BOXER AGRI HV132 User manual

WOOD CHIPPER

HV132 · HV157 · HV233 · HV285

USER MANUAL

P. de Heus en Zonen Greup B.V.

Stougjesdijk 153

3271 KB Mijnsheerenland

The Netherlands

Tel: +31 (0) 18 66 12 333

E-mail: info@boxeragri.nl

WOOD CHIPPER | User manual May 2021

EN | ENGLISH

TRANSLATION OF THE ORIGINAL MANUAL

CONTENT

May 2021WOOD CHIPPER | User manual

1. INTRODUCTION .......................................................................................................................... 4

2. SAFETY ....................................................................................................................................... 5

2.1 Safety symbol ....................................................................................................................................... 5

2.2 Safety instructions................................................................................................................................ 6

2.3 Safety guidelines .................................................................................................................................. 7

2.4 Safety decals......................................................................................................................................... 8

2.4.1 Safety decal place ................................................................................................................. 8

2.5 Preparation......................................................................................................................................... 11

2.6 Safe maintenance............................................................................................................................... 11

2.6.1 Maintenance intervals ........................................................................................................ 12

2.7 Operational safety.............................................................................................................................. 13

2.8 Hydraulic safety.................................................................................................................................. 14

2.9 Storage safety..................................................................................................................................... 14

2.10 Transport safety ................................................................................................................................. 14

3. INSTALLATION .......................................................................................................................... 15

4. OPERATIONAL SAFETY .............................................................................................................. 26

4.1 For the new user or owner................................................................................................................. 27

4.2 First use .............................................................................................................................................. 27

4.3 Checklist before use ........................................................................................................................... 27

4.4 Length of the power take-off ............................................................................................................. 28

4.5 Machine commissioning..................................................................................................................... 29

4.6 Transport............................................................................................................................................ 35

5. SPECIFICATIONS ....................................................................................................................... 36

5.1 Torque ................................................................................................................................................ 36

5.2 Torque for hydraulic fittings............................................................................................................... 38

6. TROUBLESHOOTING ................................................................................................................. 39

7. PARTS DRAWINGS .................................................................................................................... 40

8. CE DECLARATION OF CONFORMITY .......................................................................................... 52

Page 4/52

WOOD CHIPPER | User manual May 2021

1. INTRODUCTION

Congratulations with your choice of a 3-point wood chipper to carry out your work. This machine has been designed

and manufactured to meet the requirements of the demanding wood and landscape industries.

A safe, efficient and problem-free operation of your wood chipper requires that you and everybody who uses or

maintains the wood chipper reads and understands the safety, operation, maintenance and troubleshooting

information in this operating manual.

This manual discusses the 3-point wood chipper HV132/HV157/HV233/HV285. Use the table of contents as a

guideline to find the required information.

Keep this manual close so that you can frequently refer to it and to pass it onto new users or owners.

ATTENTION: The left, right, forwards and revers as specified in this manual are determined when you are sitting

in the driver's seat of the tractor and you are looking towards the driving direction.

Page 5/52

May 2021WOOD CHIPPER | User manual

2. SAFETY

2.1 Safety symbol

This safety symbol means: CAUTION! ATTENTION IMPORTANT FOR YOUR SAFETY!

The safety symbol highlights important safety messages on the Boxer wood chipper

and in the manual. If you see this symbol, take the possibility of physical injury or

death into account. Observe the instructions given in the safety message.

• Accidents can lead to injury or death.

•Accidents cost money.

• Accidents can be prevented.

PAY ATTENTION WORDS

Pay attention to the HAZARD, WARNING and ATTENTION words in the safety messages. The suitable pay attention

word for each message was selected based on the following guidelines:

HAZARD – Indicates an immediate dangerous situation that can lead to serious injury or death if not prevented. This

pay attention word may only be used for the most extreme situations that usually occur in relation to machine parts

that cannot be screened off due to functional reasons.

WARNING – Indicates a possible dangerous situation that can lead to serious injury or death if not prevented. This

concerns, for example, hazards that people are exposed to when covers are removed. This may also be related to

unsafe practices.

ATTENTION – Indicates a possible dangerous situation that can lead to slight or moderate injury or death if not

prevented. This may also be related to unsafe practices.

Page 6/52

WOOD CHIPPER | User manual May 2021

2.2 Safety instructions

You are responsible for the safe operation and maintenance of your 3-point wood chipper. You must make sure you

and everybody who uses, maintain or work with the wood chipper are aware of the procedures for use and

maintenance and the related safety information in this manual.

This manual will guide you step-by-step through your working day and will tell you which safety instructions you

must observe.

Make sure everybody that uses this machine is aware of the recommended use and maintenance procedures and

observe all precautions. Most accidents can be prevented. If you ignore sound safety measures, you run the risk of

being injured or, worse, death.

• Owners of the wood chipper must give operating instructions to users and/or employees before they are

allowed to use the machine. These instructions must be repeated at least once a year.

• Safe use is of utmost importance. The user is responsible for reading, understanding and following ALL safety

and operating instructions in the manual. Most accidents can be prevented.

• A person who has not read and understood all use and safety instructions is not qualified to use the machine.

An untrained user exposes himself/herself and people around him/her to possible serious injury or death.

• Do not adjust the machine in anyway. An unauthorized modification may have a negative impact on its

operation or safety and may influence the equipment's service life.

• Think in terms of Safety! Work Safely!

