© Brüel & Kjaer Vibro ●October 2017 ● C106635002 / V01 ●█Page 9 of 20

Technical alterations reserved!

© Brüel & Kjaer Vibro │Instruction VC-850 Functionality EN

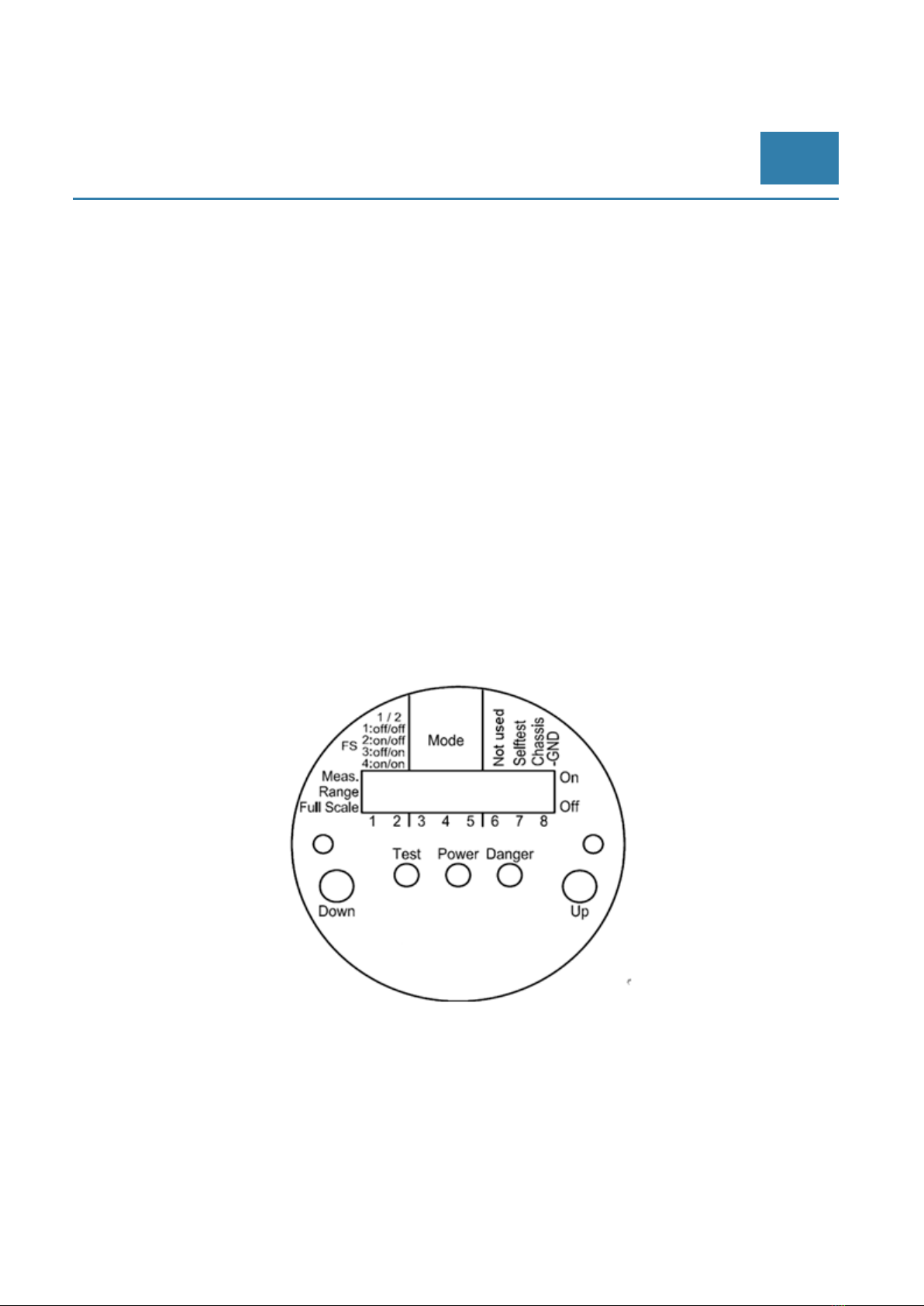

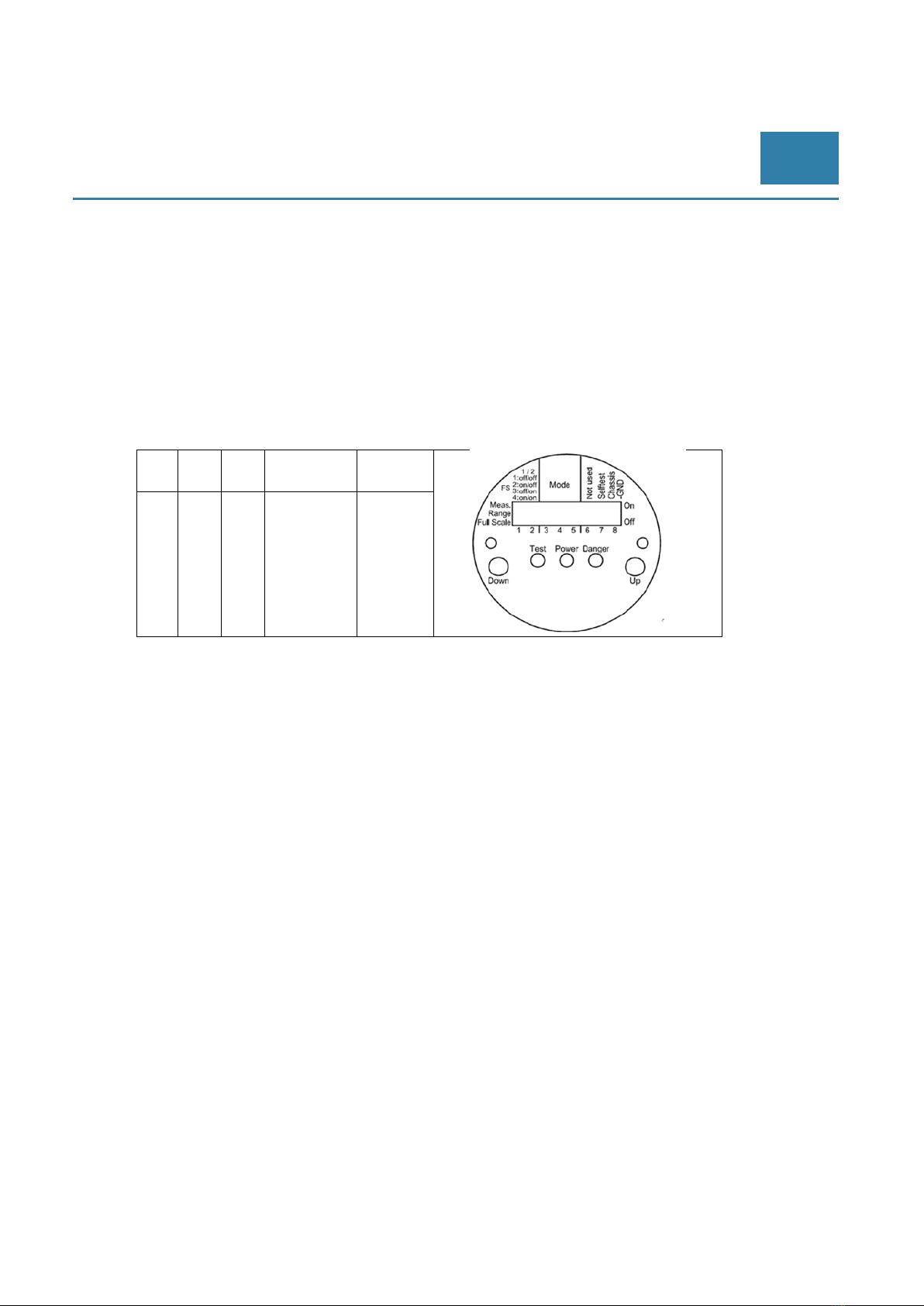

3.9 Danger Alarm Trigger Level

The Danger Alarm Trigger Level is the vibration level at the analogue output that must be exceeded for

at least the Danger alarm delay time for the Danger alarm to become activated.

By default the Danger alarm trigger level is set to be 55 % of full scale in Band 1.

The customer can set the Danger alarm trigger level by using the following procedure:

•Remove the lid that covers the VIBROCONTROL 850.

•Connect a digital multi meter in DC mA mode with a full-scale deflection of at least 20 mA to

the wires “GND” (-) and “4-20 mA Output” (+).

•Set DIP-switches 3, 4 & 5 in position (Off – On – Off)

•The analogue output can be changed to any value between 1 % and 100 % of full scale by

pushing the buttons “On” and “Off” at the left and right bottom of the round plate. Each pushing

of the button will decrease or increase the limit by 0.5 % of full scale. Stop pushing the buttons

when the required Danger alarm trigger level has been reached. When one of the buttons is

held down it will continuously change the Danger alarm trigger level.

•When finished put the DIP-switches 3, 4 & 5 into the position Off – Off – Off, which will bring

the VIBROCONTROL 850 back into normal monitoring mode with the new settings in place.

Failing to put the DIP-switches 3, 4 & 5 in Off – Off – Off position after the setting is finished,

