1

Read and Follow These Important Safety Instructions

You will see Warning and Caution statements on the following Pages.

Read and follow these safety instructions carefully. Failure to do so could result in serious personal injury or death.

Warning means that severe injury or death may result from failure to follow instructions

Caution means that property damage or injury may result from failure to follow instructions

•

• Be sure to read and follow all instructions carefully.

• To reduce the risk of electric shock, this equipment has a grounding type plug, that has a third (grounding) pin.

This plug will only fit into a grounding type outlet. If the Plug does not fit into the outlet, contact a qualified

electrician to install the proper outlet. Do not change the plug in any way.

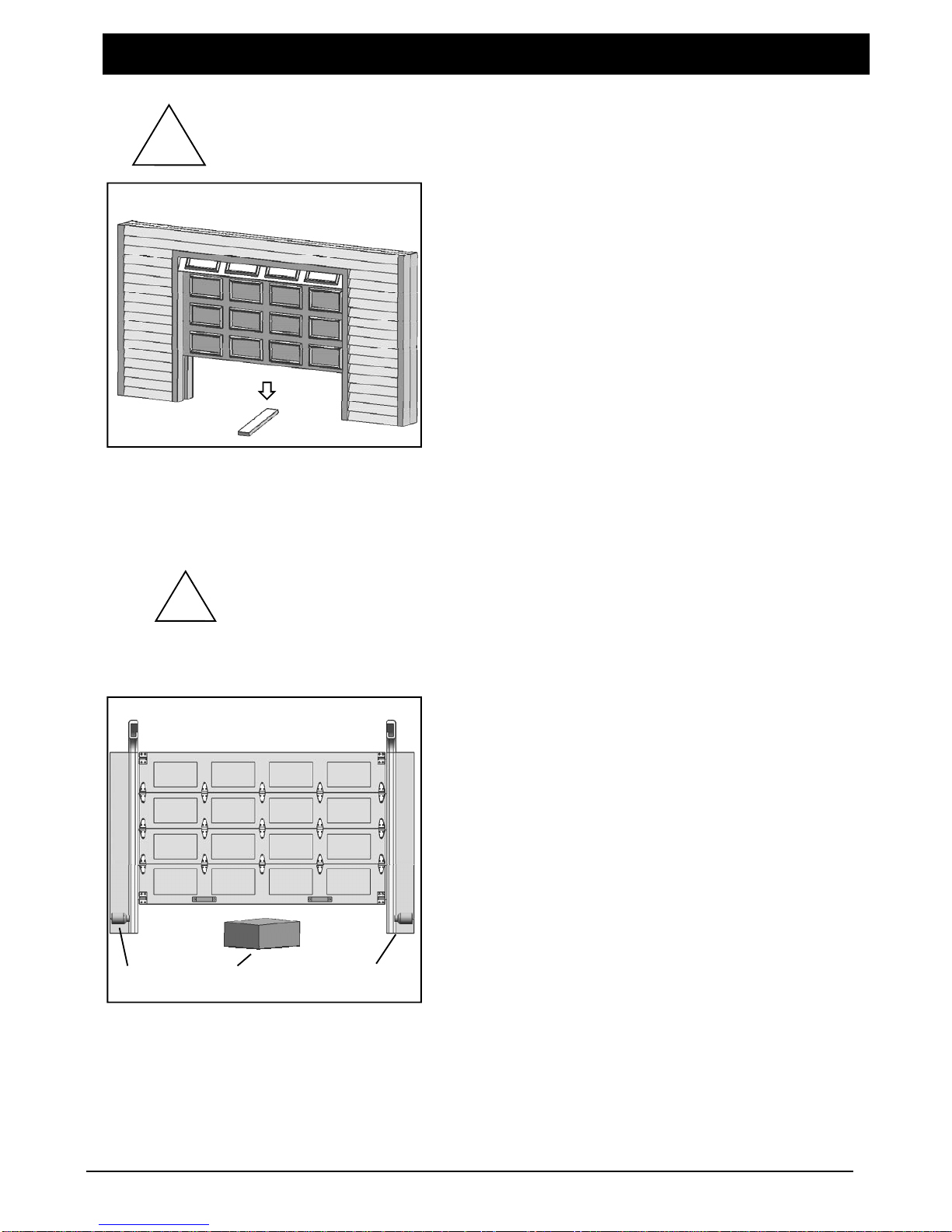

• Check to make sure the garage door is properly installed and balanced. Garage door & parts are under

extreme tension and under no circumstance should you attempt to adjust on your own. Have a qualified

garage door service person make repairs to cables, spring and other hardware before installing the opener.

