B+B Sensors LogBox AA IP65 User manual

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

01 / 25

Description

Datenlogger

Log Box AA IP65 / 67

Data Logger LogBox AA IP65/67

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

02 / 25

Dear customer,

We thank you for having purchased the LogBox IP65/67 and we are very glad that you decided to buy a product of

B+B Thermo-Technik GmbH. We hope this product will fully satisfy you and will assist you effectively in your work.

This Device has been developed to be technically highly up-to-date and has been designed in accordance with the

regnant European and German national directives and rules. For a proper and effective usage of the product the customer

shall observe the following Operating Instructions. In the case that against one’s expectations any trouble occurs which

you can not resolve yourself, please contact our service centers or our authorized dealer. We will provide you rapid and

competent help to minimize the risk of long time outfalls.

The following operating Instruction is an indispensable part of this Product. It contains important advices for the starting up

and further use of the device.

Foreword

This Operation Manual is intended to serve as an aid in the proper setup, installation and operating of the B+B product.

All essential details of the equipment and all actions required on the part are clearly presented and explained. We thus ask

that you read this manual carefully before proceeding to work with the equipment. Keep this manual available for ready

reference in a convenient and conspicuous location near the equipment.

General Information

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

03 / 25

Content

Foreword 02

General Information

Symbols Employed 04

Warning Signs

Safety Instructions 05

Intendend Use 06

Disposal

1. Product Description 07

2. Scope of Delivery

3. Optional or accessory

4. Identication 08

5. Properties

6. Memory Capacity

7. Input Signals

8. Operation 09

8.1. Drivers and software installation

8.2. Start LogChart-II Software 10

8.3. Conguration the logger 11

8.4. General Information 12

8.5. Acquisition

8.6. Start Logging Field 13

8.7. Stop Loggings

8.8. Channels Field

8.9. Electrical connections 14

9. IP65 Model 15

9.1. IP67 Model

9.2. Input Connections 16

9.3. External Battery Switch

9.4. Digital Input

9.5. Installation Recommendations 17

9.6. Ofoading and Data Visualisation

9.7. Graph Window

9.8. Acquisitions Table Window 18

9.9. General Information table

10. Visualizing the data 19

10.1. Monitoring Acquisition

10.2. Conguring the logger - Settings

10.3. Downloading Data from the Logger 22

10.4. File Visualization

10.5. Transfering Data to your Desktop

11. Observations 23

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

04 / 25

Symbols Employed

Sign Meaning Notice

Advice It is necessary to read the following advices before using the product.

The used symbols in the manual acts rst of all as eye catcher for secu-

rity risks. The symbols do not replace the security advices. The text must

be read completely.

Necessarily to observe This symbol designates important advices and tips which are necessary

for the success of a procedure. They have to be followed in order to get

good results.

Warning Signs Meaning

This symbol advises the user of danger for persons, material or environment. The text gives information

that must be necessarily followed to avoid any risks

Caution against hot surfaces (BGV A8, GUV-V A8/W26) and hot liquids or substances

Caution against liquids and hot substances

Caution against dangerous explosive substances (BGV A8, GUV-V A8/W02)

Caution against moving maschines (W29)

Caution against moving parts

Caution against electromagnetic elds (BGV A8, GUV-V A8/W12)

Caution against severe cold (BGV A8, GUV-V A8/W17)

Caution against dangerous high electrical voltage (BGV A8, GUV-V A8/W08)

Caution against dangerous explosive atmosphere (BGV A8, GUV-V A8/W21)

Electronic waste

Warning Signs

13. Most frequent problems

14. Maintenance

Dimensions

Technical Data 24

Questions 25

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

05 / 25

Safety Instructions

For damages caused by failure to observe these safety and operating instructions, takes over the B+B Thermo-Technik GmbH

is not liable.

This device has been designed and tested in accordance to the safety regulations for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the standard safety measures and special safety

advises given in this manual will be adhered to when using it.

Trouble-free operation and reliability of the device can only be guaranteed if it is not subjected to any other climatic conditions

than those started under “Specication”.

