Boumatic ViewPoint 9e947c User manual

ViewPoint™ Touch Screen

9e947c

www.boumatic.com

G

e

n

t

l

y

,

Q

u

i

c

k

l

y

a

n

d

C

o

m

p

l

e

t

e

l

y

™

Installation Instructions

11/2017

ISO 5707:2007(E) Conformance

This product has been tested to and meets or exceeds the pulsation system requirements

listed in section 6 of the ISO 5707 International Standard for Milking Machine Installations –

Construction and Performance.

Installation Responsibilities and Tips

Procedures in these instructions are to be performed according to all applicable codes

(state, local, and other) by the person(s) qualified (licensed if applicable) to do so –

that is:

Any welding must be done by a qualified welder.

High Voltage AC power wiring must be done by a qualified (licensed) electrician in

compliance with the latest edition of the ANSI/NFPA Standard 70, National Electrical Code,

(USA) or either LVD 73/23/EEC or EMC 89/336/EEC (Europe) and in compliance with the

local wiring codes as applicable.

Other installation, major maintenance, and service work must be done by an authorized

BouMatic dealer.

Product/system evaluation and troubleshooting to be performed by an authorized

BouMatic dealer.

Deviation from these instructions could affect product performance or create a hazardous

situation. Under no circumstances will BouMatic be responsible for any problems caused

in whole or in part by any deviation from the procedures specified in these instructions

without prior written approval from BouMatic.

Operation steps may be performed by the owner/operator once the dealer or technician

has successfully finished the product/system evaluation. The owner/operator is responsible

for properly operating, maintaining, and monitoring the product/system to ensure that it

works properly.

Close compliance with the procedures herein is essential for the owner to get maximum

performance and benefit from this product/system.

Disclaimers

No warranties are contained in these instructions. The division of responsibilities, stated

above, is a general reminder of those provisions in the applicable dealer contract and

does not change any agreement between BouMatic and the Dealer. Information in these

instructions is not all-inclusive and cannot cover all unique situations.

MySmartDairy.com SmartDairy™ ViewPoint™ Touch Screen Installation Instructions - 9E-947C-1110 © 2017 BouMatic.

9e947c

11/24/17

3

ViewPoint Touch Screen Installation Instructions

Table of Contents

1. Safety ......................................................................................................................................... 4

1.1 Reviewing Personal Safety Messages ................................................................................... 4

2. Preparation .................................................................................................................................. 4

2.1 Verifying Part and Tool Requirements: ................................................................................ 4

2.2 Required Boumatic Components ......................................................................................... 4

2.3 Dealer Supplied Parts ........................................................................................................ 4

2.4 Special Tools .................................................................................................................... 4

2.5 Specifications ................................................................................................................... 4

2.5.1 Power......................................................................................................................... 4

2.5.2 Weight........................................................................................................................... 4

2.5.3 Temperature Rating ....................................................................................................... 4

2.5.3.1 Operational ................................................................................................................ 4

2.5.3.2 Storage and Transport ................................................................................................. 4

2.5.4 Touch Screen Dimensions ............................................................................................... 4

2.6 Calibrating the touch screen ............................................................................................... 4

3. Installation .................................................................................................................................. 5

3.1 Power Supply Installation .................................................................................................. 5

3.2 Ethernet Switch Installation ............................................................................................... 5

3.3 Wall Mounted Arm Installation ............................................................................................ 7

3.4 Floor Stand Installation ...................................................................................................... 9

3.5 Spare parts list ............................................................................................................... 10

Junction box .............................................................................................................. 10

Mount Assy, Touch Screen, Wall ................................................................................... 11

Mount assy, Touch Screen, Floor .................................................................................. 12

3.6 Assembly Instructions, Touch Screen ................................................................................ 13

4. Commissioning Checklist ............................................................................................................. 14

9e947c

11/24/17

4

ViewPoint Touch Screen Installation Instructions

1. Safety

1.1 Reviewing Personal Safety

Messages

To prevent possible bodily injury, follow the safety

messages below and throughout the booklet. Safety

should be everyone’s primary concern. By follownig

these instructions the major hazards of being pinched

or falling can be avoided. Note that the owner is re-

sponsible for replacing safety labels should they be-

come illegible.

