BR EMO User manual

Installation, operation and maintenance manual

Outdoor cooling units for door or wall mounting

EMO

ATTENTION!

Read carefully and completely before installation. Keep the manual until unit decommissioning.

C17000298R01

1. Cooling unit application..............................................................................................................................................6

1.1 Intended use......................................................................................................................................................6

1.2 Improper use.....................................................................................................................................................6

2. Supply.......................................................................................................................................................................6

3. Updates....................................................................................................................................................................6

4. Technical features....................................................................................................................................................6

5. Transport and handling............................................................................................................................................6

6. Installation................................................................................................................................................................6

7. Condensate discharge hose.....................................................................................................................................6

8. Electrical connection................................................................................................................................................6

8.1 Safety.................................................................................................................................................................6

8.2 Alarm pins..........................................................................................................................................................6

9. First start up and adjustment.....................................................................................................................................6

10. Maintenance..........................................................................................................................................................7

11. Technical information.............................................................................................................................................7

11.1 Operating principle........................................................................................................................................7

11.2 Safety devices...............................................................................................................................................7

11.3 Disposal.........................................................................................................................................................7

12.Troubleshooting.......................................................................................................................................................7

13. Pictograms ......................................................................................................................................................16-17

14. Technical data .......................................................................................................................................................18

15. Performances........................................................................................................................................................19

16. Dimensions...........................................................................................................................................................20

17. Spare parts .....................................................................................................................................................21-22

18. Wiring diagram.....................................................................................................................................................23

19. Guarantee........................................................................................................................................................24-25

20. Assistance service ................................................................................................................................................26

21. Notes.....................................................................................................................................................................27

ENGLISH - «Translation of the original instructions» ENG

1. Cooling unit application

The EMO series cooling units described in this

manual are designed and built to cool the air in-

side electrical switchboards in order to protect

components sensitive to thermal shock.

At the same time, the cooling units provide IP54

ingress protection against contaminating and

aggressive/corrosive substances.

1.1 Intended use

The EMO cooling unit must be used:

- For cooling electrical switchboards for external

use

- With external air temperature between a mini-

mum of -20°C and a maximum of +50°C (+55°C

for units where this is expressly indicated on the

data plate)

- Within the voltage supply limits indicated on the

data plate of the cooling unit and also given in

chapter 14 of this manual

- Away from any sources of heat or hot air

- In an environment with adequate air exchange

- On switchboards with IP54 rating or higher. If

these requirements are not respected, exces-

sive condensation build-up may occur. As a con-

sequence, cable entry points or any other open-

ings in the cabinet should be well sealed.

To ensure correct operation, the specied sched-

uled maintenance operations (see section 10)

must be performed regularly. Incorrect or care-

less use may cause irreparable damage to the

cooling unit and may lead to hazardous situa-

tions.

1.2 Improper use

The EMO cooling unit must NOT be used:

- Under any condition except those described in

section 1.1

- Outdoors, with excessive concentration of solid

contaminants and/or aggressive chemical con-

taminants

- With the doors of the electrical switchboard

open, or installed on enclosures without a mini-

mum IP54 rating, due to excessive condensate

formation

- With the temperature set below the dew point

of the ambient air

- In explosive atmospheres, or those with ag-

gressive chemicals or high concentrations of

dust or oil suspended in the air

- In potentially inammable atmospheres

- With the condensate line closed or blocked off,

or in any case in which the condensate is not al-

lowed to run off freely

- Without the front panel

- With the cooling unit intake and outlet air ows

obstructed by walls or objects that are too close

To this end, check the minimum distances as

regards the external air ow (gure F.02), and

make sure there are no obstructions caused by

the switchboard components as regards the in-

ternal air ow.

