BR-Automation X20CP1301 User manual

X20(c)CP1301, X20CP1381 and X20CP1382

Data sheet V1.21 1

X20(c)CP1301, X20CP1381 and X20CP1382

1 General information

Compact CPUs are available with processor speeds of 200 MHz and 400 MHz. Depending on the variant, up to

256 MB RAM and up to 32 kB nonvolatile onboard RAM is available. A built-in flash drive is available to store up

to 2 GB of application and other data.

All CPUs come equipped with Ethernet, USB and one RS232 interface. In both performance classes, integrated

POWERLINK and CAN bus interfaces are also available. If additional fieldbus connections are needed, the CPU

can be upgraded with an interface module from the standard X20 product range. These CPUs do not require fans

or batteries and are therefore maintenance-free. 30 different digital inputs and outputs and 2 analog inputs are

integrated in the devices. 1 analog input can be used for PT1000 resistance temperature measurement.

•CPU is Intel x86 200/400 MHz compatible with integrated I/O processor

•Ethernet, POWERLINK with poll-response chaining and USB onboard

•1 slot for modular interface expansion

•30 digital inputs/outputs and 2 analog inputs integrated in the device

•1/2 GB flash drive onboard

•128/256 MB DDR3 SDRAM

•Fanless

•No battery

•Battery-backed real-time clock

2 Coated modules

Coated modules are X20 modules with a protective coating for the electronics component. This coating protects

X20c modules from condensation and corrosive gases.

The modules' electronics are fully compatible with the corresponding X20 modules.

For simplification purposes, only images and module IDs of uncoated modules are used in this data

sheet.

The coating has been certified according to the following standards:

•Condensation: BMW GS 95011-4, 2x 1 cycle

•Corrosive gas: EN 60068-2-60, method 4, exposure 21 days

X20(c)CP1301, X20CP1381 and X20CP1382

2 Data sheet V1.21

3 Order data

Model number Short description

X20 CPUs

X20CP1301 ZX20 CPU, with integrated I/O, x86-200, 128 MB DDR3 RAM, 16 kB FRAM, 1 GB onboard flash

drive, 1 insert slot for X20 interface modules, 1 USB interface, 1 RS232 interface, 1 Ethernet

interface 10/100BASE-T, 14 digital inputs, 24 VDC, sink, 4 digital inputs, 2 µs, 24 VDC, sink, 4

digital outputs, 24 VDC, 0.5 A, source, 4 digital outputs, 2 µs, 24 VDC, 0.2 A, 4 digital inputs/out-

puts, 24 VDC, 0.5 A, 2 analog inputs ±10 V or 0 to 20 mA / 4 to 20 mA, 1 PT1000 instead of

an analog input, includes power supply module, 3x terminal block X20TB1F, slot cover and X20

end cover plate X20AC0SR1 (right) included

X20cCP1301 X20 CPU coated, with integrated I/O, x86-200, 128 MB DDR3 RAM, 16 kB FRAM, 1 GB onboard

flash drive, 1 insert slot for X20 interface modules, 1 USB interface, 1 RS232 interface, 1 Ethernet

interface 10/100BASE-T, 14 digital inputs, 24 VDC, sink, 4 digital inputs, 2 µs, 24 VDC, sink, 4

digital outputs, 24 VDC, 0.5 A, source, 4 digital outputs, 2 µs, 24 VDC, 0.2 A, 4 digital inputs/out-

puts, 24 VDC, 0.5 A, 2 analog inputs ±10 V or 0 to 20 mA / 4 to 20 mA, 1 PT1000 instead of

an analog input, includes power supply module, 3x terminal block X20TB1F, slot cover and X20

end cover plate X20AC0SR1 (right) included

X20CP1381 X20 CPU, with integrated I/O, x86-200, 128 MB DDR3 RAM, 16 kB FRAM, 1 GB onboard flash

drive, 1 insert slot for X20 interface modules, 2 USB interfaces, 1 RS232 interface, 1 CAN bus in-

terface, 1 POWERLINK interface, 1 Ethernet interface 10/100BASE-T, 14 digital inputs, 24 VDC,

sink, 4 digital inputs, 2 µs, 24 VDC, sink, 4 digital outputs, 24 VDC, 0.5 A, source, 4 digital outputs,

2 µs, 24 VDC, 0.2 A, 4 digital inputs/outputs, 24 VDC, 0.5 A, 2 analog inputs ±10 V or 0 to 20

mA / 4 to 20 mA, 1 PT1000 instead of an analog input, includes power supply module, 3x terminal

block X20TB1F, slot cover and X20 end cover plate X20AC0SR1 (right) included

X20CP1382 X20 CPU, with integrated I/O, x86-400, 256 MB DDR3 RAM, 32 kB FRAM, 2 GB onboard flash

drive, 1 insert slot for X20 interface modules, 2 USB interfaces, 1 RS232 interface, 1 CAN bus in-

terface, 1 POWERLINK interface, 1 Ethernet interface 10/100BASE-T, 14 digital inputs, 24 VDC,

sink, 4 digital inputs, 2 µs, 24 VDC, sink, 4 digital outputs, 24 VDC, 0.5 A, source, 4 digital outputs,

2 µs, 24 VDC, 0.2 A, 4 digital inputs/outputs, 24 VDC, 0.5 A, 2 analog inputs ±10 V or 0 to 20

mA / 4 to 20 mA, 1 PT1000 instead of an analog input, includes power supply module, 3x terminal

block X20TB1F, slot cover and X20 end cover plate X20AC0SR1 (right) included

Table 1: Order data

Content of delivery

Model number Quantity Short description

- 1 Interface module slot cover

X20AC0SR1 1 X20 end cover plate, right

X20TB1F 3 X20 terminal block, 16-pin, 24 VDC keyed

Table 2: Content of delivery

X20(c)CP1301, X20CP1381 and X20CP1382

Data sheet V1.21 3

4 Technical data

Model number X20CP1301 X20cCP1301 X20CP1381 X20CP1382

Short description

Interfaces 1x RS232, 1x Ethernet, 1x USB, 1x X2X Link 1x RS232, 1x Ethernet, 1x POWER-

