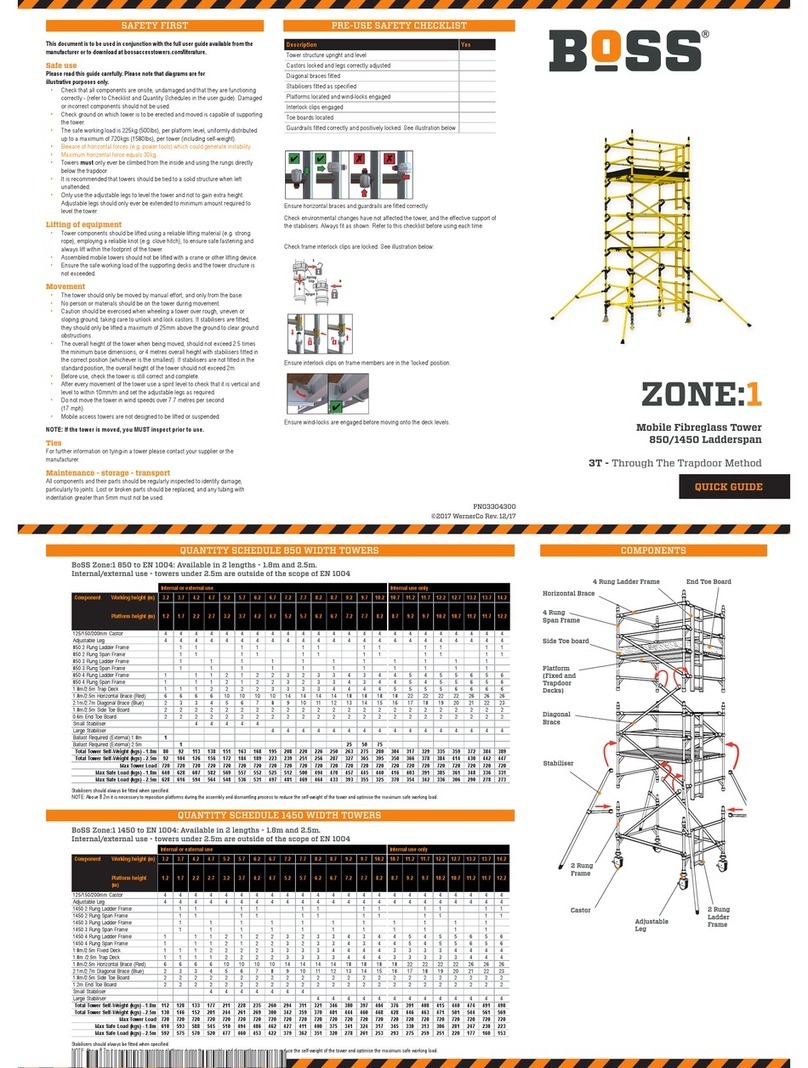

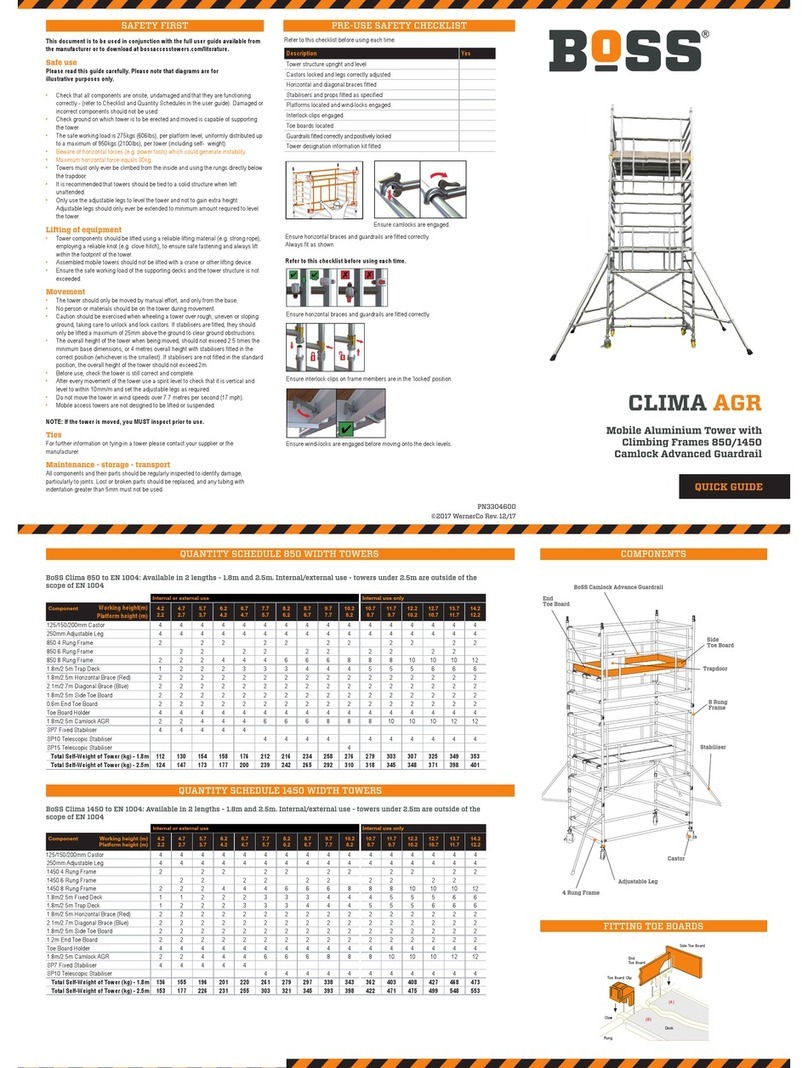

BOSSCO Stairmax 700 MK2 User manual

BoSS Stairmax700 MK2 User Guide

Aluminium Tower

700 Climbing Rung

3T - Through The Trapdoor Method

USER GUIDE

STAIRMAX700 MK2

BoSS Stairmax700 MK2 User Guide

1

Contents

Safety First

Component Diagram

Component Quantity & Safety Data Schedule

Build Method

Pre-use Safety Inspection Checklist

9

10

11-12

13-19

20

BoSS Stairmax700 MK2 User Guide

2

bossaccesstowers.com

Safety First

Introduction

Contents

Please read this user guide carefully. Please note that

diagrams are for illustrative purposes only. User guides

are also available to download from our website at

bossaccesstowers.com.

BoSS mobile aluminium towers are light-weight scaffold towers

used throughout the building and construction industry for both

indoor and outdoor access solutions where a stable and secure

platform is required. Ideal for maintenance and installation work

or short-term access, the highly versatile towers provide a strong

working platform for a variety of heights.

This user guide provides you with step by step instructions to

ensure your system is erected easily and safely, using the 3T

(Through The Trapdoor) method.

The law requires that personnel erecting, dismantling or altering

towers must be competent. Any person erecting a BoSS mobile

tower must have a copy of this user guide. For further information

on the use of mobile access and working towers consult the

PASMA operators code of practice.

If you need further information, design advice, additional user guides

or any other help with this product, please contact the manufacturer

BoSS Stairmax700 MK2 User Guide

3

Safety First

Safe use

•Check overhead that the area into which the structure is to be

erected contains no obstructions, particularly electrical or radio

radiation hazards.

•Ensure the ground on which the mobile access tower is to be

erected is capable of supporting the tower in use. Refer to Safety

Data Schedule.

•The tower has a single working level with a safe working load

of 275kg. All platforms may be used for working, but only one

should be used at any one time.

•Before each use:

•Check that each prefabricated tower scaffold is complete and

correctly assembled.

•Check that the prefabricated tower scaffold is vertical and make

any adjustments as required.

•Check that no environment changes will affect the safe use of

the structure.

•Adjustable legs should only be used for levelling purposes and

never to gain extra height.

•Do not use ladders, steps, boxes or similar, to gain additional

working height.

•Only climb the tower from the inside using the access method

provided.

•Tower scaffolds are not designed to be lifted or suspended.

•Beware of horizontal forces (e.g. power tools) which could

generate instability.