-WARNING---------------

Keep the power turned off and lockout to the power

supply until all system wiring is completed and

inspected. Failure to do so could cause serious injury

or death.

2. Preparation

2.1 Verifying Part and Tool

Requirements:

3560986 Kit, Touch Screen, wall mount

3560987 Kit, Touch Screen, floor mount

3562637 Touch Screen sp wo engrav. logo

3562638 Touch Screen sp w.engrav.logo

3562622 Packed parts, touch screen 19"

2.2 Required Boumatic

Components

•Smart Dairy Controller

•TouchPoint, Viewpoint, or ProVantage meters

•PC Configured with Smart Dairy application

2.3 Dealer Supplied Parts

Cat 5 Ethernet Cable, and Connectors

2.4 Special Tools

•Metric Wrenches (13mm)

•3/16“ Allen Wrench

•Screw Drivers - Flat Blade, #2 Phillips

•Electrical Wire Stripper

2.5 Specifications

2.5.1 Power

Power Consumption: Typical 47W, Max 60W

Voltage: +24VDC, regulated, 20 to 28 volts

2.5.2 Weight

Touch screen: 24 lbs

Wall mount arm: 10 lbs

2.5.3 Temperature Rating

2.5.3.1 Operational

•32°F to 109°F (0°C to 43°C)

2.5.3.2 Storage and Transport

• -4°F to 140°F (-20°C to 60°C)

2.5.4 Touch Screen Dimensions

•18”W x 14½”H x 4½”D

2.6 Calibrating the touch screen

•No calibration required! If the cursor accuracy

has been lost, please contact BouMatic for

service or return the touch screen.

