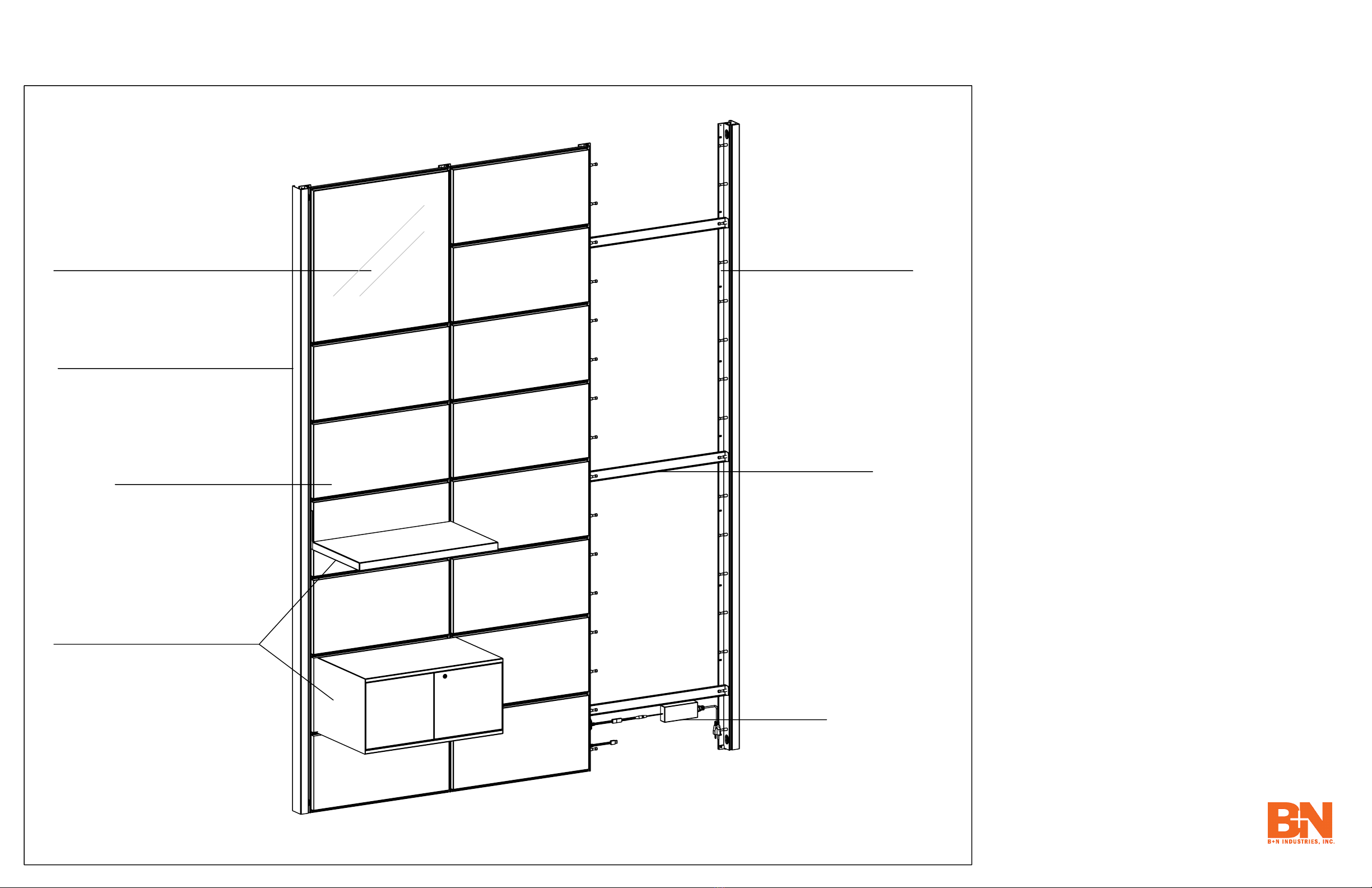

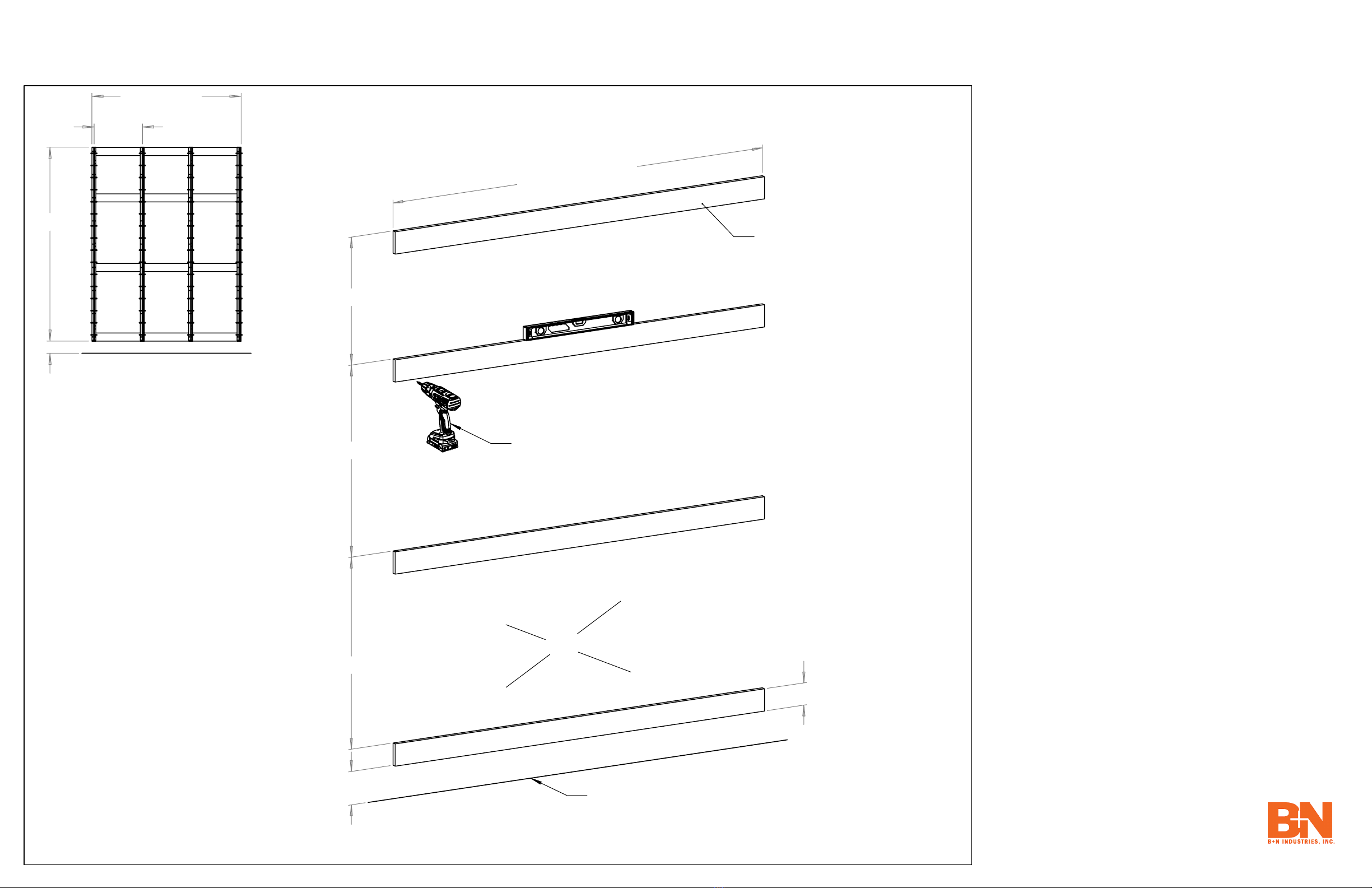

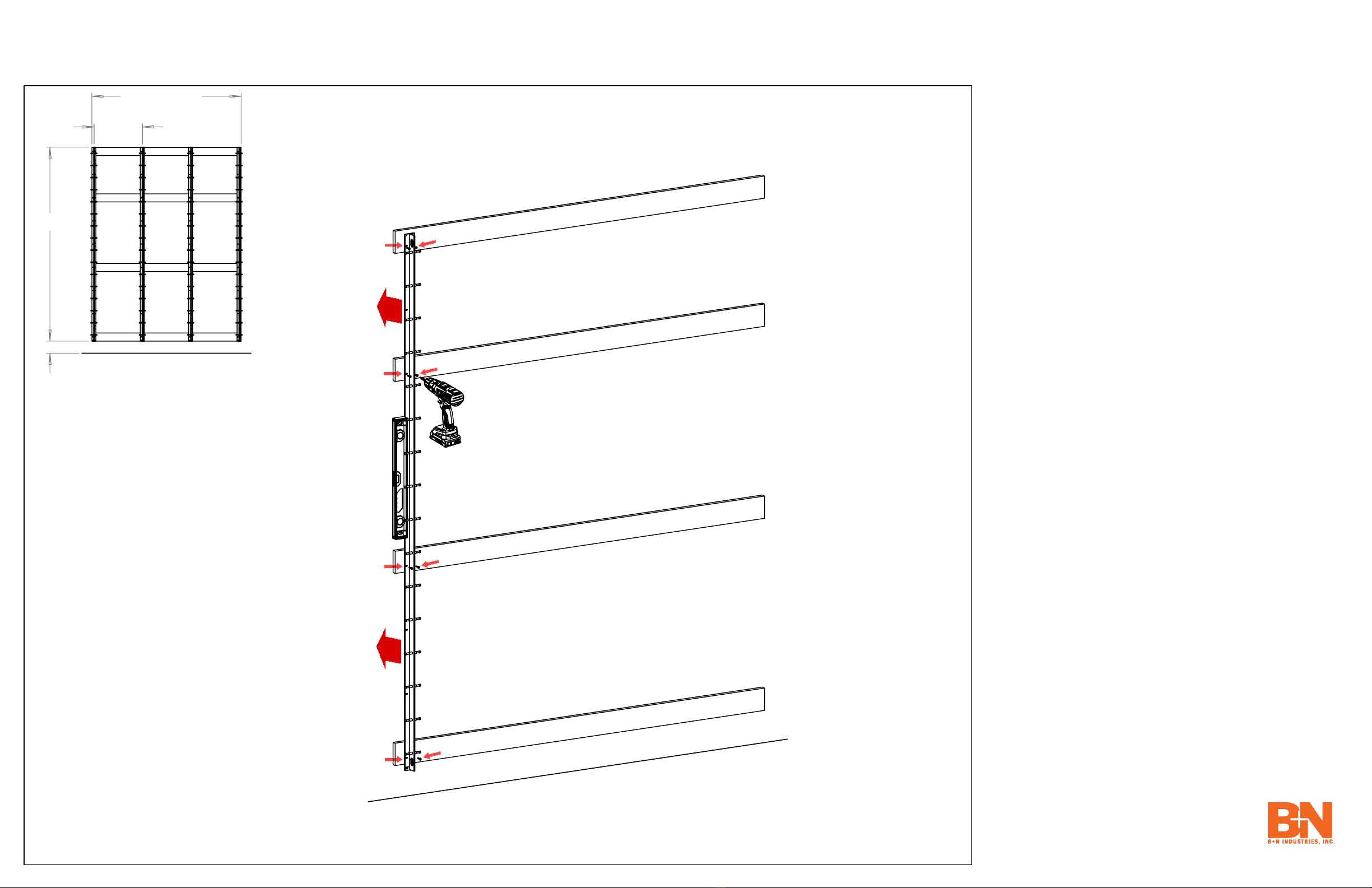

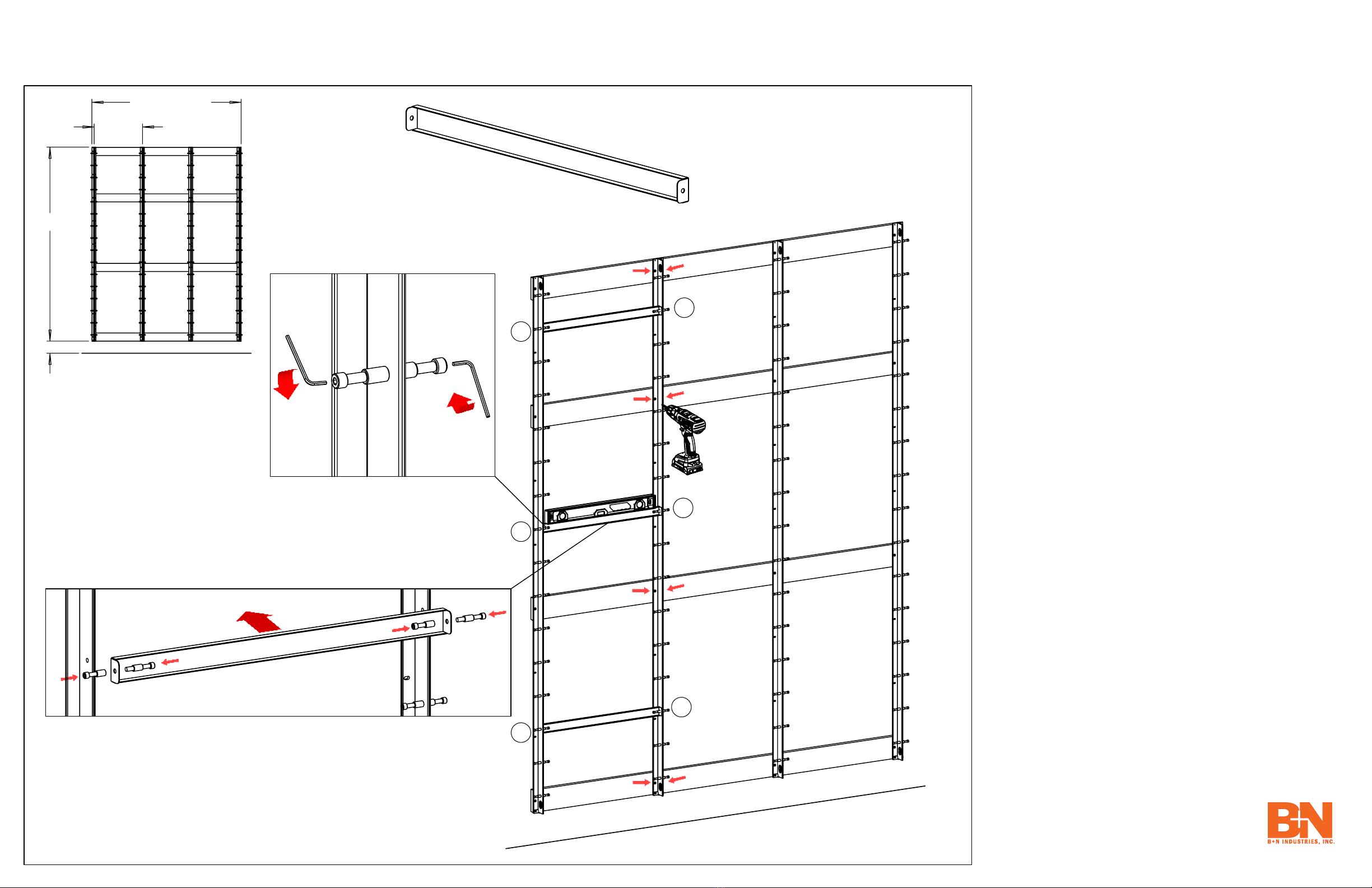

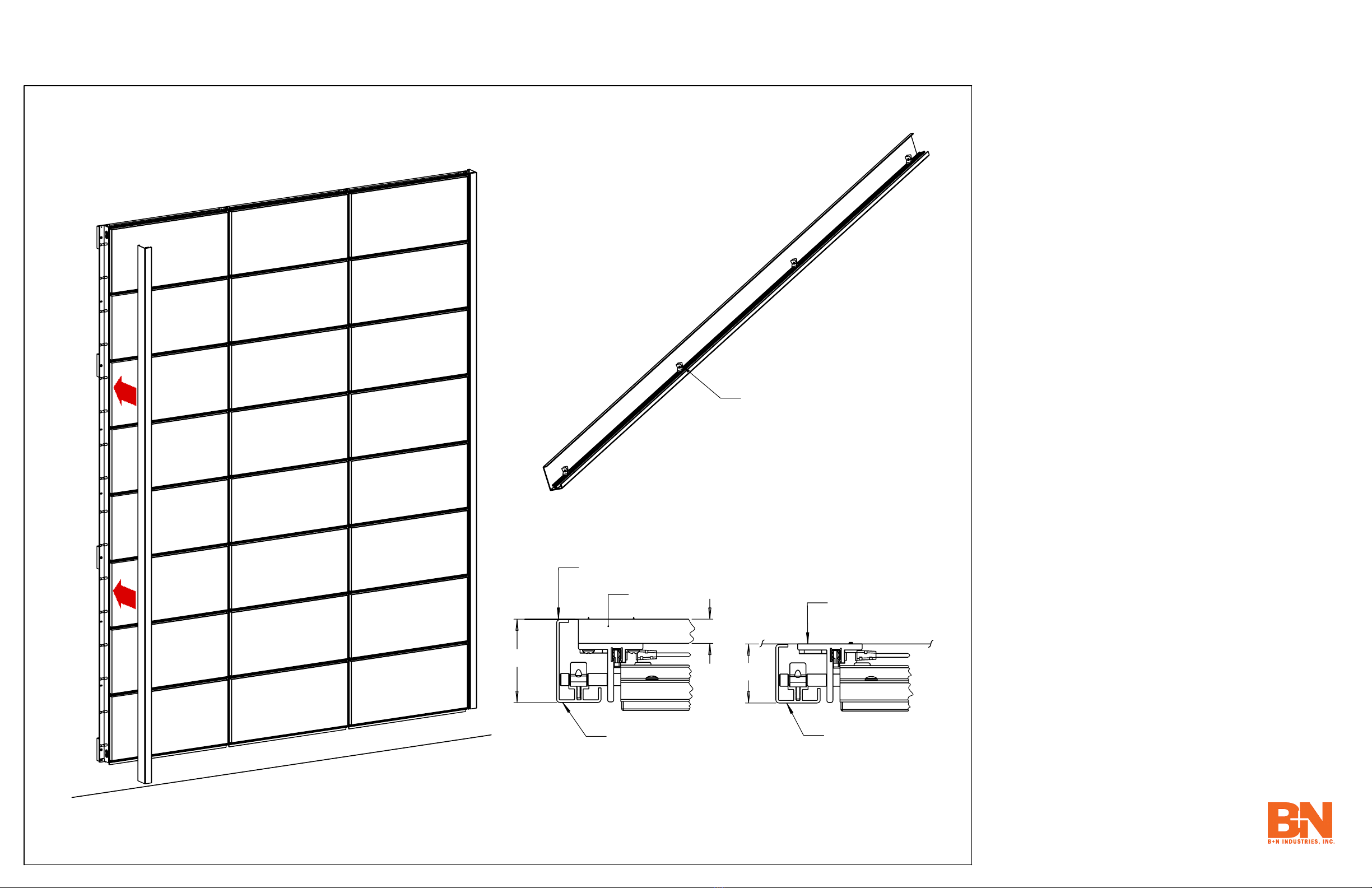

