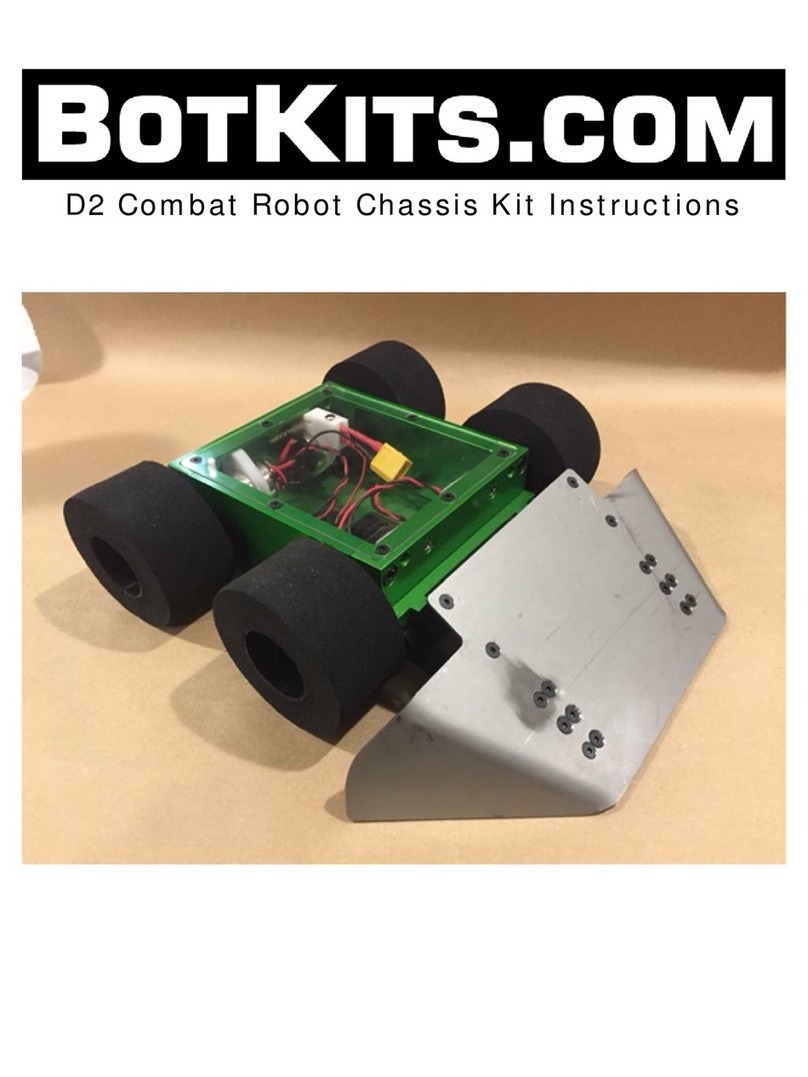

BotKits.com D2 COMBAT ROBOT KIT User manual

D2CombatRobotChassisKitInstructions

CAUTION:THISROBOTISPOWERFULANDFAST!MAKESUREYOUONLYOPERATE

THEROBOTINANAREAWHEREITCANNOTCAUSEDAMAGEORINJURY!