9e947c

11/24/17

5

ViewPoint Touch Screen Installation Instructions

3. Installation

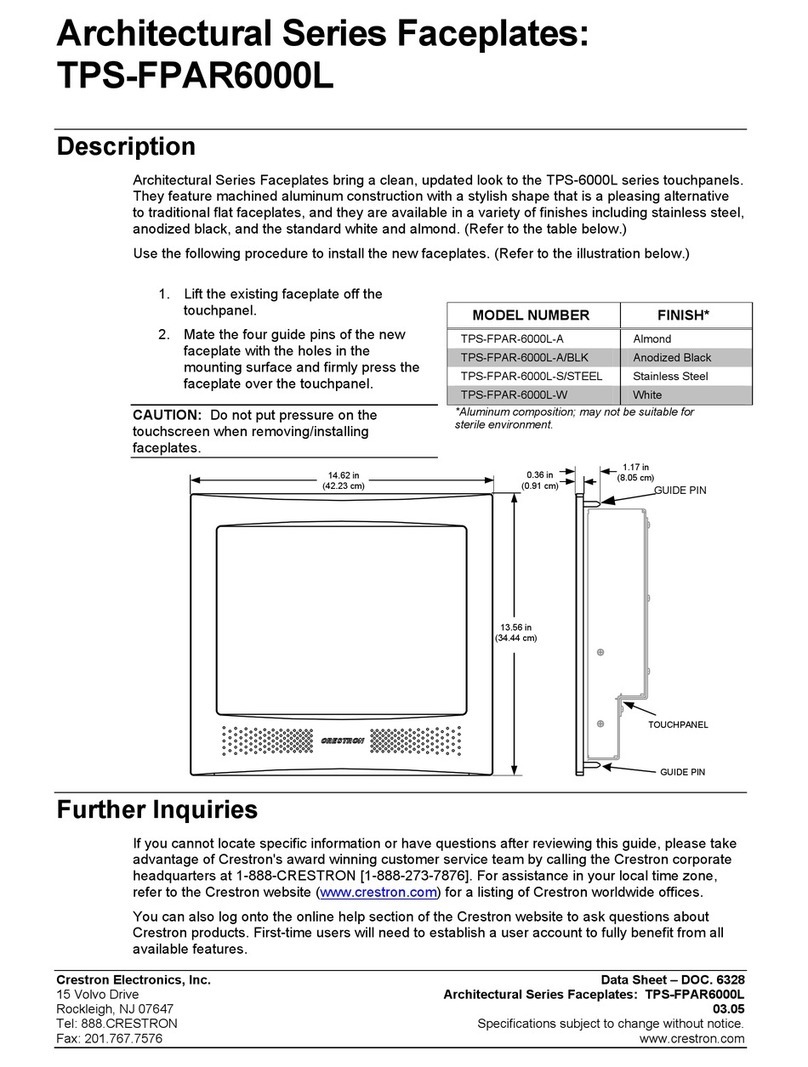

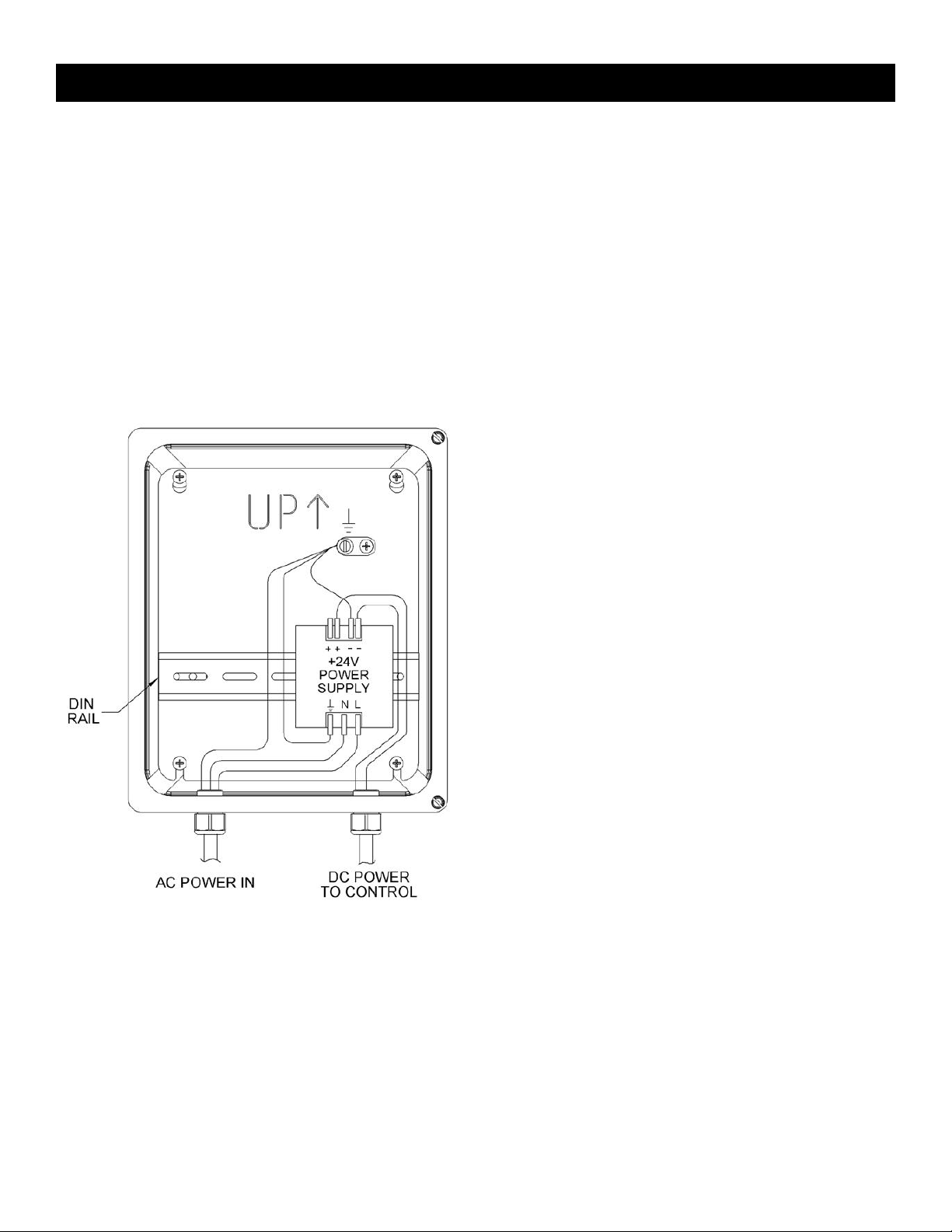

3.1 Power Supply Installation

The power supply and ethernet switch should be

mounted with the provided enclosure and located in

the parlor office near the Smart Dairy Controller. The

range for proper operation is 24VDC+/- 6.0 VDC,

(20-28 VDC). The DC common terminal of the DC

supply must be connected to earth ground, (PE) at

the DC power supply for proper operation.

