Boulevard DVLL41FP92(N Quick start guide

LUXURY DIRECT VENT ZERO CLEARANCE

GAS FIREPLACE HEATER

CONTEMPORARY

DVLL41FP92(N,P)-3

TRADITIONAL

DVTL41BP90(N,P)-1

UL FILE NO. MH30033

INSTALLATION INSTRUCTIONS

AND

OWNER’S MANUAL

WARNING: If not installed, operated and maintained

in accordance with the manufacturer’s instructions,

this product could expose you to substances in fuel

or from fuel combustion which can cause death or

serious illness.

This appliance may be installed in

an aftermarket, permanently located,

manufactured home (USA only) or mobile

home, where not prohibited by state or local

codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with other

gases, unless a certied kit is used.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death or

property damage.

— Do not store or use gasoline or other am-

mable vapors and liquids in the vicinity of

this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the re department.

— Installation and service must be per-

formed by a qualied installer, service

agency or the gas supplier.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

�

GAS-FIRED

Page 1

33598-6-0115Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INFORMATION ......................................................................................... 3

SAFETY INFORMATION FOR USERS OF LP GAS ..................................................................... 4

REQUIREMENTS FOR MASSACHUSETTS ................................................................................ 5

INTRODUCTION ........................................................................................................................... 6

SPECIFICATIONS ......................................................................................................................... 7

FIREPLACE DIMENSIONS ........................................................................................................... 7

CLEARANCES .............................................................................................................................. 8

LOCATING FIREPLACE................................................................................................................ 9

GAS SUPPLY .............................................................................................................................. 10

SPECIAL VENT SYSTEMS ......................................................................................................... 11

INSTALLATION....................................................................................................................... 11-13

VENTING FIREPLACE...........................................................................................................14-19

EXAMPLES - TOP VENT RUN...............................................................................................20-21

TERMINATION CLEARANCES................................................................................................... 22

VENT CLEARANCES.................................................................................................................. 23

VENT SYSTEM IDENTIFICATION .............................................................................................. 24

VENTING FRAMING AND FINISHING...................................................................................25-26

HORIZONTAL TERMINATION..................................................................................................... 27

VERTICAL TERMINATION .....................................................................................................28-29

DVVK-4F FLEX VENT INSTRUCTIONS ..................................................................................... 30

FINISHING THE WALL...........................................................................................................31-32

DVTL LOG & EMBER PLACEMENT ........................................................................................... 33

DVLL DECORATIVE MEDIA INSTALLATION.............................................................................. 34

LIGHTING INSTRUCTIONS........................................................................................................ 35

OPERATING INSTRUCTIONS...............................................................................................36-37

MAINTENANCE INSTRUCTIONS..........................................................................................37-38

WIRING DIAGRAM...................................................................................................................... 38

MAINTENANCE AND SERVICE ................................................................................................. 39

ACCESSORIES........................................................................................................................... 40

OPTIONAL PORCELAIN PANELS (DVTL ONLY) ....................................................................... 40

OPTIONAL DECORATIVE GLASS PANELS (DVLL ONLY)........................................................ 41

DVLL PARTS LIST....................................................................................................................... 42

DVLL EXPLODED VIEW ............................................................................................................. 43

DVTL PARTS LIST....................................................................................................................... 44

DVTL EXPLODED VIEW ............................................................................................................. 45

MASTER PARTS DISTRIBUTOR LIST ....................................................................................... 46

HOW TO ORDER REPAIR PARTS ............................................................................................. 46

JUNCTION BOX WIRING INSTALLATION INSTRUCTIONS...................................................... 47

ACCENT LAMP LIGHT REPLACEMENT - DVLL........................................................................ 47

QUICK REFERENCE GUIDE.................................................................................................48-49

WARRANTY ................................................................................................................................ 50

APPLIANCE SERVICE HISTORY ............................................................................................... 51

SECTION PAGE

33598-6-0115 Page 3

DO NOT OPERATE THIS APPLIANCE WITHOUT GLASS FRONT PANEL INSTALLED

Before enclosing the vent pipe assembly, operate the appliance to ensure it is venting properly.

• If this appliance is installed directly on carpeting,

tile or other combustible material other than wood

ooring the appliance shall be installed on a metal

or wood panel extending the full width and depth of

the appliance.

The base referred to above does not mean the

reproof base as used on wood stoves. The protection

is for rugs that are extremely thick and light colored

tile.

• Children and adults should be alerted to the hazards

of high surface temperatures and should stay away

to avoid burns or clothing ignition.

• Young children should be carefully supervised when

they are in the same room as the appliance.

• Clothing or other ammable material should not be

placed on or near the appliance.

• Adequate accessibility clearances for servicing and

proper operation.

• This appliance must not share or be connected to a

ue serving a separate solid-fuel burning appliance.

• Keep the area around your appliance clear of

combustible materials, gasoline and other ammable

vapor and liquids.

• Under no circumstances should any solid fuels

(wood, coal, paper or cardboard etc.) be used in this

appliance.

• The ow of combustion and ventilation air must not

be obstructed in any way.

• Young children should be carefully supervised

when they are in the same room as the appliance.

Toddlers, young children, and others may be sus-

ceptible to accidental contact burns. A physical

barrier is recommended if there are at-risk individ-

uals in the house. To restrict access to a replace

or stove, install an adjustable safety gate to keep

toddlers young children, and other at-risk indiv-

icuals out of the room and away from hot surfaces.

• A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this appli-

ance and shall be installed for the protection of

children and other at-risk individuals.

• If the barrier becomes damaged, the barrier shall

be replaced with the manufacturer’s barrier for

this appliance.

• Any safety screen, guard, or barrier removed for

servicing an appliance must be replaced prior to

operating the appliance.

• Due to high temperatures the appliance should be

located out of trafc and away from furniture and

draperies.

• Theglassfrontoranypartremovedforservicingthe

appliance must be replaced prior to operating the

appliance.Workshouldbedonebyaqualiedservice

person.

• Keepburnerandcontrolcompartmentclean.

• Ventcapishotwhilereplaceisinoperation.

• Installationandrepairshouldbedonebyaqualied

service person. The appliance should be inspected

beforeuseandatleastannuallybyaqualiedservice

person.Morefrequentcleaningmayberequireddue

toexcessivelintfromcarpeting,beddingmaterials,etc.

Itisimperativethatcontrolcompartments,burnersand

circulatingairpassagewaysoftheappliancebekept

clean.

• Donotputanythingaroundthereplacethatwillobstruct

theowofventilationair.

• Clearanceinaccordancewithlocalinstallationcodes

andtherequirementsofthegassupplier.

• Do keep the appliance area clear and free from

combustible material, gasoline and other ammable

vaporsandliquids.

• Doexamineventingsystemperiodicallyandreplace

damagedparts.

• Domakeaperiodicvisualcheckofpilotandburners.

Cleanandreplacedamagedparts.