LINK, 2x USB, 1x X2X Link, 1x CAN bus

System module CPU

General information

Cooling Fanless

B&R ID code 0xE35B 0xEB58 0xE35C 0xDABB

Status indicators CPU function, Ethernet, RS232, CPU power sup-

ply, I/O power supply, I/O function per channel

CPU function, Ethernet, POWERLINK, RS232,

CAN bus, CAN bus terminating resistor, CPU pow-

er supply, I/O power supply, I/O function per channel

Diagnostics

Outputs Digital outputs: Yes, using status LED and software (output error status)

CPU function Yes, using status LED

CAN bus data transfer - Yes, using status LED

RS232 data transfer Yes, using status LED

Inputs Analog inputs: Yes, using status LED and software

Ethernet Yes, using status LED

I/O power supply Yes, using status LED

POWERLINK - Yes, using status LED

Supply voltage monitoring Yes, using status LED

Overtemperature Yes, using software

Terminating resistor - Yes, using status LED

Controller redundancy possible No

ACOPOS support Yes

reACTION-capable I/O channels No

Visual Components support Yes

Power consumption without interface

module and USB

4.3 W 4.8 W 5.5 W

Power consumption of X2X Link power

supply 1)

0.8 W

Power consumption 1)

Internal I/O 0.8 W

Additional power dissipation caused

by actuators (resistive) [W]

-

Type of signal lines Shielded cables must be used for all high-speed digital inputs/outputs, cable length: Max. 20 m

Certifications

CE Yes

EAC Yes

UL cULus E115267

Industrial control equipment

HazLoc cCSAus 244665

Process control equipment

for hazardous locations

Class I, Division 2, Groups ABCD, T5

ATEX Zone 2, II 3G Ex nA nC IIA T5 Gc

IP20, Ta (see X20 user's manual)

FTZÚ 09 ATEX 0083X

DNV GL Temperature: B (0 - 55°C)

Humidity: B (up to 100%)

Vibration: B (4 g)

EMC: B (bridge and open deck)

CPU and X2X Link power supply

Input voltage 24 VDC -15% / +20%

Input current Max. 1 A

Fuse Integrated, cannot be replaced

Reverse polarity protection Yes

X2X Link power supply output

Nominal output power 2 W

Parallel connection Yes 2)

Redundant operation Yes 3)

Input I/O power supply

Input voltage 24 VDC -15% / +20%

Fuse Required line fuse: Max. 10 A, slow-blow

Output I/O power supply

Nominal output voltage 24 VDC

Permissible contact load 10 A

Controller

Real-time clock Backed up for at least 300 hours, typ. 1000 hours at 25°C, 1 s resolution, -18 to 28 ppm accuracy at 25°C

FPU Yes

Table 3: Technical data

X20(c)CP1301, X20CP1381 and X20CP1382

4 Data sheet V1.21

Model number X20CP1301 X20cCP1301 X20CP1381 X20CP1382

Processor

Type Vx86EX

Clock frequency 200 MHz 400 MHz

L1 cache

Data code 16 kB

Program code 16 kB

L2 cache 128 kB

Integrated I/O processor Processes I/O data points in the background

Modular interface slots 1

Remanent variables 16 kB FRAM, retention >10 years 4) 32 kB FRAM, re-

tention >10 years 4)

Shortest task class cycle time 2 ms 1 ms

Typical instruction cycle time 0.0419 µs 0.0199 µs

Standard memory

RAM 128 MB DDR3 SDRAM 256 MB DDR3 SDRAM

Application memory

Type 1 GB eMMC flash memory 2 GB eMMC flash memory

Data retention 10 years

Writable data amount

Guaranteed 40 TB

Results for 5 years 21.9 GB/day

Guaranteed erase/write cycles 20,000

Error-correcting code (ECC) Yes

Interfaces

Interface IF1

Signal RS232

Variant Connection made using 16-pin X20TB1F terminal block

Max. distance 900 m

Transfer rate Max. 115.2 kbit/s

Interface IF2

Signal Ethernet

Variant 1x RJ45 shielded

Line length Max. 100 m between 2 stations (segment length)

Transfer rate 10/100 Mbit/s

Transfer

Physical layer 10BASE-T/100BASE-TX

Half-duplex Yes

Full-duplex Yes

Autonegotiation Yes

Auto-MDI / MDIX Yes

Interface IF3

Fieldbus - POWERLINK managing or controlled node

Type - Type 4 5)

Variant - 1x RJ45 shielded

Line length - Max. 100 m between 2 stations (segment length)

Transfer rate - 100 Mbit/s

Transfer

Physical layer - 100BASE-TX

Half-duplex - Yes

Full-duplex - POWERLINK mode: No / Ethernet mode: Yes

Autonegotiation - Yes

Auto-MDI / MDIX - Yes

Interface IF4

Type USB 1.1/2.0

Variant Type A

Max. output current 0.5 A

Interface IF5

Type - USB 1.1/2.0

Variant - Type A

Max. output current - 0.1 A

Interface IF6

Fieldbus X2X Link master

Interface IF7

Signal - CAN bus

Variant - Connection made using 16-pin X20TB1F terminal block

Max. distance - 1000 m

Transfer rate - Max. 1 Mbit/s

Terminating resistor - Integrated in module

Controller - SJA 1000

Digital inputs

Quantity 14 standard inputs, 4 high-speed inputs and 4 mixed channels, configuration as input or output using software