To allow for voltage drops in the wiring, the DC pow-

er supplies should be adjusted to 25.5 VDC, without

any loads connected.

-NOTICE----------------------------

Do not apply DC power to the touch screen served

by the power supply until all connections have been

made between the power supply and the touch

screen. If power is applied to the touch screen before

all connections have been made, the power supply

may become overloaded, causing a circuit breaker

to trip or other power supply damage to result or

possibly causing damage to products served by the

power supply.

-NOTICE---------------------------

Main AC power supplied to DC supply enclosure may

utilize provided power cord, or for aesthetics, route

through conduit.

3.2 Ethernet Switch Installation

•Mount Ethernet switch next to DC power

supply.

•Wire connections to the power supply using

the following figures.

•Run the power and Ethernet cables from the

power supply box to the mounting location

of the touch screen arm.

•Use the supplied 2 conductor power cable PN

3559265.

•Extra strain reliefs have been provided to ac-

commodate entry to the supply enclosure.

•Use the 1/2” ID strain relief for the Ethernet

cable entry. PN 8506904 vinyl hose should

be slit open and inserted over Ethernet

cable. Insert Ethernet cable and vinyl hose

through strain relief, and hand tighten.

The AC input of the DC supply should have transient

(lightning) protection installed. The protection de-

vice should be installed as close as possible to the

DC power supply.

Figure 1: 24 VDC Power Supply

9e947c

11/24/17

6

ViewPoint Touch Screen Installation Instructions

An enclosure has been provided for the Ethernet

switch, and power supply. An Ethernet cable will be

run from the PC to the Ethernet switch. Also, an

Ethernet cable will run from the Smart Dairy

Controller to the switch. For each touch screen, an

Ethernet cable will also run to the switch.

The Ethernet switch has diagnostic lights

which indicate when the devices are

successfully connected and transmitting. The

connections can be hooked up after the

switch is wired for power and the power is

turned on.

-NOTICE-----------------------------

Maximum length for the power wires and Ethernet cable is 91m [300 ft].

Figure 3: Ethernet Switch detail

Figure 2: Power Supply wiring detail

24VDC 0VDC GND

VIEWPOINT

0VDC

VIEWPOINT

24VDC

+ - G

9e947c

11/24/17

7

ViewPoint Touch Screen Installation Instructions

3.3 Wall Mounted Arm

Installation

•Assembly Arm using the provided hardware

kit, figure 4.

Figure 4: Wall Mounting Arm Details

•Mounting the Arm: Mount the arm securely to

a wall. Fasteners must tie into the wall fram-

ing. Concrete anchors must be used if mount-

ing to a concrete wall. The holes in the mount-

ing plate are sized for a Ø3/8” [Ø10mm] bolt.

See Figure 5 for installed reference dimen-

sions.

Figure 5

•Power Supply Location: The power supply

and Ethernet switch should be mounted in-

side the provided enclosure. The power sup-

ply enclosure should then be mounted in the

parlor office near the SmartDairy controller. The

24VDC power wiring and Ethernet cable should

be routed in rigid conduit from the power sup-

ply enclosure out to the junction box in the touch

screen console. See Figure 6. Make sure to leave

extra wire for the possibility to relocate the touch

screen if necessary.

•The 24VDC power wiring and Ethernet cable

should be routed inside the arm from the power

supply enclosure out to the junction box in the

touch screen console. See figure 6.

Figure 6

•Cables installed correctly: Make sure both

the ethernet cable and the power supply

cable are ready for installation.

Figure 7: Mounting the arm on the wall

9e947c

11/24/17

8

ViewPoint Touch Screen Installation Instructions

•Install the junction box on the cover

plate for the touch screen. See Assembly

Instructions, Touch Screen for details.