• CAUTION:Theglassusedinyourreplaceisceramic

glass.Iftheglassiscrackedordamagedinanyway,it

shouldbereplacedonlywithacompleteglassframe

assemblyfromEmpire.See parts list on Pages 42

to 45.

• Donotusethisreplaceifanyparthasbeenunder

water.Immediatelycallaqualiedservicetechnician

to inspect the heater and to replace any part of the

controlsystemand anygascontrolwhichhas been

underwater.

• Any safety screen or guard removed for servicing

anappliancemustbereplacedpriortooperatingthe

appliance.

IMPORTANT SAFETY INFORMATION

33598-6-0115Page 4

Some people cannot smell well. Some people cannot smell the

odor of the chemical put into the gas. You must nd out if you

can smell the odorant in propane.Smokingcandecreaseyour

abilitytosmell.Beingaroundanodorforatimecanaffectyour

sensitivityorabilitytodetectthatodor.Sometimesotherodorsin

theareamaskthegasodor.Peoplemaynotsmellthegasodor

ortheirmindsareonsomethingelse.Thinkingaboutsmellinga

gasodorcanmakeiteasiertosmell.

The odorant in LP-Gas is colorless, and it can fade under

some circumstances.Forexample,ifthereisanunderground

leak,themovementofthegasthroughsoilcanltertheodorant.

OdorantsinLP-Gasalsoaresubjecttooxidation.Thisfadingcan

occurifthereisrustinsidethestoragetankorinirongaspipes.

Theodorantinescapedgascanadsorborabsorbontoorintowalls,

masonryandothermaterialsandfabricsinaroom.Thatwilltake

someoftheodorantoutofthegas,reducingitsodorintensity.

LP-Gasmaystratifyinaclosedarea,andtheodorintensitycould

varyatdifferentlevels.Sinceitisheavierthanair,theremaybe

moreodoratlowerlevels.Alwaysbesensitivetotheslightestgas

odor.Ifyoudetectanyodor,treatitasaseriousleak.Immediately

gointoactionasinstructedearlier.

Propane (LP-Gas) is a ammable gas which can cause res

and explosions. In its natural state, propane is odorless and

colorless. You may not know all the following safety precautions

which can protect both you and your family from an accident.

Read them carefully now, then review them point by point

with the members of your household. Someday when there

may not be a minute to lose, everyone’s safety will depend

on knowing exactly what to do. If, after reading the following

information, you feel you still need more information, please

contact your gas supplier.

• Learn to recognize the odor of LP-Gas. Your local LP-Gas

Dealercangiveyoua“ScratchandSniff”pamphlet.Useitto

ndoutwhatthepropaneodorsmellslike.Ifyoususpectthat

yourLP-Gashasaweakorabnormalodor,callyourLP-Gas

Dealer.

• Ifyouarenotqualied,donotlightpilotlights,performservice,

ormakeadjustmentstoappliancesontheLP-Gassystem.If

youarequalied,consciouslythinkabouttheodorofLP-Gas

priortoandwhilelightingpilotlightsorperformingserviceor

makingadjustments.

• Sometimes a basement or a closed-up house has a musty

smellthatcancoveruptheLP-Gasodor.Donottrytolight

pilotlights,performservice,ormakeadjustmentsinanarea

wheretheconditionsaresuchthatyoumaynotdetecttheodor

iftherehasbeenaleakofLP-Gas.

• Odorfade,duetooxidationbyrustoradsorptiononwallsof

newcylindersandtanks,ispossible.Therefore,peopleshould

beparticularlyalertandcarefulwhennewtanksorcylinders

areplacedinservice.Odorfadecanoccurinnewtanks,or

reinstalledoldtanks,iftheyarelledandallowedtosettoo

longbeforerelling.Cylindersandtankswhichhavebeenout

ofserviceforatimemaydevelopinternalrustwhichwillcause

odorfade.Ifsuchconditionsaresuspectedtoexist,aperiodic

snifftestofthegasisadvisable.If you have any question

about the gas odor, call your LP-Gas dealer. A periodic

sniff test of the LP-Gas is a good safety measure under

any condition.

• If,atanytime,youdonotsmelltheLP-Gasodorantandyou

thinkyoushould,assumeyouhavealeak.Thentakethesame

immediateactionrecommendedabovefortheoccasionwhen

youdodetecttheodorizedLP-Gas.

• Ifyouexperienceacomplete“gasout,”(thecontainerisunder

novaporpressure),turnthetankvalveoffimmediately.Ifthe

containervalveislefton,thecontainermaydrawinsomeair

throughopeningssuchaspilotlightorices.Ifthisoccurs,some

newinternalrustingcouldoccur.Ifthevalveisleftopen,then

treatthecontainerasanewtank.Alwaysbesureyourcon-

tainerisundervaporpressurebyturningitoffatthecontainer

beforeitgoescompletelyemptyorhavingitrelledbeforeitis

completelyempty.

• Donotoperateelectricswitches,lightmatches,useyourphone.

Donotdoanythingthatcouldignitethegas.

• Geteveryoneoutofthebuilding,vehicle,trailer,orarea.Do

thatIMMEDIATELY.

• Closeallgastankorcylindersupplyvalves.

• LP-Gasisheavierthanairandmaysettleinlowareassuchas

basements.Whenyouhavereasontosuspectagasleak,keep

outofbasementsandotherlowareas.Stayoutuntilreghters

declarethemtobesafe.

• Useyourneighbor’sphoneandcallatrainedLP-Gasservice

person and the re department. Even though you may not

continuetosmellgas,donotturn onthegasagain.Donot

re-enterthebuilding,vehicle,trailer,orarea.

• Finally,lettheservicemanandreghterscheckforescaped

gas.Havethemairouttheareabeforeyoureturn.Properly

trained LP-Gas service people should repair the leak, then

checkandrelightthegasapplianceforyou.

SOME POINTS TO REMEMBER

NO ODOR DETECTED - ODOR FADE

LP-GAS WARNING ODOR

If a gas leak happens, you should be able to smell the gas because of the odorant put in the LP-Gas.

That’s your signal to go into immediate action!

SAFETY INFORMATION FOR USERS OF LP GAS

33598-6-0115 Page 5

REQUIREMENTS FOR MASSACHUSETTS

Forallsidewallhorizontallyventedgasfueledequipmentinstalled

ineverydwelling,buildingorstructureusedinwholeorinpartfor

residential purposes, including those owned or operated by the

Commonwealthandwherethesidewallexhaustventtermination

is less than seven (7) feet above nished grade in the area of

the venting, including but not limited to decks and porches, the

followingrequirementsshallbesatised:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS.

