ENGLISH 3 / 35 CHAP. 2 - INDEX

OPA-100

CHAP. 2 - INDEX

CHAP. 1 - GENERAL INFORMATION ........................................................................................................ 2

CHAP. 2 - INDEX ......................................................................................................................................... 3

CHAP. 3 - SAFETY CONDITIONS .............................................................................................................. 4

3.1 IMPORTANT INFORMATION CONCERNING PERSONAL SAFETY ...................................... 4

3.2 IMPORTANT INFORMATION ABOUT THE SAFETY OF THE INSTRUMENT ........................ 7

3.3 GENERAL NOTES..................................................................................................................... 8

3.3.1 INSTALLATION .......................................................................................................................... 8

3.3.2 IMPORTANT INFORMATION ABOUT THE BATTERY............................................................. 8

3.3.3 IMPORTANT INFORMATION ABOUT OPERATING SAFETY ............................................... 10

3.3.4 WHEN THE INSTRUMENT IS NOT USED.............................................................................. 11

3.3.5 CLEANING ............................................................................................................................... 11

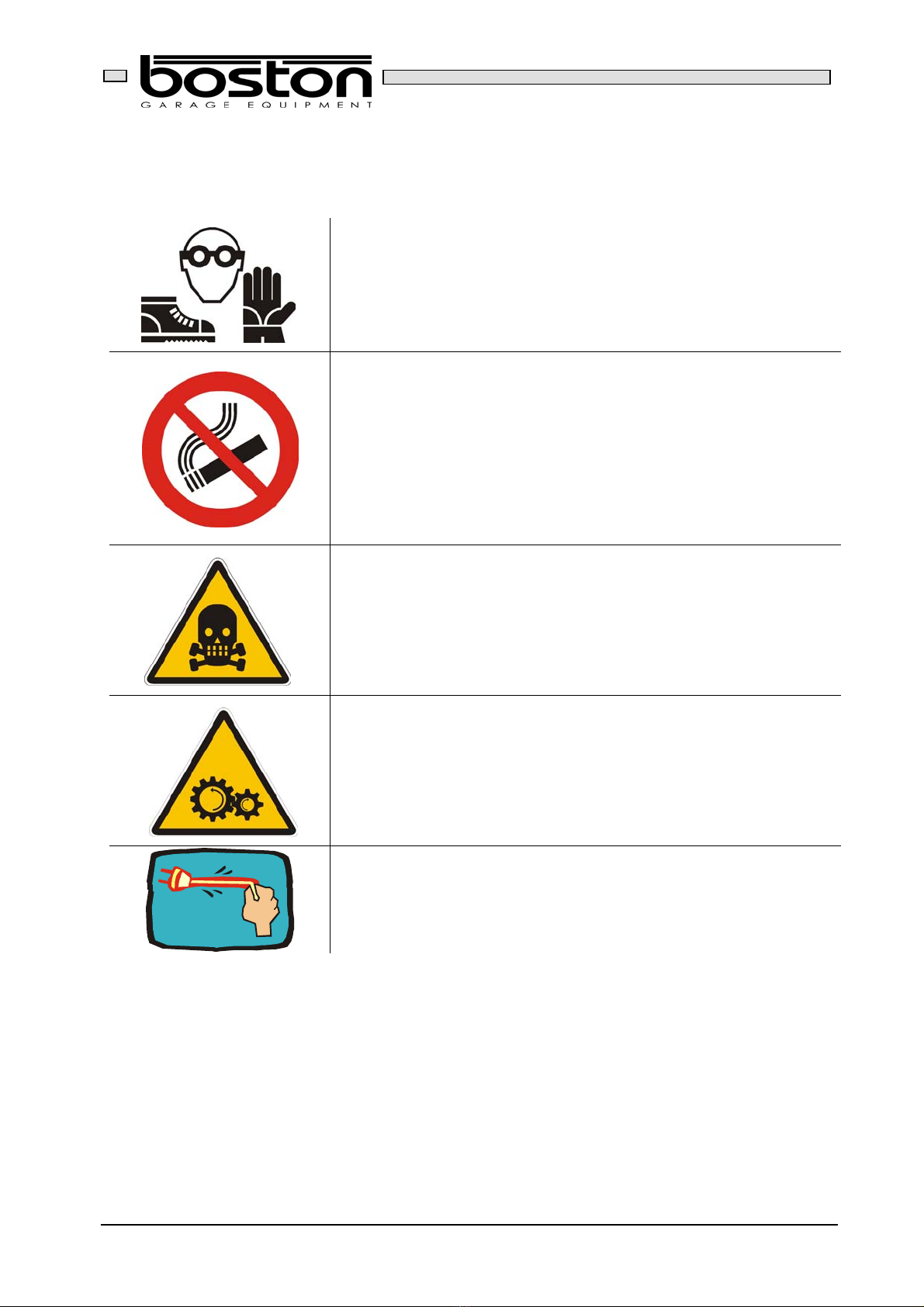

3.4 SYMBOLS ................................................................................................................................ 12

3.4.1 SAFETY.................................................................................................................................... 12

3.4.2 MARKING ................................................................................................................................. 12

CHAP. 4 - GENERAL DESCRIPTION....................................................................................................... 13

4.1 CONSTRUCTIONAL SPECIFICATIONS OF OPA-100 ........................................................... 13

4.1.1 EXTERNAL ASPECT OF OPA-100 ......................................................................................... 13

4.1.2 SUPPLIED ACCESSORIES..................................................................................................... 14

CHAP. 5 - GENERAL SPECIFICATIONS ................................................................................................. 15

5.1 GENERAL SPECIFICATIONS ................................................................................................. 15

CHAP. 6 - PRELIMINARY OPERATIONS ................................................................................................16

6.1 INSTALLATION ........................................................................................................................ 16

6.2 HOW TO INSTALL THE SOFTWARE ..................................................................................... 18