If the device is transported from a cold to a warm environment condensation may result in a failure of the function. In such a

case make sure the device temperature has adjusted to the ambient temperature before trying a new start-up.

If device is to be connected to other devices the circuitry has to be designed most carefully. Internal connection in third party

devices (e.g. connection GND and earth) may result in not-permissible voltages impairing or destroying the device or another

device connected.

Warning:

Just devices with mains input: If device is operated with a defective mains power supply (e.g. short circuit from mains voltage to

output voltage) this may result in hazardous voltages at the device (e.g. at sensor socket)

If there is a risk whatsover involved in running it, the device has to be switched off immediately and to be marked accordingly to

avoid re-starting. Operator safety may be a risk if:

●There is visible damage to the device

●The device is not working as specied

●The device has been stored under unsuitable conditions for a longer time

In case of doubt, please return device to manufacturer for repair or maintenance.

Caution:

Do not use these product as safety or emergency stop devices, or in any other application where failure of the product could

result in personal injury or material damage. Failure to comply with these instructions could result in death or serious injury and

material damage.

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

06 / 25

Intendend Use

Disposal

The use of the unit in elds other than those indicated under “SAFETY INSTRUCTIONS” is not allowed for safety reasons.

This instruction manual does not at all substitute any additional instruction manual of connected accessoriy!

This unit has been marked in accordance with the European Device 2002/96/EC on waste electrical and electronic

equipment (WEEE).

At the end of its useful operating life, dispose of the unit as electrical scrap.

Please ask either B+B Thermo-Technik GmbH or your specialist dealer for information on your local collection point.

Within the scope of application if this Directive, B+B Thermo-Technik GmbH is responsible for proper disposal of this unit.