Nominal voltage 24 VDC

Input voltage 24 VDC -15% / +20%

Table 3: Technical data

X20(c)CP1301, X20CP1381 and X20CP1382

Data sheet V1.21 5

Model number X20CP1301 X20cCP1301 X20CP1381 X20CP1382

Input current at 24 VDC X1 - Standard inputs: Typ. 3.5 mA

X2 - Standard inputs: Typ. 2.68 mA

X2 - High-speed inputs: Typ. 3.5 mA

X3 - Mixed channels: Typ. 2.68 mA

Input filter

Hardware Standard inputs and mixed channels: ≤200 μs

High-speed inputs: ≤2 μs, when used as standard inputs: ≤200 μs

Software Default 1 ms, configurable between 0 and 25 ms in 0.1 ms intervals

Connection type 1-wire connections

Input circuit Sink

Additional functions X2 - High-speed digital inputs:

2x 250 kHz event counting, 2x AB counter, ABR incremental encoder, direction/frequency, peri-

od measurement, gate measurement, differential time measurement, edge counters, edge times

Input resistance X1 - Standard inputs: 6.8 kΩ

X2 - Standard inputs: 8.9 kΩ

X2 - High-speed inputs: 6.8 kΩ

X3 - Mixed channels: 8.9 kΩ

Switching threshold

Low <5 VDC

High >15 VDC

AB incremental encoder

Quantity 2

Encoder inputs 24 V, asymmetrical

Counter size 32-bit

Input frequency Max. 100 kHz

Evaluation 4x

Encoder power supply Module-internal, max. 300 mA

Overload characteristics of encoder

power supply

Short circuit protection, overload protection

ABR incremental encoder

Quantity 1

Encoder inputs 24 V, asymmetrical

Counter size 32-bit

Input frequency Max. 100 kHz

Evaluation 4x

Encoder power supply Module-internal, max. 300 mA

Overload characteristics of encoder

power supply

Short circuit protection, overload protection

Event counter

Quantity 2

Signal form Square wave pulse

Evaluation 1x

Input frequency Max. 250 kHz

Counter frequency 250 kHz

Counter size 32-bit

Edge detection / Time measurement

Possible measurements Period measurement, gate measurement, differential time measurement, edge counter, edge times

Measurements per module Each function up to 2x

Counter size 32-bit

Input frequency Max. 10 kHz

Timestamp 1 µs resolution

Signal form Square wave pulse

Analog inputs

Input ±10 V or 0 to 20 mA / 4 to 20 mA, via different terminal connections

Input type Differential input

Digital converter resolution

Voltage ±12-bit

Current 12-bit

Conversion time 1 channel enabled: 100 µs

2 channels enabled: 200 µs

Output format

Data type INT

Voltage INT 0x8001 - 0x7FFF / 1 LSB = 0x0008 = 2.441 mV

Current INT 0x0000 - 0x7FFF / 1 LSB = 0x0008 = 4.883 μA

Input impedance in signal range

Voltage 20 MΩ

Current -

Load

Voltage -

Current <300 Ω

Input protection Protection against wiring with supply voltage

Permissible input signal

Voltage Max. ±30 V

Current Max. ±50 mA

Table 3: Technical data

X20(c)CP1301, X20CP1381 and X20CP1382

6 Data sheet V1.21

Model number X20CP1301 X20cCP1301 X20CP1381 X20CP1382

Output of digital value during overload Configurable

Conversion procedure SAR

Input filter 3rd-order low pass / cutoff frequency 1 kHz

Max. error at 25°C

Voltage

Gain 0.18% (Rev. <C0: 0.37%) 6)

Offset 0.04% (Rev. <C0: 0.25%) 7)

Current

Gain 0 to 20 mA = 0.15% (Rev. <C0: 0.52%) / 4 to 20 mA = 0.25% 6)

Offset 0 to 20 mA = 0.1% (Rev. <C0: 0.4%) / 4 to 20 mA = 0.15% 8)

Max. gain drift

Voltage 0.017 %/°C 6)

Current 0 to 20 mA = 0.015 %/°C / 4 to 20 mA = 0.023 %/°C 6)

Max. offset drift

Voltage 0.008 %/°C 7)

Current 0 to 20 mA = 0.008 %/°C / 4 to 20 mA = 0.012 %/°C 8)

Common-mode rejection

DC 70 dB

50 Hz 70 dB

Common-mode range ±12 V

Crosstalk between channels <-70 dB

Nonlinearity

Voltage <0.025% 7)

Current <0.05% 8)

Resistance measurement temperature inputs

Quantity 1

Input Resistance measurement with constant current supply for 2-wire connections

Digital converter resolution 13-bit

Conversion time Only temperature input enabled: 200 µs

Temperature and analog input enabled: 400 µs

Conversion procedure SAR

Output format INT or UINT for resistance measurement

Sensor

PT1000 -200 to 850°C

Resistance measurement range 0.1 to 4000 Ω

Temperature sensor resolution 1 LSB = 0x0005 = 0.16°C

Resistance measurement resolution 1 LSB = 0x0005 = 0.49 Ω

Input filter 1st-order low pass / cutoff frequency 7 Hz

Sensor standard EN 60751

Common-mode range 1 V

Linearization method Internal

Measurement current 1 mA

Permissible input signal Short-term max. ±30 V

Max. error at 25°C

Gain 0.3% (Rev. <C0: 1.93%) 9)

Offset 0.15% (Rev. <C0: 0.32%) 10)

Max. gain drift 0.023 %/°C 9)

Max. offset drift 0.012%/°C 10)

Nonlinearity <0.05% 10)

Standardized range of values for resis-

tance measurement

0.1 to 4000.0 Ω

Crosstalk between channels <-70 dB

Common-mode rejection

50 Hz >60 dB

Temperature sensor normalization

PT1000 -200 to 850°C

Digital outputs

Quantity 4 standard outputs, 4 high-speed outputs and 4 mixed channels, configuration as input or output using software