1|Page

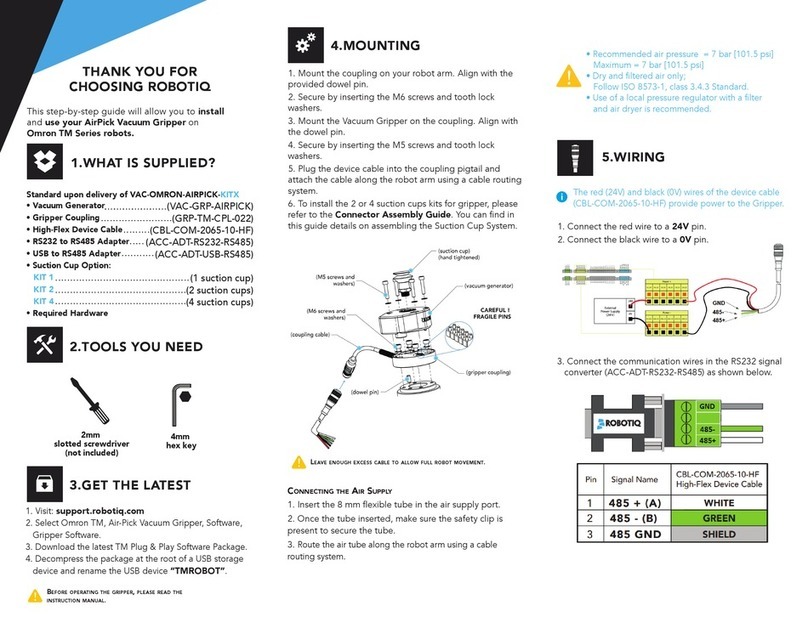

1 ADDITIONALPARTSREQUIRED:

Speedcontroller(weusetheScorpionMiniElectronicSpeedControl[ESC])

Radio(weusetheSpektrumDX3CtransmitterandaSR301receiver)

Battery(weusetheTurnigyNano‐Tech850mAh4SLiPopack)

Batteryplugfortheprimaryleadsplugonyourselectedbattery(XT60forourbatteries)

Foamsheetorbubblewraptosecurebattery(weusebubblewrap)

LiPobatterycharger

2 TOOLSREQUIRED:

(TorxT10screwdriver–providedwithkit)

SAEAllenwrenchset

#2Philipsheadscrewdriver

Wirestripper

Solderingironandsolder

BlueLoctite

2.1 ATTENTION:

Pleasepaycloseattentiontowhichfastenersgowhere.Trytokeepthemintheirindividually

labeledpouchesuntiltheyarereadyforinstallation.Manyofthemlookthesame,butareslightly

differentinlength.Usequalitytools!IfanAllenwrenchorscrewdriverfitsalittleloose,fastener

damageandfrustrationwillresult.Takeyourtime,havefun!!

2|Page

3 A

SSEMBLY

:

3.1 S

TEP

1

–

T

EMPORARYASSEMBLY

:

Formthebasicchassisbyassemblingthe2sides,2ends,4motors,switch,andpowerLED:

Attachall4oftheplasticmotorbracestothealuminumendpiecesusingthesupplied#6x5/8”

flatheadsheetmetalscrewsanda#2Phillipsscrewdriver.

Slidethemotorsintothemotorbores,untiljusttheblackheadofthemotor(wheretheshaft

comesout)isextendingbeyondthesideoftherobot.

Looselyinstall4ofthe10‐24x3/4socketheadcapscrewsinthelowerholesoneachend(e.g.

floppily)toconnecttheendstothesides.Thereisnoup/down/left/right.Allofthesidesand

endscanbeusedinanyposition(thelargehollowedoutareasgotowardstheinsides).

Snug(e.g.,fingertight)the4screwssothemotorsaretemporarilyheldinplace.

Attachthealuminumbottomplatetothechassisusing4oftheM3x6mmmachinescrewsand

theincludedTorxscrewdriver.

3|Page

3.2 S

TEP

2

–

A

RRANGE

E

LECTRONICS

:

Arrangeyourbattery,receiver,andspeedcontrolleronthebottomplate,asyouexpecttoplacethemin

thefinishedrobot.

Thebatteryisintherejusttomakesuresufficientroomisbeing

leftforit.

Makesurethereissufficientclearancebetweeneverythingand

themotors,allowingforspacingupofthereceiverandspeed

controlwhentheyareattachedusingtheincludedVelcro.

Markthelocationofyourreceiverandspeedcontrolleronthe

bottomplate.

3.3 S

TEP

4

–

A

TTACH

E

LECTRONICS

:

AttachyourreceiverandspeedcontrollerusingtheVelcro.

MakegooduseoftheVelcrobymakingsurethatpartsaremountedfirmlyenough(as

shown).

3.4 S

TEP

5

–

W

IRING

P

REPARATION

:

Determinewirelengthsneededtoconnectyourmotorstoyourspeedcontrolandfromthebatteryto

theswitchandspeedcontrol:

Measurefromthemotorsolderlugstothespeedcontrollugs.