Figure 8: Install the junction box

•Junction box connections: the cables

must be routed as illustrated.

Figure 9

•Mounting the power supply cable:

Mounting the 24VDC power supply cable

only in the 2 middle terminals.

Figure 10

Polarization of the 24VDC power supply unit

is indifferent because of the rectifier.

•Install the 2 ethernet cables. Make sure to

place the rubber sleeves when the nut is

tightened.

Figure 11

•Connect the ethernet cables using an

adaptor inside the junction box.

Figure 12

•Place excess cable around the junction box

before installing the console with the touch

screen.

Figure 13

9e947c

11/24/17

9

ViewPoint Touch Screen Installation Instructions

•Plug in the ethernet and the power supply

cables from the junction box.

Figure 14

•Install the touch screen and the console.

See Assembly Instructions, Touch Screen

for details.

•The wall arm mounted.

The finished installation of the wall mounted

screen.

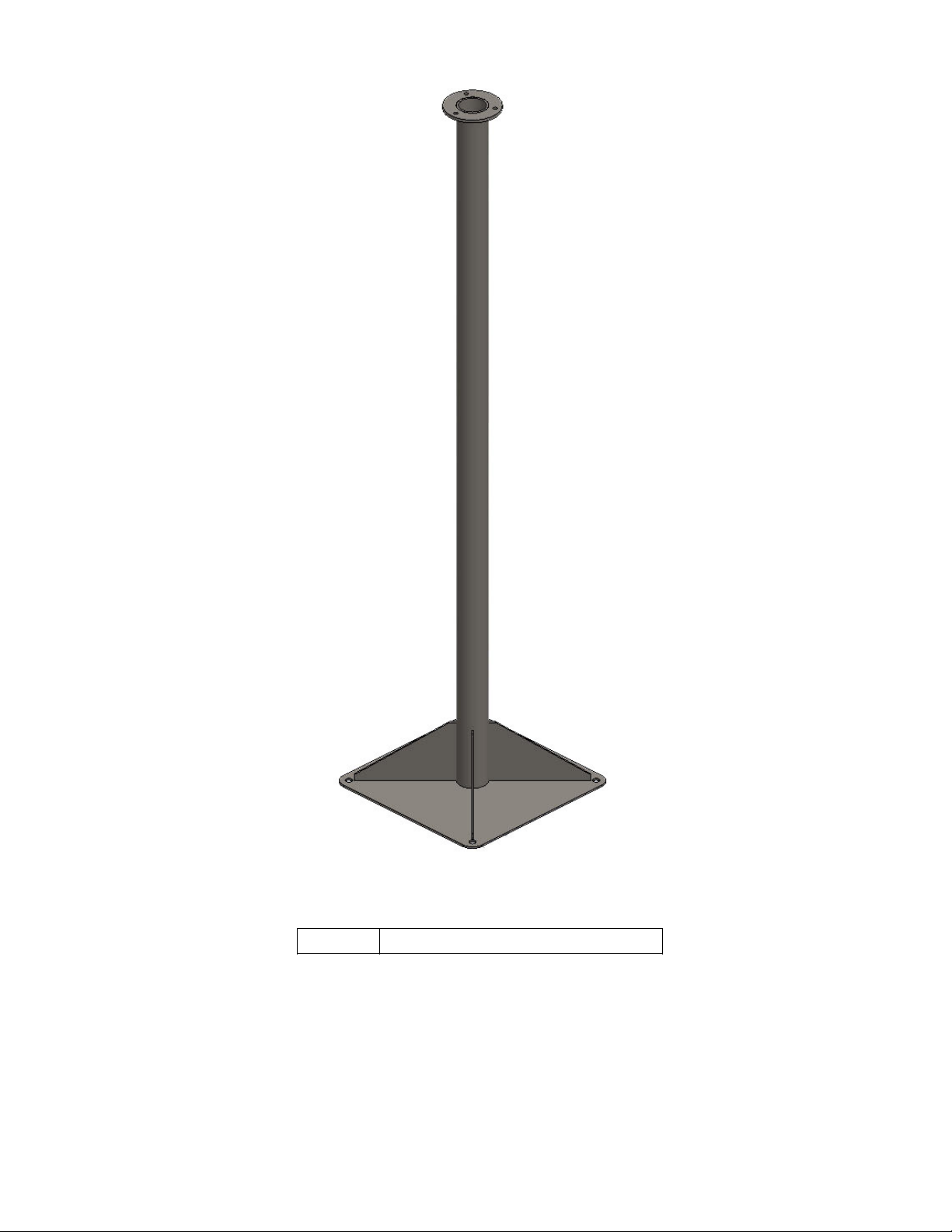

3.4 Floor Stand Installation

The floor stand installation is nearly identical to the

wall mounted arm installation with a few exceptions.

•It is recommended to mount the floor stand

near a wall where the junction box can be

mounted.

•The floor stand will need to be anchored to

the floor instead of the wall. Appropriate

concrete anchors or lag bolts will need to be

used here.

•The suggested floor stand configuration is

shown in Figure 17.

The conduit should be routed alongside, or inside,

the floor stand post.

See Assembly Instructions, Touch Screen.