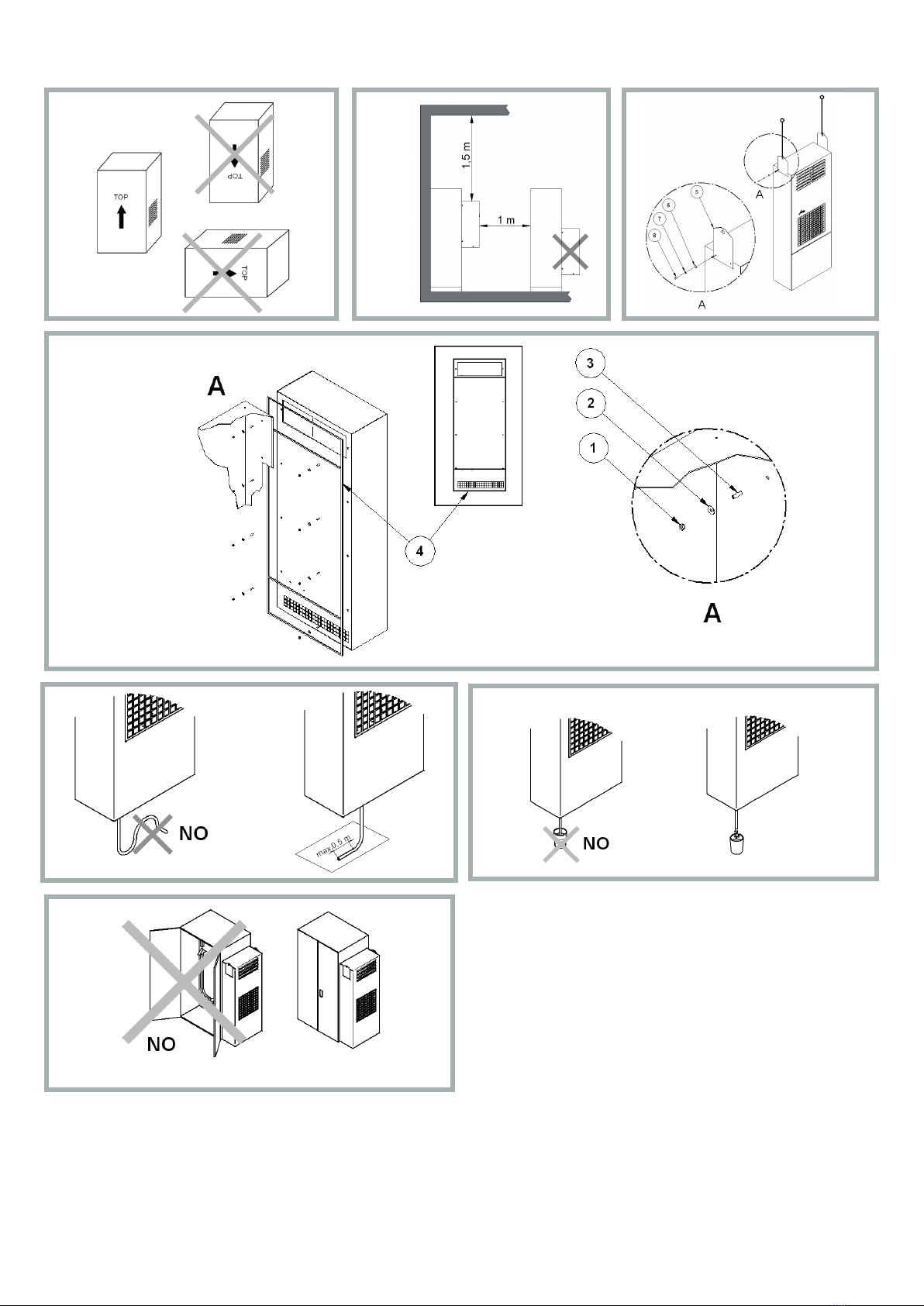

2. Supply

Inside the packaging you will nd:

1 Cooling unit

1 Installation, operation and maintenance manual

1 CE conformity certicate

1 Test certicate

1 A4 drilling template

1 Installation kit containing (F.04):

- Flanged nuts (p.1)

- Flat washers (p.2)

- Grub screws (p.3)

1 Self-adhesive sealing strip (F.04, p.4)

Handling brackets (F.03)

3. Updates

Pavarini Components reserves the right to up-

date its products and the corresponding man-

uals based on technical progress without prior

notice. Please note that at the time of sale, this

manual and the corresponding product may not

be considered inadequate only because they are

not subject to the above-mentioned updates.

