Overcurrent Elements Page 1 of 7 20120723

Hands-On Relay Testing Session

Overcurrent Elements

Exercise Objectives

After completing this exercise, you should be able to do the following:

•Identify overcurrent element settings.

•Determine effective overcurrent protection settings.

•Validate relay settings.

In this exercise, the instructor will introduce the SEL-387A Current Differential and Overcurrent Relay

overcurrent elements, determine how to set the elements for transformer backup protection, and

demonstrate how to enter the settings.

You will then enter the overcurrent settings into ACSELERATOR QuickSet®SEL-5030 Software. After

sending your settings to the relay, you will validate the settings and verify the protection scheme.

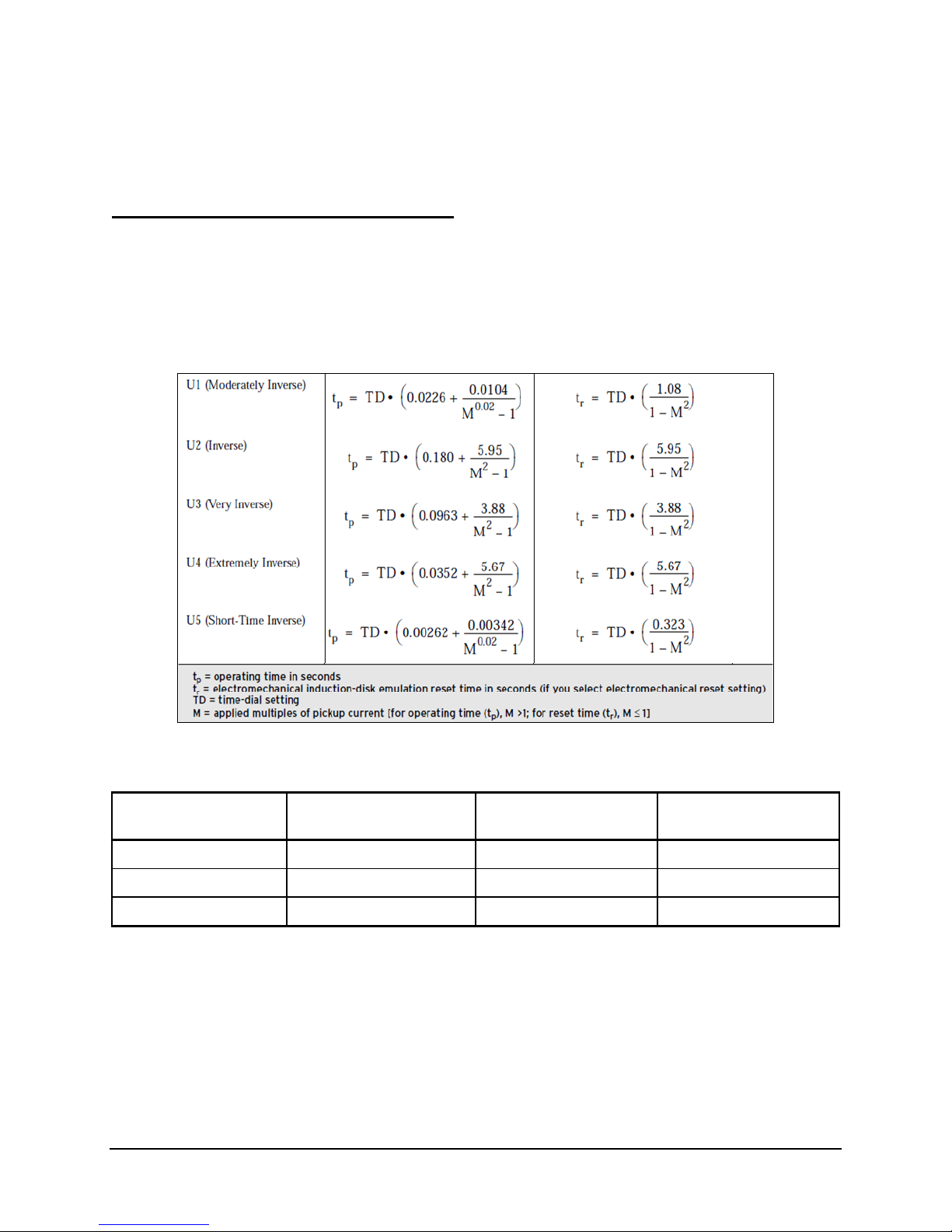

SEL-387A Time-Overcurrent Elements

The SEL-387A provides numerous overcurrent elements, as many as 11 per winding and 5 per neutral