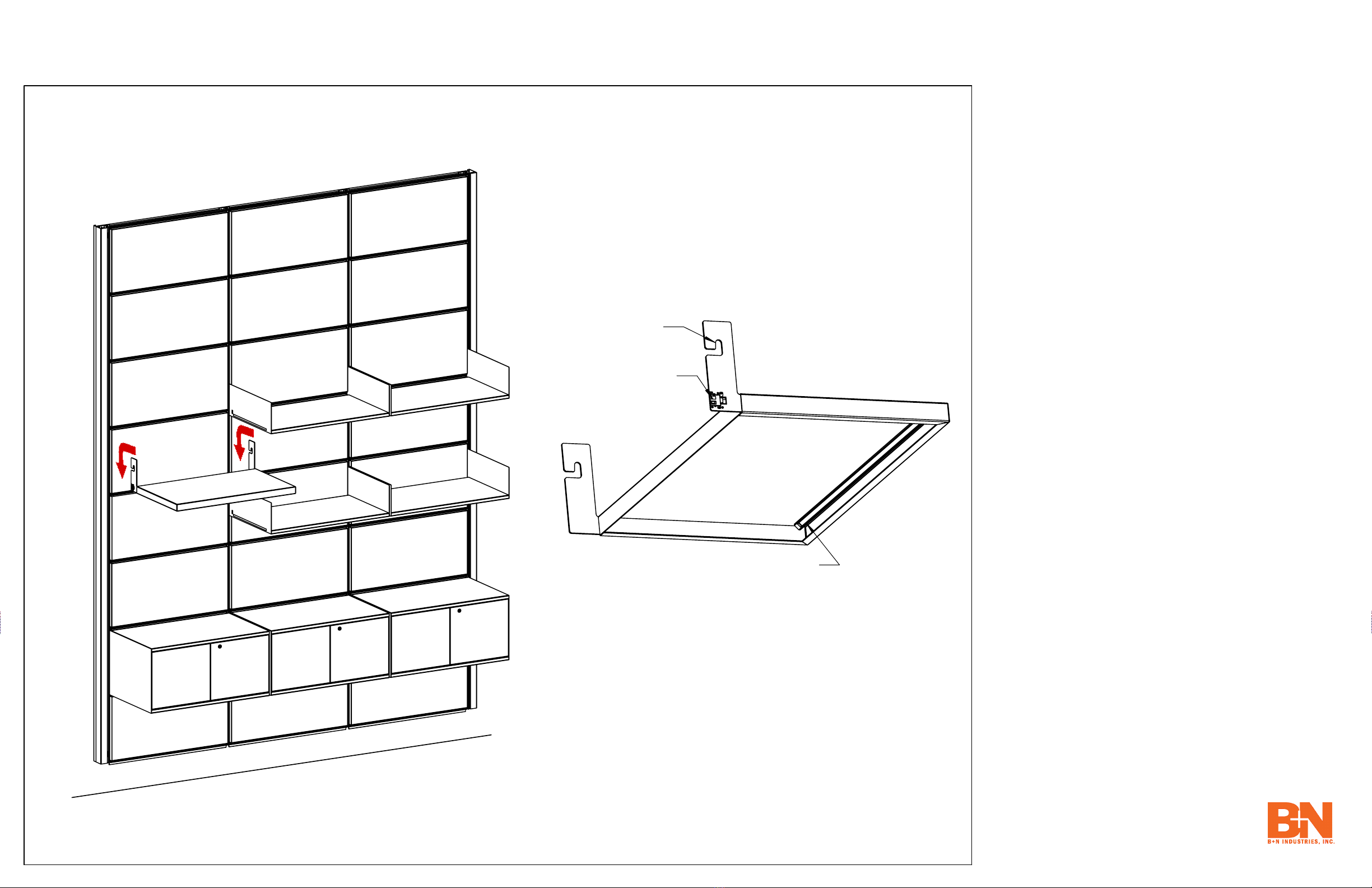

B+N INDUSTRIES SYSTEM 1224 User manual

Table of contents

Popular Indoor Furnishing manuals by other brands

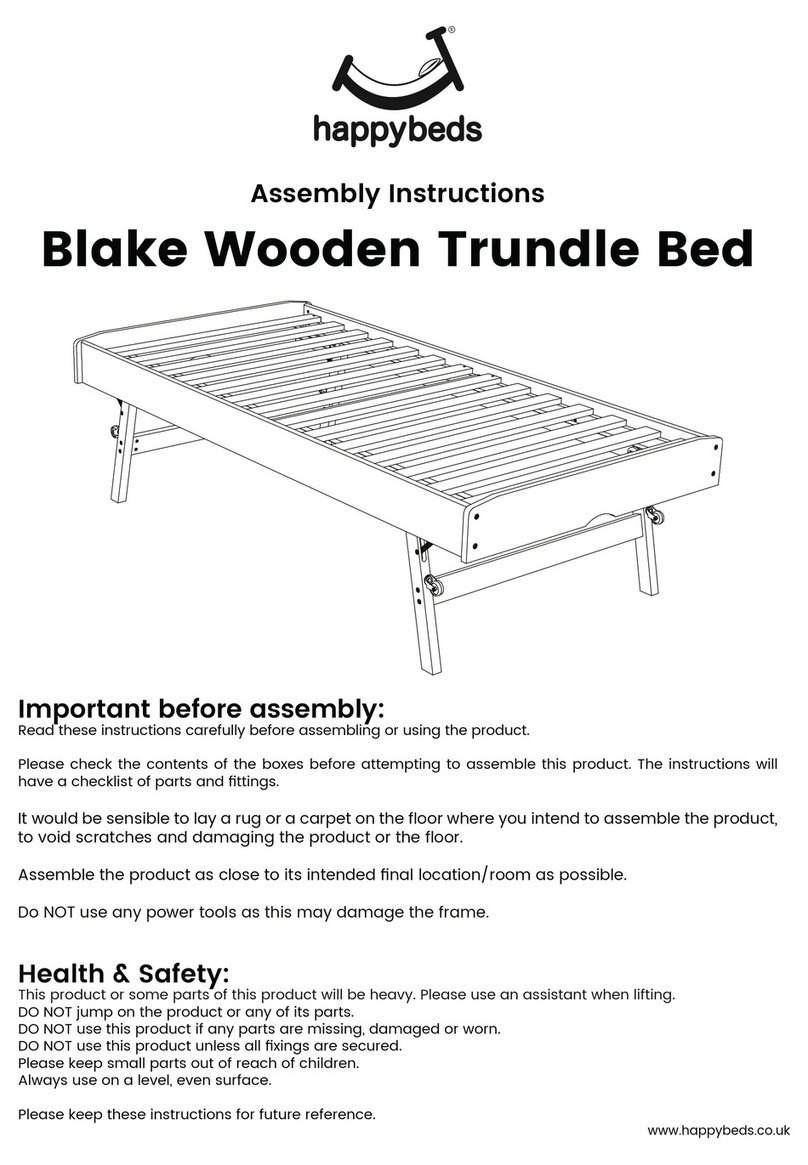

Happy Beds