• Read and understand the manual and all safety messages before using,

maintaining, changing or cleaning the 3-point wood chipper.

• A fire-extinguisher and first aid kit must be within arm’s reach. Make sure

people know how to use them.

• Do not allow anybody to hitch a ride on the machine.

• Use the suitable personal protective equipment. This list

includes the following but is not limited to this:

- A safety helmet

- Safety shoes with anti-slip soles

- Safety goggles or face shield

-Work gloves

- Protective clothing for all types of weather conditions

- Hearing protection

- Half face mask or dust mask

• Put all covers in place and make sure they are fastened

properly before you start.

• Use suitable hearing protection if you are exposed long term

to excessive noise.

• Switch off the machine and, next, switch off the engine of the tractor, remove the ignition key and put it in your

pocket, engage the parking brake and wait until all moving parts have come to a complete standstill before

performing maintenance, adjustment, repair or uncoupling activities.

• Make sure no people and certainly no small children are in the vicinity before you use the machine.

• Study the safety information on an annual basis with all staff who will use or maintain the wood chipper.

Page 7/52

May 2021WOOD CHIPPER | User manual

2.3 Safety guidelines

1. Strictly follow all safety instructions. Safety is everybody's responsibility. By following the recommended

procedures, a safe working environment is offered to all users and bystanders. To prevent physical injury or

death, you and those who work with you must follow the following precautions.

2. To provide a more complete picture, specific photos or figures in this manual may show a part regarding which

the guard or protective cover has been removed. The machine may, however, never be used under those

conditions. All protective covers and guards must be in their places. If a protective cover has been removed, it

must be put back before the machine can again be used.

3. Replace all the illegible or missing safety or instruction signs. The locations where you can find such safety signs

are indicated in this manual.

4. Never drink alcohol or take medication that may negatively affect your alertness or coordination when you use

the machine. Consult your general practitioner if you take prescription medication.

5. Young children may never work with this machine. People may only use or install the machine if they have read

this manual and correctly understand the operation and safety instructions. Study the safety instructions with

all users on an annual basis.

6. This machine is dangerous for children and people who are not familiar with its operation. The user must be a

responsible, correctly trained and physically capable person who is familiar with machines and trained in the

use of this equipment. If elderly people are also working, physical impairments must be taken into

consideration.

7. Never exceed the limits of a machine. If there are any doubts about whether the machine can tackle a job or

can tackle it safely, do not try it.

8. Do not adjust the machine in anyway. Every unauthorized adjustment can result in serious injury or death and

negatively impact the operation and service life of the equipment.

9. In addition to the design and configuration of this machine including the safety labels and facilities, limiting

hazards and preventing accidents will depend on the awareness, carefulness and correct training of personnel

who is involved in the operation, transport, maintenance and storage of the machine. See also the safety and

use instructions in each of the relevant chapters of the motor and machine manuals. Pay careful attention to

the safety signs on the tractor and the machine.