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

07 / 25

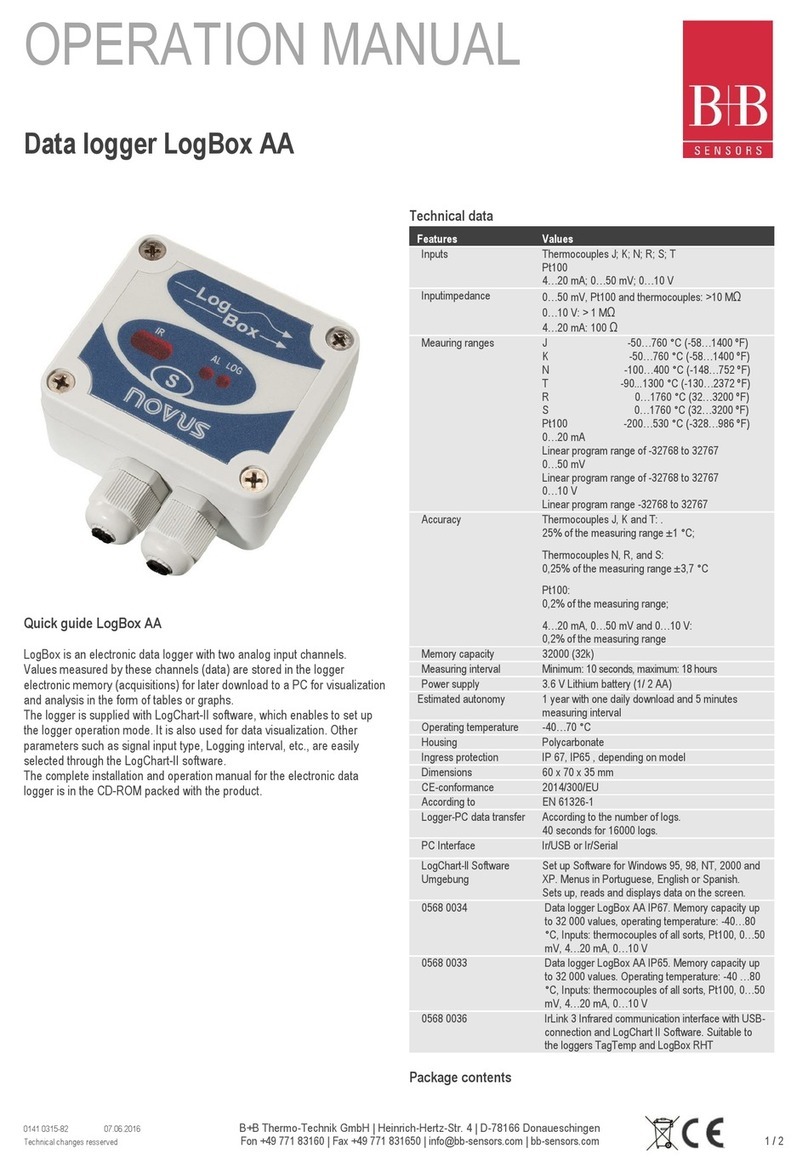

1. Product Description

The LogBox-AA is an electronic data logger with two analog input channels, which accept a variety of standard sensors and

0 (4) to 20 mA, 0 to 50 mV or 0 to 10V signals. It also provides a signal for commanding an external power supply (battery)

of a device connected to the logger. This feature allows that the power supply of external devices, such as a transmitter, occurs

only during the measurement sample time, thus extending the service life of these external batteries. It can be supplied either in

the IPtwo.

The measured values are stored in the logger electronic memory (acquisitions) for later download to a PC for visualization and

analysis in the form of tables or graphs. Data can be easily exported to spreadsheets.

The conguration of the logger can be effected only with use of the IrLink 3 infrared communication interface.

The LogChart-II is the software used to congure the logger, download and visualize data. The logger conguration allows

dening the logger operation mode, including the start/stop time of data acquisition. Other parameters such as signal input type,

logging interval, etc., is easily selected through the LogChart-II software.

2. Scope of Delivery

Article Name Article Number Description

Datenlogger AA IP 65 0568 0033 1 x Data Logger LogBox AA IP65,

1x CD-ROM with Logchart-II Software and a USB Treiber,

2x wires for Sensor Wiring, 1x Quick Logger Operating Instruc-

tions, 1x Ordering Informations

Datenlogger AA IP 67 0568 0034 1 x Data Logger LogBox AA IP67,

1x CD-ROM with Logchart-II Software and a USB Treiber,

2x wires for Sensor Wiring, 1x Quick Logger Operating Instruc-

tions, 1x Ordering Informations

3. Optional or accessory

Article Name Article Number Description

Communication interface 0568 0036 IR-Interface with USB-Connection

Datenlogger LogBox-AA

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

08 / 25

6. Memory Capacity

Two memory storage capacities are offered:

32k Model: Allows up to 32,000 records

64k Model: Allows up to 64,000 records

Memory capacity is always shared between enabled channels. In case there are two channels enabled, each gets 50 %

of the memory available. When only a single channel is enabled, it has the entire memory at its disposal.

Memory capacity is indicated on the identication label placed on the logger rear panel.

7. Input Signals

The input channels 1 and 2 measure analog electric signals, which can be Pt100, Thermocouple (J, K, T, E, N, R, S or B),

voltage (0 to 50 mV or 0 to 10 V) or current (0 to 20 mA or 4 to 20 mA), according to user-dened settings.

Note: Besides conguration performed through the software, the denition of input signal requires two internal jumpers to

be congured.

Data Acquisition (logging)

Data can be acquired through different modes. The logger can be congured to perform a single measurement within a time

interval storing the value read or perform ten measurements within the time interval and store the mean of values measured.

Yet, it can store the minimum or maximum values read in the interval.

5. Properties

Parameter

Start-/stop button (S) This button can be congured to start or stop the temperature measurement process.

IR communication window PC-Logger communication area. During download, the communication interface must be

constantly directed towards this window

Status indicator (LOG) While in stand-by (not logging) or after a series of measurements, it ashes once at every

four seconds. During logging it ashes twice at every four seconds

Alarm indicator (AL) Warns the user as to alarm conditions. Whenever an alarm situation takes place it will ash

once at every four seconds, until a new conguration is applied to the logger

4. Identication

The identication label is on the logger body. Check if the features described are in accordance with your order.