Figure 17

Figure 15

Figure 16

9e947c

11/24/17

10

ViewPoint Touch Screen Installation Instructions

3.5 Spare parts list

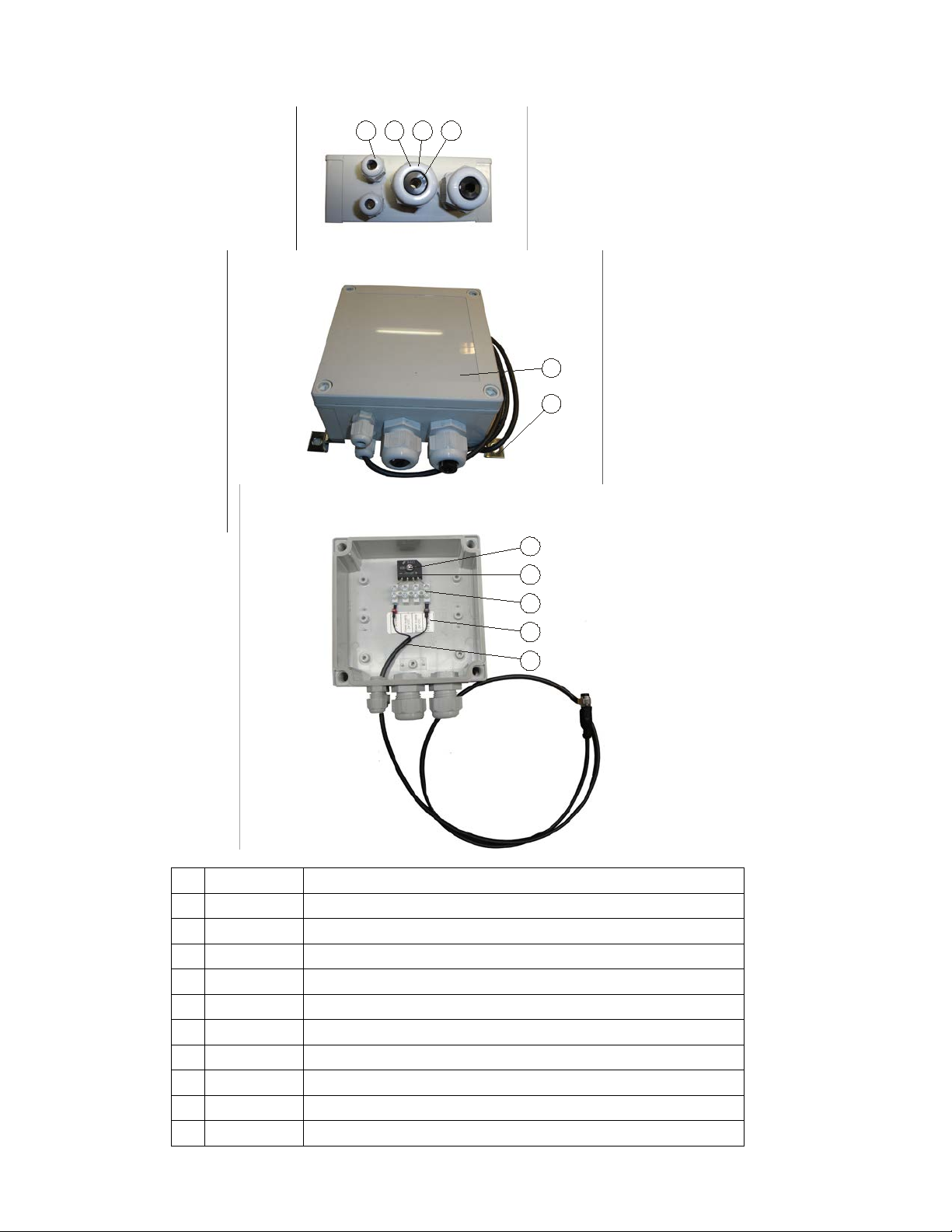

Junction box

2 3 41

6

5

10

9

8

7

11

01

601229235

SCREWED CONNECTION M12 Ø1,5-5

02

601229244

SCREWED CONNECTION M25 Ø9-18

03

601229248

UNION NUT FOR M25 SCREWED CONNECTION

04

601225645

CABLE SHEATH PVC BLACK 15X0,5 MM

05

601229057

MOUNTING BOX 130X130X60 MM INCL. LID, GREY

06

608553153

BRACKET,BOX,BENT,TOUCHSCREEN

07

691776308

Ø3,5X13 SHEET-METAL SCREW W/CROSSHEAD, DIN 7981 A2

08

601225698

RECTIFIER 600V 4-KBL 6A

09

601229500

TERMINAL 2,5 MM2 12-POLED (CASTELLATED SLEEVE)