At the time of installation of the side wall horizontal vented

gasfueledequipment,theinstallingplumberorgasttershall

observethatahardwiredcarbonmonoxidedetectorwithan

alarmandbatteryback-upisinstalledontheoorlevelwhere

thegasequipmentistobeinstalled.Inaddition,theinstalling

plumber or gastter shall observe that a battery operated

or hard wired carbon monoxide detector with an alarm is

installedoneachadditionallevelofthedwelling,buildingor

structureservedbythesidewallhorizontalventedgasfueled

equipment.Itshallbetheresponsibilityofthepropertyowner

tosecuretheservicesofqualiedlicensedprofessionalsfor

theinstallationofhardwiredcarbonmonoxidedetectors

a. In the event that the side wall horizontally vented gas

fueledequipmentisinstalledinacrawlspaceoranattic,

thehardwiredcarbonmonoxidedetectorwithalarmand

battery back-up may be installed on the next adjacent

oorlevel.

b. Intheeventthattherequirementsofthissubdivisioncan

notbe metatthe timeofcompletion ofinstallation, the

ownershallhaveaperiodofthirty(30)daystocomplywith

theaboverequirements;provided,however,thatduring

said thirty (30) day period, a battery operated carbon

monoxidedetectorwithanalarmshallbeinstalled.

2. APPROVED CARBON MONOXIDE DETECTORS. Each

carbonmonoxidedetectorasrequiredinaccordancewiththe

aboveprovisionsshallcomplywithNFPA720andbeANSI/

UL2034listedandIAScertied.

3. SIGNAGE. A metal or plastic identication plate shall be

permanently mounted to the exterior of the building at a

minimumheightofeight(8)feetabovegradedirectlyinline

with the exhaust vent terminal for the horizontally vented

gas fueled heating appliance or equipment. The sign shall

read, in print size no less than one-half (1/2) inch in size,

“GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL

OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side

wall horizontally vented gas fueled equipment shall not

approvetheinstallationunless,uponinspection,theinspector

observes carbon monoxide detectors and signage installed

in accordance with the provisions of 248 CMR 5.08(2)(a) 1

through4.

(b) EXEMPTIONS:Thefollowingequipmentisexemptfrom

248CMR5.08(2)(a)1through4:

1. The equipment listed in Chapter 10 entitled

“EquipmentNotRequiredToBeVented”inthemost

currenteditionofNFPA54asadoptedbytheBoard;

and

2. ProductApprovedsidewallhorizontallyventedgas

fueled equipment installed in a room or structure

separate from the dwelling, building or structure

usedinwholeorinpartforresidentialpurposes.

(d) MANUFACTURER REQUIREMENTS - GAS

EQUIPMENT VENTING SYSTEM NOT PROVIDED.

When the manufacturer of a Product Approved side

wallhorizontallyventedgasfueledequipment doesnot

providethepartsforventingtheuegases,butidenties

“special venting systems”, the following requirements

shallbesatisedbythemanufacturer:

1. Thereferenced“specialventingsystem”instructions

shall be included with the appliance or equipment

installationinstructions;and

2. The “special venting systems” shall be Product

Approved by the Board, and the instructions for

that system shall include a parts list and detailed

installationinstruction.

(e) A copy of all installation instructions for all Product

Approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists for

ventinginstructions,and/orallventingdesigninstructions

shall remain with the appliance or equipment at the

completionoftheinstallation.

33598-6-0115Page 6

Instructions to Installer

1. Installer must leave instruction manual with owner after

installation.

2. Installermusthaveownerlloutandmailwarrantycardsupplied

withthereplace.

3. Installer should show owner how to start and operate the

replace.

Thisdirectvent gasreplaceheateris designedtooperatewith

allcombustionairbeingsiphonedfromtheoutsideofthebuilding

andallexhaustgasesexpelledtotheoutsideofthebuilding.The

informationcontainedinthismanualpertainstoallmodelsandgas

controlsystemsunlessotherwisenoted.

Warning: This unit is not for use with solid fuels.

Appliance Certication

This replace is design certied in accordance with American

NationalStandard/CSAStandardANSIZ21.88/CSA2.33andby

UnderwritersLaboratoriesasaDirectVentGasFireplaceHeater

andshallbeinstalledaccordingtotheseinstructions.

Consultyourlocalbuildingcodeagency,priortoinstallation,toensure

compliancewithlocalcodes-includingpermitsandinspections.

The replace, when installed, must be electrically grounded in

accordancewithlocalcodesor,inabsenceoflocalcodes,withthe

National Electric Code ANSI/NFPA 70 or Canadian Electric code,

CSA C22.1,ifanexternalelectricalsourceisutilized.

Thesemodelsmaybeinstalledinabedroomorbed-sittingroom

intheU.S.A.andCanada.

Qualied Installing Agency

Installationandreplacementofgaspiping,gasutilizationequipment

or accessories and repair and servicing of equipment shall be

performedonlybyaqualiedagency.Theterm“qualiedagency”

meansanyindividual,rm,corporationorcompanywhicheitherin

personorthrougharepresentativeisengagedinandisresponsiblefor

(a)theinstallationorreplacementofgaspipingor(b)theconnection,

installation,repairorservicingofequipment,whoisexperiencedin

suchwork,familiarwithallprecautionsrequiredandhascomplied

withalltherequirementsoftheauthorityhavingjurisdiction.

StateofMassachusetts:Theinstallationmustbemadeby

alicensedplumberorgastterintheCommonwealthof

Massachusetts.

Theinstallationmustconformwithlocalcodesor,intheabsenceof

localcodes,withtheNational Fuel Gas Code ANSI Z223.1/NFPA

54* Natural Gas and Propane Installation Code, or CSA B149.1 in

Canada. *Available from the American National Standards Institute,

Inc. 11 West 42nd St., New York, N.Y. 10036.

Warning:ANYCHANGETOTHISFIREPLACEORITS

CONTROLS CAN BE DANGEROUS.

Improperinstallationoruseofthereplacecancause

seriousinjuryordeathfromre,burns,explosions,orcarbon

monoxidepoisoning.

Any alteration of the original design, installed other than as

shown in these instructions or use with a type of gas not

shown on the rating plate is the responsibility of the person

and company making the change.

Important

AllcorrespondenceshouldrefertocompleteModelNumber,Serial

Numberandtypeofgas.

High Altitude

Wheninstalling thisunit atan elevationabove 2000feet (inthe

UnitedStates)itmaybenecessarytodecreasetheinputratingby

changingthe existingburneroricetoa smallersize.Generally,

inputshouldbereduced4percentforeach1000feetabovesea

level.However,iftheheatingvalueofthegashasbeenreduced,

thisgeneralrulemaynotapply.Checkwithlocalgasutilityforproper

oricesizeidentication.

Canadian High Altitude

Altitude:0-4500feet(0-1370m)

Wheninstallingthisunitatanelevationabove4500feet(inCanada),

checkwithlocalauthorities.

Consultyourlocalgasutilityforassistanceindeterminingtheproper

oriceforlocation.

Preparation

Thisdirectventgasreplaceanditscomponentsaretestedand

safe when installed in accordance with this Installation Manual.

Reporttoyourdealeranypartsdamagedinshipment,specically

checkglasscondition.Donotinstallunitwithdamaged,incomplete,

orsubstituteparts.Readallinstructionsbeforestartinginstallation

andfollowtheseinstructionscarefullyduringinstallationtoinsure

maximumbenetandsafety.Failuretofollowthemwillvoidyour

warrantyandmaypresentarehazard.