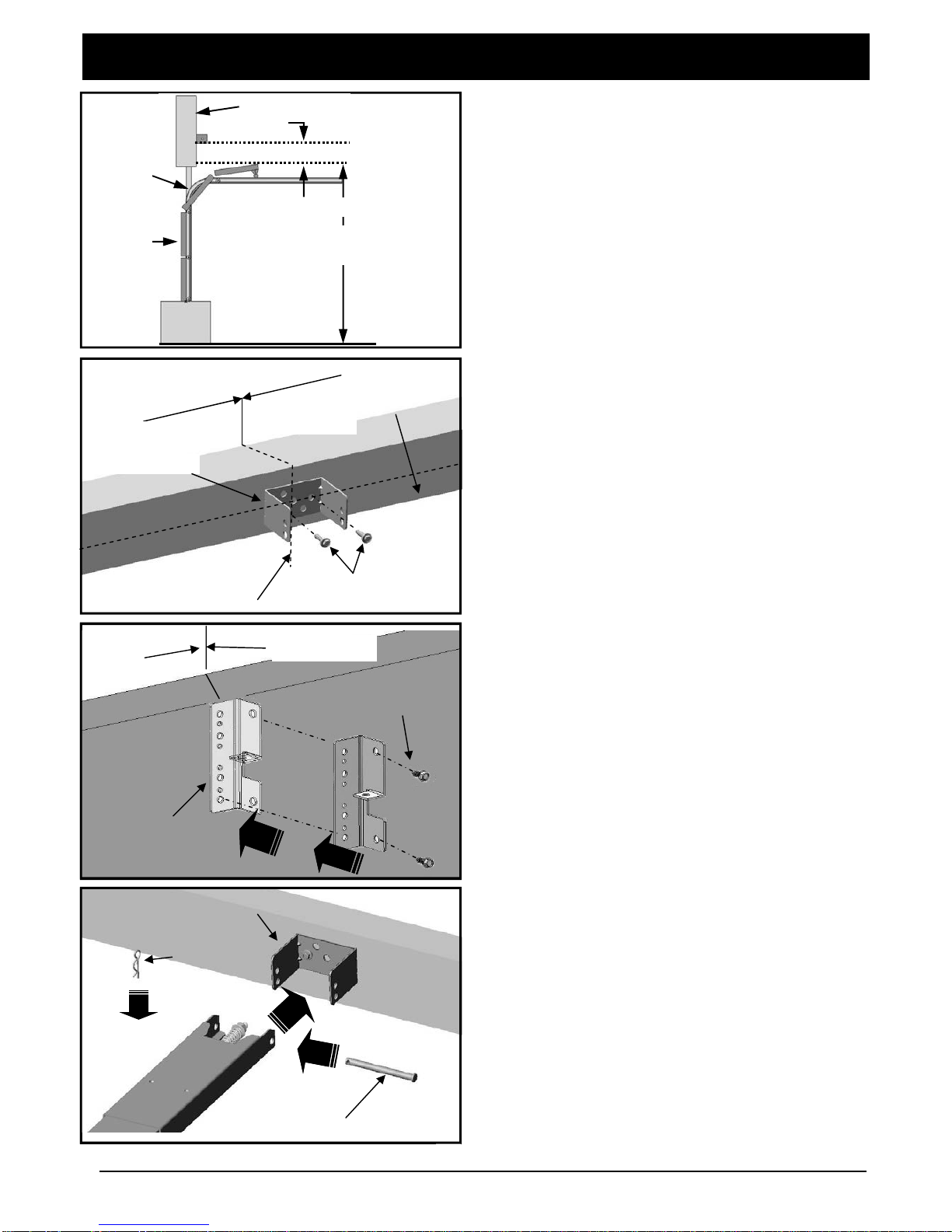

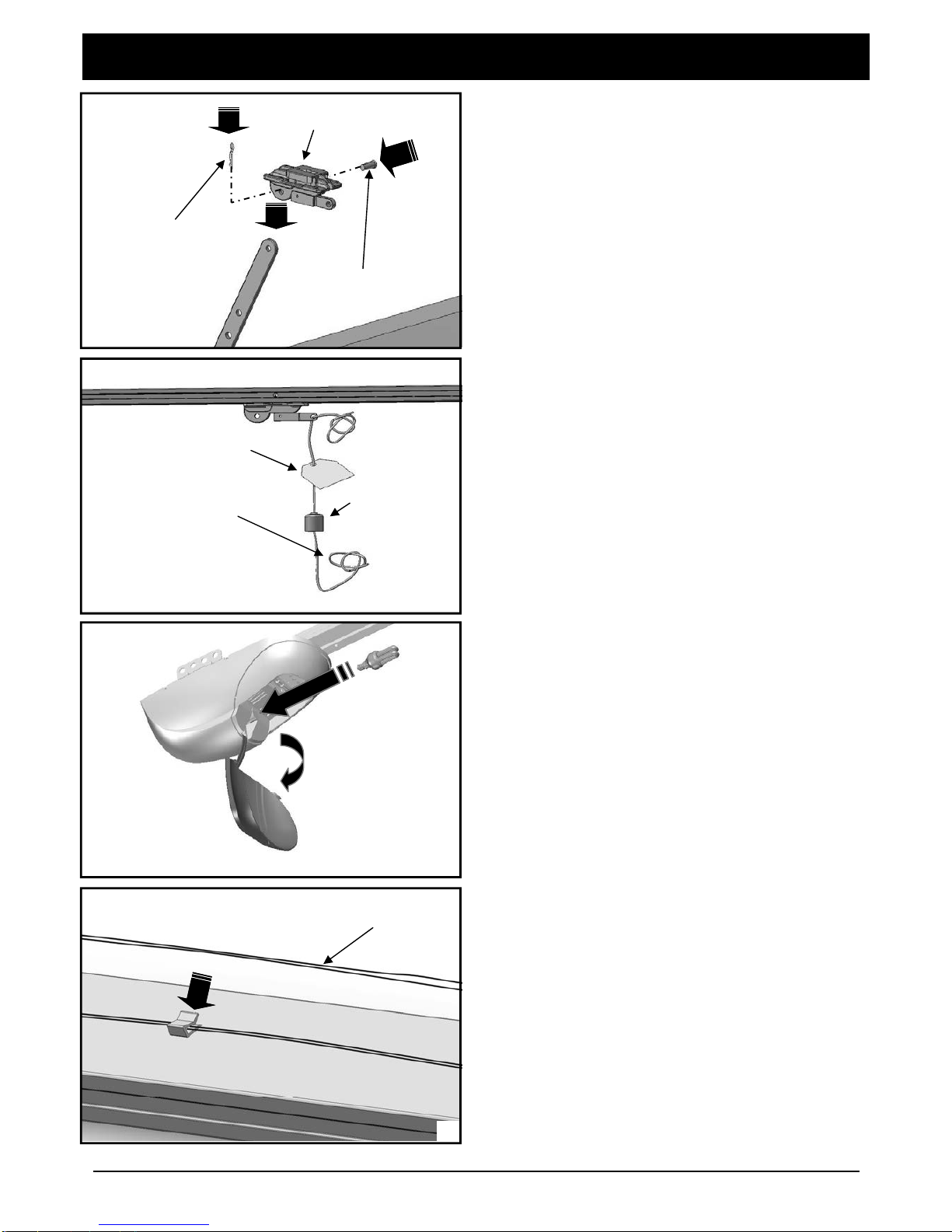

• Install Entrapment Warning Label next to control button. Read the Control Adjustment Warning Label. Install

Emergency Release Tag to the Emergency Release Cord. Mount the Emergency Release Knob 180cm from the

floor. Use the manual release only to disengage the trolley. Do not use the Red Release Cord and Knob to pull

door up or down. If possible, use the Emergency Release only when the door is closed.