Variant Standard outputs and mixed channels: FET positive switching

High-speed outputs: Push-Pull

Nominal voltage 24 VDC

Switching voltage 24 VDC -15% / +20%

Nominal output current Standard outputs and mixed channels: 0.5 A

High-speed outputs: 0.2 A

Total nominal current Standard outputs and mixed channels: 4 A

High-speed outputs: 0.8 A

Connection type 1-wire connections

Output circuit Standard outputs and mixed channels: Source

High-speed outputs: Sink or source

Output protection 11) Thermal cutoff if overcurrent or short circuit occurs (see value "Peak short circuit current")

Internal inverse diode for switching inductive loads (see section "Switching inductive loads")

Table 3: Technical data

X20(c)CP1301, X20CP1381 and X20CP1382

Data sheet V1.21 7

Model number X20CP1301 X20cCP1301 X20CP1381 X20CP1382

Pulse width modulation 12)

Period duration 5 to 65535 µs corresponds to 200 kHz to 15 Hz

Pulse duration 0 to 100%, minimum 2.5 µs

Resolution for pulse duration 0.1% of the configured frequency

Diagnostic status Standard outputs and mixed channels: Output monitoring with 10 ms delay

High-speed outputs: Output monitoring with 10 µs delay

Leakage current when switched off Standard outputs and mixed channels: 5 µA

High-speed outputs: 25 µA

RDS(on) 140 mΩ 13)

Residual voltage Standard outputs and mixed channels: <0.1 V at nominal current 0.5 A

High-speed outputs: <0.9 V at nominal current 0.1 A

Peak short-circuit current Standard outputs and mixed channels: <3 A

High-speed outputs: <20 A

Switching on after overload or short-

circuit cutoff

Standard outputs and mixed channels: Approx. 10 ms (depends on module temperature)

High-speed outputs: No switch-on

Switching delay

0 → 1 Standard outputs and mixed channels: <300 µs

High-speed outputs: <3 µs

1 → 0 Standard outputs and mixed channels: <300 µs

High-speed outputs: <3 µs

Switching frequency

Resistive load 14) Standard outputs and mixed channels: Max. 500 Hz

High-speed outputs: 50 kHz, max. 200 kHz (see section "Switching frequency derating for high-speed digital outputs")

Inductive load See section "Switching inductive loads"

Braking voltage when switching off in-

ductive loads

Standard outputs and mixed channels: Typ. 45 VDC

Electrical properties

Electrical isolation Ethernet (IF2) and X2X (IF6) isolated from

each other, from other interfaces and from PLC

Channel isolated from bus

Channel not isolated from channel or PLC

Ethernet (IF2), POWERLINK (IF3) and X2X (IF6) isolat-

ed from each other, from other interfaces and from PLC

Channel isolated from bus

Channel not isolated from channel or PLC

Operating conditions

Mounting orientation

Horizontal Yes

Vertical Yes

Installation elevation above sea level

0 to 2000 m No limitation

>2000 m Reduction of ambient temperature by 0.5°C per 100 m

Degree of protection per EN 60529 IP20

Ambient conditions

Temperature

Operation

Horizontal mounting orientation -25 to 60°C

Vertical mounting orientation -25 to 50°C

Derating See section "Switching frequency derating for high-speed digital outputs".

Storage -40 to 85°C

Transport -40 to 85°C

Relative humidity

Operation 5 to 95%, non-condensing Up to 100%, condensing 5 to 95%, non-condensing

Storage 5 to 95%, non-condensing

Transport 5 to 95%, non-condensing

Mechanical properties

Note X20 end cover plate (right) included in delivery

3 X20 terminal blocks (16-pin) included in delivery

Interface module slot cover included in delivery

Dimensions

Width 164 mm

Height 99 mm

Depth 75 mm

Weight 300 g 310 g

Table 3: Technical data

1) The specified values are maximum values. For examples of the exact calculation, see section "Mechanical and electrical configuration" of the X20 system

user's manual.

2) When operated in parallel, the nominal power of 2 W is not permitted to be added to the total power.

3) Up to 2 W bus load.

4) The size of the memory used for remanent variables is configurable in Automation Studio.

5) See Automation Help under "Communication / POWERLINK / General information / Hardware - IF/LS" for more information.

6) Based on the current measured value.

7) Based on the 20 V measurement range.

8) Based on the 20 mA measurement range.

9) Based on the current resistance value.

10) Based on the entire resistance measurement range.

11) For the high-speed digital outputs, derating must be taken into account at a switching frequency >50 kHz (see section "Derating for switching frequency of

high-speed digital outputs"). Overtemperature protection is not provided.

X20(c)CP1301, X20CP1381 and X20CP1382

8 Data sheet V1.21

12) The high-speed digital outputs can be used for pulse width modulation.

13) Only for standard outputs and mixed channels.

14) Standard outputs and mixed channels: At loads ≤ 1 kΩ

5 LED status indicators

5.1 Slot X1

Figure LED Color Status Description

On SERVICE or BOOT operating mode

Blinking The "E" LED blinks red and the "RF" LED blinks yellow when there is a license

violation.

E Red

Double flash Firmware update1)

On Application runningGreen

Blinking Boot mode system start:

CPU initializing the application, all bus systems and I/O modules1)

R

Red On During reset

On SERVICE or BOOT operating modeRF Yellow

Blinking The "RF" LED blinks yellow and the "E" LED blinks red when there is a license

violation.

SE Green/Red Status/Error LED. LED states are described in section "LED "S/E" (LED "Sta-

tus/Error")" on page 8.

On A link to the Ethernet remote station has been established.ET Green

Blinking A link to the Ethernet remote station has been established. The LED blinks when

Ethernet activity is taking place on the bus.

On A link to the POWERLINK peer station has been established.PL Green

Blinking A link to the POWERLINK peer station has been established. The LED blinks

when Ethernet activity is taking place on the bus.

Off Open circuit or disconnected sensor

Blinking Input signal overflow or underflow

A1 - A2 Green

On Analog/digital converter running, value OK

1 - 4 Green Input state of the corresponding digital input

C Yellow On CPU transmitting or receiving data via the CAN bus interface

S Yellow On CPU transmitting or receiving data via the RS232 interface

T Yellow On The terminating resistor integrated in the CPU is switched on.

