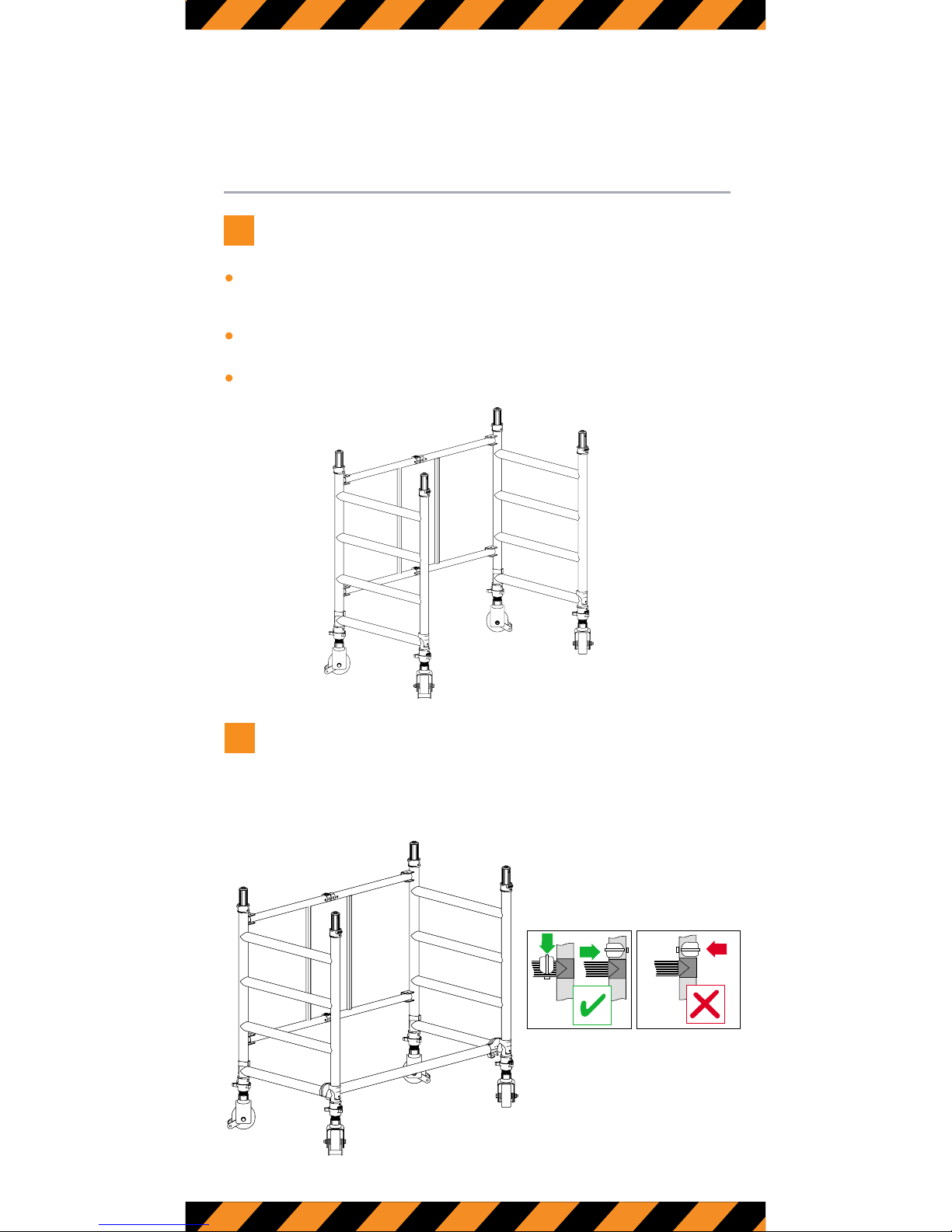

When building a BoSS tower:

Insert castor into adjustable leg. Apply brake by pushing

the lever down, release frame interlock clips and t the leg and

castor assembly into a 1m base frame. Repeat with the remaining

legs and castors. Adjustable legs should only be used for levelling.

1

bossaccesstowers.com

12

Build Method

FOLDING BASE METHOD:

Release brakes on castors at one end frame until the locks

engage on the rear folding frame.

Ensure both hinges positively lock into position.

Engage brakes on second frame.

2

Locate the horizontal brace on the lowest rung with

the hooks facing downwards - check the brace is correctly

locked on the tube at both ends. Check the base unit is square and

level using a spirit level. Adjust legs only to level and not to gain

additional height.