The following elements are shown in the logger front:

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

09 / 25

8. Operation

The logger operation mode is user-defined in the Log-

Chart-II software. To access or change this conguration,

the Communication interface is required. The user must

install the LogChart-II software in a computer and run the

logger conguration according to instructions dened in

the LogChart-II installation section of this manual.

After conguration and input electric connections made,

the device is ready to measure and log input signals. The

status indicators show the logger current status.

Essential Accessories:

• A PC-System with Windows®2000 oder Windows XP®

• CD-ROM device

• A free USB-Port

The status lights of the logger startes ashing according to

the current status of the logger:

• A ash every four seconds (stand-by) means the log-

ger is ready for a new measurement or the logger has

completed a series of measurements and is waiting

for a new command.

• Flashes twice every four seconds, a current measurement is active.

The settings of the data logger operation will be done in the LogChart-II software. Each setting must be dened and its

action can be controlled. The data logger starts and stops his notes as they are predened in the settings.

8.1. Driver and Software Installation

In the Communication Interface model is a USB/Ir communication interface, which must be connected to the available

USB-port. Windows®will request a proper driver installation, which is found in the CD-ROM that is provided with the logger.

The driver installation steps may vary according to the machine, even for the same version of an operating system.

The following screenshots and steps are only to provide guidance.

1. Insert the CD shipped with the logger in the CD-ROM

drive.

2. Connect the communication interface IrLink-3 to the PC

USB-port. Windows®will acknowledge the presence of

new hardware and a few seconds later it will start the

driver installation process.

3. The window “found new hardware wizard” will be dis-

played, and you will be asked if you want to install the

driver from the Windows Update website. Select “No, not

this time”, and then click Next.

4. Select “Install from a list or specic location (Advanced)”

and click “Next”.

5. Select “Search for the best driver in these locations” and

check “Search removable media”. Click “Next”.If installati-

on les are not in a CD, check “Include this location in the

search” and show the le path.

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

10 / 25

In later uses of the interface, Windows®may require

the driver installation again. In this case, the same

installation wizard will be displayed, and you will have

to select the option “Install software automatically

(recommended), as the driver may already be in the

computer.

Logchart-II Software installation:

1. Insert the supplied CD-ROM in the CD-drive of

the PC.

2. The software installation wizard will start automa-

tically. If it does not, please run the

„LC_II_Setup.exe“ program provided from your

CD-drive.

To do so, please follow the steps below:

• From the start menu of Windows run Windows

Explorer. Choose the CD drive

• Double click on the icon „LC_II_Setup.exe“ to run

the setup-program.

• Follow the steps described in the setup-wizard

8.2. Running LogChart-II

By starting the program, the main window will appear on

the screen:

The LogChart-II requires a communication port to talk to

the logger. Clicking on the menu Port, all free communication

ports available in the computer will be listed, including the

USB port if the driver is installed. Select one and connect the

corresponding wand to it. The chosen port will be remembe-

red next times the LogChart-II is initiated.

Displays the Cong-

uration Setup dialog box

Press this button

to represent the last 10

measurements taken

Press this button to

the current contents of the logger

download store

Stops current

Measurements

6. If a prompt warns you that it does not support Windows® XP or that signature verication failed, click “Continue anyway”.

7. The interface driver les will be copied to the computer and after a few seconds a screen is displayed informing you that the

software installation has been concluded. Click “Finish”.

8. In some situations, the steps described above may be repeated again. Follow the same procedures.

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

11 / 25

8.3. Conguration the logger

Make sure the communication interface is connected to the PC-port which is selected. The interface must be constantly

directed towards the communication window on front part of the logger at a maximum distance of 0,5 m.

After the serial port is selected, click the “GO” button:

The following Parameters conguration dialog box is then displayed:

In this dialog box the user can dene the logger operation mode and also obtains general information about the device.

The different elds and their meaning are listed in the following.

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

12 / 25

8.4. General Information

General information on the top of the screen informs about the model, serial number, logger current date/time, PC date/time,

rmware version (logger model version), memory capacity and the used memory. This information is displayed in the upper

part of the LogChart-II conguration screen. The time is permanently updated in this screen, provided that the logger and the

PC are communicating.