Maximum horizontal force per working bay = 30kg

•Tools and materials should be lifted using a reliable lifting material (e.g.

a strong rope) employing a reliable knot (e.g. clove hitch) to ensure

safe fastening and always lift within the footprint of the prefabricated

tower scaffold (i.e. within the area bounded by the stabilisers).

•Safe working loads, normally expressed in kN/m², are expressed

below in kg per dened working area.

BoSS Stairmax700 MK2 User Guide

4

bossaccesstowers.com

Safe use

Dened

working

area

Max. safe

working load

(uniformly

distributed

including

persons)

Load

class Max no. of

persons*

A x Z 275kg 3 1

*Persons are assumed to be 122kg (Reference to HSE

- Revision of body size criteria in standards protecting

people who work at height - Research report 342)

Safety First

Access classes

The Access Class provided for climbing this tower is: Access Class

'D' (Vertical Ladder).

Lifting of individual tower components

Movement of the assembled prefabricated

tower scaffold

Raising and lowering components, tools and/or materials by rope

should be conducted within the tower base (i.e. within the area

bounded by the stabilisers). Ensure that the safe working load of

the supporting decks and the tower structure is not exceeded.

•The BoSS StairMAX 700 Mk2 tower system MUST NOT be

moved once erected.

•Always dismantle it and rebuild at the new location.

• The pre-use checklist on the nal page shall be used to

determine tower integrity.

BoSS Stairmax700 MK2 User Guide

5

Safety First

During assembly, use and dismantling

•As part of the risk assessment, wind conditions must be taken

into account and reviewed regularly, depending on the duration

the structure is onsite.

•The structure has been assessed for wind loads equating to 27

mph (43 kph, 12 m/s).

•The effect of onsite wind conditions must be considered prior

to the assembly of a tower. The tower must not be used in wind

speeds stated above. If greater wind speeds are forecast, the

tower must be dismantled while it is still safe to do so.

•Sheets, tarpaulins, cladding or similar, must not be attached to

the tower as these will signicantly increase any side loads from

wind and will potentially make the tower unstable.

•Beware of wind turbulence, funnelling effects around buildings

and updraughts on stairways.

The maximum allowable side load on a tower is 30kg.

•CAUTION: Excessive side loads due to working from the

tower may cause the structure to become unstable. Special

consideration should be given to side loads including vibrations.

•Do not abuse equipment. Damaged, incorrect or incompatible

components should not be used.

Maintenance - Storage - Transport

•All components and their parts should be regularly inspected to

identify damage, particularly to joints. Lost or broken parts should

be replaced and any tubing with indentation greater than 5mm

shall be replaced. Adjustable leg threads should be cleaned and

lightly lubricated to keep them free running.

•Brace claws, frame interlock clips, trapdoor latches, camlocks and

platform wind-locks should be regularly checked to ensure they

lock correctly.

•Refer to the BoSS Inspection Manual for detailed inspection and

maintenance advice: www.bossaccesstowers.com

•Components should be stored in clean, dry conditions with due

care to prevent

•Ensure components are not damaged by excessive strapping

forces when transported.

BoSS Stairmax700 MK2 User Guide

6

bossaccesstowers.com

Safety First

Tower designation & safety data

Wind

Description Beaufort

Scale Beaufort

No. Speed in

mph Speed in

m/sec

Medium Breeze Raises dust and

loose paper, twigs

snap off 4 8-12 4-6

Strong Breeze Large branches in

motion, telegraph

wires whistle 6 25-31 11-14

Gale Force Walking is difcult 8 39-46 17-21

In accordance with the prefabricated tower scaffold standards,

the ‘Tower Designation & Safety Data’ shall be positioned at

the base of the prefabricated tower scaffold as shown within

the user guide, by means of the ‘Tower Designation Information

Assembly’. It must be clearly visible so that users are aware of the

conditions of safe use. Refer to Safety Data Schedule for content.

CAUTION:

Always ensure the portal ladder is in closed position when

descending the tower. If the portal ladder is in open position, from

the protected position of the trapdoor deck (i.e. seated) close the

portal ladder ensuring the locking claw has been fully engaged.

•The structure is highly conductive and must not be used when

there is a risk of lightning strikes.