will have the consequence that the analogue output will continuously be showing the Alert

alarm delay time and the vibration guard will therefore NO LONGER react on any alarm trigger

levels, i.e. neither from Alert nor Danger alarms.

3.10 Danger Alarm Delay Time

The Danger Alarm Delay Time is the minimum time the vibration level must exceed the pre-set Danger

alarm trigger level before the alarm gets activated. This is to avoid false alarms in situations where an

allowed short-lived shock (transient) is imposed on the machine. This could be when e.g. a new piece

of raw material is placed in or taken out of the machine.

The Danger alarm delay time is 1 second.

The customer can set the Danger alarm delay time by the following procedure:

•Remove the lid that covers the VIBROCONTROL 850.

•Connect a digital multi meter in DC mA mode with a full-scale deflection of at least 20 mA to

the wires “GND” (-) and “4-20 mA Output” (+).

•Set DIP-switches 3, 4 & 5 in position (Off – Off – On).

•The analogue output can be changed to any value between 0 seconds and 100 seconds by

pushing the buttons “On” and “Off” at the left and right bottom of the round plate. 0 seconds is

4 mA and 100 seconds is 20 mA. Each pushing of the button will decrease or increase the

Danger alarm delay time by half a second. When one of the buttons is hold down it will

continuously change the Danger alarm delay time. Stop pushing the buttons when the required

Danger alarm delay time has been reached.

•When finished put the DIP-switches 3, 4 & 5 into the position Off – Off – Off, which will bring

the VIBROCONTROL 850 back into normal monitoring mode with the new settings in place.