6.3 INSTALLATION IN THE WINDOWS ENVIRONMENT ............................................................... 18

6.4 SETTINGS................................................................................................................................ 18

6.4.1 GARAGE DATA ENTRY .......................................................................................................... 19

6.4.2 DATE AND TIME SETTING ..................................................................................................... 20

6.4.3 SERIAL PORT SETUP............................................................................................................. 21

6.4.4 REVOLUTION COUNTER SET-UP ......................................................................................... 22

CHAP. 7 - USE OF THE INSTRUMENT.................................................................................................... 23

7.1 PROGRAM USE ON A PERSONAL COMPUTER .................................................................. 23

7.1.1 SMOKE VALUE READING IN CONTINUOUS MODE............................................................. 24

7.1.2 OFFICIAL UK MOT TEST PROCEDURE ................................................................................ 26

7.1.2.1 WEEKLY CALIBRATION CHECK .......................................................................................................... 26

7.1.2.2 VEHICLE DATA ENTRY ......................................................................................................................... 27

7.1.2.3 OIL TEMPERATURE MEASUREMENT.................................................................................................. 28

7.1.2.4 OPACITY READING ............................................................................................................................... 29

7.1.2.5 PRINT-OUT OF RESULTS...................................................................................................................... 30

7.1.2.6 EMISSION LIMITS................................................................................................................................... 30

7.1.3 CHECKING THE CALIBRATION DUE DATE .......................................................................... 31

CHAP. 8 - MAINTENANCE........................................................................................................................ 32

8.1 HOW TO CLEAN THE FILTERING SYSTEM........................................................................................ 32

8.2 ANNUAL RE-CALIBRATION OF THE OPA-100...................................................................... 33

8.3 REPAIRS.................................................................................................................................. 33

CHAP. 9 - ERRORS................................................................................................................................... 34

CHAP. 10 - ACCESSORIES...................................................................................................................... 35