Page 8/52

WOOD CHIPPER | User manual May 2021

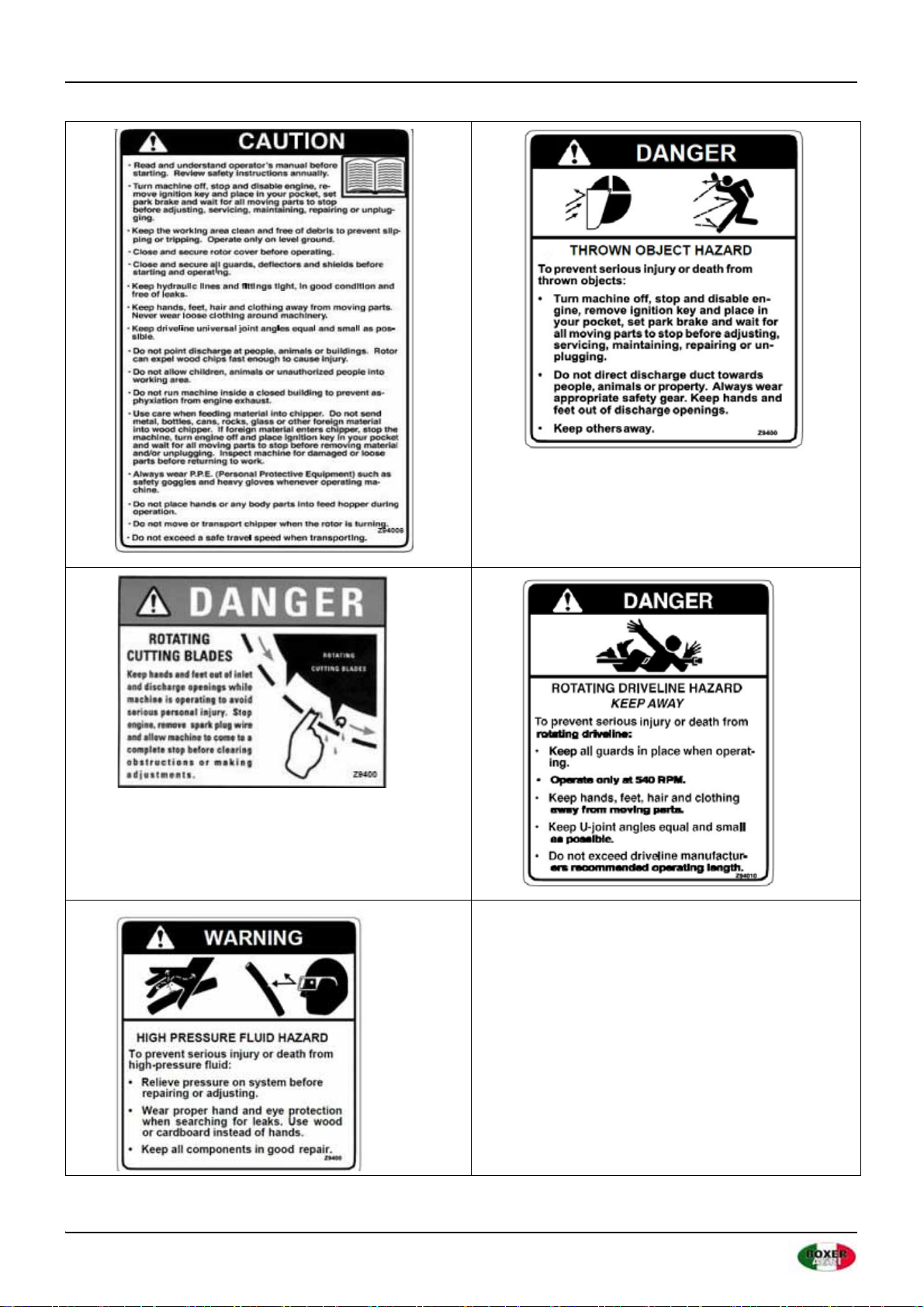

2.4 Safety decals

• Make sure all safety decals are clean and legible.

• Replace all damaged or missing decals.

• Replaced parts with safety decals must display the relevant safety decals.

• Item numbers can be found on the safety decals specified in chapter 3 on the right at the bottom. Use these

item numbers when you order replacement parts.

• Safety decals can be obtained from your dealer or importer.

How to affix safety decals:

1. Make sure the place where you want to affix them is clean and dry.

2. Make sure the temperature is higher than 10 °C (50 °F).

3. Determine the exact place before removing the paper on the rear side.

4. Remove the smallest section of the paper on the rear side.

5. Keep the decal at the required place and carefully press on the smallest sticky part.

6. Remove the rest of the paper and careful smooth the rest of the decal until it is in the right place. Small air

bubbles can be pricked with a needle and smoothed using a bit of the backing paper.

2.4.1 Safety decal place

The safety symbol types and their locations on the machine are shown in the following figures. Good safety requires

that you become familiar with the various safety alerts and the warning type and area or a specific function related

to that area where you need to bear safety in mind.

Page 9/52

May 2021WOOD CHIPPER | User manual

REMEMBER – If the safety alert is damaged, removed or illegible or parts have been replaced without safety alerts,

new decals must be affixed. New safety decals can be obtained from your authorized dealer.

Page 10/52

WOOD CHIPPER | User manual May 2021

AD

BE

C

Page 11/52

May 2021WOOD CHIPPER | User manual

2.5 Preparation

1. Never commission the machine before you have read and fully

understood this manual, the manual of the tractor and all safety

messages and decals on the tractor and the machine.

2. Personal protective equipment including a safety helmet,

safety goggles, safety shoes and gloves are recommended

when mounting, installing, operating, adjusting maintaining,

repairing, disassembling cleaning or moving the machine. Avoid

long hair, loose clothing or jewelry in the vicinity of moving

parts.

3. Long-term exposure to loud noise can lead to permanent

hearing damage! Powerful machines with or without

connected equipment will often be sufficiently loud to cause

permanent or partial hearing loss.

We recommend using hearing protection since the noise from

the operating panel is higher than 80 dB. Noise higher than 85 dB can lead to hearing loss in the long term.

Noise levels of 90 dB or more may cause permanent and full hearing loss in the long term.

REMARK: Hearing loss due to loud noises (of tractors, chainsaws, radios and other similar sources near your

ears) is cumulative during your life without a chance of being naturally restored.

4. Remove all obstacles that can become hooked on or become stuck in the work area since they may lead to

injury or damage.

5. Only use the machine during daylight or in good artificial light.

6. Always check in advance whether the machine has been correctly mounted, has been adjusted and is in a good

condition.

7. Make sure in advance that all safety protections and symbols have been installed correctly and are in good

condition.

2.6 Safe maintenance

1. Good maintenance is your responsibility. Poor maintenance is inviting problems.

2. Keep the service area clean and dry.

3. Make sure power points and tools have been grounded in the correct manner.

4. Make sure there is always sufficient light.

5. Make sure there is sufficient ventilation. Never start an engine in a closed space. Exhaust gases may lead to

suffocation.

6. Before you perform maintenance or installation work on the machine, switch off the engine, engage the brake

and switch off the fuel supply.

7. Never work underneath the machine unless it is securely raised.

8. Always use personal protective equipment such as eye, hand and hearing protectors when performing service

or maintenance work. Use heavy-duty or leather gloves when handling blades.

9. If replacement parts are required for regular maintenance and service, original factory parts must be used to

make sure your machine meets the original specifications. The manufacturer cannot be held responsible for

injury or damage caused by the use of non-approved parts and/or accessories.

Page 12/52

WOOD CHIPPER | User manual May 2021

10. A fire-extinguisher and first aid kit must be within arm’s

reach when performing maintenance and servicing the

machine.

11. Tighten all bolts regularly. Also check regularly whether

all electrical and fuel connections are fastened correctly.