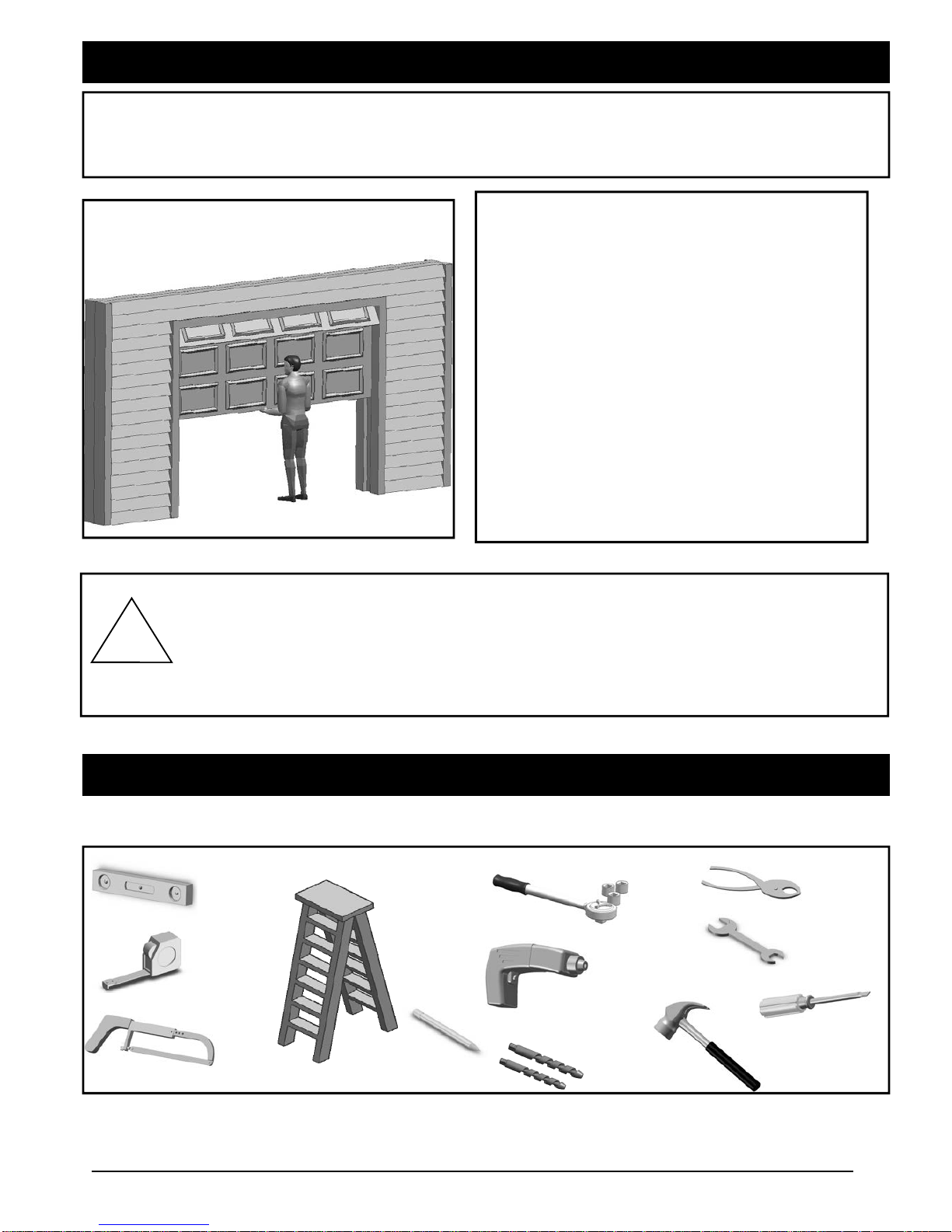

• Do not connect opener to power source until instructed. Install door opener 210cm or more above floor.