Happy Beds Blake Wooden Trundle Bed Assembly instructions

GT Racing

GT Racing GT890MF Assembly instructions

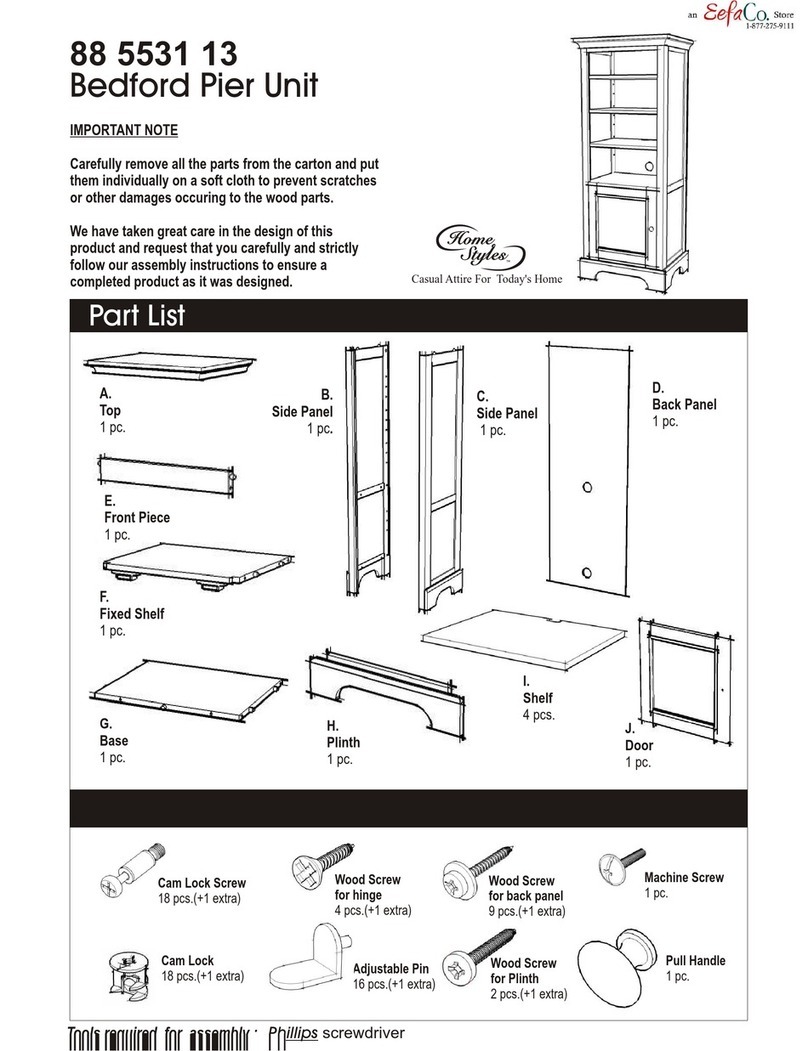

Home Styles

Home Styles 88 5531 13 Assembly manual

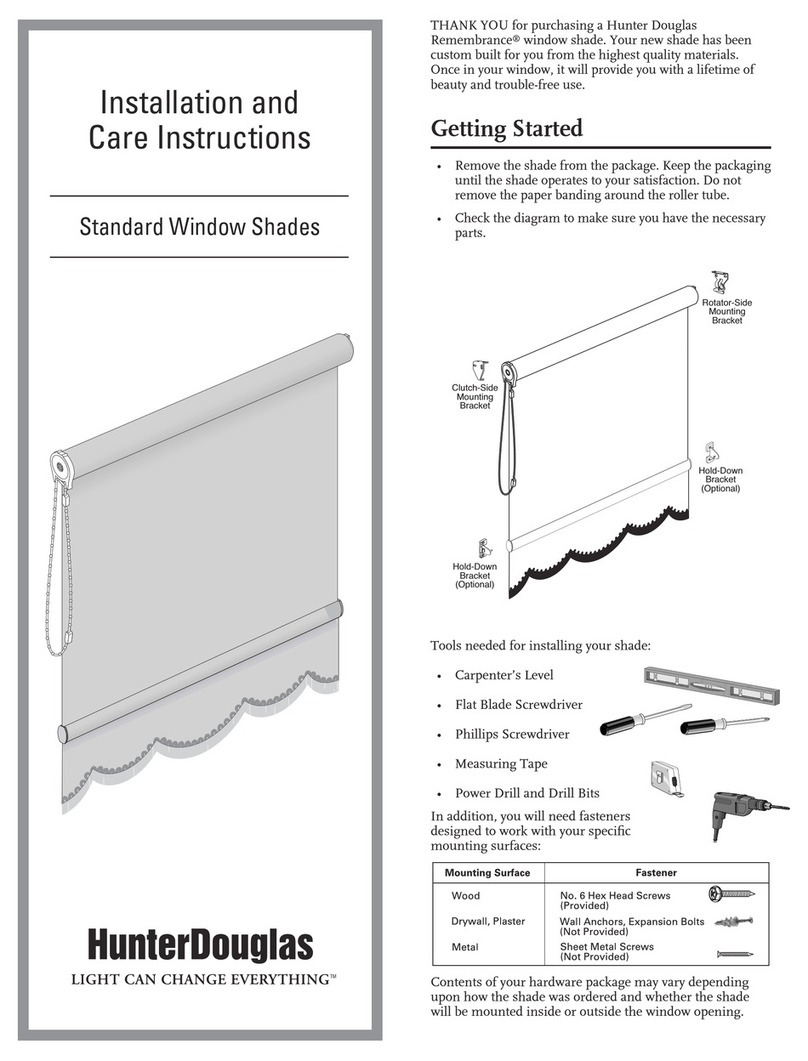