Placethebatteryinthechassis,anddeterminewirelengthsneededtoconnecttothepower

switch.Thenegativewillgofromthebatterytothenegativecontactontheboardandthe

positivewilldothesamebutwillbeinterruptedbytheswitch.

Trimthewirestosizeandstriptheendsallowinga5mmcontactoneachend.

Foreasierassembly,tinthewiresaftertheyhavebeencutandstripedtolength.

Atthesametime,trimthepowerLEDleadstoanappropriatelengthtoconnecttothepower

lugsonthespeedcontrol,andtinifdesired.

4|Page

3.5 S

TEP

6

‐

W

IRING

:

Youwillbesolderingthewirestothemotorsandbatteryplugandconnectingthemtothespeed

controller.

Removeoneofthesidesoftherobottoallowforeasyspeedcontrolleraccess.

Solderwirepairstothemotorlugs,beingcarefulnottooverheatthemotorlugs.IMPORTANT:

DoNOTusesilversolder.Thehighertemperatureoverheatsthemotorinternals,causing

prematuremotorfailure.Wefinditeasiesttotinthewireendsandmotorlugs,thenjointhem.

ConnecttheLEDtothemainpowerinputonthespeedcontrol,sothatitiseasytotellwhenthe

robotislive.

Soldermainpowerpositivewirestothepowerswitch.Attachtheotherendtothepositive

terminalofanappropriateplugforyourselectedbattery.

Soldermainpowernegativewiretothenegativeterminalofthebatteryplug.

Placetheswitchinthe3Dprintedmounttokeepitoutoftheway.

Slide2ofthemotorsintothechassis.IMPORTANT:Themotorsarewiredinparallel,soitis

importantthatplacethefirst2motorsonthesameside.Itdoesnothowevermatterwhich

portontheSpeedcontrollertheypluginto(shown).

FitthefourmotorwiresintomotoroutputC4,positiveintopositiveandnegativeintonegative.

Thentightentheterminals.

5|Page

SlotthenexttwomotorsintotheirmountsandplacethefourwiresinterminalC3tightening

theterminalswhenfinished.

ConnectTHRandSTRtoyourradiotransmitterofchoice,asshown.Note:Itwillnotdamage

theelectronicsifyouflipthembutitwillreversedrivingandturningcontrols.

3.6 S

TEP

7

‐

A

SSEMBLETHEROBOT

:

Carefullyattachalloftheplatesastheendofconstructiondrawsnear.

Slidetheothersideplatebackontothechassis.

Snugthebottomscrews

Addtheuppersetof10‐24machinescrews,thentightentheupperscrews.Thiswillresultinthe

lowerscrewsbecomingtight,asweachieveacompressionfitaroundthemotorgearbox.Hint:

Whileevenlytighteningthe10‐24x¾screws,lookcloselyattheairgapbetweenthesideplates

andendplates.Tightenthescrewsinsmallincrementstokeeptheairgapseven.Evenairgaps

equalasquarelyassembled,strongrobot.

Attachthelowerplate,using8ofthesuppliedM3machinescrews.UseblueLoctitetokeep

thesescrewsfromcominglooseduringcombat!

Lightlyplacetheclearupperplateonthechassisandgentlyattachitwiththe4M3screws.

Lightlyattachingitisimportantbecauseyouwillwanttoaccesstheelectronicsalittlelater.

Ifyouwillbefightinginanarenawithasteelfloor,weofferoptionalmagnetsthatcanbe

attachedtothebottomoftherobottoincreasetraction.

3.7 S

TEP

8

‐

A

TTACH

W

HEELS

:

Attachaxleadaptersontheaxlesandmountthewheels.

Looselyscrewthesupplied4‐40machinescrewsintotheblackaluminumaxleadapters.

Slideeachaxleadapterfullyontoamotorshaft,withtheclampportiontowardsthechassis,and

tightenthe4‐40machinescrewstosecuretheadapterstothemotorshafts.

Slideawheelontoeachoftheaxleadapters,andsecurewiththesupplied6‐32machinescrews.