8.5. Acquisition

Parameter Function

Period It determines the interval between readings in the hh:mm:ss format. New data is stored in the

logger memory after each time interval. In the Average, Minimum and Maximum reading modes,

the logger executes 10 readings within this interval

External Battery Switch time Denes the time at which the logger turns on the external power supply, before proceeding with

any reading. This time is limited to 10 seconds and must be less than half of the interval between

readings

Estimated time It informs about the estimated time for the accomplishment of programmed readings based on

the logging “Interval” and on the number of programmed readings

Daily Repetition Allows loggings to be repeated everyday, for example, recording data from 8 AM to 5 PM day after

day. The start and stop times are dened in the elds “Start time” and “Stop time”

8.6. Start Logging Field

Parameter Function

Immediately The logger starts logging as soon as the conguration is applied. Not valid when the option

„Daily Repetition“ is selected

Day/ Hour Logging starts at a predened date and time. The date dened is used for the Daily

Repetitions option as well

Through Start Button Starts and stops logging by holding the Start button pressed for three seconds

Digital Input Starts readings when the digital input is activated (closed) and stops readings when the digital

input is deactivated (open)

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

13 / 25

8.8. Channels Field

By selecting the “Channels” option, the user is able to choose the individual settings for each input channel.

Parameter Function

At Full Memory Loggings can be stored up to the full memory capacity is reached

Wrap around Logging never stops. The LogBox will keep on recording the readings and when the memory is full it

will overwrite the oldest record in a circular or wrap around manner

After a dened number of readings The logger will stop logging after the number of readings dened here is reached. Not valid

when the option ‘Daily Repetition’ is selected

Day / Hour The LogBox will stop logging at the user-dened date and time. Not valid when the option ‘Daily

Repetition’ is selected

8.7. Stop Loggings

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

14 / 25

8.9. Electrical connections

Only the input connections and the External Battery Switch (when used) are needed. The logger is exclusively powered by its

internal battery.

In the IP65 models, the inputs and the signal for activating the external power supply are located inside the logger case, which

must be opened for accomplishing the connections.

In the IP67 models, proper connectors are provided for this purpose.

The case cover should be opened only if necessarily required. If this is the case, the cover must be properly tightened back in

its place such as to assure the stated IP Ingress protection index.

Parameter Function

TAG Denes a name (up to 8 characters) for identifying the variable to be measured in the channel

Inputs The signal applied to the logger input is dened here. The list shows all the input options available.

The selected option must be in accordance with the internal conguration of the jumpers J1 and J2.

For more information refer to section 7 electrical connections

Unit Denes the variable unit

Scale Denes the range, in engineering units, to represent the input variable measured. Adjustable from –32000 to

+32000 for 4-20 mA, 0-20 mA, 0-50 mV and 0-10 inputs, for the remaining input types the scale is xed.

Offset Allows ne offset corrections on the measured value

Value Denes readings recording modes:

Instantaneous The instant value read at the logging time

Average 10 equidistant readings at each reading interval are taken.

The average value of readings is built and the resulting value

recorded

Minimum 10 readings at each reading interval. The lowest value found

is recorded

Maximum 10 readings at each reading interval. The highest value

found is recorded

Alarm Denes a limit range of variables measured, that once exceeded, trigger the alarm. Once activated

the alarm LED indicator stays so, even after the alarm-triggering situation has ceased, till a new

conguration is applied to the logger.

Low Denes the minimum value under which the alarm

is triggered

High Denes the maximum value above which the alarm is

triggered

After lling all the elds for both channels, send the conguration to the logger by clicking on the button

The new settings and PC current date/time are then sent to the logger. All Data in the logger memory will be lost.

The parameters are:

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

15 / 25

9. IP65 Model

Open the logger’s cover to get access to the block terminals and the conguration jumpers. Connection-cables must

pass through the compress tting located at the bottom of the case. The following gure shows the internal terminals

distribution.