HunterDouglas

HunterDouglas Remembrance INSTALLATION AND CARE INSTRUCTIONS

Simpli Home

Simpli Home 3AXCSAW-03 manual

feather&black

feather&black Shoreditch operating instructions

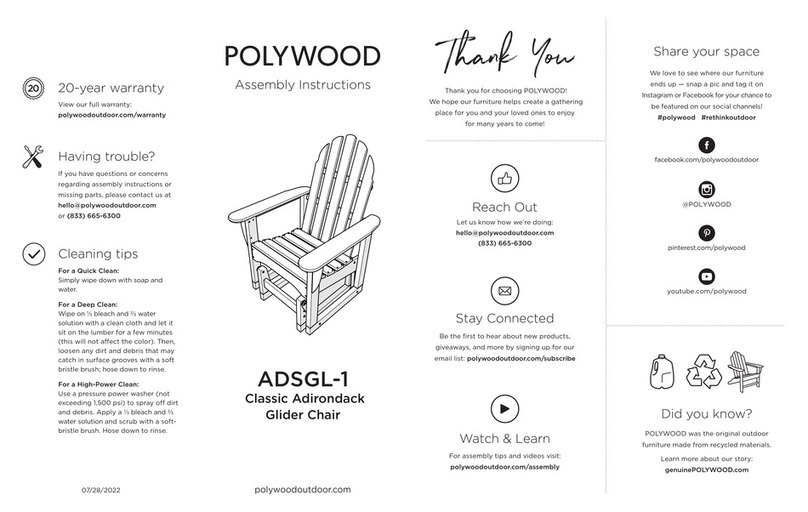

Polywood

Polywood ADSGL-1 Assembly instructions

Jason.L

Jason.L Switch System Small Round Meeting Table Assembly instructions

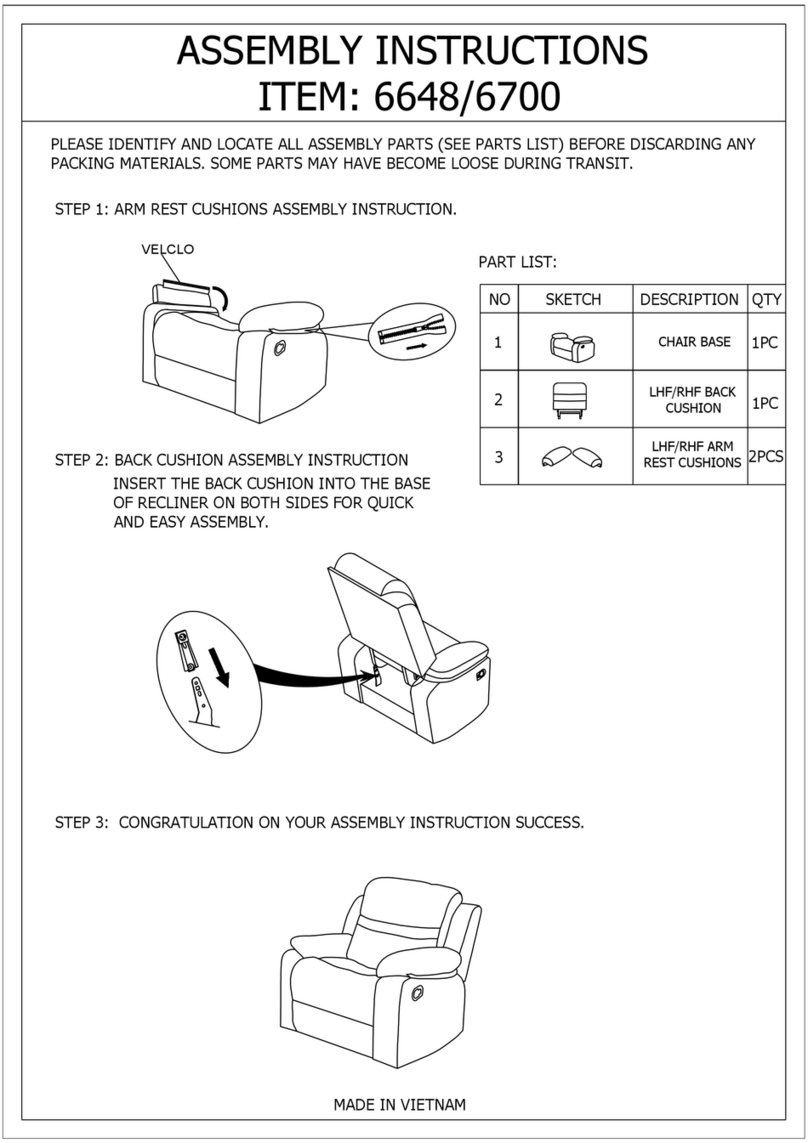

HOMEDEPOT