12. When completing the maintenance or service work, make

sure all safety protections and parts are installed before

commissioning the machine.

2.6.1 Maintenance intervals

8 hour or daily

Lubricate the power take-off lubrication points.

40 hour or weekly

Lubricate the power take-off telescopic part.

Check the sharpness of the rotor/stationary blades.

Disassemble, sharpen or replace if required.

100 hours

Lubricate the roller bearings.

Front rotor bearing Rear rotor bearing

Power take-off lubrication points

Telescopic part

Page 13/52

May 2021WOOD CHIPPER | User manual

2.7 Operational safety

1. It is important that you read and observe the safety decals on the wood chipper. Clean or replace safety decals

that are difficult to read or understand in view of your safety and that of others. You, the user, are responsible

for the safe use of this machine.

2. Everything with moving parts may represent a hazard. A careful, safety-focused user who recognizes possible

hazards and is committed to safety practices is best. The manufacturer has designed this wood chipper to be

used with all safety facilities installed correctly to limit the chances of accidents occurring to a minimum. Read

this manual to determine whether all safety facilities are present.

3. Close and fasten the rotor cover before using the machine.

4. Close and fasten all covers, deflectors and protection covers or guards before starting and using the machine.

5. Read and understand the manual before starting the machine. Study the safety instructions every year.

6. Personal protective equipment including a safety helmet, safety goggles, safety

shoes and gloves are recommended when assembling, positioning, using,

changing, maintaining, repairing, removing, cleaning or moving the machine.

Avoid long hair, loose clothing or jewelry in the vicinity of moving parts.

7. Make sure hydraulic lines and fittings are fixed securely, in good condition and

leak-free.

8. Keep limbs away from moving parts during the assembly, positioning, using,

maintenance, repairing or moving or when removing obstructions.

9. Switch off the engine, stop and switch off the engine, take the key out of the

ignition and put it in your pocket, engage the park brake and wait until all

moving parts come to a standstill before performing maintenance, changes or repairs or removing

obstructions.

10. Do not leave the machine running in a closed building to prevent suffocation by exhaust gases.

11. Be careful when you put material in the wood chipper. Do not insert metal, bottles, tins, stones, glass or other

foreign material in the wood chipper. If material that should not be there ends in the wood chipper, you must

stop the machine, switch off the engine, put the ignition key in your pocket and wait until all moving parts have

stopped running before you remove any material and/or obstructions. Check the machine for damage or loose

parts before resuming your work.

12. Never drink alcohol or take medication that may impede your alertness or coordination during the use of this

machine. Consult your general practitioner if you take prescription medication.

13. Do not allow anybody to hitch a ride on the machine. There is no safe place for passengers.

14. Never allow children or unauthorized people to be around the machine or 'work' with it.

15. Never reach into the rotor or the openings of the feed hopper while the engine is running. Position the

protective covers and guards and secure them in place before starting the engine.

16. Keep the workplace clean and free from waste to prevent stumbling. Only work on level ground.

17. Do not point the discharge hopper towards people, animals or buildings. The rotor can eject wood chips so fast

that injury is caused.

18. Do not move or transport the wood chipper while the rotor is turning and the machine is operational.

19. Do not exceed the safe driving speed during transport.

Page 14/52

WOOD CHIPPER | User manual May 2021

2.8 Hydraulic safety

1. Make sure all parts of the hydraulic system are in good condition and clean.

2. Before you put the system under pressure, make sure all parts are fastened correctly and all lines, hoses and

couplers are undamaged.

3. Do not try to repair lines, fittings or hoses provisionally using tape, clamps or binding agents. The hydraulic

system works under extremely high pressure. Such repairs will break suddenly and will therefore lead to a

dangerous and unsafe situation.

4. Use suitable hand and face protection when searching for a leak in the

hydraulic system. Use a piece of wood or cardboard as a backstop

instead of your hands to identify and isolate a leak.

5. If you are injured by a concentrated jet of hydraulic liquid under high

pressure, you must immediately seek medical assistance. Hydraulic

liquid that penetrates the skin may lead to an infection or a toxic

reaction.

6. Remove the pressure from the hydraulic system before performing

maintenance or work on the system.

2.9 Storage safety

1. Store the machine away from the vicinity of human activities.

2. Do not allow children to play on or around the stored machine.

3. Store the machine in a dry and flat location. Support the frame using, for example, wooden blocks if required.

2.10 Transport safety

1. Comply with all national, provincial and local legislation in relation to the safety and transport of machines on

public roads.

2. Check whether all lights, reflectors and other lighting facilities are installed and in good working order.

3. Do not exceed a safe driving speed. Slow down on rough terrain and when taking bends.

4. Fold up the filling funnel before moving or transporting the wood chipper.

5. Make sure the machine has been fastened properly to the tractor and there is a locking pin through the

mounting pins.

6. Do not drink alcohol if you have to drive.

7. Be a safe, thoughtful and considerate driver. Always give priority to oncoming vehicles under all conditions

such as narrow bridges, intersections, etc. Pay careful attention to other road users.