Thewarrantywillbe voidedby,andthewarranterdisclaimsany

responsibilityforthefollowingactions:

• Installation of any damaged fireplace or vent system

component.

• Modicationofthereplaceordirectventsystem.

• InstallationotherthanasinstructedbyEmpireComfortSystems,

Inc.

• Improperpositioningofthelogs,glassdoorordecorativemedia.

• Installationand/oruseofanycomponentpartnotmanufactured

orapprovedbymanufacturer.

INTRODUCTION

33598-6-0115 Page 7

Figure 1

NOTE: Airshuttersettingsarefactoryminimumsettings.Someventingcongurationsmayrequireminorairshutteradjustmentsfor

optimumperformance.

SPECIFICATIONS

FIREPLACE DIMENSIONS

DVLL NAT DVLL LP DVTL NAT DVTL LP

InputBtu/hrMaximum 34,500 31,500 34,500 31,500

Btu/hrMinimum 18,000 20,500 17,000 16,700

KWH(Maximum) 10.1 9.2 10.1 9.2

(Minimum) 5.3 6.0 5.0 4.9

Orice #32, P211 #51, P210 #32, P211 #51, P210

Min.RateScrew #41 #52 #41 #52

AirShutterOpening-Front 9/16in. FULL OPEN 9/16 FULL OPEN

Heightwithoutstandoff 24-1/4in.(616mm) 24-1/4in.(616mm) 24-1/4in.(616mm) 24-1/4in.(616mm)

Width 51-1/16in.(129.7cm) 51-1/16in.(129.7cm) 51-1/16in.(129.7cm) 51-1/16in.(129.7cm)

Depth 15-13/16in.(402mm) 15-13/16in.(402mm) 15-13/16in.(402mm) 15-13/16in.(402mm)

GasInletShutoffValve

(Pipe) 1/2NPT 1/2NPT 1/2NPT 1/2NPT

DIMENSIONS

ininches(metric)

DVLL(DVTL)

A51-1/16

(129.7cm)

B44-1/2

(113.0cm)

C16-1/2

(419mm)

D36-5/8

(930mm)

E24-5/8

(625mm)

F15-13/16

(402mm)

G6-9/16

(167mm)

H9-1/4

(235mm)

I23-7/8

(606mm)

J1-9/16

(40mm)

K1-1/4

(32mm)

E

JUNCTION BOX

K

12”

(305mm)

LEFT SIDE VIEW

RIGHT SIDE VIEW

TOP VIEW

A

B

C

D

JUNCTION BOX FRONT VIEW

33598-6-0115Page 8

Mantel Chart

A20"(508mm) J17-1/2"(444mm)

B21-1/2"(546mm) K17"(431mm)

C13-1/2"(343mm) L16-1/2"(419mm)

D12"(305mm) M16"(406mm)

E20-1/2"(521mm) N15-1/2"(394mm)

F19-1/2"(495mm) O15"(381mm)

G19"(482mm) P14-1/2"(368mm)

H18-1/2"(469mm) Q14"(356mm)

I18"(457mm) R13"(330mm)

Figure 4

Ceiling Height and Side Wall Clearances

Minimum ceiling height is 46-3/4" (1.17m) from top of replace

opening.

Clearancefromsideofreplacetoadjacentsidewallis2"(51mm).

Note:Somedecorativefrontsrequiremorethan2"clearancedue

tofrontsize.

Figure 5

CLEARANCES

Clearance to Combustibles - Shown in inches (metric)

Back 1-1/4(32mm)

Side 3-1/8(79mm)

Floor 0(0mm)

TopStand-off 12(305mm)

TopFramingEdge 12(305mm)

MinimumHeightfromTopofFireplace

OpeningToCeiling 46-3/4(1.17m)

Figure 2

Combustible Material

Nogreetingcards,stockingsorornamentationofanytypeshould

be placed on or attached to the replace. The ow of heat can

ignitecombustibles.

ONLY NON-COMBUSTIBLE MATERIALS

ALLOWED OVER THE FIREPLACE FACE

ON EACH SIDE

3-1/8” (79mm) 3-1/8” (79mm)

1-1/4” (3mm)

Figure 3

Television Considerations

Installingatelevisionaboveareplacehasbecomeincreasingly

popular;however,theareaaboveanyreplacegetshotandmost

TVmanufacturersrecommendagainstplacingtheirproductsnear

aheatsource.

Ifyouinstallatelevisionabovethisreplace,EmpireComfortSys-

temsacceptsnoresponsibilityfordamageorinjuries.Followthe

television manufacturer’s installation instructions, including any

recommendationsregardingproximitytoheatsources.

IfyouhaveaTVaboveyour replace,turnoffthereplaceand

letitcoolcompletelybeforeservicingortouchinganybuttonson

theTV.

33598-6-0115 Page 9

Figure 6

CORNER INSTALLATION

ANGLED CORNER

INSTALLATION

ISLAND

INSTALLATION

ROOM DIVIDER

INSTALLATION

FLUSH WALL

INSTALLATION

CABINET

INSTALLATION

LOCATING FIREPLACE

Note: IslandandRoomDividerinstallationispossibleaslongasthehorizontalportionoftheventsystemdoesnotexceed

20feet(609.6cm)withaminimumverticalrunof8feet(243.8cm).SeedetailsinVentingSection.See Figure 6.

33598-6-0115Page 10

GAS SUPPLY

The gas pipeline can be brought in through the left side of the

appliance.ConsultthecurrentNationalFuelGasCode,ANSIZ223.1

CAN/CGA-B149(.1or.2)installationcode.