DC Yellow On CPU power supply OK

Table 4: LED status indicators on the integrated X1 I/O slot

1) The process can take several minutes depending on the configuration.

5.1.1 LED "S/E" (LED "Status/Error")

This LED is a green/red dual LED and indicates the state of the POWERLINK interface. The LED states have a

different meaning depending on the operating mode of the POWERLINK interface.

5.1.1.1 Ethernet mode

In this mode, the interface is operated as an Ethernet interface.

LED "S/E"

Green Red Description

On Off The interface is being operated as an Ethernet interface.

Table: LED "S/E": Interface in Ethernet mode

X20(c)CP1301, X20CP1381 and X20CP1382

Data sheet V1.21 9

5.1.1.2 POWERLINK V2 mode

Error message

LED "S/E"

Green Red Description

Off On The interface is in the error mode (failed Ethernet frames, increased number of collisions on the network, etc.).

Note:

Several red blinking signals are displayed immediately after the device is switched on. These are not errors, however.

Blinking On If an error occurs in the following modes, then the green LED blinks over the red LED:

•PRE_OPERATIONAL_1

•PRE_OPERATIONAL_2

•READY_TO_OPERATE

t

t

t

LED "S/E"

Status

Green

Error

Red

Table: LED "S/E" - Error message (interface in POWERLINK mode)

Interface status

LED "S/E"

Green Red Description

Off Off Mode: NOT_ACTIVE

The interface is either in mode NOT_ACTIVE or one of the following modes or errors is present:

•The device is switched off.

•The device is in the startup phase.

•The interface or device is not configured correctly in Automation Studio.

•The interface or device is defective.

Managing node (MN)

The network is monitored for POWERLINK frames. If a frame is not received within the configured time window (timeout), the

interface immediately enters mode PRE_OPERATIONAL_1.

If POWERLINK communication is detected before the time has elapsed, however, the MN is not started.

Controlled node (CN)

The network is monitored for POWERLINK frames. If a frame is not received within the configured time window (timeout), the

interface immediately enters mode BASIC_ETHERNET. If POWERLINK communication is detected before this time expires,

however, the interface immediately enters mode PRE_OPERATIONAL_1.

Flickering

(approx.

10 Hz)

Off Mode: BASIC_ETHERNET

The interface is in mode BASIC_ETHERNET. The interface is operated in Ethernet mode.

Managing node (MN)

This mode can only be exited by resetting the controller.

Controlled node (CN)

If POWERLINK communication is detected during this mode, the interface enters mode PRE_OPERATIONAL_1.

Off Mode: PRE_OPERATIONAL_1

The interface is in mode PRE_OPERATIONAL_1.

Managing node (MN)

The MN is in "reduced cycle" operation. The CNs are configured in this mode.

Cyclic communication is not yet taking place.

Controlled node (CN)

The CN can be configured by the MN in this mode. The CN waits until it receives an SoC frame and then switches to mode

PRE_OPERATIONAL_2.

Single flash

(approx. 1 Hz)

On Controlled node (CN)

If the red LED lights up in this mode, this means that the MN has failed.

Off Mode: PRE_OPERATIONAL_2

The interface is in mode PRE_OPERATIONAL_2.

Managing node (MN)

The MN starts cyclic communication (cyclic input data is not yet evaluated).

The CNs are configured in this mode.

Controlled node (CN)

The CN can be configured by the MN in this mode. A command then switches the mode to READY_TO_OPERATE.

Double flash

(approx. 1 Hz)

On Controlled node (CN)

If the red LED lights up in this mode, this means that the MN has failed.

Table: LED "S/E" - Interface state (interface in POWERLINK mode)

X20(c)CP1301, X20CP1381 and X20CP1382

10 Data sheet V1.21

LED "S/E"

Green Red Description

Off Mode: READY_TO_OPERATE

The interface is in mode READY_TO_OPERATE.

Managing node (MN)

Cyclic and asynchronous communication. Received PDO data is ignored.

Controlled node (CN)

The configuration of the CN is completed. Normal cyclic and asynchronous communication. The transmitted PDO data corre-

sponds to the PDO mapping. However, cyclic data is not yet evaluated.

Triple flash

(approx. 1 Hz)

On Controlled node (CN)

If the red LED lights up in this mode, this means that the MN has failed.

On Off Mode: OPERATIONAL

The interface is in mode OPERATIONAL. PDO mapping is active and cyclic data is evaluated.

Blinking

(approx.

2.5 Hz)

Off Mode: STOPPED

The interface is in mode STOPPED.

Managing node (MN)

This mode does not occur for the MN.

Controlled node (CN)

Output data is not being output, and no input data is being provided. This mode can only be reached and exited by a corre-

sponding command from the MN.

Table: LED "S/E" - Interface state (interface in POWERLINK mode)

Blink times

200

200

1000

200

200

200

200

1000

200

200

All times in ms

Flickering

Blinking

Single flash

Triple flash

200

200

200

1000

Double flash

5.1.2 System stop error codes

A system stop error can occur due to incorrect configuration or defective hardware.

The error code is indicated by LED "S/E" blinking red. The blinking signal of the error code consists of 4 switch-on

phases with short (150 ms) or long (600 ms) duration. The error code is repeated every 2 seconds.

All times in ms

RAM error

Hardware error

150 150 150300 300 300 600 2000

150 150

300 300300600 2000600

Error Error description

RAM error The device is defective and must be replaced.

Hardware error The device or a system component is defective and must be replaced.