HOMEDEPOT 6648 Assembly instructions

Simpli Home

Simpli Home Ralston AXCRAL40-RNAB manual

Omnimount

Omnimount LS31 instruction manual

Twin Star Home

Twin Star Home TC68-90481 manual

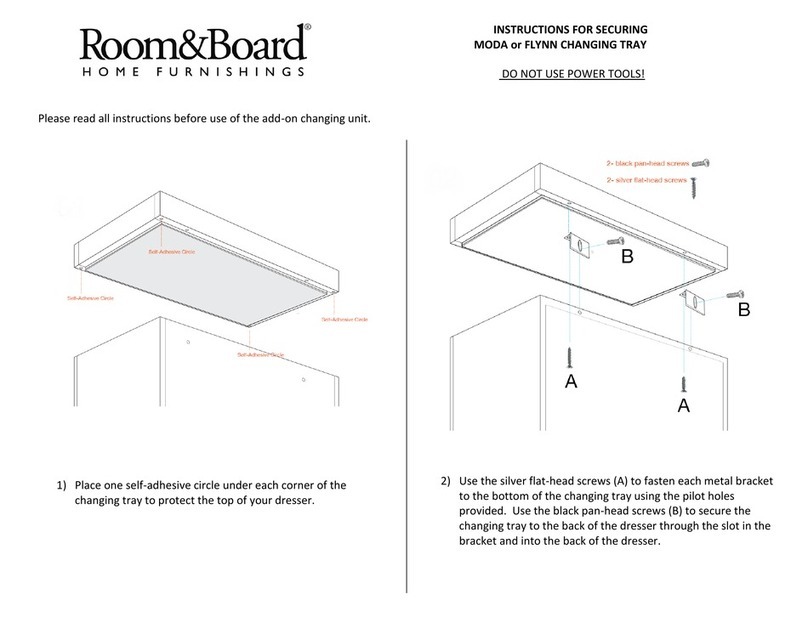