8. Never transport people or animals on the machine.

Page 15/52

May 2021WOOD CHIPPER | User manual

3. INSTALLATION

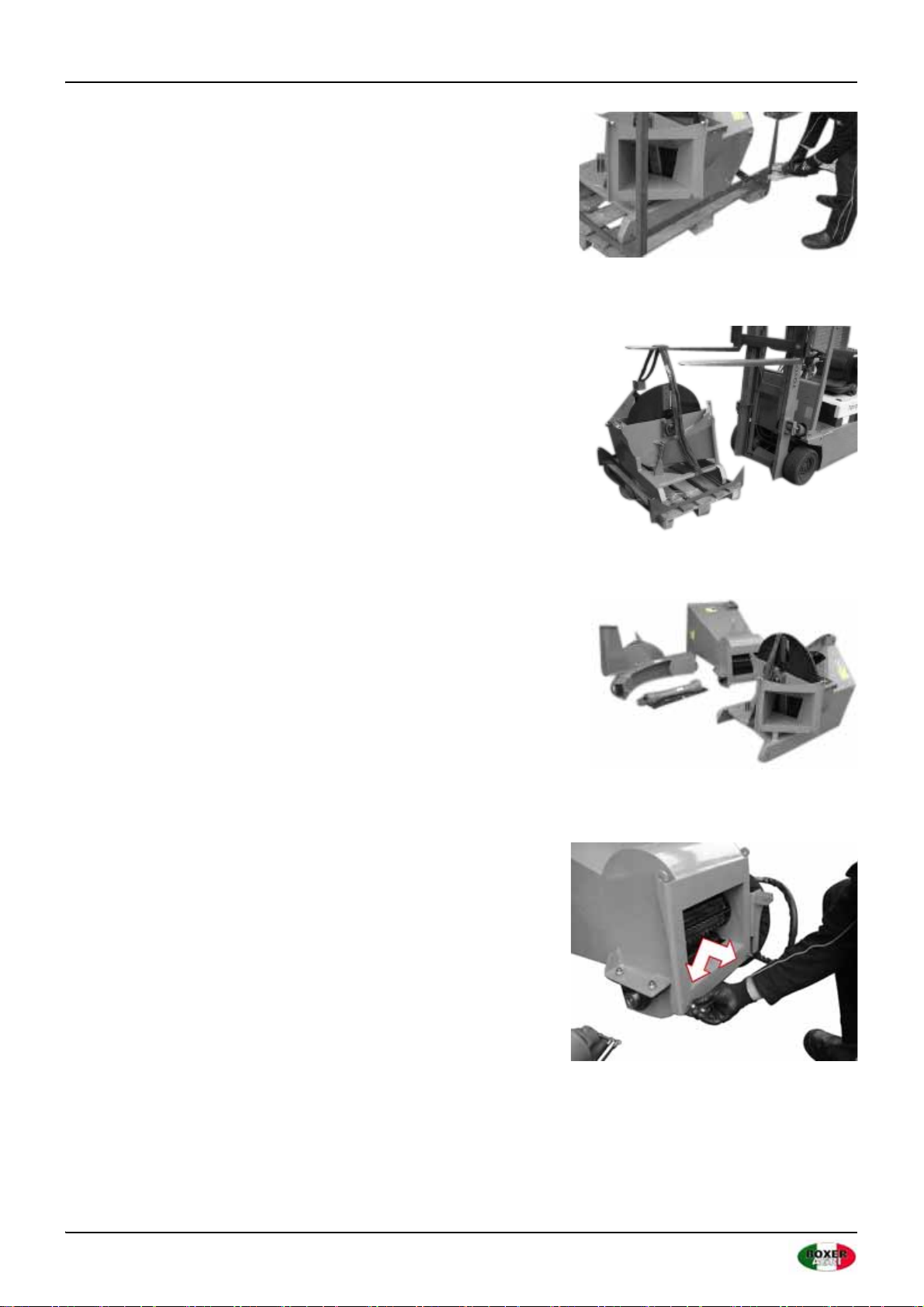

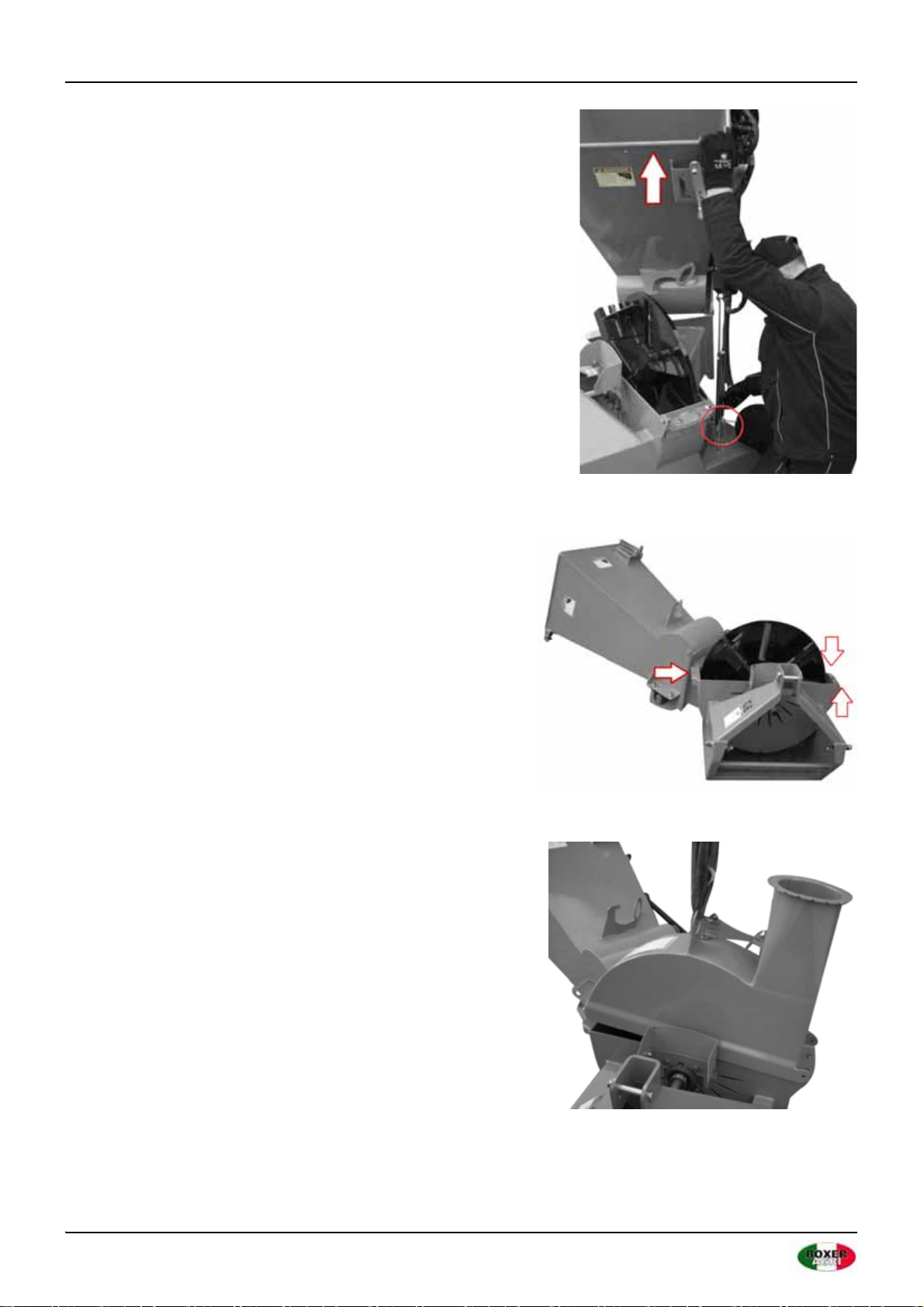

The machine is delivered in transport configuration from the

factory. Always use tools, equipment and forklift trucks with

suitable dimensions and power for the installation. Always

make sure there are two persons present to lift, move and

assemble the machine.

When the machine is delivered, follow these instructions

during the preparation:

1. Make sure there are no people, animals and especially

children in the area.

2. Use a forklift truck to lift or move the pallet/machine.

Keep the center of gravity near to the ground.

3. Move the machine to the location where you want to

install the machine. Make sure there is sufficient space

around the machine.

4. Cut through the fastening straps.

5. Lift the top part (feed hopper) and carefully move it to one

side by using a forklift truck.

6. Position the individual components next to the machine.

7. Remove the protective film/packaging from all

components.

Transport fastening

straps and crate

Lifting the feed hopper

Gather all components

Page 16/52

WOOD CHIPPER | User manual May 2021

8. Remove the steel frame with an angle grinder.

9. Use a forklift truck to hoist and lift the main component.

10. Remove the pallet and place the machine on the floor.

11. Remove both screws on the rear side of the feed hopper

and the hopper for the main components.