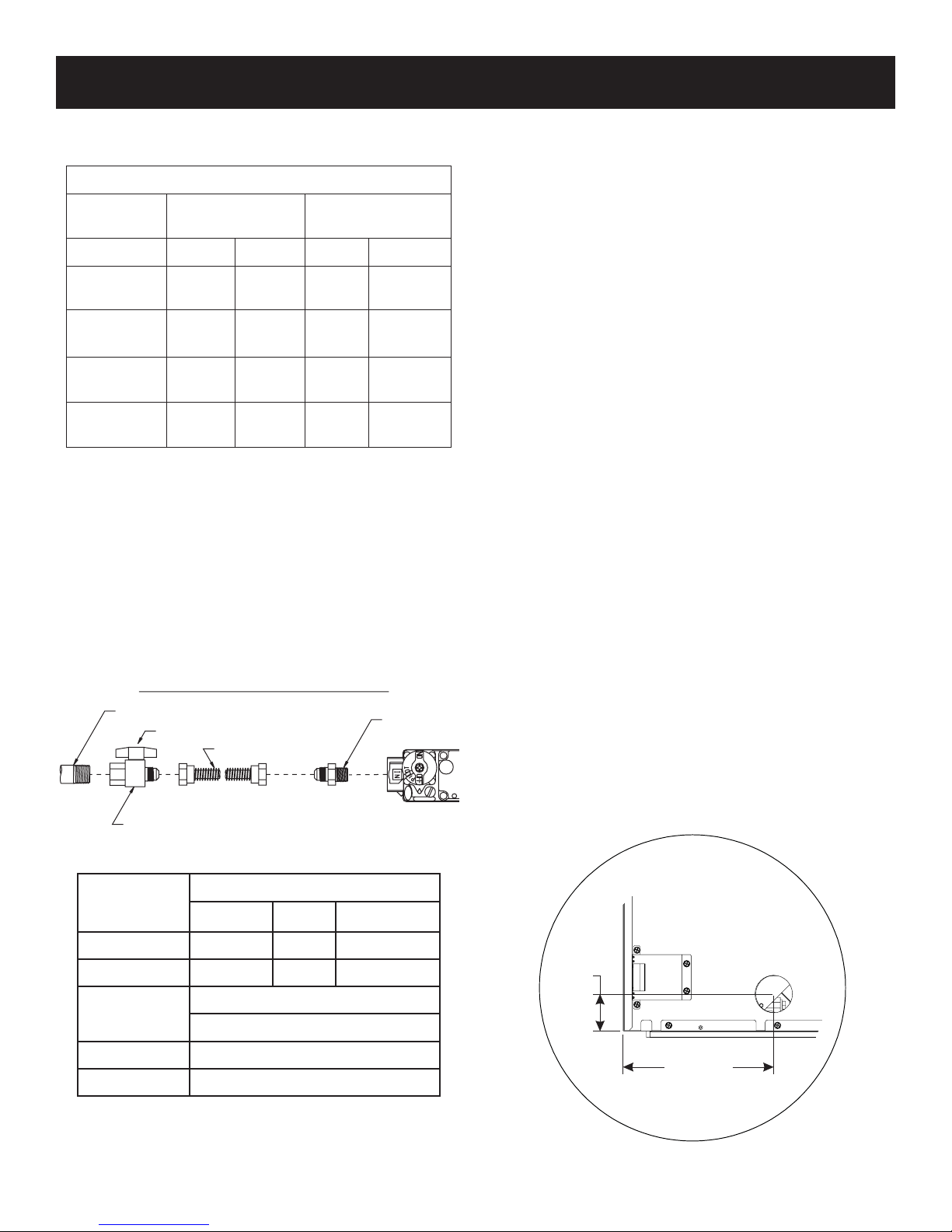

Recommended Gas Pipe Diameter

Pipe Length Schedule 40 Pipe

Inside Diameter

Tubing, Type L

Outside Diameter

Nat. L.P. Nat. L.P.

0-10ft

0-3m

1/2in.

12.7mm

3/8in.

9.5mm

1/2in.

12.7mm

3/8in.

9.5mm

11-40ft

4-12m

1/2in.

12.7mm

1/2in.

12.7mm

5/8in.

15.9mm

1/2in.

12.7mm

41-100ft

13-30m

1/2in.

12.7mm

1/2in.

12.7mm

3/4in.

19mm

1/2in.

12.7mm

101-150ft

31-46m

3/4in.

19mm

1/2in.

12.7mm

7/8in.

22.2mm

3/4in.

1.9mm

Note:Neveruseplasticpipe.Checktoconrmwhetheryourlocal

codesallowcoppertubingorgalvanized.

Note:Sincesomemunicipalitieshaveadditionallocalcodes,itis

alwaysbesttoconsultyourlocalauthorityandinstallationcode.

Theuseofthefollowinggasconnectorsisrecommended:

— ANSZ21.24ApplianceConnectorsofCorrugatedMetalTubing

andFittings.

— ANSZ21.45AssembledFlexibleApplianceConnectorsofOther

ThanAll-MetalConstruction

Theaboveconnectorsmaybeusedifacceptablebytheauthority

having jurisdiction. The state of Massachusetts requires that a

exibleapplianceconnectorcannotexceedthreefeetinlength.

▲

►

▼

◄

◄

FLEXIBLE GAS LINE CONNECTION

GAS SUPPLY

TEE HANDLE

FLEX TUBING

FLARE SHUT OFF VALVE

FLARE

FITTING

Figure 7

GasSupplyPressure(inchesw.c.)

Minimum Normal Maximum

NaturalGas 5.0 7.0 14.0

LP(Propane) 10.8 11.0 14.0

ManifoldPressure(inchesw.c.)

Normal(HI)

NaturalGas 3.5

LP(Propane) 10.0

Installing a New Main Gas Cock

Eachapplianceshouldhaveitsownmanualgascock.

Amanualmaingascockshouldbelocatedinthevicinityoftheunit.

Wherenoneexists,orwhereitssizeorlocationisnotadequate,

contactyourlocalauthorizedinstallerforinstallationorrelocation.

Compoundsusedonthreadedjointsofgaspipingshallberesistant

totheactionofliqueedpetroleumgases.Thegaslinesmustbe

checkedforleaksbytheinstaller.Thisshouldbedonewithasoap

solutionwatchingforbubblesonallexposedconnections,andif

unexposed,apressuretestshouldbemade.

Never use an exposed ame to check for leaks. Appliance must

be disconnected from piping at inlet of control valve and pipe

capped or plugged for pressure test. Never pressure test with

appliance connected; control valve will sustain damage!

NOTE:Thegascontrolsareequippedwithacapturedscrewtype

pressuretestpoint,thereforeitisnotnecessarytoprovidea1/8in.

testpointupstreamofthecontrol.

Whenusingcopperorexconnectoruseonlyapprovedttings.

Theapplianceanditsindividualshutoffvalvemustbedisconnected

fromsupplypipingsystemduringanypressuretestingofthatsystem

attestpressuresinexcessof1/2psig(3.5kPa).

Theappliancemustbeisolatedfromthegassupplypipingsystem

byclosingitsindividualmanualshutoffvalveduringanypressure

testingofthegassupplypipingsystemattestpressuresequalto

orlessthan1/2psig(3.5kPa).

Attention!Ifoneoftheproceduresresultsinpressuresinexcess

of1/2psig(14in.w.c.)(3.5kPa)onthereplacegasvalve,itwill

resultinahazardouscondition.

Checking Manifold Pressures

Both Propane and Natural gas valves have a built-in pressure

regulatorinthegasvalve.Naturalgasmodelswillhaveamanifold

pressureofapproximately3.5in.w.c.(.871kPa)atthevalveoutlet

withtheinletpressuretothevalvefromaminimumof5.0in.w.c.

(1.245kPa)forthepurposeofinputadjustmenttoamaximumof

14.0in.w.c.(3.484kPa).Propanegasmodelswillhaveamanifold

pressure approximately 10.0 in. (2.49kPa) at the valve outlet

withtheinletpressuretothevalvefromaminimumof10.8in.w.c.

(2.68kPa) for the purpose of input adjustment to a maximum of

14.0in.w.c.(3.484kPa).