4. Technical features

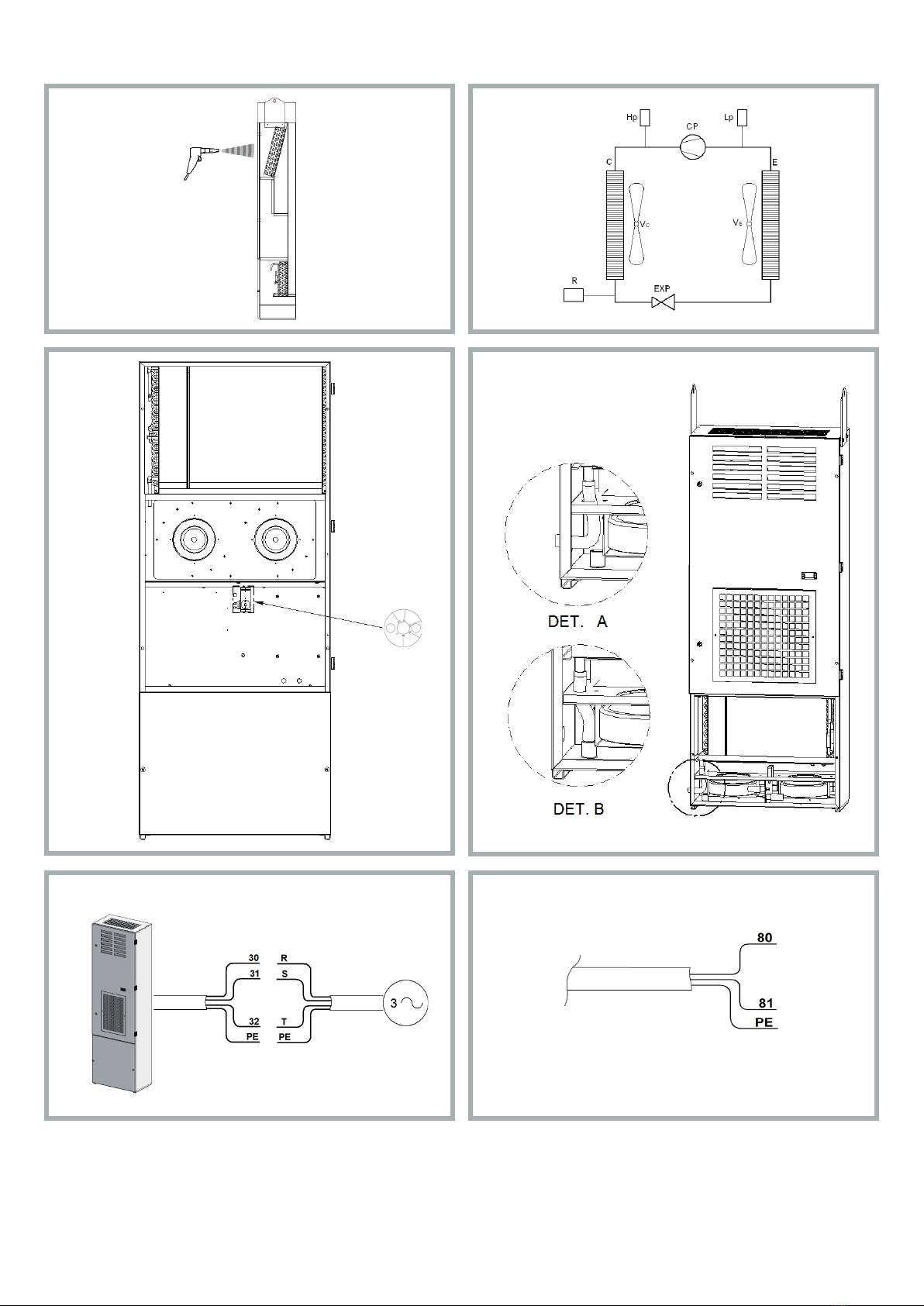

(gures F. 14 and F. 15)

The unit’s technical features and CE marking are

given on the data plate attached to the cooling

unit.