Channel Connections

Channel 1 CN1 connector – Terminals 1, 2 and 3

Channel 2 CN1 connector – Terminals 4, 5 and 6

External Battery Switch CN2 connector – Terminals 7, 8 and 9

Digital Input CN2 connector – Terminals 7, 10 and 9

Note: Make sure that the compress tting is perfectly tightening the cables, thus

assuring proper Ingress protection IP65.

IP65: Totally dust-tight and protected against water jets.

Channel 1 cable (right) Connection

Brown CN1-3

Blue CN1-2

Black CN1-1

Channel 2 cable (left) Connection

Brown CN1-6

Blue CN1-5

Black CN1-4

9.1. IP67 Model

In the IP67 version, an M8 connector is provided for signal input.

Two connectors provide external access to the input channels as

shown in the gure. The cables are supplied with the logger.

Note: The case cover should not be opened unless it is really ne-

cessary. If this is the case, the cover must be properly tightened

back in its place such as to assure the Ingress protection IP67.

IP67 - Totally dust-tight and protected from temporary immersion

in water.

Wire connections:

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

16 / 25

9.2. Input Connections

Both models have the same input connections schema:

In the IP67 version, an M8 connector is provided for signal input. Two connectors provide external access to the input

channels as shown in the gure. The cables are supplied with the logger.

Note: The case cover should not be opened unless it is really necessary. If this is the case, the cover must be properly

tightened back in its place such as to assure Ingress protection IP67.

IP67 - Totally dust-tight and protected from temporary immersion in water.

9.3. External Battery Switch

The example below shows the usage of the external battery switch for commanding the power supply of external devices.

Channel 1 is congured to 4-20 mA input signal. A battery is used to provide power to the 4-20 mA loop. The battery switch

“turns on” the power to the loop a moment (dened in the conguration) before the measurement is taken, enabling the trans-

mitter (pressure, temperature, etc.) to start up and stabilize the output.

9.4. Digital Input (DE)

The Digital Input can be used to externally trigger the start and stop of readings. It is available in terminals

7 (-) and 10 (+) of CN2.

Input signal Channel 1, J1 position Channel 2, J2 position

4-20 mA / 0-20 mA A A

Pt100 / Thermocouple / 0-50 mV B B

0-10 V C C

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

17 / 25

9.5. Installation Recommendations

Signal wires should be installed in grounded conduits and away from power or contactor wires. Instruments must be

powered only by an exclusive power supply.

System failure should always be taken into account when designing a control panel to avoid irreversible damage

to equipment or people. Installing RC lters (47R and 100nF, serial) is strongly recommended at contactor coils or

any other inductors.

9.6. Ofoading and Data Visualisation

The transfer of data to a PC is accomplished by using the LogChart II software. Data can be collected anytime and saved in les

for future analysis (menu “File Save” or “File Save as”). Help can be accessed from the LogChart-II software when necessary.

Ofoading data: Data ofoad is accomplished by clicking on the button „Ofoading“

or using the LogChart-II menu. During data transfer, a status bar indicates remaining data to be transferred. Data ofoading time

is proportional to the number of readings logged. At the end of data transfer, the Graph window is displayed with the downloaded

data plotted.