•Exercise caution when touching unprotected metal components

in extreme high or low temperatures.

•If the tower is damaged in any way while in service, it shall not be

used again until the damaged components are replaced.

BoSS Stairmax700 MK2 User Guide

7

Stabilisers

Props

• Stabilisers shall always be tted when

specied.

•Attach one stabiliser to each corner of the

tower as shown. Ensure stabilisers feet are

equally spaced to form a square.

•Telescopic stabilisers must always be fully

extended.

•Position the lower clamp so that the lower arm is as close to

horizontal as possible.Adjust the position of the upper clamp to

ensure the stabiliser foot is in contact with the ground. Ensure

clamps are secure.

Safety First

BoSS StairMAX 700 Mk2 tower with platform heights above 5.0m

shall be adequately propped or tied to prevent all movement in the

horizontal plane. They must be tted at a minimum of 4.0m vertical

intervals. To improve stability, additional props or ties can also be

tted at lower levels.

Props and ties should conform to the guidance in NASC TG20.

The method shown below illustrates the use of BoSS Conned

Space Stabilisers.

Attach one conned space stabiliser to each corner of the tower as

shown (see page 16). Ensure stabiliser feet are touching the walls -

adjust conned space stabilisers as necessary to achieve this.

If you require further advice, please contact the manufacturer.

BoSS Stairmax700 MK2 User Guide

8

bossaccesstowers.com

Assembly Procedure

Safety First

This tower structure must be assembled, and components

oriented, in accordance with this instruction manual.

Deviation from this instruction manual is not permitted.

A minimum of two persons are recommend for assembly and

disassembly of this prefabricated tower structure. The maximum

number of persons permitted on the tower during assembly is

stated in the safety data schedule.

Platforms must be installed with vertical distances between them

not exceeding 2m when assembling and dismantling.

The maximum number of people on a working platform level

permitted to simultaneously exert a horizontal load of 30kg is:

- 1 person per bay for bays less than 4m long and

- 2 persons per bay for bays greater than 4m in length

Check that all components, tools and safety equipment are on

site (refer to quantity schedule), undamaged and that they are

functioning correctly, particularly the brace claw locking mechanism.

Full inspection guidance can be found at www.bossaccesstowers.com.

Damaged or incorrect components shall not be used.

Component weights can be found in the quantity schedule and on

the corresponding BoSS Product Datasheets.

Check that the ground on which the tower structure is to be erected

and moved is capable of supporting the tower in use and within the

levelling limits of the tower system.

Check overhead that the area into which the tower structure is to be built

contains no obstructions, particularly electrical or radio radiation hazards.

Never stand on an unguarded platform positioned above the

rst rung of a tower structure. If your risk assessment shows it

necessary, you may also need to guardrail platforms at this level.

Tower components should be lifted using a reliable lifting material (e.g.

a strong rope) employing a reliable knot (e.g. clove hitch) to ensure

safe fastening and always lift within the footprint of the tower structure.

‘Tower Designation & Safety Data’ content for the ‘Tower

Designation Information Assembly’ can be found in the ‘Safety

Data Schedule’. This assembly must be positioned at the base of

the prefabricated tower scaffold and clearly visible for users. Refer

to Safety Data Schedule for content.

Adjustable legs should only be used for levelling purposes and

never to gain extra height.

BoSS Stairmax700 MK2 User Guide

9

Assembly Procedure

Safety First

Ensure horizontal braces and guardrails are tted correctly.

Ensure interlock clips on frame members are in the 'locked' position.

Ensure wind-locks are engaged before moving onto the deck levels.

BoSS Stairmax700 MK2 User Guide

10

bossaccesstowers.com

Ensure wind-locks are engaged before moving onto the deck levels.

Component Diagram

Component Diagram

Rear

Front

Aluminium

Folding

Toe Board Kit

1.64m

Diagonal

Brace

1.3m

Trapdoor

deck

Stabiliser

1.3m

Horizontal

Brace

1.64m

Diagonal

Brace

Upstair

End

Downstair

End

Confined Space

Stabiliser

Portal Ladder

Frame MK2

1.0m 4

Rung 700

Boss Solo

Frame

User

Guide

Tower Designation

Information

Assembly

Adjustable

Leg and Base

Plate

BoSS Stairmax700 MK2 User Guide

11

Component quantity &

safety data schedule

(Working and Platform heights are measured from underside of lowest base plate.)