3

BoSS SOLO700 User Guide

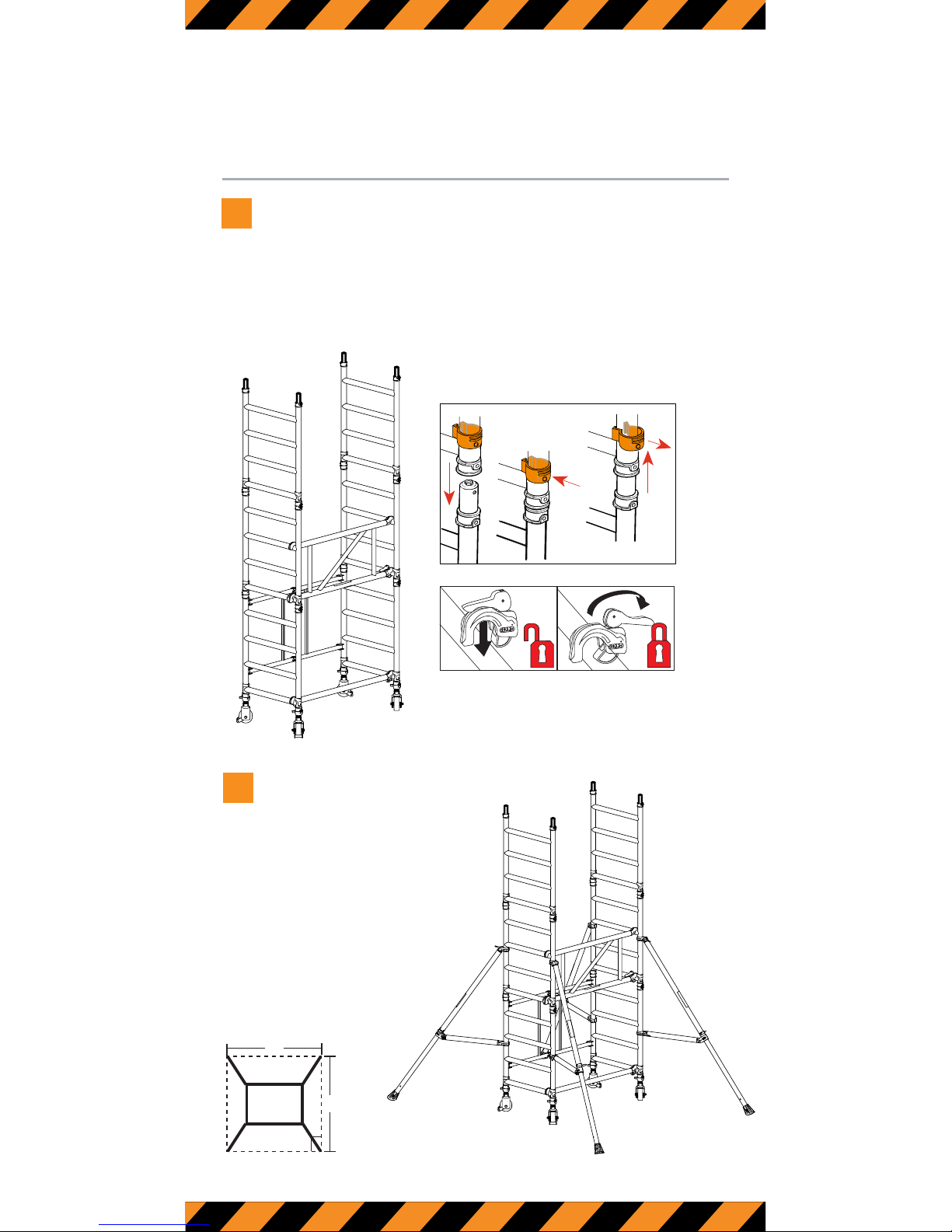

Fit stabilisers to tower before

extending telescopic leg.

Position top clamp above rung 6,

second clamp locates above rung 2.

Extend telescopic leg by removing

the interlock clip. Slide the leg out

until the leg reaches the ground.

Rotate the leg until the interlock

clip holes line up. Lock the leg

by using the interlock clip

and adjust the stabiliser to

ensure the stabilisers are

engaged.

13

Build Method

X

X

90%

STEP 1: Connect two, 4 rung frames together.

Check the interlock clips are engaged and add onto the base unit.

Repeat for the other side.

4

STEP 2: Position one camlock guardrail unit. The top hooks should

locate on the 7th rung from base level.