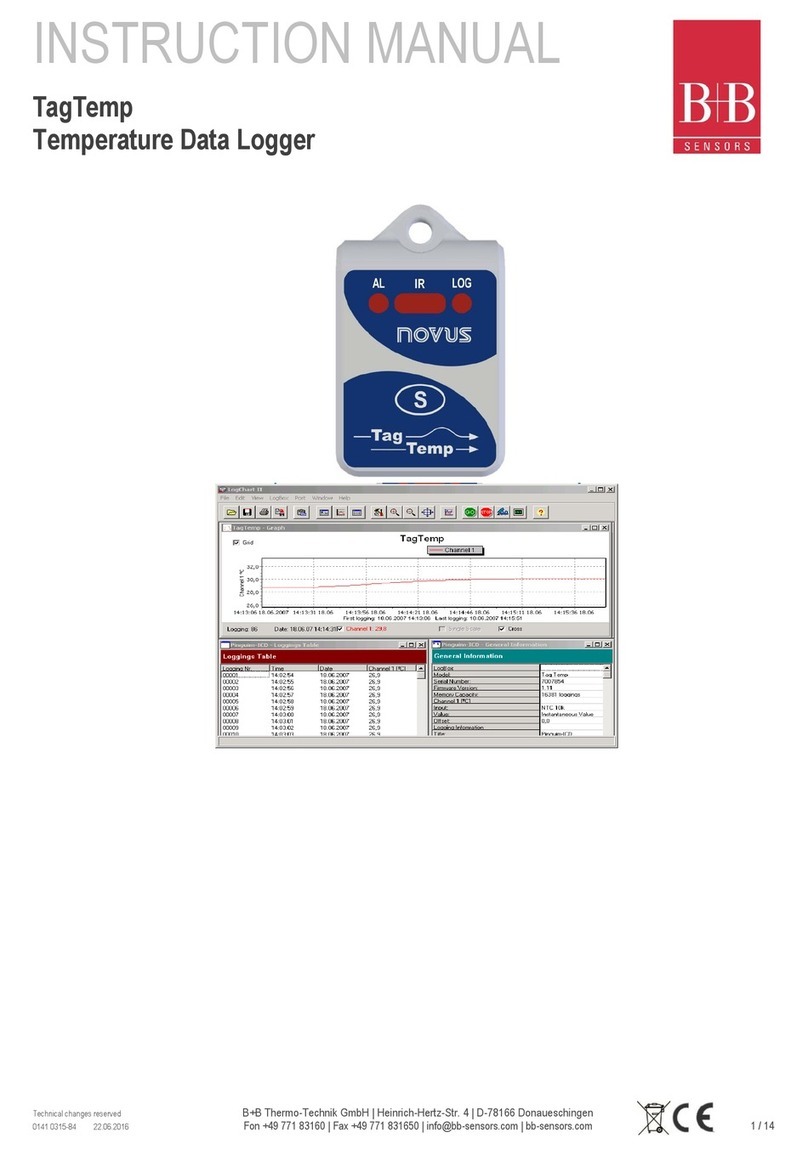

10.6. Graph Window

The Graph-window is a convenient tool for analysis.

It enables the logger acquisitions to be read in the form of

a “values vs. time” graph. As one moves the mouse in the

chart area, the time and the value of the records of each

channel are shown in the eld located in the bottom of

the window.

Zooming in and out are implemented. It is possible to

select an area by clicking and dragging the mouse, thus

creating a zoom region, starting at the upper left position

of the region of interest.

The command „Ofoad acquisitions“ does not interrupt

the process of data logging and reading.

Other two windows can be easily opened:

• Acquisitions Table Window

• General information table

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

18 / 25

9.8. Acquisitions Table Window

Data acquired by one or both input channels

(user-dened) are displayed in engineering units in

a table format. The table displays register number,

date/time and the record values.

9.9. General information table

Displays information about the logger:

• Features

• Congurations

• Details about data acquired

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

19 / 25

10. Visualizing the data

Three windows support data visualization: Graph, Acquisitions Table and General Information windows.

Data can be originated from direct reading from the logger or from a le previously recorded in a computer.

Once the windows are open, data can be saved in a le (.lch), printed on a graph or exported to a

text le (.txt or .dat).

10.1. Monitoring Acquisitions

To online visualize current measurement in a graph format, use the monitor On-line command

by clicking the button while pointing the IR-LINK3 interface to the logger.

INSTRUCTION MANUAL

Technical changes reserved

B+B 0141 0315-21 June 2011

B+B Thermo-Technik GmbH | Heinrich-Hertz-Straße 4 | D-78166 Donaueschingen

20 / 25

The parameters are analogous to the LogChart-II parameters.