input. Four levels of phase instantaneous or definite-time elements are available for overcurrent

protection, breaker failure protection, overcurrent phase selection for targeting, transformer backup

protection, and so on. Two levels of negative-sequence and residual instantaneous elements provide

protection against unbalanced conditions and ground faults. Phase, negative-sequence, and residual time-

overcurrent elements are available for system backup protection. The SEL-387A also has neutral

instantaneous or definite-time elements available.

For a more detailed description of each of the overcurrent elements, refer to the SEL-387A Instruction

Manual (available at http://www.selinc.com).

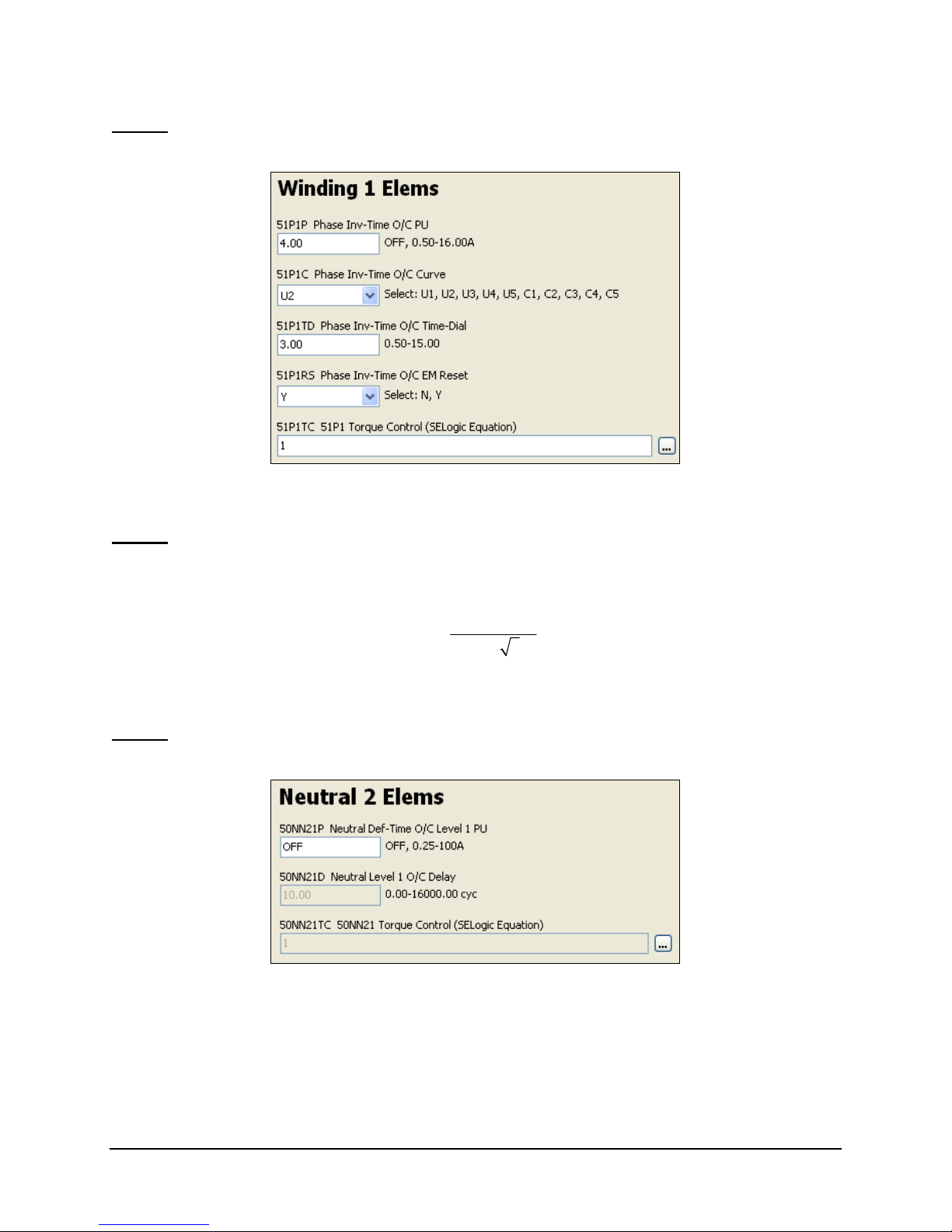

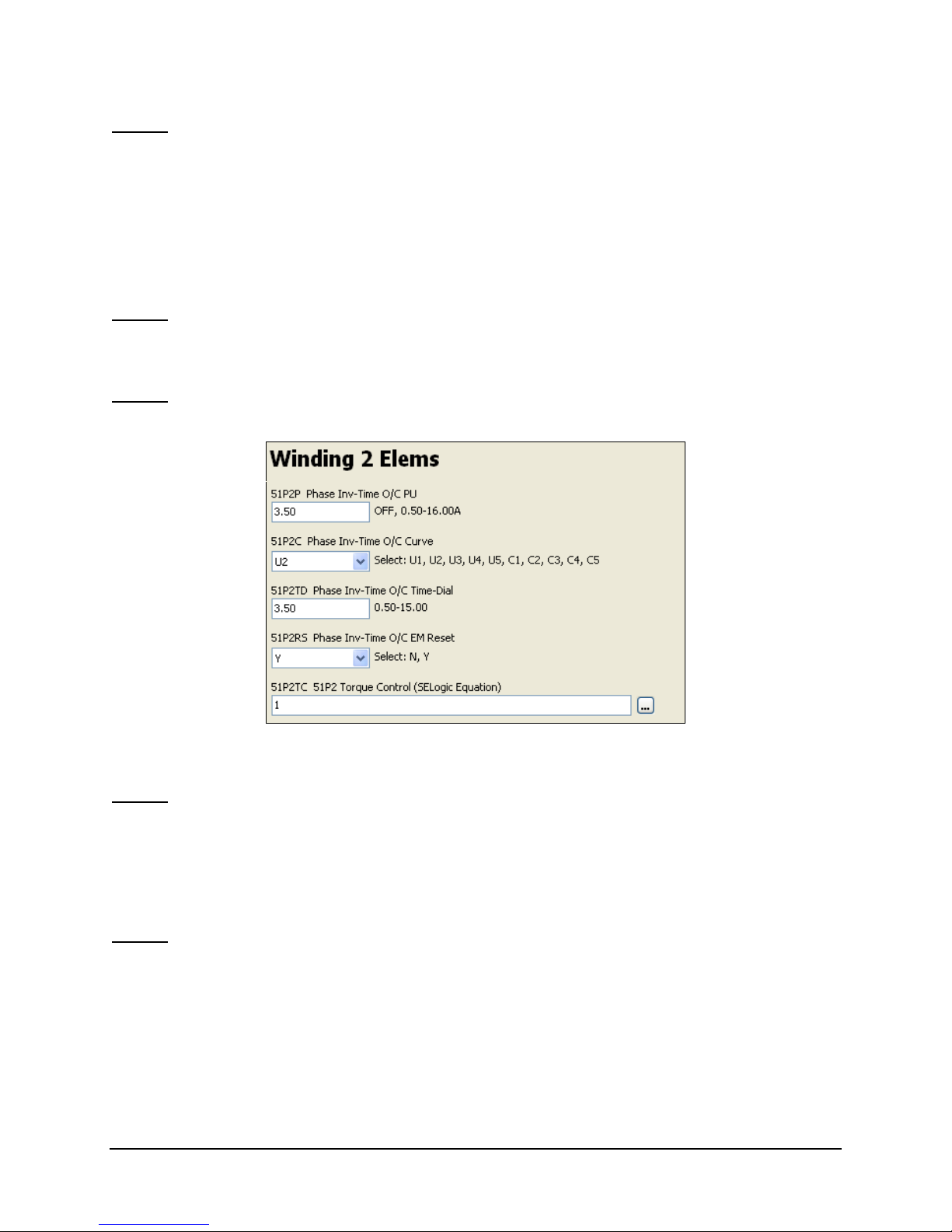

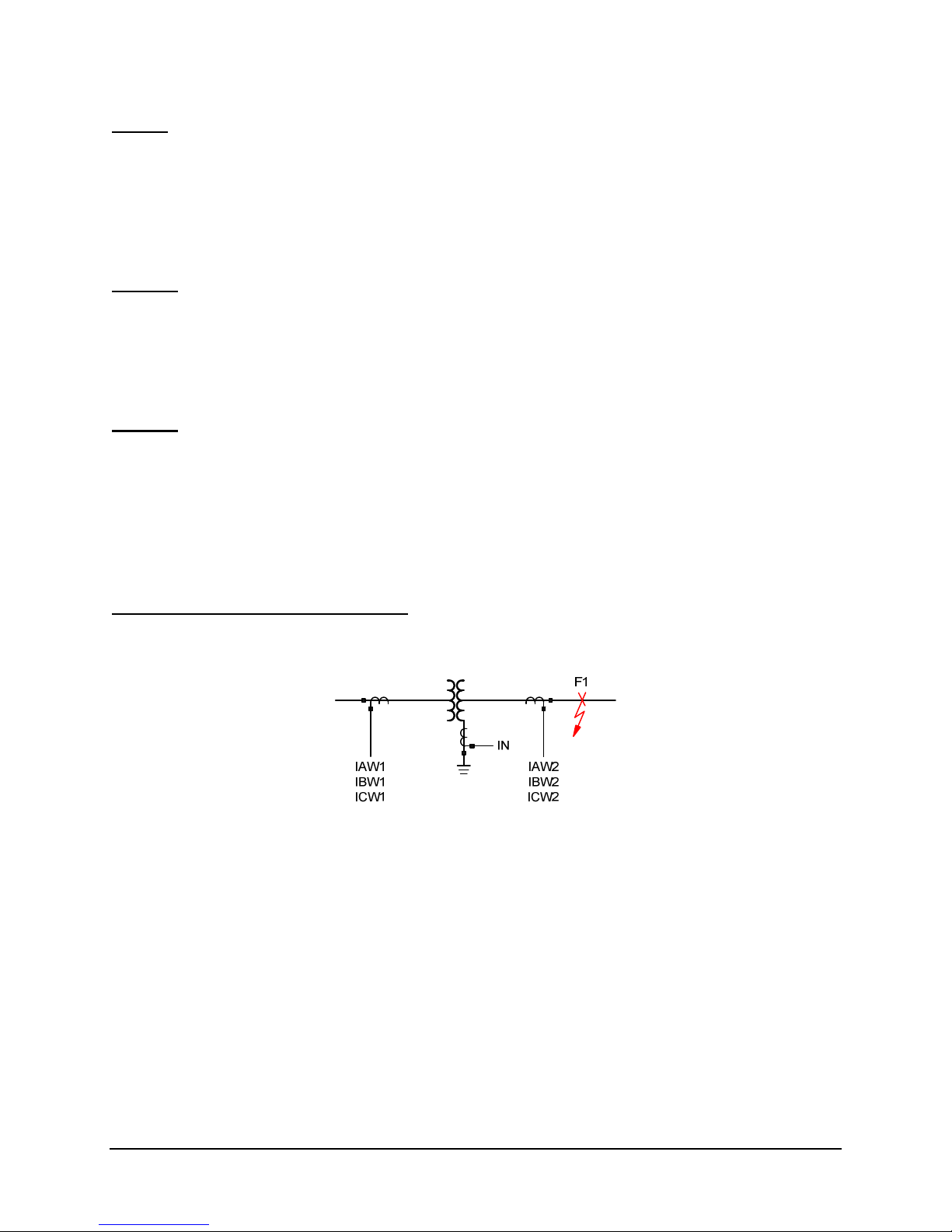

Hands-On Activity 1: Enable Overcurrent Elements

In this hands-on activity, you will enable the element for a particular winding and enter settings for

backup overcurrent protection. Write your answers in the space provided.