5. Transport and handling

During transport and storage the cooling unit

must be kept in a vertical position, as indicated

on the packaging (gure F.01), and must not be

exposed to temperatures above 70°C or below

-30°C. Upon receipt, check that the packaging

has not been damaged during shipping.

To lift the cooling unit in a safe manner, use the

handling brackets installed on the top of the unit

(gure F.03).

6. Installation

Installation of the unit should only be performed

by qualied and authorised personnel.

The cooling unit must be installed with the en-

closure air intake hole in the highest possible

point.

Ensure the xing elements and couplings will

not interfere with the equipment inside the en-

closure itself.

The unit must be installed in the vertical position

indicated. Maximum permitted deviation from

the vertical is 2°.

Disconnect power before starting any work in-

side the switchboard.

The cooling unit must be installed on the outside

of the electrical switchboard using the stand-

ard accessory kit supplied with the unit. Drill the

holes and make the cuts required in the switch-

board (gure F.04) using the supplied drilling

template.

Fit the sealing strip on the cooling unit on the

side connected to the enclosure and follow the

assembly diagram (gure F.04).

7. Condensate discharge hose

The condensate which, depending on the ambi-

ent temperature and humidity conditions, forms

on the heat exchanger which cools the enclo-

sure air, is not a malfunction but a normal phe-

nomenon of the cooling unit.

The condensate is taken outside the cooling unit

via a hose at the bottom of the unit (gure 11.B).

A plastic hose must be connected to this outlet to

carry the condensate to another point, allowing it

to be discharged where there can be no slipping

hazard for personnel.

In this case, make sure the condensate ows

without any hindrance. Avoid horizontal lengths

of more than 0.5 metres, uphill sections and the

accidental formation of traps (gure F.05). The

end of the condensate discharge hose must al-

ways be free and not underwater, so never place

the end of the discharge hose inside a conden-

sate collection container (gure F.07).

The condensate drain connection can also be

taken out the side of the cooling unit by modi-

fying the position of the internal rubber tube (g-

ure F.11A).

If the cooling unit is used with the doors of the

enclosure open, excessive quantities of conden-

sate will form and this is an unauthorised condi-

tion of use (gure F.07). We suggest using a po-

sition switch on the door connected to the cool-

ing unit’s digital input to stop the unit if the door

is opened. (See section 8.2)

8. Electrical connection

8.1 Safety

Warning! Electrical connections must only

be performed by specialised and authorised

personnel. Switch power off to the enclosure

before making the connection. Check that

there is no power to the switchboard and that

the supply voltage corresponds to the character-

istics given on the cooling unit’s data plate. The

power supply must be protected using appropri-

ate time-delay fuses (type T) or circuit breakers

with K-curve, as per the indications given in table

F.14. Connect the power-supply cable as shown

in gure F14. Ensure you respect the sequence

R-S-T. Disconnect the cooling unit before per-

forming testing on the enclosure.

8.2 Alarm management cable

(gure F.13)

The alarm signal output from the cooling unit can

be taken from wires 80 and 81 using a two-pole

cable

9. First start up and adjustment

If, prior to installation, the cooling unit was left in

an incorrect position (gure F.01), wait at least 8

hours before switching it on. Otherwise, 30 min-

utes is more than enough time for the oil to re-

turn to the compressor, after which the cooling

unit can be powered up. The enclosure air intake

fan starts working immediately, making the tem-

perature inside the enclosure even.

