Page 4 of 8 █ © Brüel & Kjaer Vibro ●January 2018 ● C106833.002 / V01

Technical alterations reserved!

EN

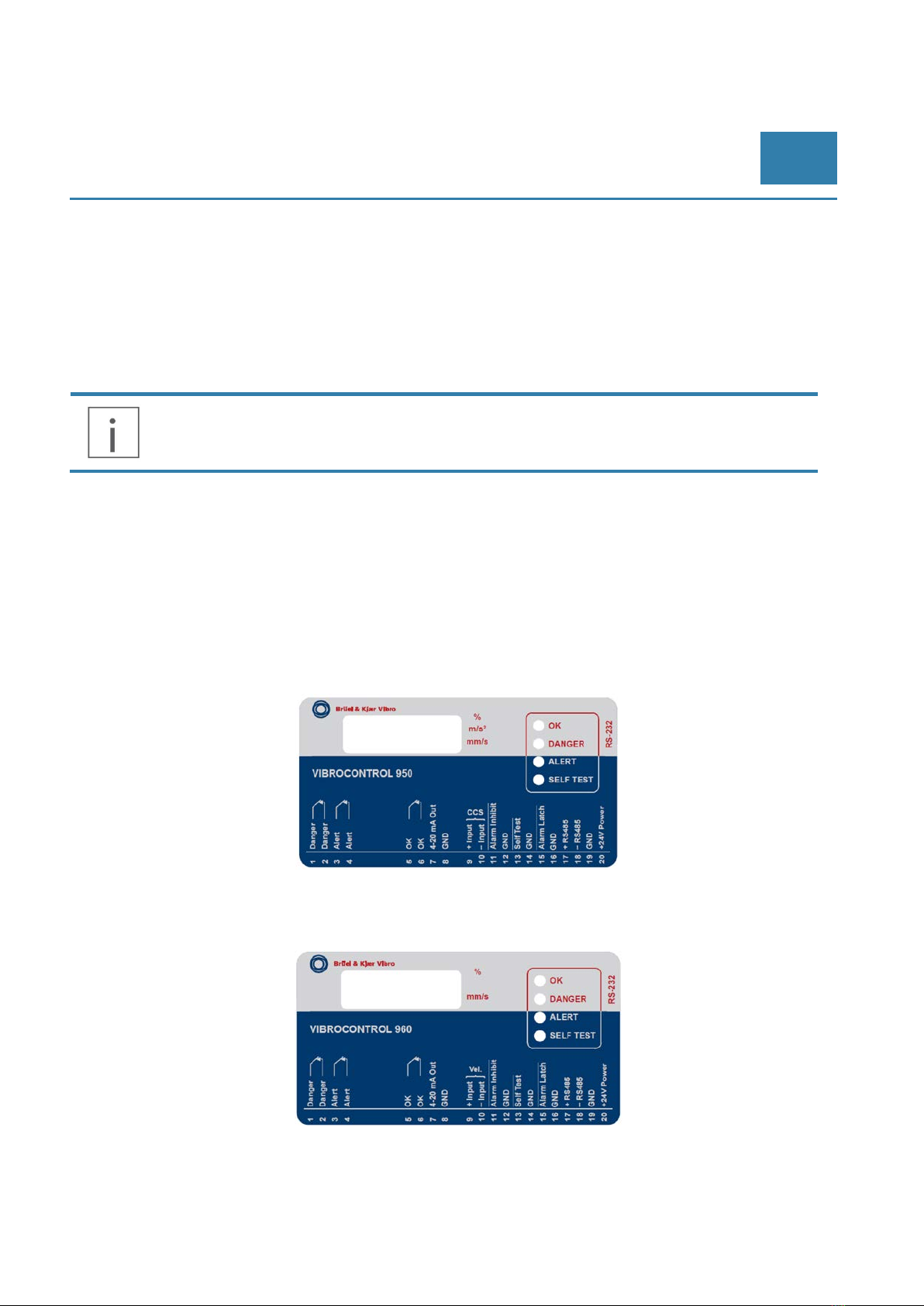

3 Hints for safe operation of VIBROCONTROL 950/960

General:

Please carefully read the operating instructions prior to set-up of the device. Make sure that your

VIBROCONTROL 950/960 device is suitable for your application without any restrictions.

Improper use:

Any improper or non-intended use may lead to malfunctions of the VIBROCONTROL 950/960 device

or to unwanted effects in your application. If the VIBROCONTROL 9x0 is used in a way not described

in the relevant user manuals, function and protection may be impaired and serious personal damage,

death or serious, irreversible injuries may result.

EU-directives:

All versions of the VIBROCONTROL 950/960 device conform to the relevant regulations and EC

directives.

Installation and operation:

Installation, electrical connection, set-up, operation and maintenance of your VIBROCONTROL

950/960 device(s) must only be carried out by qualified/trained personnel (electrician) authorised by

the machine operator in accordance with local- and national regulations for the installation of electrical

equipment.

Changing the setup parameters:

Before applying a new set of setup parameters to the VIBROCONTROL 950/960 device, please make

sure that doing so cannot cause any damage to persons and/or machinery.

Connecting the sensor(s):

Please make sure to meet the safe extra-low voltage (SELV) criteria when any sensors are connected

to the VIBROCONTROL 950/960 device so that no dangerous contact voltages are applied to the

sensor and/or transferred to the device. The sensor and the power supply of the VIBROCONTROL

950/960 device are not galvanic isolated.

Sensor cable mounting:

To prevent negative effects on the functioning of the VIBROCONTROL 950/960 device caused by

noise voltages, please lay shielded sensor cables and load cables separately.

Ingress protection (IP):

The VIBROCONTROL 950/960 is ranked as IP20. The VIBROCONTROL 950/960 device must be

mounted in a control cabinet with an ingress protection of at least IP54. The control cabinet should be

installed in accordance with local- and national rules and regulations.

Mounting:

Mount the VIBROCONTROL 950/960 device on a 35 mm DIN rail inside the control cabinet. Mount the

device vertically but make sure to leave enough space between the unit and the top and/or bottom of

the control cabinet. Only this way the air circulation will be sufficient to avoid excessive heating of the

device.

Connecting to a power supply:

The VIBROCONTROL 950/960 device has a voltage tolerance of +24 VDC ±5 %

Before connecting the VIBROCONTROL 950/960 device to a +24 VDC supply voltage, please make

sure that all terminal blocks are completely inserted.

The external +24 VDC supply voltage must be generated and supplied according to the SELV

requirements.

Protect the +24 VDC supply voltage externally with max. 2A. The ground (GND) of the DC supply is

directly connected with the ground (GND) of the sensor supply, if any. The SELV criteria must

therefore be met for the DC supply (safety extra-low voltage, circuit electrically isolated from other

circuits, not grounded). If the DC circuit is to be grounded (e.g. due to national regulations), the