X20(c)CP1301, X20CP1381 and X20CP1382

Data sheet V1.21 11

5.2 Slot X2

Figure LED Color Status Description

1 - 14 Green Input state of the corresponding digital input

Table 5: LED status indicators on the integrated X2 I/O slot

5.3 Slot X3

Figure LED Color Status Description

DC Yellow On I/O power supply OK

Off Everything OKE Red

Double flash No power to module

1 - 4 Yellow Output status of the corresponding digital output

5 - 8 Yellow Input or output status of the corresponding digital input or output

9 - 12 Yellow Output status of the corresponding high-speed digital output

Table 6: LED status indicators on the integrated X3 I/O slot

X20(c)CP1301, X20CP1381 and X20CP1382

12 Data sheet V1.21

6 Operating and connection elements

X20CP1301

Integrated flash drive

Connections for:

- Power supplies

- I/O channels

- IF1 - RS232

3 integrated I/O slots:

X1, X2 and X3

LED status indicators

Button for

reset and operating mode

IF4 - USB

IF6 - X2X Link

IF2 - Ethernet

X1 X2 X3

Top-hat rail

locking mechanism

Slot for

interface module

X20CP1381 and X20CP1382

Integrated flash drive

LED status indicators

Button for

reset and operating mode

IF4 - USB

IF5 - USB

Top-hat rail

locking mechanism

Slot for

interface module

Switch for CAN bus

terminating resistor

Connections for:

- power supplies

- I/O channels

- IF1 - RS232

- IF7 - CAN bus

3 integrated I/O slots:

X1, X2 and X3

IF6 - X2X Link

IF2 - Ethernet

IF3 - POWERLINK

X1 X2 X3

X20(c)CP1301, X20CP1381 and X20CP1382

Data sheet V1.21 13

6.1 Button for reset and operating mode

Figure 1: Button for reset and operating mode

6.1.1 Reset

The button must be pressed for less than 2 seconds to trigger a reset. This triggers a hardware reset on the CPU,

which means that:

•All application programs are stopped.

•All outputs are set to zero.

The PLC then boots into service mode by default. The startup mode that follows after pressing the reset button

can be defined in Automation Studio.

•Service mode (default)

•Warm restart

•Cold restart

•Diagnostic mode

6.1.2 Operating mode

3 operating modes can be configured using different button sequences:

Operating mode Button sequence Description

BOOT Boot mode is enabled by the following button sequence:

•Press the button for less than 2 seconds.

As soon as the "R" LED on the X1 I/O slot is lit RED, the

button can be released.

•Then press the button within 2 seconds for longer than

2 seconds.

As soon as the "R" LED is no longer lit, the button can be

released.

The default Automation Runtime system is started and the runtime

system can be installed via the online interface (Automation Studio).

User flash memory is deleted only after the download begins.

RUN Press the button for less than 2 seconds.

As soon as the "R" LED on the X1 I/O slot is lit RED, the button

can be released.

RUN mode:

The triggering and boot behavior are the same as what happens

when a hardware reset is triggered (see "Reset" on page 13).

DIAGNOSE Press the button for more than 2 seconds.

The "R" LED on the X1 I/O slot lights up RED and then goes out.

As soon as the "R" LED is no longer lit, the button can be re-

leased.

Boots the CPU in diagnostic mode. Program sections in User RAM

and User FlashPROM are not initialized. After diagnostic mode, the

CPU always boots with a cold restart.

6.2 Flash drive

This application memory is integrated on a flash drive.

6.3 Project installation

Project installation is described in Automation Help under "Project management / Project installation".

X20(c)CP1301, X20CP1381 and X20CP1382

14 Data sheet V1.21

6.4 RS232 interface (IF1)

The non-electrically isolated RS232 interface is primarily intended to serve as an online interface for communication

with the programming device. It is located on the X1 I/O slot.

RS232 RXD

GND

E

RF

C

T

ET

A1

1

3

R

S

PL

A2

2

4

E

S

DC

RS232 TXD

Figure 2: RS232 interface (IF1) on the X1 I/O slot - Pinout

6.5 Ethernet interface (IF2)

The IF2 interface is designed for 10BASE-T / 100BASE-TX transmission.

The INA2000 station number can be set using the Automation Studio software.

Information about cabling X20 modules with an Ethernet interface can be found in the module's download section

at (www.br-automation.com).

Information:

The Ethernet interface (IF2) is not suitable for POWERLINK (see "POWERLINK interface (IF3)" on page

15).

Pinout

PinoutInterface

Pin Ethernet

1 TXD Transmit data

2 TXD\ Transmit data\

3 RXD Receive data

4 Termination

5 Termination

6 RXD\ Receive data\

7 Termination

1

Shielded RJ45 8 Termination

X20(c)CP1301, X20CP1381 and X20CP1382

Data sheet V1.21 15

6.6 POWERLINK interface (IF3)

Compact CPUs X20CP1381 and X20CP1382 are equipped with a POWERLINK V2 interface.

POWERLINK

By default, the POWERLINK interface is operated as a managing node (MN). In the managing node, the node

number is set to a fixed value of 240.

If the POWERLINK node is operated as a controlled node (CN), a node number from 1 to 239 can be set in the

POWERLINK configuration in Automation Studio.

Ethernet mode

In this mode, the interface is operated as an Ethernet interface. The INA2000 node number is set using the B&R

Automation Studio software.

Pinout

For information about wiring X20 modules with an Ethernet interface, see section "Mechanical and electrical con-

figuration - Wiring guidelines for X20 modules with Ethernet cables" of the X20 user's manual.

PinoutInterface

Pin Ethernet

1 RXD Receive data

2 RXD\ Receive data\

3 TXD Transmit data

4 Termination

5 Termination

6 TXD\ Transmit data\

7 Termination

1

Shielded RJ45 8 Termination

X20(c)CP1301, X20CP1381 and X20CP1382

16 Data sheet V1.21

6.7 USB interfaces (IF4 and IF5)

IF5 - USBIF4 - USB

IF4 and IF5 are non-galvanically isolated USB interfaces. The connection is made via a USB interface (1.1/2.0).

The USB interfaces can only be used for devices approved by B&R (e.g. floppy disk drive, DiskOnKey or dongle).