Room & Board

Room & Board FLYNN installation instructions

guide craft

guide craft G97045 Market Loft Assembly instructions

System Build

System Build 7242025P Assembly instruction

MD SPORTS

MD SPORTS BLL090_177P Assembly instructions

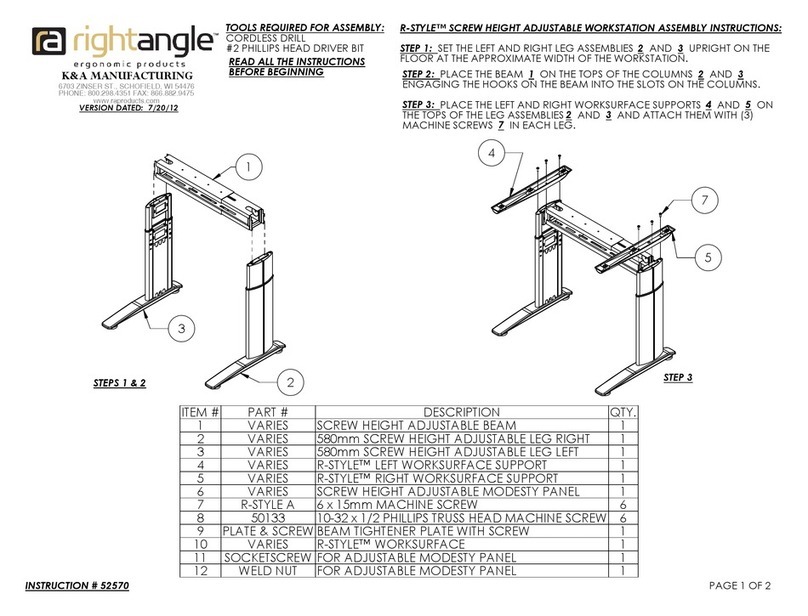

RIGHT ANGLE

RIGHT ANGLE R-STYLE Series Assembly instructions

HAMPTON BAY

HAMPTON BAY ROCK CLIFF FRS60605IRS-2PB Use and care guide