Remove the steel frame

Lift the main component

Parts without a pallet and packaging

Remove the screws

from the feed hopper

Page 17/52

May 2021WOOD CHIPPER | User manual

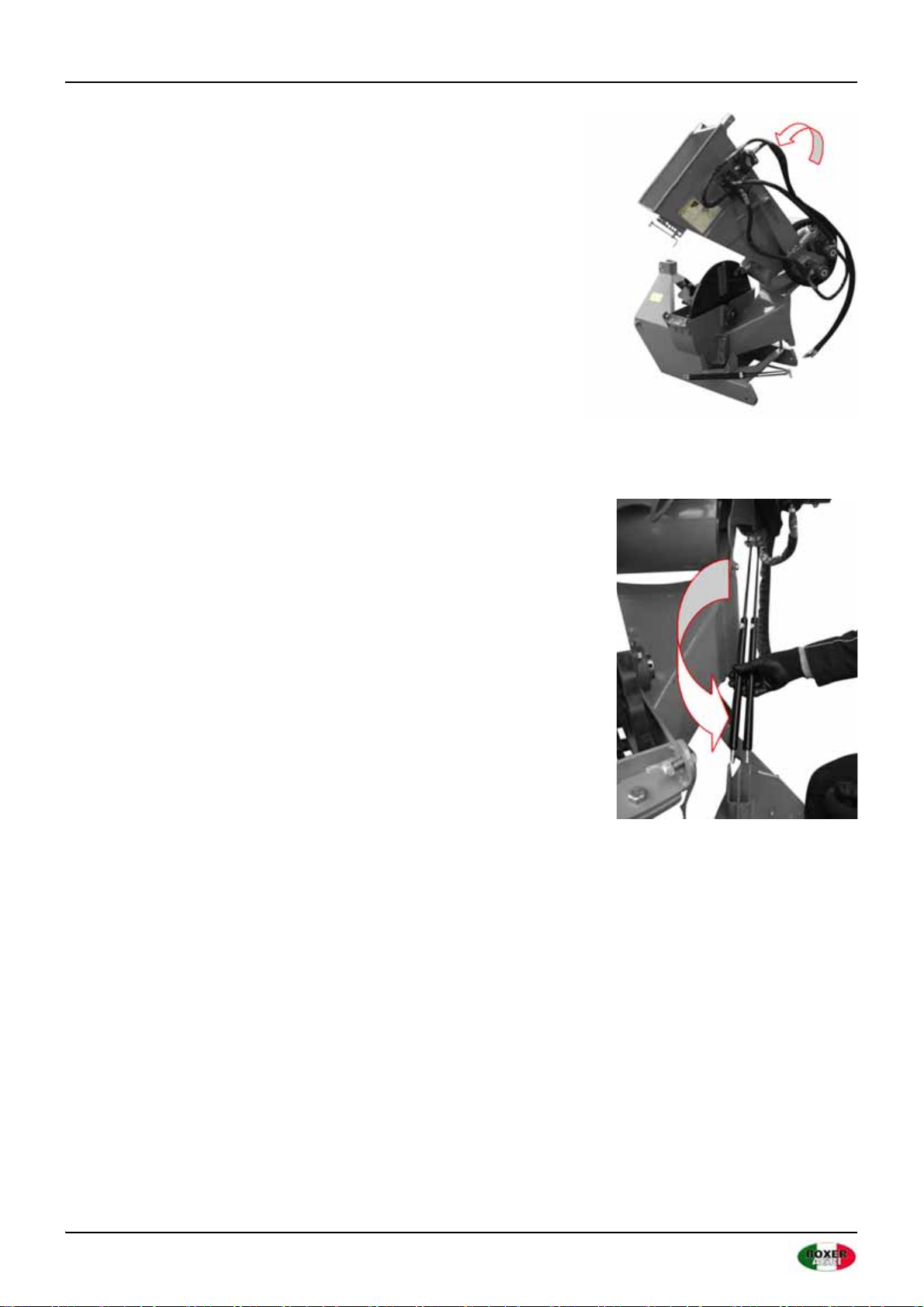

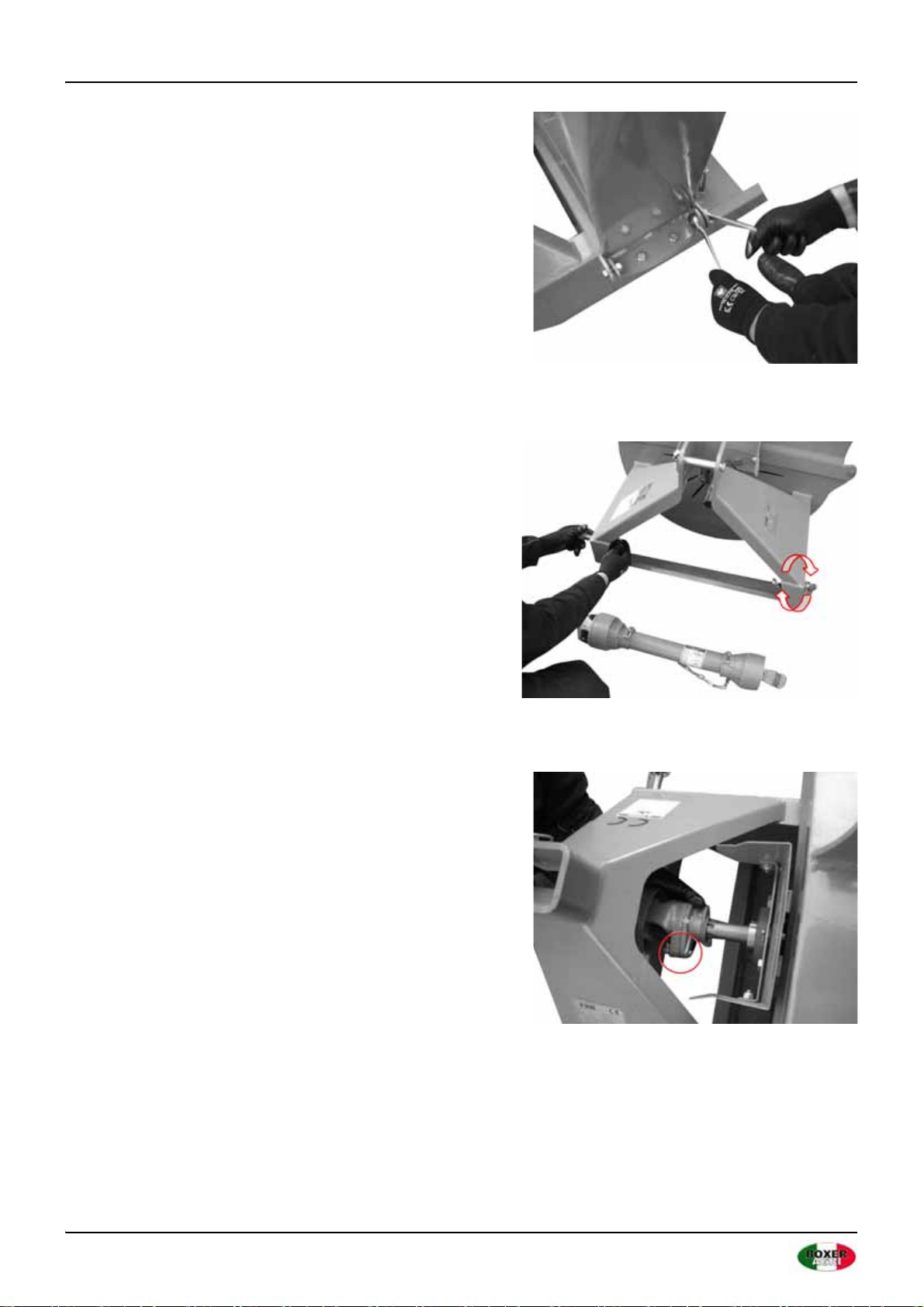

12. Lift the feed hopper using a forklift truck and position it

straight in front of the hopper for the main component.