2-7/16”

(61 mm)

8-1/4”

(209.5mm)

Figure 8

33598-6-0115 Page 11

Vent Pipe Clearance

Note:Maintainoneinch(1in.)ofclearancearoundverticalvent

pipe.See Figure 9.Forhorizontalvent,maintainaminimum1in.

clearancetothebottom,twoinchestothesidesofthevent,and3

in.clearancetocombustiblesabovetheventpipe.See Figure 10.

►

◄

VENT PIPE

1” (25mm) MINIMUM

CLEARANCE AROUND VENT PIPE

Figure 9

2” (50.8mm)

TOP OF VENT PIPE

4”

DIAMETER

FLUE

6-5/8”

DIAMETER

INTAKE VENT

3” (76mm)

1”

(25.4mm)

Figure 10

INSTALLATION

Attention: Horizontal venting through a wall requires a wall

thimbleontheinteriorsideofthewallabovethepipe.

SPECIAL VENT SYSTEMS

ThefollowingventsystemsareacceptableforusewithDV(TL,LL)41FPseriesreplaces:

Simpson Duravent® GS 4" - 6 5/8"

Selkirk Direct-Temp® 4" - 6 5/8"

Security Secure Vent® 4" - 6 5/8"

EmpireFlexventKitDVVK-4F,refertopage30.

33598-6-0115Page 12

INSTALLATION

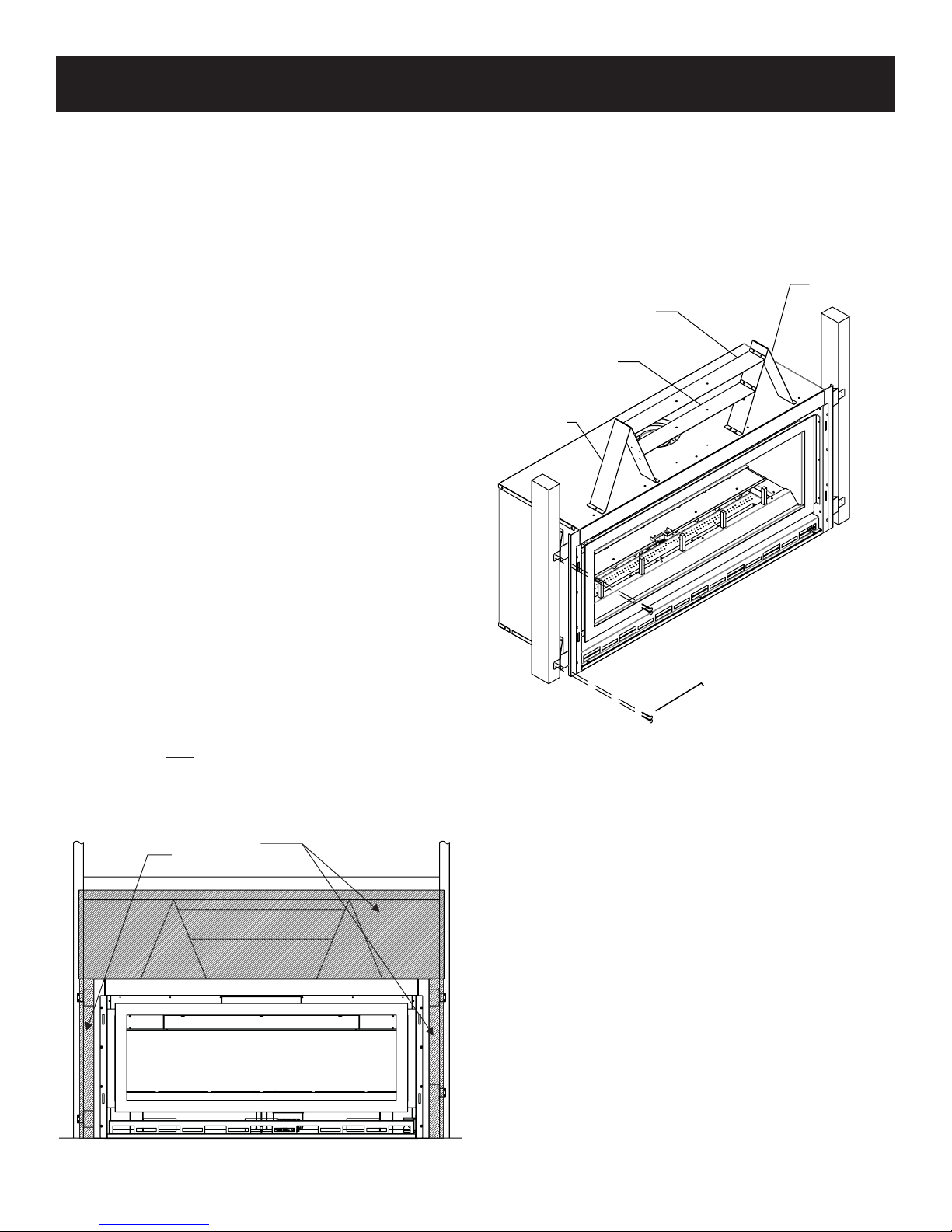

Framing and Finishing

NOTE: You must use the standoffs that are supplied with the

replace. The standoffs are shipped in a at-state on top

of the replace.

1. Locatethetwo(2)steelstandoffsandtwo(2)headershields

attachedtothebackofthereplace.

2. Removethetwo(2)screwsthatsecurethestandoffsandheader

shieldsinplace;savethescrews.

3. Therightandleftstandoffshaveaperforationlocatedinthe

middle.Bendthemattheperforationtoalittlemorethan90°.

4. Bendtheshorttabsoneachendtheoppositedirection.Secure

thestandoffstothereplacetopwiththree(3)screwseach

fromthehardwarebag.Therearepilotholeslocatedinthe

topofthereplaceforeachstand-off.

5. Verifythatthefrontofthestandoffsare1/2in.(13mm)back

from the face of the replace. Verify that the stand-off is

12in.(305mm)tall.

6. Locatethebottomheadershield;itistheshorterone.Using

four(4)screws,attachitbetweenthestandoffs.

7. Locatethetopheadershield;itisthelongerone.Usingfour

(4)screws,attachitbetweenthestandoffs.See Figure 12.

8. Removethenon-combustibleboardthatisshippedbetween

thereplaceandpallet.

9. Frameinreplacewithaheaderacrossthetop.

IMPORTANT:Allowfornishedfacewhensettingthedepth

oftheframe.

10. Attachthereplacetotheframing.See Figure 12.

11. Installthenon-combustibleboardacrossthetopandsidesof

thereplace.Theboardsitsonthe1/2in.surfaceontopofthe

replaceandinfrontofthestandoffs.See Figure 11.

IMPORTANT: IN ORDER TO USE SOME OPTIONAL FRONTS

YOU MUST RAISE THE FIREPLACE ON A HEARTH SO THE

BOTTOM OF THE FIREPLACE IS A MINIMUM DISTANCE

ABOVE THE TOP OF THE HEARTH EXTENSION FINISHING

MATERIAL. CHECK DECORATIVE FRONT DIMENSIONS

PRIOR TO SETTING THE HEIGHT OF THE FIREPLACE

HEARTH EXTENSION.