Your4‐40sizedAllenwrenchcanbeusedtohelpaligntheholesinthewheelhubwiththe

tappedholesintheaxleadapters.

6|Page

3.8 S

TEP

9

‐

A

TTACH

B

LADE

A

SSEMBLY

:

Mountthetitaniumblade,completingthebuild.

Attachthebladetothebladebrackets,usingthesuppliedM3machinescrewsandtheTorx

screwdriversuppliedwithyourD2CombatRobotChassiskit.Thesmalltipsofthebracketsgo

towardstheloweredgeoftheblade.UseblueLoctitetokeepthesescrewsfromcomingloose

duringcombat!

Attachthebladebracketstotheblademount,usingthesupplied¼‐20x0.875”socketheadcap

screws.Leavethescrewslooseenoughthatthebracketsrotatefreelyonthemount.Secure

the¼‐20machinescrewsbyusingthesupplied¼‐20nuts,sothemachinescrewscan’tunscrew

duetovibration,etc.

AttachtheblademounttotheD2CombatRobotChassis,using

thesupplied¼‐20x0.75”socketheadcapscrews.Youcanmount

thebladeontheendthatyouwanttobethe“front”.Useblue

Loctitetokeepthesescrewsfromcominglooseduringcombat!

Youwillwanttogrind,sandorfilethebottomedgeoftheblade:

Ifthearenayouwillfightinhasaveryflatfloor,youcanlowertheleadingedgeofthebladebygrinding,

sanding,orfilingtheloweredgecarefully.Ifyoumakeittoosharp,however,itcancatchonseamsin

thefloor,sobemindfulofhowmuchtosharpentheblade.

7|Page

3.9 STEP10‐POWERONTEST:

CAUTION:THISROBOTISPOWERFULANDFAST!MAKESUREYOUONLYOPERATE

THEROBOTINANAREAWHEREITCANNOTCAUSEDAMAGEORINJURY!

Makesuretherobotpowerswitchisoff.

Attachthebatteryandsecureitinthechassisbywrappingitwithanappropriateamountof

foamsheetorbubblewraptotakeupexcessspaceinthechassisaroundthebattery.

Ifyouhavenotyetboundyourradiotothereceiver,dothatnow,followingtheinstructions

providedwithyourradio.

Attachtheclearplastictopcoverusingthe8suppliedM3machinescrews.Theplastictop

willallowyourradiotoreachthereceiverwithouthavingtheantennaoutsideoftherobot.

Turnonyourradioandtherobot,andtestmovement.Thereisnofrontorbackonthe

robotuntilyouattachaweapon.Ifyouhaveapreferredfront(e.g.,weliketohavethe

batteryatthe“front”oftherobot),andtherobotisgoingbackwardstotheinputyougive

ontheradio,powerdowntherobotandreversethemotorpowerleadsonthespeed

control.

4 HINTSANDTIPS:

4.1 USEBLUELOCTITEWHEREINDICATEDINTHEINSTRUCTIONS:

Bottompanelscrews

Screwsthatattachthewedgetothewedgebrackets

Screwsthatattachthewedgemounttothemainchassis

Otherscrewsusedinthekitdonotseemtocomelooseduringcombat,buttheabovescrewswill

comeloosewithoutusingathreadlocker.

4.2 SWAPAMOTOR:

Youdonothavetofullydisassembletherobottochangeamotor:

Removethetopcover

Disconnecttheleadsfromthespeedcontrolfortheaffectedmotor.

LoosentheM3screwsonthebottomthatscrewintotheendwiththebadmotor

Loosenthe10‐24screwsontheendwiththebadmotor.

Slideoutthebadmotor

Soldertheleadstoagoodmotor,slideitbackin,tightenup,attachtheaxleadapterand

wheel,andyouarereadytogo!

Ifyouhavesparemotorswithleadsalreadyattached,thismakestheswapeasierandfaster!

Haveasuggestion?Contactusviahttp://www.botkits.com

Other manuals for D2 COMBAT ROBOT KIT

1

Table of contents

Other BotKits.com Robotics manuals