STEP 3: Engage camlocks as shown to lock guardrail unit in position.

INTERLOCK CLIP

Locked

Unlocked

5

bossaccesstowers.com

14

Build Method

From the ground level, position a trapdoor deck on

rung 8. Engage the wind-locks. Locate assembly bracket No. 1

on front face of lowest camlock guardrail. Locate the second assembly

bracket on rung 10 of the end frames.

6

Hang four camlock guardrail units in order on the front

assembly bracket and then 1 x folding toe board.

Place the last camlock guardrail on the end frame assembly bracket

No 2. Hang two pairs of connected 4 rung frames on the end bracket

No 2. then hang the second trapdoor deck on the bracket.

7

2 x Guardrail

Frames

1 x Folding

Toe Board

2 x Guardrail

Frames

2 x Guardrail Frames

2 x 21m End Frames

1 x 1.3m Deck

WARNING: ASSEMBLY BRACKETS ARE DESIGNED AND

INTENDED ONLY TO AID ASSEMBLY AND DISMANTLING.

BoSS SOLO700 User Guide

15

Climb the tower from the inside and from a protected position

on the trapdoor. Reach to the side bracket and take one camlock

guardrail. Position the guardrail on the rear of the tower as shown. All

guardrails should x to the 2nd and 4th rung above the platform deck.

Repeat with second camlock guardrail frame on the front of tower to

fully secure platform. Engage and lock camlock claws.

DO NOT CLIMB ON TO DECK UNTIL ALL GUARDRAILS ARE IN PLACE.

8

Build Method

Standing up on the protected platform, lift the second trapdoor

deck onto the platform. Store by the rear guardrail clear of the

end frames.

9

bossaccesstowers.com

Add the connected pairs

of end frames taking care to

engage the locking clips. Add a

camlock guardrail to rungs 13

& 15 and lock.

10

16

Remove the end frame

assembly bracket from

rung 10 of the end frame and

re-position on the top camlock.

Position the folding toe board

set and then the remaining two

camlock frames on the uppermost

bracket.

11

Build Method

BoSS SOLO700 User Guide

17

Place the trapdoor deck onto the 16th rung of the tower and

engage wind-locks. Climb the end frame from within and from

the protected trapdoor position, t the camlock guardrails as shown.

12

Build Method

bossaccesstowers.com

18

Unclip the storage strap from the folding toe board set, unfold

and t the toe board into position on the working platform. Move

assembly brackets to base of the tower and t to the lowest rungs of

the end frames.

13

Build Method

Platform loading

Simply follow the assembly steps in reverse, ensuring that the 3T

method is followed.

BoSS SOLO700 User Guide

19

Build Method

Storage Trolley Assembly:

Assemble the folding base frame with one trapdoor deck

placed on the bottom rung forming the base of the trolley.

Lower all adjustable legs as far as possible.