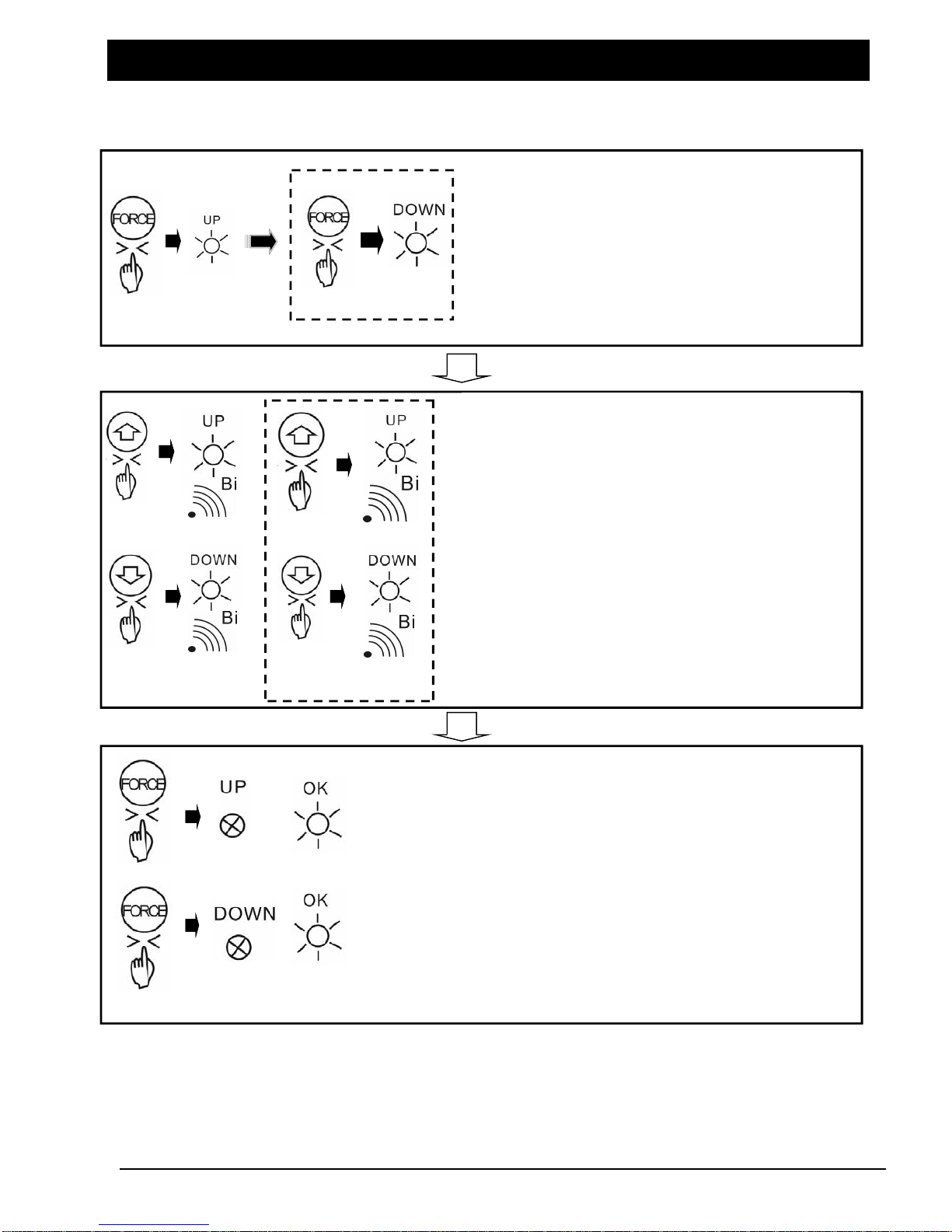

• After installing opener, the door must reverse when it comes in contact with a 5cm high object. Check this safety

feature often.

• REMOVE ALL ROPES CONNECTED TO THE GARAGE DOOR.

• DISENGAGE ALL EXISTING GARAGE DOOR LOCKS TO AVOID DAMAGE TO THE GARAGE DOOR.

• Fiberglass, aluminum and steel doors must be reinforced to prevent damage. Consult with manufacturer for

recommendations.

• All installation and wiring must be done in strict compliance with local and state building and electrical codes.

Connect the power cord to a properly grounded outlet only. Do not in any way alter or remove the grounding pin.

