Symptom Probable Cause Solution

Cannot adjust tine angle to a more

aggressive position Too much draft force on the tines

Temporarily reduce ADF pressure or

stop harrowing. Adjust as required.

Return to previous settings.

Tine angle is uneven from section

to section Tine angle hydraulics are out of phase

Rephase tine angle hydraulics by

extending tine angle cylinders and hold

remote for several seconds before

readjusting.

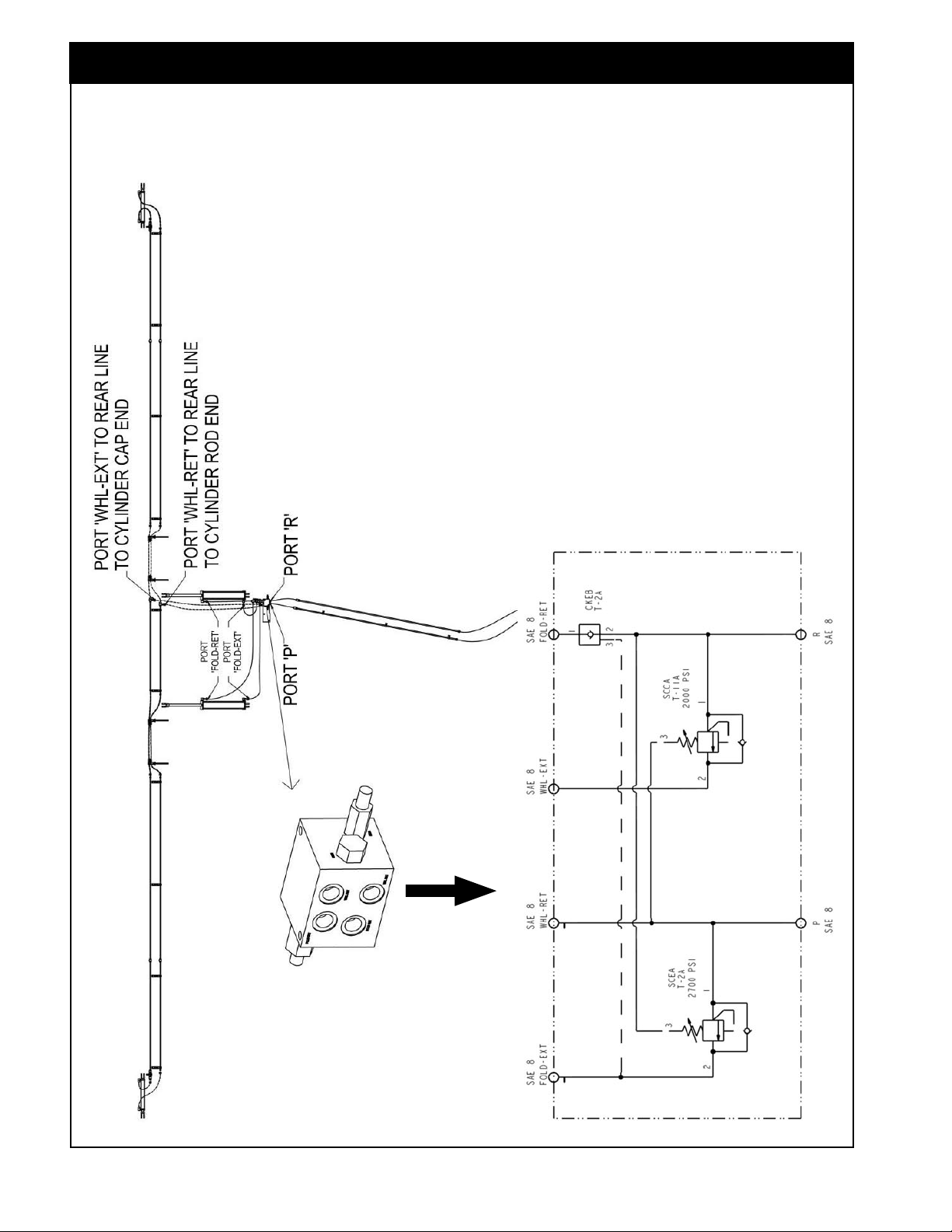

Boom wheel lock valve is closed Open boom wheel lock valve.

Sequence valve is not adjusted properly See section 5.2.1 for adjustment

instructions

Transport lock pins are still in place Remove transport lock pins

Sequence valve is not adjusted properly See section 5.2.1 for adjustment

instructions

Wing booms are too far forward

compared to the cart.

Drive forward until boom will begin to

fold down. If auto-fold arms come out

of latches, tip boom down only slightly

then drive backward before continuing

to unfold.

Auto-fold lataches do not engage

over the auto-fold arms when

putting unit into field position

Auto-fold arm is set at improper angle

Adjust the angle by adding or removing

shim plate behind the arm pivot

mounting plate.

Auto-fold arms become

disengaged when adjusting the

main transport lift

The transport latches will disengage auto-

fold arms when wings are lifted.

Move the transport latch cable from the

bottom hole to the top hole on the

center boom prior to operaton. Refer to

section 4.10.3.

Cable in windrow position. Move cable position. Refer to section

4.10.3.

Excessive stretch in cable. Adjust cable length.

Transport fold or unfold happens

out of sequence

Boom will not fold down out of

transport position

Auto-fold arms do not disengage

when put into transport position