Information:

•The USB interfaces cannot be used as online communication interfaces.

•Only devices isolated from GND are permitted to be connected to the USB interfaces.

•Current-carrying capacity is listed in the technical data.

Only interface IF4 is available on the entry level CPU.

X20(c)CP1301, X20CP1381 and X20CP1382

Data sheet V1.21 17

6.8 CAN bus interface (IF7)

With the exception of the entry level CPU, all compact CPUs are equipped with a non-electrically isolated CAN

bus interface. It is located on the X1 I/O slot.

6.8.1 Pinout

CAN low

CAN high

GND

E

FRF

C

T

ET

A1

1

3

R

S

PL

A2

2

4

E

S

DC

Figure 3: CAN bus interface (IF7) on the X1 I/O slot - Pinout

6.8.2 Terminating resistor

Terminating resistor switch

On Off

Integrated I/O slot

X1

X2

X3

Figure 4: Switch positions for the CAN bus terminating resistor

A terminating resistor is already installed on the X1 I/O slot. It can be turned on and off with a switch on top of the

housing. An active terminating resistor is indicated by the "T" LED.

6.9 Slot for interface modules

These CPUs are equipped with one slot for interface modules.

Various bus and network systems can easily be integrated into the X20 system by selecting the corresponding

interface module.

X20(c)CP1301, X20CP1381 and X20CP1382

18 Data sheet V1.21

6.10 Data and real-time clock buffering

The CPUs do not use a battery. This makes them completely maintenance-free. The following measures make

operation without a backup battery possible.

Data and real-time clock buffering Type of buffering Note

Remanent variables FRAM This FRAM stores its contents ferroelectrically. Unlike normal SRAM, this does

not require a battery.

Real-time clock Gold foil capacitor The real-time clock is buffered for approx. 1000 hours by a gold foil capacitor. The

gold foil capacitor is completely charged after 3 continuous hours of operation.

7 CPU supply

A power supply is integrated in these compact CPUs. It has a feed for the CPU, X2X Link and the internal I/O

power supply. The supply for the CPU and X2X Link is electrically isolated.

The connections are located on the X3 I/O slot.

Power supply concept of Compact CPUs

To ensure proper operation of compact CPUs, the following items must be taken into consideration:

The supply concept Description

CPU and I/O GND The GND contact is provided 5 times on the terminal blocks of the integrated I/O slots. All GND contacts are connected to one

another. The GND contacts of the CPU and I/O power supply therefore use the same voltage.

Plug-in X20 I/O modules Supply of X20 I/O modules that can be connected to the compact CPU:

•X2X Link: Supplied by the CPU supply

•I/O channels: Supplied by the I/O power supply

Integrated X1 I/O slot All digital and analog signals as well as the RS232 and CAN bus interface are supplied by the CPU supply. Their operation is

therefore guaranteed even if there is no I/O power supply.

Integrated X2 I/O slot •All digital signals are supplied by the CPU supply. Their operation is therefore guaranteed even if there is no I/O power

supply.

•The encoder supply is supplied by the I/O power supply. If the encoder is not to be connected to the E-stop chain, then

it must be connected to an external power supply or it will be supplied by the CPU supply.

Integrated X3 I/O slot •All 12 digital signals are supplied by the I/O power supply.

•The status messages for each channel also work without an I/O power supply. This guarantees that status messages will

continue to be transferred during an E-stop.

•The status of the I/O power supply is indicated by a separate status message.

Caution!

Channels 5 to 8 are designed as mixed channels. If one of these channels is being used, it is absolutely essential to

ensure that there is no external voltage present on the I/O channel when the I/O power supply is cut off. Otherwise,

power will be regenerated back to the plus terminal of the I/O power supply via the I/O channel. This will result

in defective components.

The following solutions are available for preventing power regeneration from occurring:

•The I/O power supply of the CPU is not permitted to be switched off, which allows the reference potential

to be maintained.

•If the I/O power supply is switched off anyway (e.g. as part of the E-stop chain), then the sensor/actu-

ator supplies must also be switched off. This prevents potential power regeneration and protects com-

ponents from being destroyed.

X20(c)CP1301, X20CP1381 and X20CP1382

Data sheet V1.21 19

Pinout

+24 V CP/X2X L. +24 V I/O

GND GND

DC

1

3

5

7

9

11

E

2

4

6

8

10

12

Figure 5: Integrated power supply - Pinout

Connection example

+

_

+

_

GND

+24 VDC

GND

+24 VDC

X3

CPU/X2X Link

power supply

I/O

power supply

10 A slow-blow

Figure 6: CPU supply - Connection example

8 Overtemperature cutoff

To prevent damage, a shutdown/reset is triggered on the CPU when the processor reaches 95°C.

The following errors are entered in the logbook in the event of cutoff:

Error number Short error text

9204 PLC restart triggered by the PLC CPU's temperature monitoring.

9210 Warning: Halt/Service after watchdog or manual reset.

X20(c)CP1301, X20CP1381 and X20CP1382

20 Data sheet V1.21

9 Local I/O channels

Compact CPUs are equipped with 3 integrated I/O slots. These devices have 30 digital inputs/outputs and 2 analog

inputs.

Information about the functions of the high-speed digital inputs and outputs can be found in the section "Functions

of the high-speed digital inputs/outputs" on page 26.

The following table provides an overview of the connections to the I/O channels and their properties.

Digital inputs/outputs

Connection Terminal

connection

Channel Description

14 DI 1 24 VDC, sink, ≤200 µs, configurable software filter

24 DI 2 24 VDC, sink, ≤200 µs, configurable software filter

15 DI 3 24 VDC, sink, ≤200 µs, configurable software filter

X1

25 DI 4 24 VDC, sink, ≤200 µs, configurable software filter

11 DI 1 24 VDC, sink, ≤200 µs, configurable software filter

21 DI 2 24 VDC, sink, ≤200 µs, configurable software filter

... ... ...