1

Other manuals for SOLO700

1

Table of contents

Other BOSSCO Desktop manuals

Popular Desktop manuals by other brands

Franklin

Franklin ACE2000 User's reference manual

CTC Union

CTC Union PowerStation P7 Series Replacement manual

DIGITAL YACHT

DIGITAL YACHT aquaPro Installation & quick start guide

Dell

Dell Precision R5400 manual

HP

HP Pavilion 2159m Disassembly instructions

HP

HP m9400f - Pavilion - Elite TV Connection guide

Peace Maker Technologies

Peace Maker Technologies PM504T Basic operation guide

Knight

Knight Ergoplan Workstation Assembly instructions

HP

HP Elite 7500 Microtower manual

Acorn computer

Acorn computer A3000 Servicing

Compaq

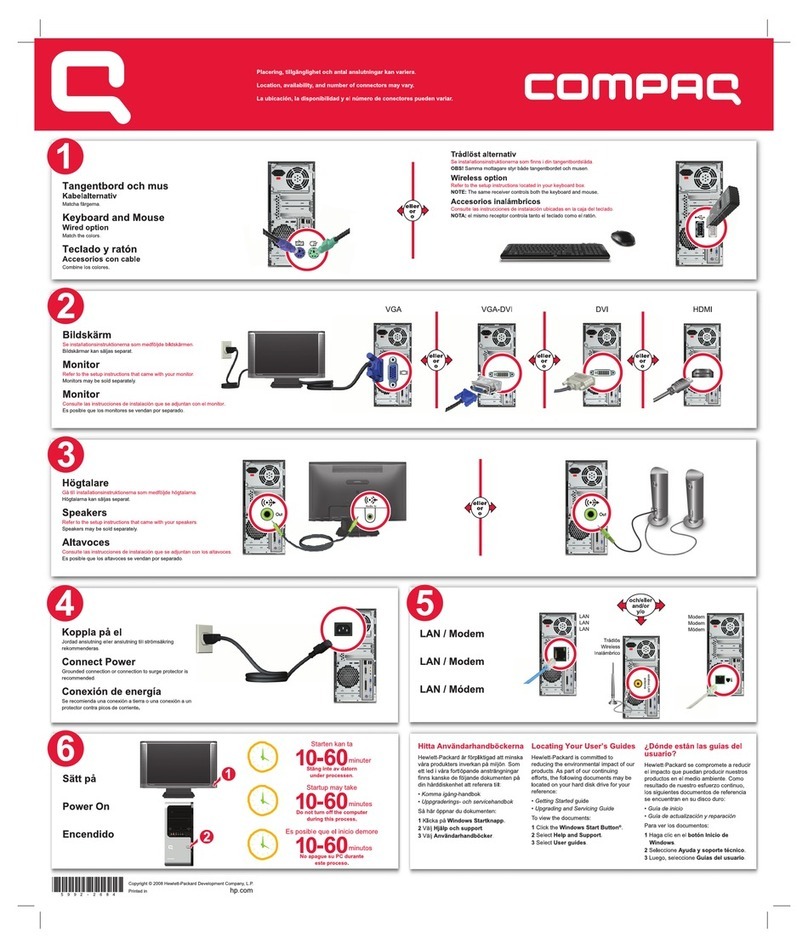

Compaq SR5605F - Presario - 1 GB RAM Quick setup

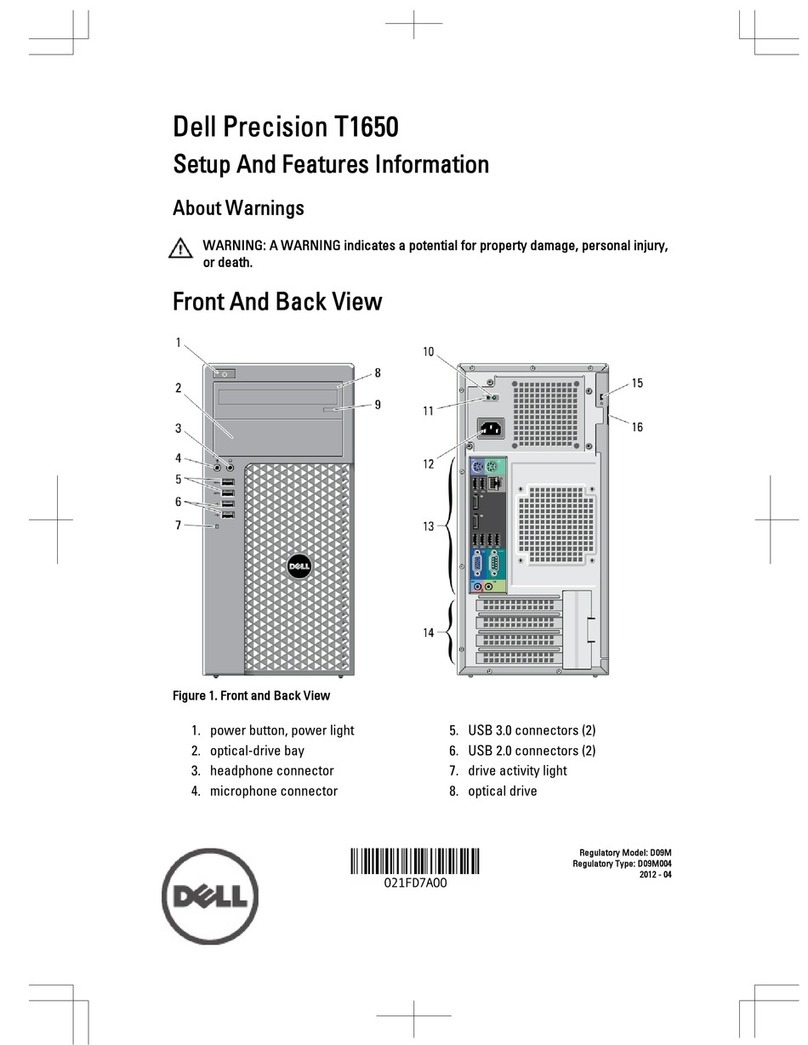

Dell

Dell PRECISION T1650 Setup & features