NOTE:

The safety data specied within the schedule above which relates to the specic

tower to be assembled must be transferred into the pre-dened boxes on the Tower

Designation Information insert found in the Tower Designation Information Kit.

Internal or

external use Internal Use Only

Component

Code Component

Description

Composite Code 61420300 61420500 61420700 61420900 61421100

Working Height (m) > 5.0 7.0 9.0 11.0 13.0

Platform Height (m) > 3.0 5.0 7.0 9.0 11.0

33041300 Base Plate 1.7 kg 4 4 4 4 4

33551300 Adjustable Leg 1.1 kg 4 4 4 4 4

67011000 1.0m 4 Rung 700 BoSS SOLO Frame 3.9 kg 3 7 11 15 19

33052600 Portal Ladder Frame Mk 2 12.8 kg 2 2 2 2 2

35651300 1.3m Horizontal Brace 1.6 kg 6 12 18 24 30

35751300 1.64m Diagonal Brace 1.9kg 5 8 11 14 17

67070100 1.3m Trapdoor Deck 9.8 kg 1 2 3 4 5

67040100 SP4 Stabiliser 4.4 kg 4 - - - -

31851300 SP10 Stabiliser 8.8 kg - 4 4 4 4

31651400 Conned Space Stabiliser 2.9 kg - - 8 8 12

67050100 Folding Toe Board Kit 4.4 kg 1 1 1 1 1

30001900 Designation Information Kit - 1 1 1 1 1

110137-01 User Guide - 1 1 1 1 1

BoSS StairMax700 Mk 2 - 1.3 x 0.7m

(Braces Guardrail)

Total Self Weight of Tower (kg) 99 158 222 262 315

Max. Exerted Leg Load (kg) 150 160 180 190 214

Max. Exerted Prop Load (kg) - - 16 16 16

BoSS Stairmax700 MK2 User Guide

12

bossaccesstowers.com

Component quantity &

safety data schedule

Build Method

When building a BoSS Tower

To comply with 'Work at Height Regulations' we show assembly

procedures with platforms every two metres in height and the

locating of guardrails in advance of climbing onto a platform to

increase safety and reduce the risk of a fall. Never stand on an

unguarded platform positioned above the rst rung of a tower. If

your risk assessment shows it necessary, you may also need to

guardrail platforms at this level.

The procedure illustrated shows a 7.0m working height tower build.

The manufacturer recommend two persons are used to build

BoSS Towers. Above 4.0m platform height, it is essential that at

least two persons are used. Only climb the tower from the inside.

The manufacturer recommend the ‘Tower Designation &

Safety Data’ is recorded within the ‘Tower Designation

Information Assembly’ before proceeding with the tower

assembly. Refer to Safety Data Schedule for content.

Insert two base plates into adjustable legs and t the leg

and base plate assemblies into one of the two portal ladder

frames. Repeat with the remaining legs and base plates. It is rec-

ommended, for ease of levelling, that a maximum gap of 50mm is

left between the bottom of the leg and the adjustable nut.

Note: Adjustable legs are for levelling only. They are not to be used

to gain extra height at the working level.

Fit one horizontal brace (red catch) onto the vertical of end

frame on the climbing side in position indicated with an arrow,

with the open section of the claw facing outwards. Ensure the gate

opens as shown.

1

2

Note: All locking claws must be opened before tting and positively

locked into position.

Note: All locking claws must be opened before tting and positively

locked into position.

D

↶

Ú

BoSS Stairmax700 MK2 User Guide

13

Build Method

Position a second portal

ladder frame higher on

stairs as shown and t other

end of horizontal brace just

above the bottom rung. Fit

another horizontal brace as

shown. This will become the

higher ‘upstair’ end of the

tower. Ensure both gates open

the same direction as shown.

