9000 Series Air SeederService & Maintenance

10.2

10.3.7 Load/Unload Conveyor ...............................................................................................10.27

10.3.7.1 Conveyor Maintenance Schedule.......................................................................10.27

10.3.7.1.1 Initial Start-Up Servicing ...........................................................................10.27

10.3.7.1.2 8 Hours or Daily ........................................................................................10.27

10.3.7.1.3 40 Hours or Weekly ..................................................................................10.27

10.3.7.1.4 200 Hours or Annually ..............................................................................10.27

10.3.7.2 Conveyor Front Support Saddle Adjustments.....................................................10.28

10.3.7.3 Conveyor Rear Support Saddle Adjustments .....................................................10.28

10.3.7.4 Conveyor Belt Maintenance................................................................................10.29

10.3.7.4.1 Standard Conveyors .................................................................................10.30

10.3.7.4.1.1 Belt Tension Adjustment..................................................................10.30

10.3.7.4.1.2 Belt Alignment (Standard Conveyors).............................................10.32

10.3.7.4.1.3 Conveyor Belt Replacement (Standard) .........................................10.34

10.3.7.4.2 Folding Conveyors....................................................................................10.36

10.3.7.4.2.1 Belt Tension Adjustment..................................................................10.36

10.3.7.4.2.2 Belt Alignment (Folding Conveyors)................................................10.38

10.3.7.4.2.3 Conveyor Belt Replacement (Folding)............................................10.40

10.3.7.4.3 Belt Relacing.............................................................................................10.42

10.3.8 Metering Auger Care...................................................................................................10.43

10.3.8.1 Metering Auger Removal ....................................................................................10.44

10.3.8.1.1 Removing Auger .......................................................................................10.44

10.3.8.1.2 Replacing an Auger ..................................................................................10.45

10.3.8.2 LinerandOriceRemoval ..................................................................................10.46

10.3.8.2.1 RemovingLinerandOrice ......................................................................10.46

10.3.8.2.2 ReplacingLinerorOrice .........................................................................10.46

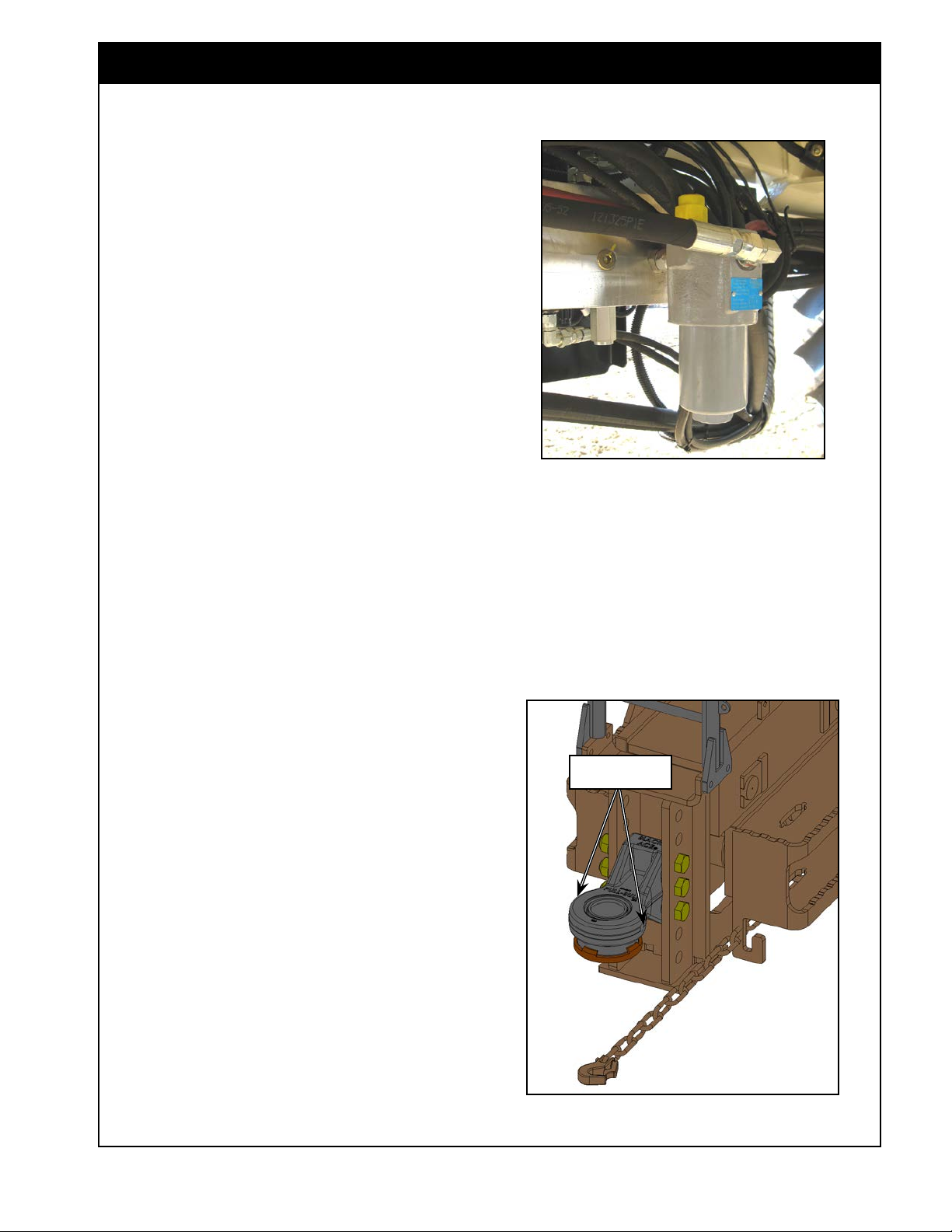

10.3.9 Tank Lid Adjustment....................................................................................................10.47