13. Fasten the feed hopper on both sides using the previously

loosened screws.

Remove the screws from the

hopper main component

Install the hopper

Fasten the hopper using the screws

Page 18/52

WOOD CHIPPER | User manual May 2021

14. Lift up the feed hopper as much as you can because the

shock absorbers can only be installed in this position.

15. Install both shock absorbers.

WARNING! Do NOT install the shock absorbers as shown

adjacently. The shock absorbers must be installed the

other way around with the thicker part installed upwards.

Lift up the feed hopper

as much as possible

Install the shock absorbers

Page 19/52

May 2021WOOD CHIPPER | User manual

16. The shock absorbers cannot be pressed manually and

therefore the hopper must be pushed a few centimeters

from behind to tighten the bottom end of the shock

absorbers.

17. Loosen the three screws on the rotor housing (1x left, 2x

right).

18. Position the protective cover on the rotor housing by

using a forklift truck.

Pressing in and fastening

Loosen the screws

Position the protective cover

Page 20/52

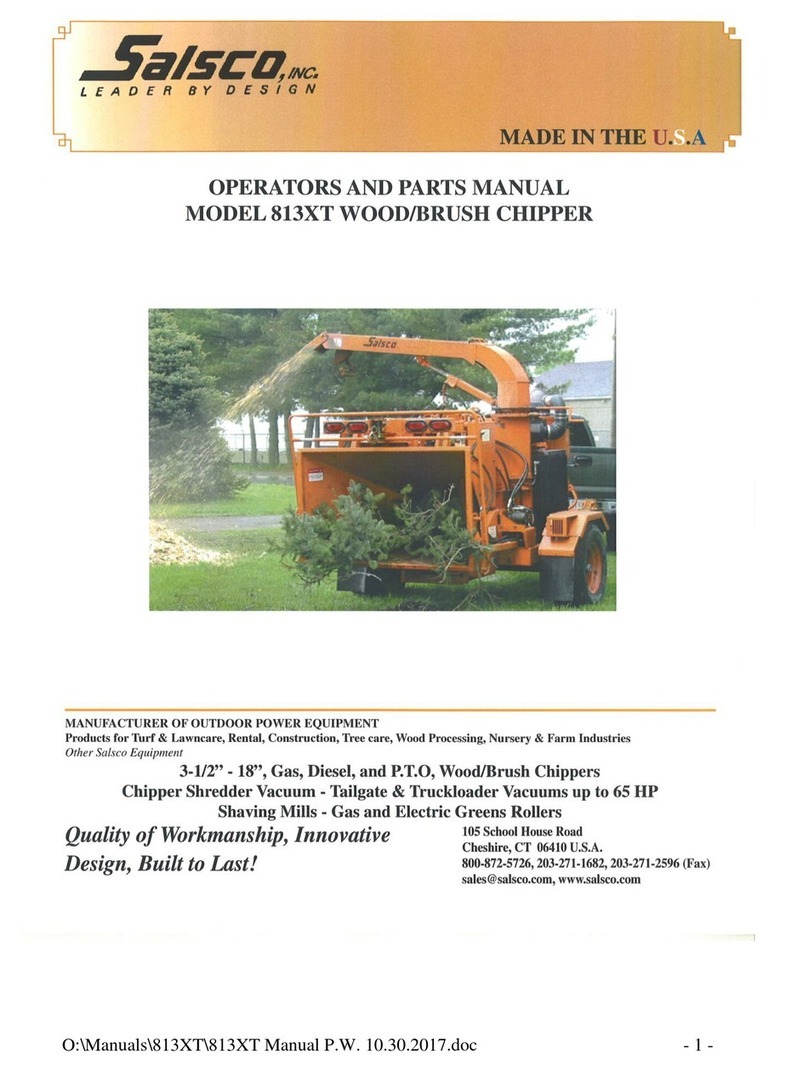

WOOD CHIPPER | User manual May 2021

19. Fasten the protective cover using the previously loosened

screws (3x).

20. Use both bottom screws of the 3-point linkage.

21. Fasten the power take-off on the engine shaft of the wood

chipper by loosening the locking pin, pushing the bracket

over the shaft and pushing the bracket until the locking

pin falls in place. It should be noted that the end with the

shear pin is fastened to the machine's shaft.

Tighten the screws

Use the bottom screws

Assemble the power take-off

This manual suits for next models

3

Table of contents

Popular Chipper manuals by other brands

Mountfield

Mountfield PATRIOT PS 2600 owner's manual

Wallenstein

Wallenstein BX52RI Operator's manual

Cub Cadet

Cub Cadet 24A-424M710 Operator's manual

Salsco

Salsco 813XT Operator and parts manual

Farmi Forest Corporation

Farmi Forest Corporation 100F OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

Garland

Garland CHIPPER 1190 TQG instruction manual