3

Position a second portal

ladder frame higher on

stairs as shown and t other

end of horizontal brace just

above the bottom rung. Fit

another horizontal brace as

shown. This will become the

tower. Ensure both gates open

the same direction as shown.

E

D

↶↶

Fit two diagonal braces

(blue catch) between

bottom rungs of both portal

ladder frames, one on each

side of the tower. Open

sections of claws must face

downwards. The structure

must be vertical to within 1cm

per metre.

Ensure the frames are

vertical and level by

checking with a spirit level

and setting the adjustable

legs as required.

4

DD

BoSS Stairmax700 MK2 User Guide

14

bossaccesstowers.com

Build Method

Connect two 4 rung frames

together and t onto portal

ladder frame as shown. Engage

interlock clips. Fit one diagonal

brace in position shown. Record

‘Tower Designation & Safety Data’

within the ‘Tower Designation

InformationAssembly’and attach to

the tower in position shown. Refer

to safety data schedule for content.

5

D

E

D

Ensure interlock clips on

frame members are in the

'locked' position

Fit one 4 rung frame onto

the portal ladder frame

at the higher level by standing

on the stairs. Engage interlock

clips. Fit one more diagonal

brace as shown.

Fit Stabilisers.

See notes on page 7.

The upper clamp of stabilisers

must be at least 1.5m above

the bottom of the frame.

Where possible, stabilisers

must also have a minimum

outstand of 1.2m.

6

7

E

D

Where possible, stabilisers

must also have a minimum

Where possible, stabilisers

E

BoSS Stairmax700 MK2 User Guide

15

M

Build Method

Fit one 1.3m trapdoor deck

onto the top rung of the

‘upstair’ portal ladder frame as

shown. Fit one diagonal brace

in position shown. Ensure the

trapdoor opens towards the rear

of the tower.

8

Ensure all wind-locks

are engaged.

Ensure all wind-locks

Ensure all wind-locks

shown. Fit one diagonal brace

in position shown. Ensure the

trapdoor opens towards the rear

Fit one 1.3m trapdoor deck

onto the top rung of the

‘upstair’ portal ladder frame as

shown. Fit one diagonal brace

Fit one 1.3m trapdoor deck

M

M

From the protected

position of the

trapdoor deck (i.e.

seated), t guardrails at

0.5m and 1.0m (in that

order) above the platform

level. Fit two more

horizontal braces onto

the vertical of end frames

in positions shown.

9

horizontal braces onto

the vertical of end frames

in positions shown.

0.5m and 1.0m (in that

order) above the platform

level. Fit two more

From the protected

position of the

trapdoor deck (i.e.

seated), t guardrails at

From the protected

M

Do not climb onto the deck until it is

fully guardrailed. Ensure the gate is

fully engaged before climbing.

Ensure all claws are

positively locked

into position

M

M

BoSS Stairmax700 MK2 User Guide

16

bossaccesstowers.com

M

M

M

Build Method

Connect two 4 rung

frames together to

create two subassemblies.

Engage interlock clips.

Whilst standing on the

protected platform deck, t

one subassembly onto the

‘downstair’ end of the tower.

Again, engage interlock clips.

Repeat for the ‘upstair’ end

of the tower.

Fit two diagonal braces in

positions shown.

Ensure all claws are

positively locked into

position.

10

positively locked into

Fit two diagonal braces in

Ensure all claws are

positively locked into

Again, engage interlock clips.

Again, engage interlock clips.

Repeat for the ‘upstair’ end

Repeat for the ‘upstair’ end

Fit two diagonal braces in

Whilst standing on the

protected platform deck, t

one subassembly onto the

‘downstair’ end of the tower.

‘downstair’ end of the tower.

Again, engage interlock clips.

Again, engage interlock clips.

Again, engage interlock clips.

Again, engage interlock clips.

Connect two 4 rung

frames together to

create two subassemblies.

Engage interlock clips.

Whilst standing on the

Connect two 4 rung

D

M

E

Fit one 1.3m trapdoor

deck onto the 8th

rung above the platform

deck as shown. Ensure

wind-locks are engaged.

Position platform to ensure

space for future diagonal

brace and aluminium folding

toe board set (see image

below).