The screen exhibits instant values of variables measured, conguration information and current logger status. The Buttons are

assigned the following functions:

Parameter Function

Search It allows you to search for another logger or reconnect communication lost for any reason. When the

handheld device nds a logger, it exhibits a new Monitoring screen with the logger information. When

other loggers are found, the Devices Found screen is exhibited again

Download Downloads logged data. Download can be partial and it does not interfere in the ongoing acquisition

process

More Infos Displays further information on the connected logger, such as model, serial number, version and

memory capacity

Settings Accesses the Settings screen, which allows modifying the logger conguration

Data base Exhibits the Recorded Data screen listing all the processes stored and processed in the PDA data base.

To access the data, tap on Details. Information required is displayed

View data Displays data in a list containing date, time and measured value

10.2. Conguring the logger - Settings

During conguration, the logger must be aligned. Click on „Settings“ in the Monitoring screen. The screen Settings is opened and

contains the required parameters for conguring the logger.

This manual suits for next models

1

Table of contents

Other B+B Sensors Other manuals

Popular Other manuals by other brands

iGenix

iGenix IG9802 user manual

Rock-Slide Engineering

Rock-Slide Engineering BD-SS-200-JK4 Installation instructions manual

ZyXEL Communications

ZyXEL Communications NWA3560-N quick start guide

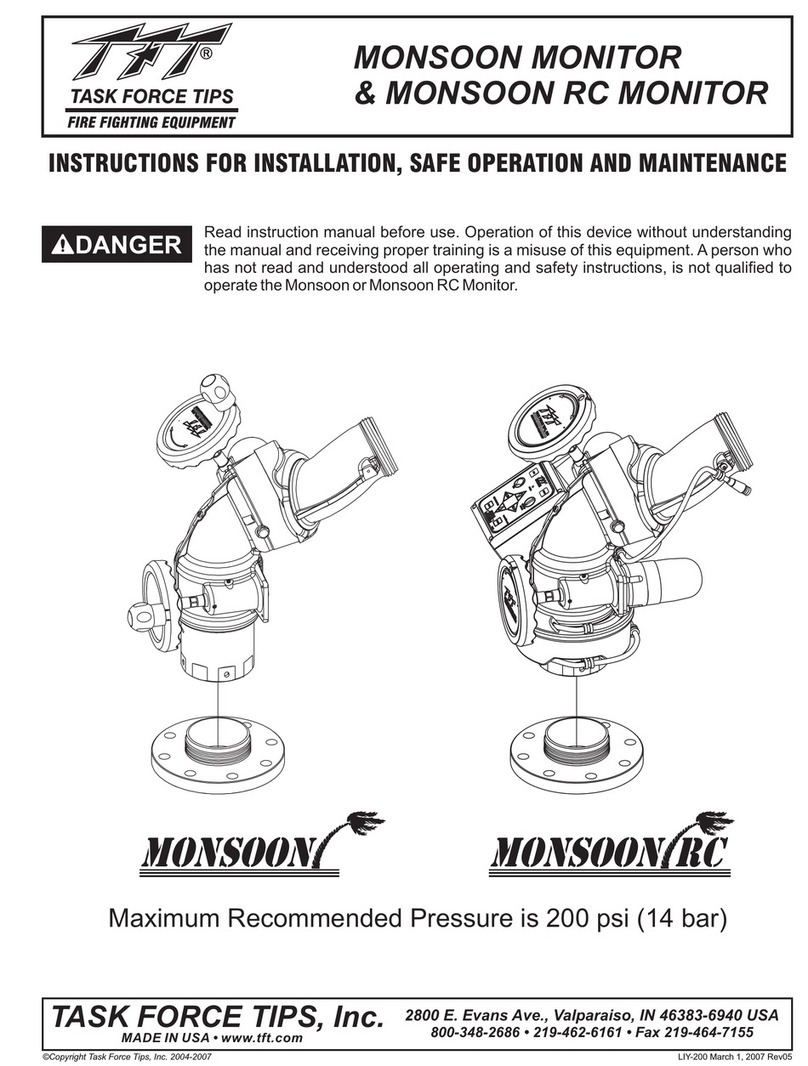

Task Force Tips

Task Force Tips MONSOON MONITOR Instructions for installation, safe operation and maintenance

FANOX

FANOX SIA-B user manual

Marson

Marson M-4 manual