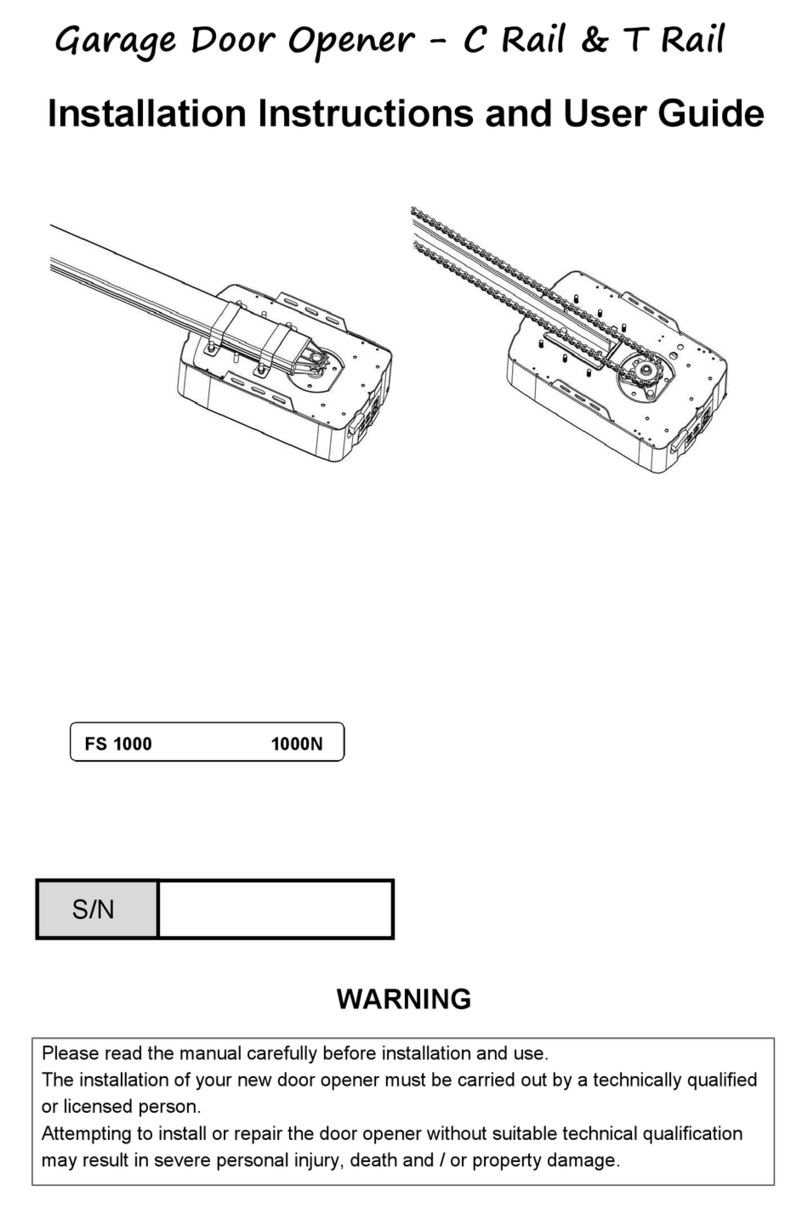

Photo Eye System must be installed properly. Boss Operators recommend Photo Eye System is installed on

every garage door for your added protection. Opening doors must not close and Closing doors must open. See

test procedure page 13 and page 16.

• Locate push button within sight of garage door, away from all moving parts and out of reach of children (minimum

150cm above floor). To reduce the risk of injury to persons, use this operator only with a sectional door.

• Never operate the opener if the system is not operating properly.

• Always disconnect electric power before making repairs or removing cover.

• Activate opener only when the door is in full view and free from obstructions.

• No one should enter or leave the garage while the door is moving. Do not allow children to play near, or operate

the door. Keep the remote control away from children.

• After Installation is complete fasten this manual near the garage door. Perform periodic safety checks and

recommended maintenance and adjustments.

• NEVER GO UNDER A STOPPED, PARTIALLY OPEN DOOR.

• Test door opener monthly. The garage door MUST reverse on contact with a 5cm high object (or a two by 4

board laid flat) on the floor. After adjusting either the force or the limit of travel, retest the door opener. Failure to

adjust the opener properly increases the risk of severe injury or death.

• For products having an emergency release, when possible, use the emergency release only when the door is

closed. Use caution when using this release with the door open. Weak or broken springs are capable of

increasing the rate of door closure and increasing the risk of severe injury or death.

• KEEP GARAGE DOORS PROPERLY BALANCED. See owner’s manual. An improperly balanced door increases

the risk of severe injury or death. Have a qualified service person make repairs to cables, spring assemblies, and

other hardware.

• Coach Screws are supplied with the door for fitting to timber. Correct and safe fastening to other materials may

require different fasteners. The install must select and use fasteners appropriate to the material into which they

are being fixed.

• NOTE– IT IS THE INSTALLER’S RESPONSIBILITY TO ENSURE THAT THE FIXING METHODS ARE SOUND

!