EN

III

Heavy Duty Diagnostic Tool HD I User’s Manual

TABLE OF CONTENTS

1. Introduction...................................................................................................1

2. General Information......................................................................................1

2.1 On-Board Diagnostics (OBD) II ..................................................................1

2.2 Diagnostic Trouble Codes (DTCs)..............................................................2

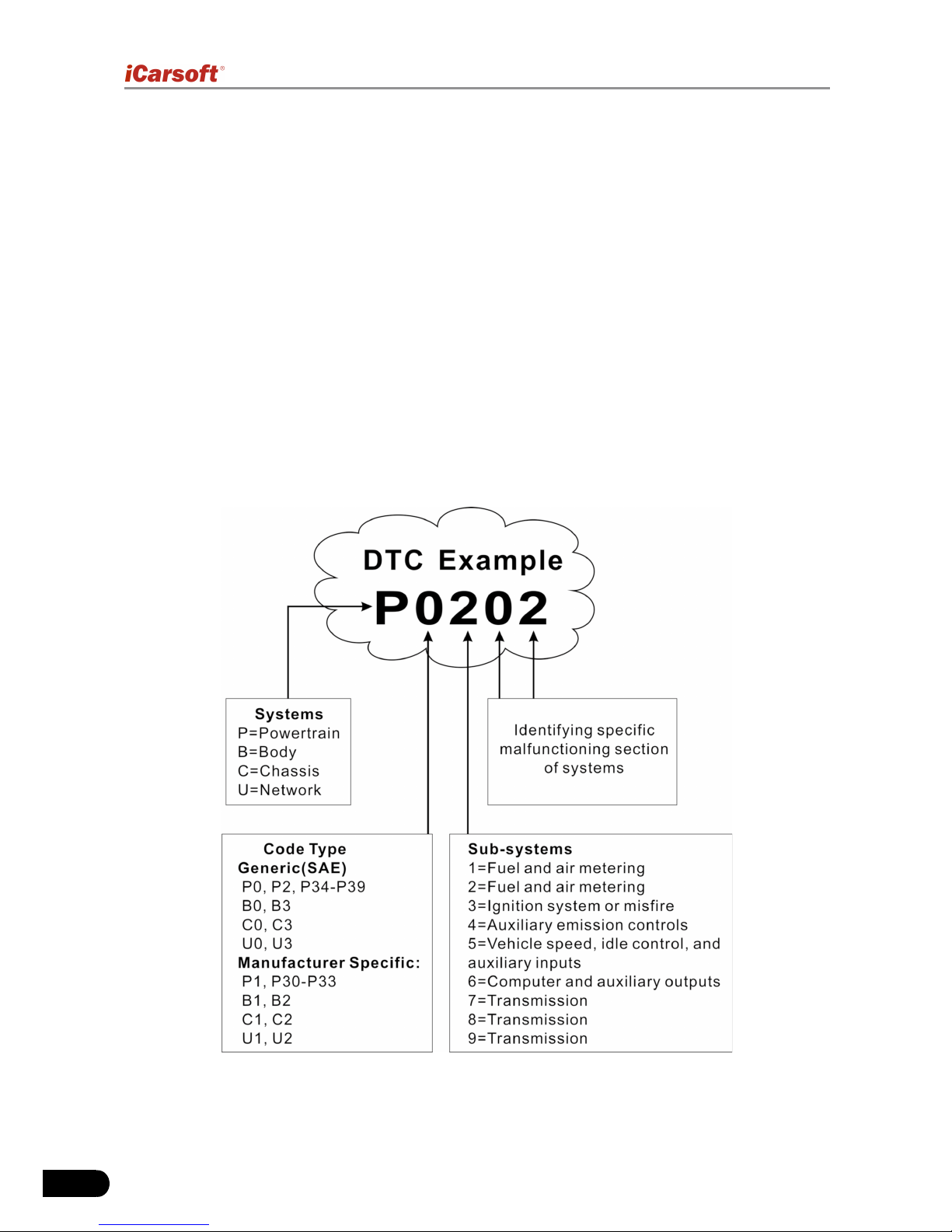

2.2.1 OBDII DTC..........................................................................................2

2.2.2 DTCs for J1587/J1708 and J1939......................................................3

2.3 J1708/J1587/J1939 ....................................................................................3

2.4 OBD II Denitions.......................................................................................4

3. Product Descriptions ....................................................................................6

3.1 Outline of HD I............................................................................................6

3.2 Specications .............................................................................................7

3.3 Accessories ................................................................................................7

3.4 Power supply..............................................................................................8

4. Connections & General Operations..............................................................9

4.1 Connections................................................................................................9

4.2 On-screen Buttons ...................................................................................10

4.3 Tool Setup.................................................................................................10

5. Diagnose ....................................................................................................11

5.1 HD OBD Diagnosing.................................................................................13

5.1.1 Read DTC.........................................................................................14

5.1.2 Clear DTC.........................................................................................14

5.1.3 Live Data...........................................................................................14

5.2 OBDII Diagnosing.....................................................................................15

5.2.1 Read Codes......................................................................................15

5.2.2 Erase Codes.....................................................................................16

5.2.3 I/M Readiness...................................................................................16

5.2.4 Data Stream......................................................................................17

5.2.5 View Freeze Frame ..........................................................................17

5.2.6 O2 sensor test ..................................................................................17

5.2.7 On-board monitor test.......................................................................17

5.2.8 Evap System.....................................................................................17

5.2.9 Vehicle Infomation ............................................................................17

6. How to Upgrade HD I .................................................................................18

6.1 HD I upgrading owchart..........................................................................18

6.2 User registration .......................................................................................18

6.3 Upgrading.................................................................................................19

7. FAQ ............................................................................................................20