If this temperature exceeds the set point on the

regulator thermostat, both the compressor and

external air fan will turn on, causing the cool-

ing cycle to start. This then stops when the in-

side temperature reaches the lower limit of the

operating temperature differential, which has a

xed value of 4 K. The thermostat is factory-set

to 35°C. Use the thermostat located inside the

cooling unit to adjust the temperature set-point.

The graduated scale allows you to set the re-

quired temperature between 20 and 46 °C (g-

ure F.10). In order to save energy and minimise

the production of condensate, it is nevertheless

recommended it not be set below 30 °C.

10. Maintenance

Warning! Caution! Before embarking on any

maintenance work, cut the current to the en-

closure.

The cooling unit is the low maintenance type.

The only maintenance required is for the internal

components, which should be checked regular-

ly, as indicated in the table given in this section,

and cleaned with compressed air at a maximum

pressure of 4 bar (gure F.08). Any repairs that

may need doing must only be performed by spe-

cialised and authorised personnel.

Job Frequency

Check, clean and, if necessary,

replace the air lter

Every 2

weeks

Check the external air heat

exchanger and clean if necessary.

Every 3

months

Check effectiveness of the con-

densate discharge.

Every 3

months

Check the fans for any overheat-

ing or excessive vibrations.

Every 6

months

ENG

11. Technical information

11.1 Operating principle

The cooling unit for electrical switchboard enclo-

sures works on the basis of a refrigeration circuit

consisting of four main components: compressor,

evaporator, condenser and expansion device

(gure F.09). The circuit is hermetically sealed

and the refrigerant circulates inside it. The refrig-

erant used, depending on the cooling unit model,

is R134a, R407C or R410a, all chlorine free and

harmless to the ozone layer. The unit is divided

into two hermetically separated sections where

the ambient air and enclosure air do not come in-

to contact with one another and are treated sep-

arately. The compressor (CP) compresses the

refrigerant, taking it to a high pressure and high

temperature. The compressor then pushes the

refrigerant through a heat-exchanger coil, called

the condenser (C), where it is cooled by ambi-

ent air, thus passing from the gas to the liquid

state. In this state it then collects in the receiver

(R), from which it then passes through the ther-

mostatic expansion valve (EXP), where it vapor-

ises. It is then received by the heat exchang-

er coil, called the evaporator (E), by means of

which it absorbs heat from the enclosure air and

passes from a liquid state to gas. The enclosure

is cooled down in this manner. The gaseous re-

frigerant is then drawn back into the compressor

and this cycle is repeated.

11.2 Safety devices.

The refrigeration circuit is tted with a high-pres-

sure pressure switch Hp and a low-pressure

pressure switch Lp (gure F.09) set to the max-

imum and minimum working pressures, respec-

tively, of the cooling unit. If one of these thresh-

olds is exceeded, the pressure switch stops the

compressor’s operation. They reset automatical-

ly. The fans and compressor have an (internal or

external) thermal cut-out switch that stops them

in the case of overheating.

11.3 Energy savings

To optimise energy savings, the cooling unit is

tted with a pressure-switch speed regulator

(RLF) which adjusts the speed of the condens-

er fans based on the pressure in the refrigera-

tion circuit, which in turn depends on the ambi-

ent temperature.

11.4 Disposal

Caution! The cooling unit contains R134a,

R407 or R410A refrigerant, depending on the

model, as well as small quantities of lubri-

cating oil. These are polluting substances and

must not be dumped. Replacement, repairs and

nal disposal must be performed by experts.

NOTE

Keep the unit’s documentation in a safe, dry

place.

Remedy

This is not a malfunction of the cooling unit.

To verify functioning when testing, lower the thermostat setting until

the compressor and external fan start working and then reset the

thermostat.

Change the adjustment (or antifreeze) thermostat

This is not a malfunction of the cooling unit.

Make sure the power cable has been connected well to the

terminals.