10.3.9.1 Setting the Tank Lid Pre-Load ............................................................................10.47

10.3.10 Tank Lid Seal Replacement ........................................................................................10.48

10.3.11 Running Gear..............................................................................................................10.50

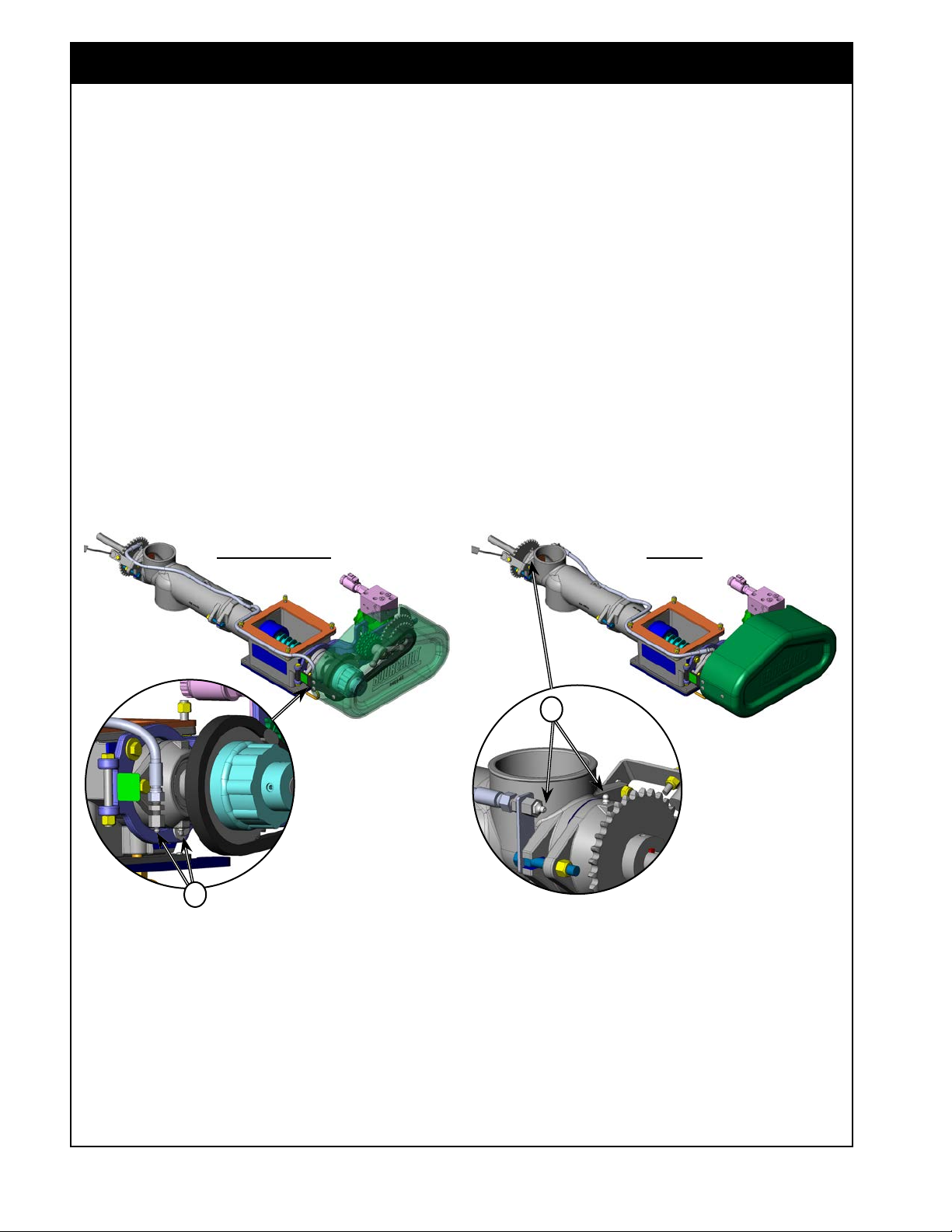

10.3.11.1 Hub Assembly.....................................................................................................10.50

10.3.11.2 Front and Rear Tires Replacement ....................................................................10.51

10.3.11.3 Rear Dual Tires Replacement ............................................................................10.52

10.3.11.4 Front Wheel Toe-In Adjust ..................................................................................10.56

10.3.12 Bolted-On Rear Axle ...................................................................................................10.57

10.3.13 ASC Primary Elbow Cleanup......................................................................................10.58

10.3.14 ASC Valve Seal Replacement and Calibration ..........................................................10.59