11

space for future diagonal

brace and aluminium folding

toe board set (see image

deck as shown. Ensure

wind-locks are engaged.

Position platform to ensure

space for future diagonal

Fit one 1.3m trapdoor

deck onto the 8th

rung above the platform

deck as shown. Ensure

M

Top platform

position

BoSS Stairmax700 MK2 User Guide

17

Build Method

From the protected

position of the trapdoor

deck (i.e. seated), t guardrails

at 0.5m and 1.0m (in that

order) above the platform

level.

Do not climb onto the deck

until it is fully guardrailed.

Ensure the gate is fully

engaged before climbing.

Ensure all claws are positively

locked into position.

12

locked into position.

Ensure the gate is fully

engaged before climbing.

Ensure all claws are positively

locked into position.

Do not climb onto the deck

until it is fully guardrailed.

Ensure the gate is fully

deck (i.e. seated), t guardrails

at 0.5m and 1.0m (in that

order) above the platform

Build Method

From the protected

position of the trapdoor

deck (i.e. seated), t guardrails

M

Unclip storage strap from

aluminium folding toe board

set, unfold and t into position on

working platform.

Ensure it sits squarely

around deck and does not

impede the opening of the

trap door in the deck.

The tower is now complete.

13

BoSS Stairmax

700

MK2

User Guide

The tower is now complete.

The tower is now complete.

D

BoSS Stairmax700 MK2 User Guide

18

bossaccesstowers.com

Build Method

When building beyond 5.0m platform height:

Continue to add two pairs of

assembled 4 rung frames,

six braces and one trapdoor

deck as shown in previous

steps. Add four con ned space

stabilisers as shown.At every

platform level add guardrails

above 2nd and 4th rungs above

the platform. Fit additional

guardrails above 1st rungs,

except working platform level.

Fit these braces from

the protected trapdoor

position. Do not climb onto

the platform until it is fully

guardrailed.

Continue until the required

height is reached.

At platform heights above

5.0m, con ned space

stabilisers must be tted at

4.0m intervals as instructed

below and on page 5.

Fit a con ned space stabiliser

to all four corners of the tower

as shown ensuring that the

stabiliser arm is horizontal.

as shown ensuring that the

Fit a con ned space stabiliser

to all four corners of the tower

as shown ensuring that the

stabilisers must be tted at

4.0m intervals as instructed

the platform until it is fully

except working platform level.

position. Do not climb onto

the platform until it is fully

platform level add guardrails

above 2nd and 4th rungs above

guardrails above 1st rungs,

except working platform level.

six braces and one trapdoor

steps. Add four con ned space

stabilisers as shown.At every

platform level add guardrails

When building beyond 5.0m platform height:

Continue to add two pairs of

D

E

E

D

Ensure the end of the stabiliser arm contacts the walls. If it does

not, adjust by unclipping and extracting the locking pin, sliding the

arm until correct length and hole alignment is achieved. Reinsert

the locking pin, ensuring clip is engaged. See images below.

Simply follow the assembly steps in reverse, ensuring that the 3T

method is followed.

To dismantle a BoSS tower:

Unclip & extract pin Extend/retract adjustable arm Reinsert pin and engage clip

BoSS Stairmax700 MK2 User Guide

19

Pre-use Safety

Inspection Checklist

Description Yes

Tower structure upright and level

Base plates and legs correctly adjusted

Horizontal and diagonal braces tted

Stabilisers and props tted as specied

Platforms located and wind-locks engaged

Interlock clips engaged

Toe boards located

Guardrails tted correctly and positively locked

Tower designation information kit tted

Table of contents

Other BOSSCO Desktop manuals

Popular Desktop manuals by other brands

Addonics Technologies

Addonics Technologies AEMMBY user guide

Shuttle

Shuttle Slim-PC Barebone XH61V quick guide

Sony

Sony PCV-L600 - Vaio Slimtop Computer user guide

AirClean systems

AirClean systems AC600 Series Operator's manual

Dell

Dell OptiPlex SX270 Setup and quick reference guide

Advantech

Advantech TPC-1282T user manual