Check that the cubicle doors and switches are closed

Call a refrigeration expert or the Manufacturer’s Technical Assist-

ance Service

Call a refrigeration expert or the Manufacturer’s Technical Assist-

ance Service

Change the internal fan’s capacitor

Change the internal fan

Change the amperometric protector

Change the relay or PTC for compressor starting

Change the capacitor for compressor starting

Call a refrigeration expert or the Manufacturer’s Technical Assist-

ance Service

Call a refrigeration expert or the Manufacturer’s Technical Assist-

ance Service

Change the contactor

Change the cooling unit with another of greater capacity

Clean the evaporator coil

See if there are any obstacles inside the enclosure to hinder the

ow of recycling air

Call a refrigeration expert or the Manufacturer’s Technical Assist-

ance Service

Check thermostat setpoint

Ventilate the premises where the enclosure is installed to keep

ambient temperature lower.

Clean the exchanger with compressed air and detergent

Ventilate the premises where the enclosure is installed to keep

ambient temperature lower.

Clean the coil with compressed air and detergent

This is not a malfunction of the cooling unit. Close the enclosure

door or disable the cooling unit

This is not a malfunction of the cooling unit. Seal enclosure open-

ings, e.g. for passage and upward path of wires

Check seal and remedy

Causes

The temperature inside the enclosure is lower than what

is set on the adjustment thermostat.

The adjustment (or antifreeze) thermostat has failed

No electricity getting to the unit.

Cooling unit empty of uid

Compressor mechanical failure

Internal fan capacitor failed

Internal fan failed

Compressor’s amperometric protector failed (external to

the compressor, where present)

Relay or PTC for compressor starting failed

Capacitor for compressor starting failed (where present)

Compressor motor electrical failure

High pressure safety switch failed

Compressor contactor failed (where present)

Cooling unit under sized for the heat dissipated inside

the enclosure

Antifreeze thermostat triggered (where present)

Insufcient gas in the cooling unit

Thermostat set point incorrect

High pressure safety switch triggered:

Ambient temperature over the maximum work-

ing limit

Heat exchanger coil (condenser) either dirty or

clogged

Thermal protector inside the compressor triggered:

Ambient temperature over the maximum work-

ing limit

Heat exchanger coil (condenser) either dirty or

clogged

Too much ambient air inside the enclosure

Enclosure protection level is below IP54

The enclosure/cooling unit connecting seal has been

tted incorrectly

Conditions

The internal fan works, the external fan and com-

pressor do not work.

No component works

Compressor, external and internal fan work

Compressor and external fan work, internal fan

does not work

External and internal fan work, compressor does

not work

External and internal fans work, compressor works

all the time

Inside fan works, external fan and compressor

work irregularly

External and internal fans work, compressor works

irregularly

Enclosure door open

Enclosure door closed

Malfunction

It fails to cool

It is not cooling enough

Too much condensate forming

•

•

•

•

•

•

•

•

12. Troubleshooting

•

•

•

•

ENG

13. Pictograms

F.01 F.03

F.04

F.06

External Mounting

Montaggio Esterno

Außenmontage

Montage externe

Montaje externo

F.07

F.02

F.05

13. Pictograms

F.08 F.09

F.10 F.11

F.12 F.13

P(W)

Useful cooling output

Ta (°C)

Ambient temperature

Ti (°C)

Enclosure internal temperature

15. Performances

F. 15

EMO80M / EMO80N EMOA0M / EMOA0N

16. Dimensions

F. 16

EMO80M / EMO80N / EMOA0M / EMOA0N

17. Spare parts / Ricambi / Ersatzteile / Pièces détachées / Piezas de repuestro

F. 17

EMO80M / EMO80N EMOA0M / EMOA0N

1Evaporator fan

2Condenser fan

3Front structure

4Evaporator

5Condenser

6Compressor

7Autotransformer

8Assembly

accessory kit

ENG

This manual suits for next models

4

Table of contents