25 DI 10 24 VDC, sink, ≤200 µs, configurable software filter

16 DI 11 24 VDC, sink, ≤2 µs, configurable software filter

26 DI 12 24 VDC, sink, ≤2 µs, configurable software filter

17 DI 13 24 VDC, sink, ≤2 µs, configurable software filter

X2

27 DI 14 24 VDC, sink, ≤2 µs, configurable software filter

11 DO 1 24 VDC, 0.5 A, source, <300 µs

21 DO 2 24 VDC, 0.5 A, source, <300 µs

12 DO 3 24 VDC, 0.5 A, source, <300 µs

22 DO 4 24 VDC, 0.5 A, source, <300 µs

13 DI 5 / DO 5 DI: 24 VDC, sink, ≤200 µs, configurable software filter

DO: 24 VDC, 0.5 A, source, <300 µs

23 DI 6 / DO 6 DI: 24 VDC, sink, ≤200 µs, configurable software filter

DO: 24 VDC, 0.5 A, source, <300 µs

14 DI 7 / DO 7 DI: 24 VDC, sink, ≤200 µs, configurable software filter

DO: 24 VDC, 0.5 A, source, <300 µs

24 DI 8 / DO 8 DI: 24 VDC, sink, ≤200 µs, configurable software filter

DO: 24 VDC, 0.5 A, source, <300 µs

15 DO 9 24 VDC, 0.2 A, push-pull, <3 µs

25 DO 10 24 VDC, 0.2 A, push-pull, <3 µs

16 DO 11 24 VDC, 0.2 A, push-pull, <3 µs

X3

26 DO 12 24 VDC, 0.2 A, push-pull, <3 µs

Analog inputs

Connection Terminal

connection

Channel Description

11, 12, 13 AI 1 ±10 V / 0 to 20 mA or 4 to 20 mA, 12-bit, 1 msX1

21, 22, 23 AI 2 ±10 V / 0 to 20 mA or 4 to 20 mA, 12-bit, 1 ms

Analog input 1 can also be used for PT1000 resistance temperature measurement.

Connection Terminal

connection

Channel Description

X1 11, 12, 13 AI 1 PT1000 resistance temperature measurement

Measurement takes place using analog input A1.

This manual suits for next models

3

Table of contents

Popular Computer Hardware manuals by other brands

Congatec

Congatec conga-QEVAL/Qseven 2.0 user guide

Advantech

Advantech MOS-1121Y Series user manual

Phanteks

Phanteks GLACIER C360A installation guide

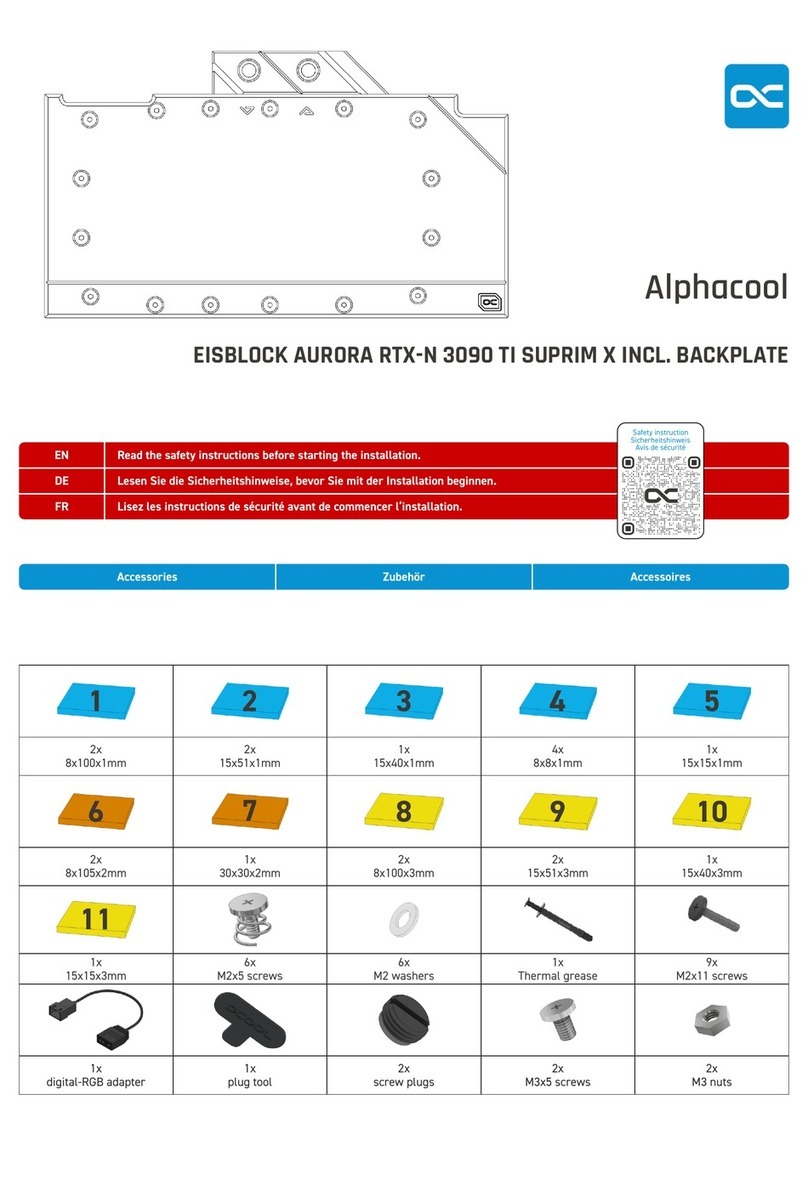

Alphacool

Alphacool EISBLOCK AURORA RTX-N 3090 TI SUPRIM X INCL.... manual

Renesas

Renesas Converter Board M3T-100LCC-QSD user manual

Analog Devices

Analog Devices ADSP-BF535 Blackfin Hardware reference