10

608553149

LABEL,TOUCHSCREEN POWER CONNECTION

11

3562623

POWER CABLE, TOUCHSCREEN

9e947c

11/24/17

11

ViewPoint Touch Screen Installation Instructions

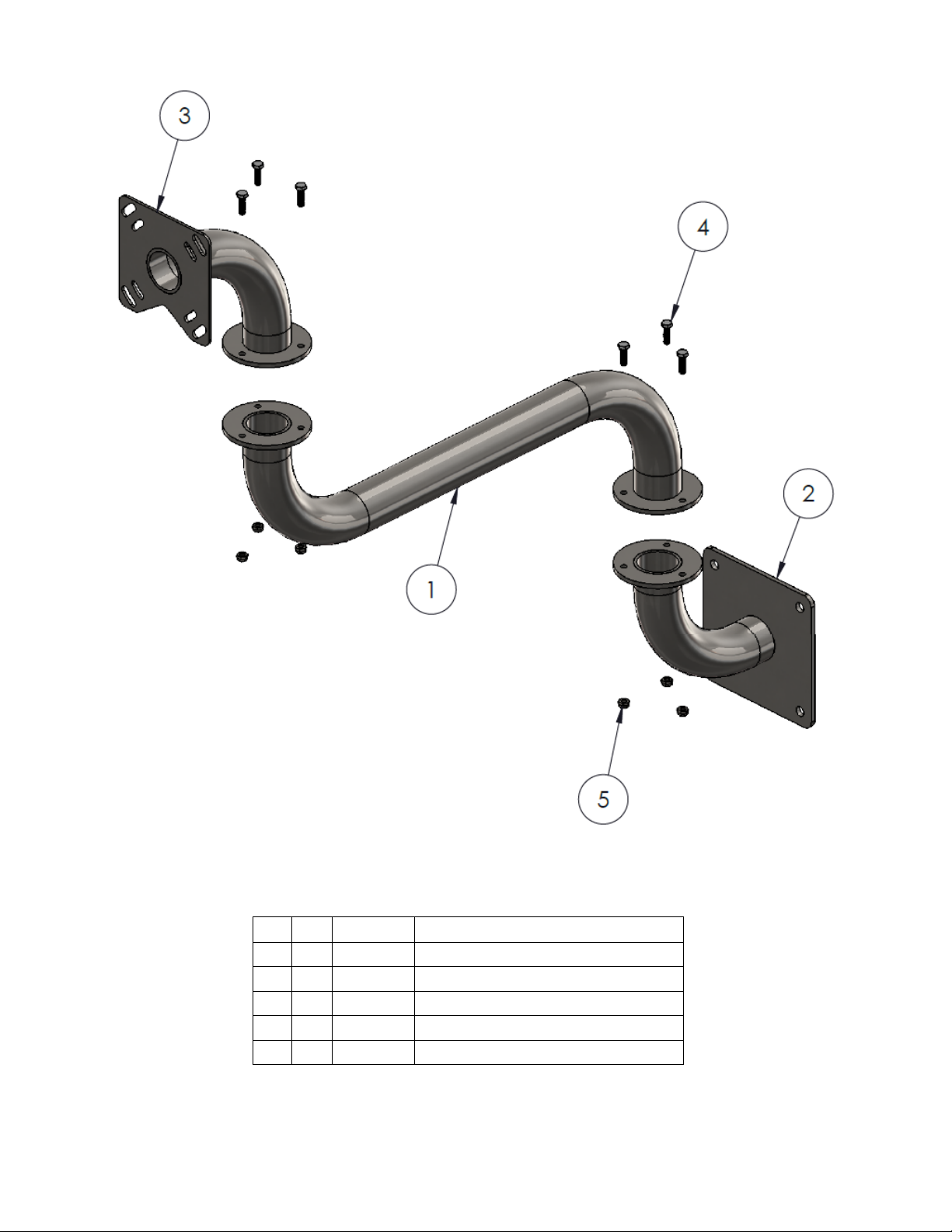

Mount Assy, Touch Screen, Wall

5 6

694070505

M6 LOCK NUT SS DIN 985-A2

4 6

690170512

M6X20 SET SCREW SS. DIN 933 A2

3 1

3562632

PIPE BEND, TOUCHSCREEN

2 1

3562634

PIPE BEND, WALL, TOUCHSCREEN

1 1

3562633

INTERMEDIATE PIPE, TOUCHSCREEN

Pos.

QTY.

Nummer

TXT

9e947c

11/24/17

12

ViewPoint Touch Screen Installation Instructions

Mount assy, Touch Screen, Floor

356098 Floor Stand, Touch Screen

A

4 X M6

4 X M6

4 X M6X16mm

4 X M6X20mm

4 X Ø6

4 X M4X10mm

B

4 X M6X16mm

3 X M6

4 X M6

3 X Ø6

4 X M4X10mm

3 X M6X20mm

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

ASSEMBLY INSTRUCTIONS,

TOUCHSCREEN

3562639

Oct 05, 2017

EHZ

EHZ

Weight: Kg

A3

SHEET 1 OF 1

SCALE:1:20

DRAWING NUMBER

DESCRIPTION

DATE

DEBURR HOLES AND SHARP

EDGES

-ALL DIMENSIONS ARE IN

MILIMETERS

SURFACES TREATMENT

APPROVED BY

ESTABLISH BY

INT.

REV.

CHANGE

This drawing is confidential and

proprietary to BouMatic. It is loaned

strictly on condition that the

information will not be used for the

benefit of any other entity.

Telefon : +45 7526 0211

Telefax : +45 7526 0396

E-mail: [email protected]

Web: www.boumatic.com

TOLERANCE UNLESS

OTHERWISE SPECIFIED

FIRST ANGLE

PROJECTION

Revision

A

8

5

6

7

E

F

Oct 11, 2017

A

CREATED IN SW.

EHZ

APPROVED DRAWING

Jernvej 2

DK 6900 Skjern

ISO

DS/EN 22768-1 m

NON

9e947c

11/24/17

14

ViewPoint Touch Screen Installation Instructions

4. Commissioning Checklist

The items below cover the steps that need to be tak-

en to ready the product for use. The checklist will be

completed by the dealer during installation and will

become part of the complete CASE document for the

installation. The second part of the CASE program

will be a verification that the system is working to

BouMatic specifications.

ACTION

CHECKMARK

Arm/Floor mount secured properly

Power supply enclosure mounted in parlor office

Power supply voltage adjusted to 25.5 VDC

Verify power and ethernet connections

Ethernet switch has power

Screen powers up

Table of contents