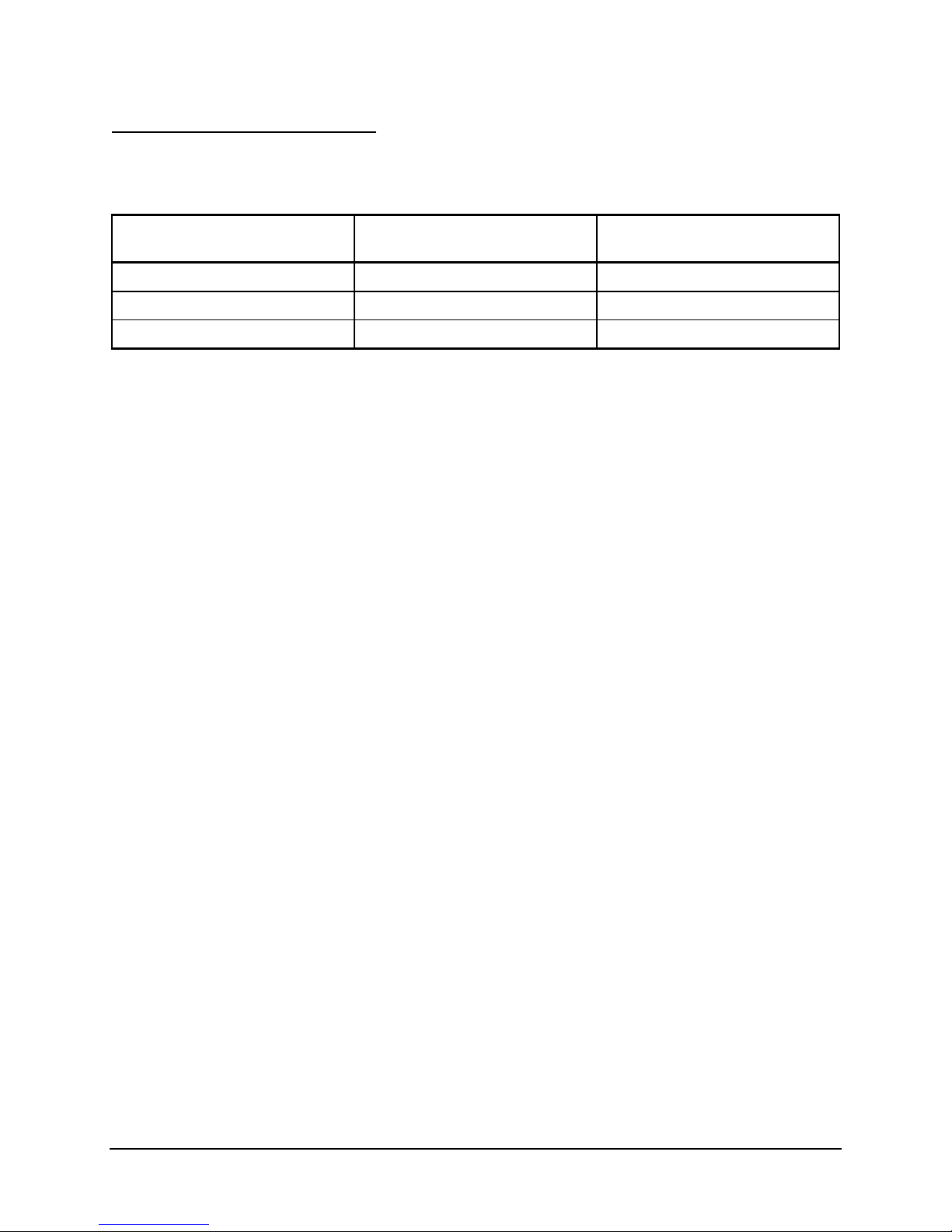

Transformer Data

Rated 50 MVA

Rated high side 161 kV (DAB)

Rated low side 14.4 kV (wye)

High-side bushing current transformer (CT) ratio (wye connected)

Low-side bushing CT ratio (wye connected)

Neutral bushing CT ratio