NON-COMBUSTIBLE

BOARD

Figure 11

Flush Mount Mantel Installation

The fireplace must extend 3/4 in. (19mm) beyond finished

wall surface when using a ush mount mantel. Refer to Figure

12 to locate nailing anges on replace sides. Mark and drill

four (4) 1/8 in. holes into replace side to mount each nailing

flange. Use eight (8) 1/2 in. hex-head screws supplied in

hardware package to attach nailing anges to replace sides.

◄

▼

▼

STAND-OFF

STAND-OFF

TOP

HEADER SHIELD

BOTTOM

HEADER SHIELD

NAIL OR OTHER SUITABLE

FASTENER

▼

Figure 12

33598-6-0115 Page 13

Finishing

Finishthewallswiththematerialofyourchoice.Figure4onpage8

showstheminimumverticalandcorrespondingmaximumhorizontal

dimensionsofmantelsorothercombustibleprojectionsabovethe

topfrontedgeofthereplace.Onlynon-combustiblematerialsmay

beusedtocoverthemetalreplaceface.

Flush Wall Installation

▼

►

▼

▼

HEADER: A DOUBLE HEADER

OR PLACING THE HEADER

VERTICALLY IS RECOMMENDED

STANDOFF 12” (305mm)

HEIGHT ABOVE TOPOF

THE FIREPLACE

FIRST 13-1/2” (343mm)

NON-COMBUSTIBLE

FINISHED WALL

TOP OF THE

FIREPLACE

Figure 14

Combustible Surround Installation

COMBUSTIBLE MANTLE

FINISHED WALL

2 X 4 HEADERS

STANDOFFS

NON-COMBUSTIBLE MA

TERIAL

13-1/2” (343mm)

NON-COMBUSTIBLE MA

TERIAL

SUPPLIED WITH FIREPLACE

Figure 15

Framing

Fireplaceframingcanbebuiltbeforeorafterthereplaceisset

inplace.Framingshouldbepositionedtoaccommodatewall

coveringandreplacefacingmaterial.Thereplaceframing

shouldbeconstructedof2x4lumberorheavier.Theframing

headersmayrestonthereplacestandoffs.Refer to Figure 13

for minimum framing dimensions.

CAUTION: MEASURE FIREPLACE DIMENSIONS AND VERIFY

FRAMING METHODS,AND WALL COVERING DETAILS BEFORE

FRAMING CONSTRUCTION BEGINS.

B

C

A

DVLL/DVTL

A36-7/8in.(937mm)

B54-1/2in.(138.4cm)

C17-1/16in.(433mm)

Figure 13

Framing dimension "A" includes a 12 in. (304 mm)

clearance for standoffs on rebox. After installing rebox

into framing, the nished wall surface must cover the

12 in. (304mm) opening above the rebox. Board provided

with replace.

ATTENTION: Ifabaseormantelisnotusedandtheapplianceis

installeddirectlyoncarpeting,tileorothercombustiblematerialother

thanwoodooring,itshallbeinstalledonametalorwoodpanel

extendingthe fullwidthanddepthof theappliance.Thevertical

dimensioninFigure 13mustbeadjustedwhenametalorwood

panelisplacedbeneaththeappliance.

CAUTION:Ifthejointsbetweenthenishedwallandthereplace

surround (top and sides) are sealed, a 300°F minimum sealant

materialmustbeused.Thesejointsarenotrequiredtobesealed.

Onlynon-combustiblematerial(using300°Fminimumadhesiveif

needed),canbeappliedasfacingtothereplacesurround.

INSTALLATION

33598-6-0115Page 14

Attention: Cold climate installation recommendation:

When installing this unit against a non-insulated exterior

wall, it is recommended that the outer walls be insulated to

conform to applicable insulation codes.

Vent Runs

Inplanningtheinstallationforthereplace,itisnecessarytoinstall

certaincomponentsbeforetheapplianceiscompletelypositioned

andinstalled.Theseincludethedirectventsystem,gaspipingfor

theapplianceandtheelectricalwiring.

Theappliancecanbemountedonanyofthefollowingsurfaces:

1. Aat,hardcombustiblesurface.

2. Araisedwoodenplatform.

3. Four(4)cornersupports.(Example:Four(4)concretemasonry

blocks.)Thesesupportsmustbepositionedsotheycontactall

four(4)perimeteredgesonthebottomoftheunitandunderthe

centerlegsupports.Twomoresupportsspacedevenlyforfront

andbackmayberequiredpendinglocalcode.

Vertical, 90° Elbow With Horizontal Termination

3” (76mm)

MINIMUM CLEARANCE

TO COMBUSTIBLES

57-3/4”

(146.7cm)

VENT CAP/THIMBLE

WALL FIRESTOP

Figure 16

IMPORTANT:

MINIMUM HEIGHT OFF THE TOP REQUIREMENTS

DVLL & DVLT -MUSTUSEa2ft.(610mm)verticalventpipeas

therstsectionBEFOREinstallingtheelbow.

Vertical, 90° Elbow To

Horizontal Out The Wall

◄

►◄

►

◄

◄

90°

ELBOW

VENT

CAP

WALL

FIRESTOP

A

PIPE LENGTH

B

C

A B C

6in. 11-3/4in.to12-3/4in.

(298mmto323mm)

4-3/4in.to6-1/4in.

(121mmto159mm)

9in. 14-1/4in.to15-3/4in.

(362mmto400mm)

7-3/4in.to9-1/4in.

(197mmto235mm)

12in. 17-1/4in.to18-3/4in.

(438mmto476mm)

10-3/4in.to12-1/4in.

(273mmto311mm)

Figure 17

VENTING FIREPLACE

33598-6-0115 Page 15

Maximum Horizontal Run For A Minimum Vertical Rise

20” (50.8 cm)

MAXIMUM

24” (609.6mm)

MINIMUM VENT

PIPE LENGTH

Figure 19

Minimum Vertical Rise For Maximum Horizontal Run

20’

(6.1M)

8’ (243.8cm)

TO TOP

OF UNIT

Figure 20

Corner Installation Vertical, 90° Elbow

To Horizontal Out The Wall

▲

►

▼

◄

►

▼

▲

►

▼

◄

◄

B

A

C

◄►

E

D

*

NOTE: YOU MUST USE A2’ (609.6mm) VERTICAL

VENT PIPE

AS YOUR FIRST SECTION BEFORE

INST

ALLING THE ELBOW.

VENT CAP

THIMBLE

WALL

FIRESTOP

*

DVLL/DVTL

A62-1/4in.

(158.1cm)

B44-1/16in.

(111.9cm)

C24-5/8in.

(62.6cm)

D88-1/16in.

(223.7cm)

E24in.

(60.9mm)

Figure 18

Note:Cornerinstallationmayrequiremoreverticalventpipe

thanjusttheminimumrequireddependingonwallthicknessand

horizontaldimension.

VENTING FIREPLACE

33598-6-0115Page 16

EXAMPLE A:

Iftheverticaldimensionfromthetopoftheunitis35ft.(10.67m),the

horizontalruntotheouterwallangemustnotexceed5ft(1.52m).

EXAMPLE B:

Iftheverticaldimensionfromthetopoftheunitis5ft.(1.52m),the

horizontalruntotheouterwallangemustnotexceed11ft.(3.35m).

Special Note: Foreach45degreeelbowinstalledinthehorizontal

run, the length of the horizontal run MUST be reduced by 18"

(45cm).Thisdoesnotapplyifthe45degreeelbowsareinstalled

ontheverticalpartoftheventsystem.Reduce3ft.(91.4cm)for

every90°elbow.

Example:Accordingtothechartthemaximumhorizontalventlength

is20ft.(6.10m)andiftwo45degreeelbowsarerequiredinthe

horizontalventitmustbereducedto17ft.(5.18m).

The maximum number of 45 degree elbows permitted per side

wallinstallationistwo.Theseelbowscanbeinstalledineitherthe

verticalorhorizontalrun.

NOTE:Therstelbowdoesnotgetcounted.

Vertical Venting

Whenventinglongstraightverticalsections,useoftheverticalvent

bafesmayberequiredforoptimalameperformance.

Toinstallverticalventbafes,alignthetwoholesonthevertical

ventbafewiththetwoholesintheuebafe.Securethevertical

ventbafewiththescrewsprovided.Repeatforbothsidesofthe

uebafe.

Figure 22

VENTING FIREPLACE

To Use the Vent Graph

1. Determinetheheightofthecenterofthehorizontalventpipe.

Usingthis dimensiononthe SidewallVentGraph, locatethe

pointitintersectswiththeslantedgraphline.

2. Fromthepointof thisintersection,drawavertical linetothe

bottomofthegraph.

3. Selecttheindicateddimension,andpositiontheunitinaccordance

withsame.

Acceptableverticalandhorizontalventrun.

(40ft.(12.19m)maximumverticaland20ft.(6.10m)maximum

horizontal)

Unacceptableverticalandhorizontalventrun.

Figure 21

33598-6-0115 Page 17

Example Of Possible Venting System Using One 90° Elbow

8 ft. (2.44 m) is listed as minimum vertical vent run with 20 ft.

(6.10m)ofmaximumhorizontalventrun.Verticaldimensionsare

basedoncenterlinetocenterlineofpipe.Horizontaldimensionsare

basedoncenterlineofpipetoexteriorofwall.

FIRE STOP AT

CEILING LEVEL

H

V

SEE GRAPH (Figure 21) FOR PERMISSIBLE

"H" AND "V" DIMENSIONS

Figure 24

Below Grade Installation

Whenitisnotpossibletomeettherequiredventterminalclearances

of12in.(305mm)abovegradelevel,asnorkelkitisrecommended.

Itallowsinstallationdepthdownto7in.(178mm)belowgradelevel.

The7in.(178mm)ismeasuredfromthecenterofthehorizontal

ventpipeasitpenetratesthroughthewall.

Ensure the sidewall venting clearances are observed. If venting

system is installed below ground, we recommend a window

well with adequate and proper drainage to be installed around

the termination area.

Typical Basement Installation

18”

(457mm)

MINIMUM

3” (76mm)

MINIMUM

COMBUSTIBLE

PROJECTION

PIPE STRAP

48”

(121.9cm)

12”

(305 mm)

ABOVE GRADE

Figure 23

VENTING FIREPLACE

33598-6-0115Page 18

Example Of Possible Venting System Using Two (2) 90° Elbows

Examplesofpossibleventingsystemsusingtwo(2)90°elbows.

VislistedasminimumverticaldimensionsandH1+H2islisted

astotalofmaximumhorizontaldimensions.Themaximumvertical

andhorizontaldistancesfortwo(2)90°elbowsasshownin Figure

25is37ft.(11.28m).

FIRE STOP AT

CEILING LEVEL

H1

H2

V

SEE GRAPH (Figure 21) FOR PERMISSIBLE

"H" AND "V" DIMENSION

NOTE: H1 AND H2 MUST BE ADDED TOGETHER TO USE

GRAPH THEN SUBTRACT 3' (91.4 cm) FOR THE SECOND

90° ELBOW

Figure 25

VENTING FIREPLACE

33598-6-0115 Page 19

VENT CAP

9” (229 mm)

MINIMUM TO SIDE WALL

Figure 27

VENTING FIREPLACE

10”

(254mm)

12”

(305mm)

A

CENTER OF FRAMING

(MINIMUM VENT)

V

CENTER

OF ELBOW

H

C

B

C

B

Figure 26

MINIMUM HOLE LOCATION DIMENSIONS FOR THROUGH THE

WALL HORIZONTAL INSTALLATIONS WITH 90 DEGREE ELBOW

OFF TOP OF FIREPLACE

Positioning the Fireplace

FIREPLACE

SERIES

HARD ELBOW DIMENSIONS

A B C

DVLL/DVTL 55-5/8in.

(141.3cm)

5in.

(127mm)

7in.

(178mm)

Determinethe exactposition ofthe applianceso thedirect vent

terminationwillbecentered(ifpossible)betweentwo(2)studs.This

willavoidanyextraframing.Allventkitpipesshouldbeassembled

ontheunitaftertheunitismovedintothenalposition.

Cutting the Hole

Afterthereplacehasbeenpositionedinitspermanentlocation,

theholethroughtheexteriorwallofthehousecanbecut.Thishole

mustbe12in.(305mm)highx10in.(254mm)widewithitscenter

linedeterminedbytheamountofverticalriseandhorizontalrunof

thetermination.See Figure 26. Whenlocatingtheholeitmustbe

notedthatthebottomofthecapmustbe12in.(305mm)abovethe

groundlevel,andtopofthecapmustbenolessthan18in.(457mm)

belowacombustibleprojection,andnocloserthan9in.(229mm)

toanywallrunningparalleltoventtermination.See Figure 27.

33598-6-0115Page 20

24”

(61 cm) MINIMUM CLEARANCE

TO COMBUSTIBLES

H1 H2

V1

Figure 28

H1 H2

V1

EXAMPLES - TOP VENT RUN

Iftotalhorizontalneedstobe8'(2.44m),thentheminimum

requiredverticalis5'(1.52m).

H=8'(+90°)=11'(equivalenthorizontal)

H=2.44m(+90°)=2.44m(equivalenthorizontal)

Fromthegraphtherequiredverticalis5'(1.52m). Figure 29

Iftotalhorizontalneedstobe10'(3.05m),thentheminimum

requiredverticalis7'(2.13m).

H=10'(90°+90°)=16'(equivalenthorizontal)

H=3.05m(90°+90°)=4.88m(equivalenthorizontal)

Fromthegraphtherequiredverticalis7'(2.13m).

This manual suits for next models

5

Table of contents